Exploring the internal structure of an ATV can greatly enhance understanding of its functionality. By breaking down various components and how they interact, users can gain a clearer picture of the vehicle’s operation. This detailed approach is particularly helpful for those who enjoy working on repairs or upgrades themselves, ensuring a better grasp of what goes into maintaining these machines.

Identifying the key elements and their placements within an off-road vehicle not only assists in troubleshooting but also allows for smoother modifications. With each component serving a vital role, a closer look at these elements reveals the importance of precision and proper assembly. Having a clear view of the system makes upkeep much more straightforward.

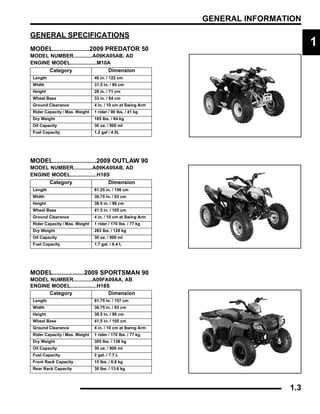

Overview of Polaris 90 Components

Understanding the essential elements of this vehicle is crucial for ensuring optimal performance and maintaining its functionality. The various sections of the machine are designed to work together, providing a smooth and reliable ride. Here, we will break down the primary sections that contribute to its operation.

Engine and Transmission System

The heart of the vehicle lies in its power generation and delivery mechanisms. The engine, along with the transmission setup, ensures effective power transfer to the wheels. These two work in tandem to deliver the necessary torque and speed adjustments, depending on terrain conditions and rider input.

Chassis and Suspension

The frame and suspension components are responsible for providing structural integrity and comfort during rides. The suspension absorbs shocks from uneven surfaces, ensuring stability and reducing vibrations. These systems play a critical role in the durability and longevity of the machine.

| Component | Function |

|---|---|

| Engine | Power generation for movement |

| Transmission | Transfers power to the wheels |

| Suspension | Absorbs shocks for smooth riding |

| Frame | Provides structural support |

Understanding the Key Engine Parts

To maintain the efficiency of any small off-road vehicle, it’s crucial to have a basic understanding of its core mechanical components. These essential elements work together to deliver power, ensure smooth operation, and prolong the engine’s lifespan. By familiarizing yourself with the primary units, you can better assess potential issues and perform maintenance when needed.

Combustion chamber: This is the heart of the engine where fuel mixes with air, igniting to create the energy that drives the vehicle. Proper functioning of this area ensures efficient energy conversion.

Piston and crankshaft: The piston moves within a cylinder, compressing fuel and air before ignition, while the crankshaft translates this motion into rotational force, ultimately propelling the vehicle forward.

Carburetor: Responsible for mixing air with fuel in the right proportions, this unit plays a key role in the engine’s responsiveness and fuel efficiency.

Cylinder: Acting as the space for piston movement, the cylinder must maintain a perfect seal to ensure proper compression and engine power output.

Cooling system: To avoid overheating, the engine relies on a cooling system that keeps temperatures under control, helping to prevent wear and maintain performance.

Detailed Look at the Suspension System

The suspension system plays a crucial role in ensuring smooth and stable operation over uneven terrain. It is responsible for maintaining control and comfort by absorbing shocks and providing stability. Let’s explore the components and their functions that contribute to a well-balanced ride.

Main Components Overview

- Shock absorbers: These are essential for absorbing impacts and reducing the bounce caused by rough surfaces.

- A-arms: The arms ensure the wheels remain aligned while navigating different terrains, providing better handling and balance.

- Springs: Together with shock absorbers, springs contribute to maintaining height and softness, enhancing the ride experience.

How It All Works Together

Each element in the suspension has a specific role in maintaining stability and comfort. The cooperation of springs and shocks ensures that impacts are minimized while offering the rider a comfortable experience. The design and positioning of components also contribute to safety by keeping the vehicle stable during high-speed maneuvers.

- Shock absorbers manage vertical motion, preventing uncontrolled bouncing.

- A-arms secure the positioning of wheels, providing precise steering.

- Springs add flexibility, balancing the load and maintaining control over rough paths.

Brake Mechanism and Safety Features

The braking system ensures smooth control over the vehicle’s motion, allowing users to safely reduce speed or stop when necessary. Proper functionality of these components is essential for maintaining safety during various driving conditions, whether on flat surfaces or rugged terrains.

Key Components of the Braking System

- Friction-based elements designed to slow down wheel rotation

- Hydraulic systems that amplify force applied by the driver

- Cables and levers that translate user input into mechanical action

Safety Enhancements

Several integrated features work alongside the braking components to ensure user protection. These mechanisms help prevent wheel locking, improve response times, and offer additional stability during sudden stops or emergencies.

- Lock-prevention technologies that maintain control during rapid deceleration

- Pressure-balancing systems to evenly distribute force across all wheels

- Enhanced grip features that improve traction during wet or slippery conditions

Electrical System Overview and Functionality

The electrical system plays a vital role in ensuring the smooth operation of any vehicle, providing power to essential components and ensuring their proper function. This system is responsible for managing energy distribution and ensuring the continuous operation of key devices. Without it, critical elements such as lighting, ignition, and various control units would cease to function efficiently.

Energy Generation: The system starts with a power source that generates electricity, typically a rechargeable unit. This power source supplies the necessary current to all the electrical components, which include various sensors, indicators, and controllers.

Power Distribution: Once energy is generated, it is distributed across multiple circuits. These circuits are carefully designed to allocate the correct amount of energy to different parts of the vehicle, ensuring that each component operates without overloading or experiencing short circuits.

Control Mechanisms: Various control units regulate the flow of power and ensure that each system component functions at its optimum level. These mechanisms are vital for managing the overall functionality, adapting to changes in operating conditions, and maintaining safety during operation.

Electrical protection is also a key feature, utilizing various fuses and relays to prevent any overloads or electrical failures from damaging critical systems.

Fuel System Components Breakdown

The fuel system is a crucial assembly that ensures efficient operation by delivering the necessary fuel to the engine. Understanding the various elements within this system is essential for maintaining optimal performance and ensuring longevity.

At the core of the fuel assembly is the fuel tank, which stores the fuel until it is required for combustion. Fuel lines transport the liquid from the tank to the engine, and these must be inspected regularly for leaks or blockages. A fuel pump is responsible for drawing fuel from the tank and pushing it through the system, while the fuel filter plays a vital role in removing impurities and preventing damage to the engine.

Another key component is the carburetor or fuel injector, which mixes the fuel with air to create a combustible mixture that powers the engine. Additionally, various sensors monitor the fuel flow and pressure, providing feedback to the engine control unit for adjustments. Together, these elements form a sophisticated system that demands attention for optimal functionality.

How the Cooling System Works

The cooling mechanism in an engine plays a vital role in maintaining optimal operating temperatures. It ensures that the engine runs efficiently, preventing overheating and potential damage. This system employs various components to regulate temperature effectively and maintain performance.

At its core, the cooling system consists of several essential elements that work together harmoniously:

- Radiator: This component dissipates heat from the coolant, allowing it to cool before circulating back to the engine.

- Water Pump: The pump circulates coolant throughout the system, ensuring a consistent flow and heat exchange.

- Thermostat: This device regulates coolant flow based on temperature, allowing the engine to reach its ideal operating range quickly.

- Coolant: A mixture of water and antifreeze, coolant absorbs heat from the engine and transfers it to the radiator for dissipation.

The process begins with the water pump drawing coolant from the radiator and sending it into the engine block. As the engine runs, it generates heat, which the coolant absorbs. The heated coolant then travels back to the radiator, where air flow cools it down before returning to the engine. This continuous cycle helps maintain a stable temperature, enhancing performance and longevity.

Moreover, any air pockets within the system can disrupt this flow, leading to hot spots and inefficiency. Therefore, proper maintenance, including checking coolant levels and inspecting components, is crucial for optimal performance.

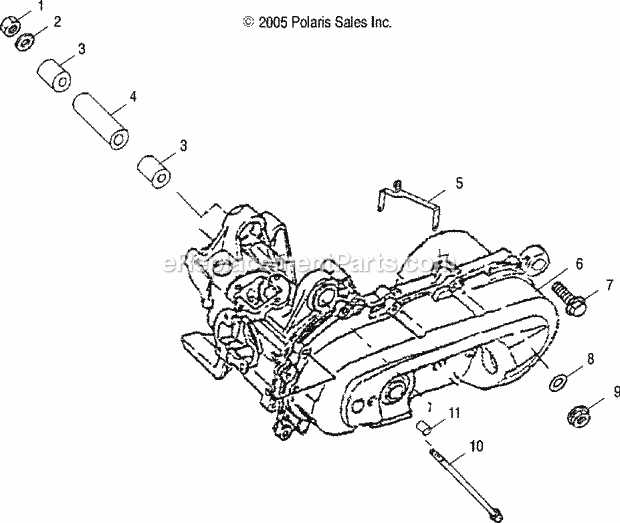

Transmission and Drive Assembly Details

The transmission and drive assembly is a critical component of any all-terrain vehicle, facilitating power transfer from the engine to the wheels. Understanding the intricate workings of this system can enhance performance and ensure proper maintenance.

This assembly comprises several key elements that work together seamlessly. Below are the primary components involved:

- Transmission Housing: The outer casing that protects internal components and provides structural integrity.

- Input Shaft: Connects to the engine, receiving power to initiate the transmission process.

- Output Shaft: Transfers power to the drive assembly, delivering torque to the wheels.

- Gears: Various gear sets facilitate speed and torque adjustments, ensuring optimal performance under different conditions.

- Clutch Mechanism: Engages and disengages the engine from the transmission, allowing for smooth acceleration and deceleration.

- Chain or Belt Drive: A system that connects the transmission to the wheels, translating power into motion.

Proper maintenance of these components is essential for longevity and efficiency. Regular inspections, along with timely replacements of worn-out parts, can prevent costly repairs and ensure a smoother ride.

Exhaust System Design and Parts

The exhaust system plays a critical role in the overall functionality and performance of any vehicle. Its primary function is to direct exhaust gases away from the engine, thereby reducing noise and emissions while enhancing efficiency. Understanding the various components that constitute this system is essential for maintaining optimal performance and ensuring compliance with environmental regulations.

Key elements of an effective exhaust system include:

- Exhaust Manifold: This component collects exhaust gases from the engine’s cylinders and channels them into the system.

- Catalytic Converter: A vital part that reduces harmful emissions by converting toxic gases into less harmful substances before they are expelled.

- Muffler: This element minimizes noise produced by the exhaust gases, ensuring a quieter operation of the vehicle.

- Tailpipe: The final segment that expels exhaust gases into the atmosphere, often designed for both aesthetic appeal and functional performance.

Each of these components must be designed and manufactured to withstand high temperatures and corrosive elements, ensuring durability and longevity. Proper installation and regular maintenance are crucial to preventing issues such as leaks or blockages, which can adversely affect engine performance and efficiency.

Additionally, modifications to the exhaust system can enhance performance, offering benefits such as increased horsepower and improved fuel efficiency. However, it is important to consider local regulations regarding noise and emissions when making any alterations.

In conclusion, a well-designed exhaust system is essential for the effective operation of any vehicle. Understanding its components and their functions allows for better maintenance practices and informed decisions regarding upgrades and modifications.

Body and Frame Structure Analysis

The analysis of the structural components and chassis framework plays a crucial role in understanding the overall performance and durability of an off-road vehicle. A well-engineered body and frame system not only enhances the aesthetic appeal but also ensures stability, safety, and efficiency during operation. By examining the materials, design, and assembly techniques, one can appreciate how these elements contribute to the vehicle’s functionality.

Key Components of the Structure

- Frame: The backbone of the vehicle, providing support and rigidity.

- Body Panels: These elements contribute to the aerodynamic profile and protection against environmental factors.

- Suspension Mounts: Critical for absorbing shocks and maintaining stability during movement.

- Crossmembers: Reinforcements that enhance the frame’s strength and structural integrity.

Material Considerations

Various materials are employed in constructing the chassis and body, each offering distinct advantages:

- Steel: Known for its strength and durability, often used in frame construction.

- Aluminum: Lightweight and resistant to corrosion, making it ideal for body panels.

- Composite Materials: Increasingly popular for their lightweight properties and ability to withstand impact.

Incorporating a combination of these materials allows manufacturers to optimize performance while minimizing weight, contributing to enhanced fuel efficiency and handling characteristics.

Steering System Components Explained

The steering mechanism plays a crucial role in providing control and direction in any vehicle. Understanding its components is essential for maintaining optimal performance and safety. This section delves into the primary elements of the steering system, outlining their functions and importance.

- Steering Wheel: The driver’s main interface for controlling direction. It translates the driver’s inputs into movement.

- Steering Column: Connects the steering wheel to the rest of the system, providing support and housing for various controls.

- Rack and Pinion: A gear mechanism that converts rotational motion from the steering wheel into linear motion, allowing for precise turning of the wheels.

- Linkages: Components that connect the steering gear to the wheels, transmitting motion and ensuring that the steering actions are reflected at the tires.

- Wheel Bearings: Allow the wheels to rotate freely and support the weight of the vehicle while providing stability during turns.

- Power Steering Pump: Assists in steering effort by supplying hydraulic fluid to the steering mechanism, making turning easier for the driver.

Each of these components contributes to the overall functionality of the steering system, enhancing the driving experience through improved responsiveness and control. Regular maintenance and inspection of these parts can prevent potential issues and ensure smooth operation.