In the world of outdoor machinery, maintaining optimal performance often hinges on having a clear understanding of the individual elements that make up the whole. Every tool or device consists of various interconnected parts, each playing a crucial role in the overall functionality. A detailed representation of these components can be invaluable for both troubleshooting and routine maintenance.

By familiarizing yourself with the arrangement and relationship of these elements, you empower yourself to tackle repairs with confidence. Whether you are an avid gardener or a landscaping professional, knowing how each piece fits together enhances your ability to keep your equipment in top shape.

Furthermore, understanding the structure not only aids in immediate repairs but also fosters a deeper appreciation for the engineering behind your tools. This knowledge can guide you in making informed decisions regarding upgrades or replacements, ensuring that your outdoor machinery continues to serve you effectively.

Poulan 3400 Overview

This section provides an insightful look into a specific model of outdoor equipment designed for efficiency and reliability. Known for its robust performance, this tool is a favorite among enthusiasts and professionals alike, making it an essential asset for various tasks.

The design emphasizes user-friendly features and a lightweight structure, allowing for ease of handling during operation. Engineered with a powerful motor, it delivers impressive cutting capabilities, making it suitable for both light and heavy-duty applications.

Maintenance is straightforward, ensuring longevity and optimal performance. Regular checks and servicing can keep the equipment functioning at peak levels, thus enhancing its overall lifespan. The availability of replacement components further supports the ease of upkeep, making it a practical choice for users.

In summary, this model stands out due to its blend of power, convenience, and ease of maintenance, catering to a diverse range of outdoor tasks efficiently.

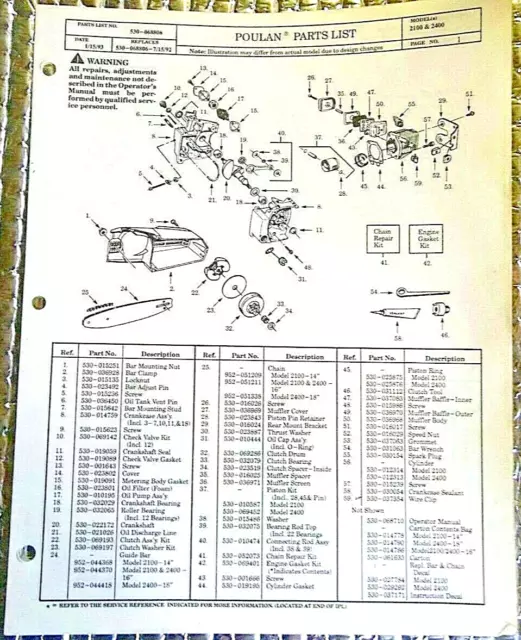

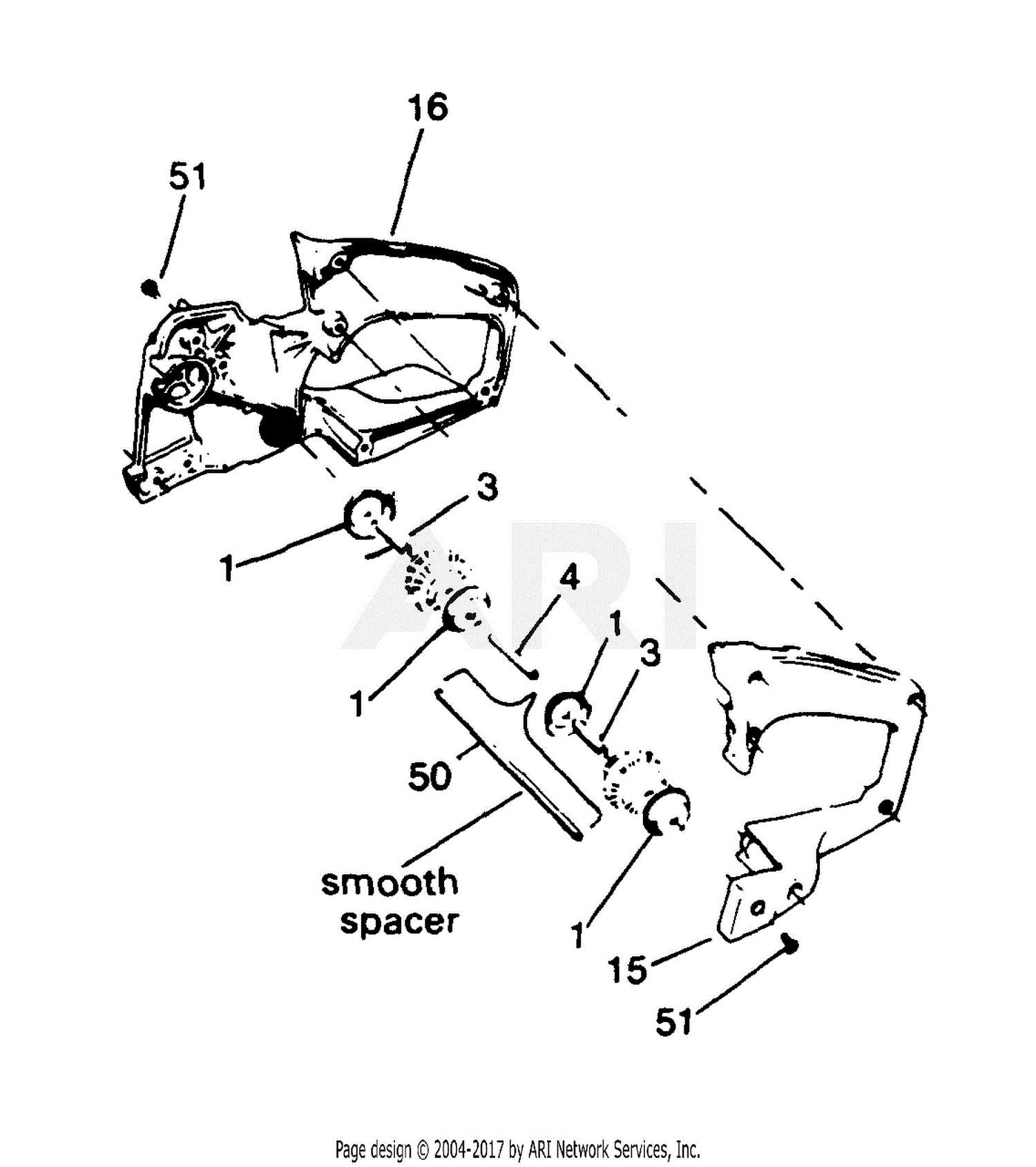

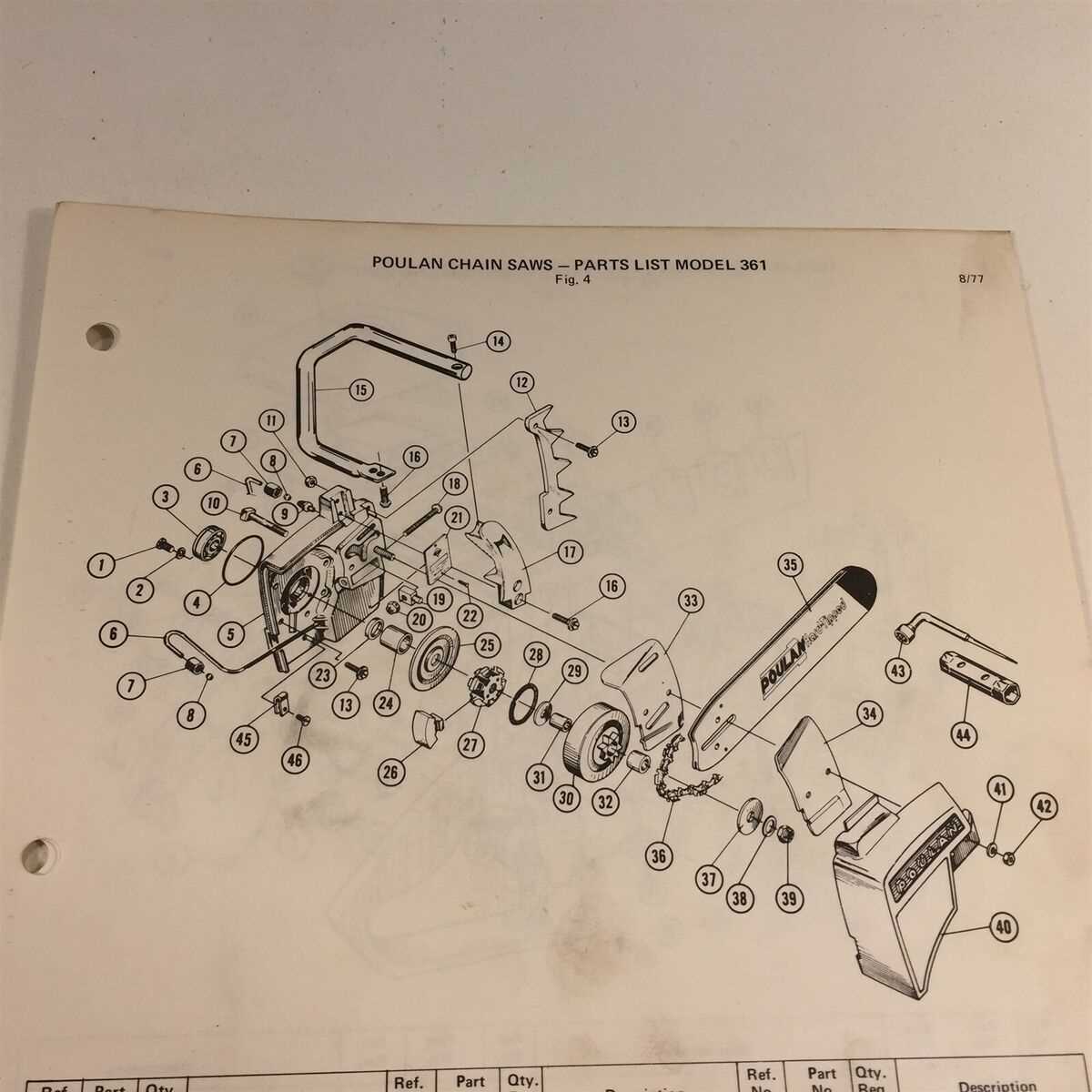

Understanding Parts Diagrams

Exploring visual representations of components is essential for effective maintenance and repair. These illustrations serve as a guide, allowing users to identify, locate, and understand various elements within a machine. By breaking down complex systems into manageable parts, one can enhance their knowledge and skills in troubleshooting and assembly.

Importance of Visual Guides

Visual aids simplify the process of learning about intricate systems. They help in recognizing how different pieces interact, ensuring that users can approach repairs with confidence. Moreover, these guides are invaluable for ordering replacements, ensuring that the right components are selected.

Key Components in Visual Representations

| Element | Description |

|---|---|

| Labels | Identify specific parts and their functions. |

| Numbers | Indicate the order of assembly or parts to be replaced. |

| Connections | Show how components fit together or relate to each other. |

Key Components of Poulan 3400

This section explores the essential elements that contribute to the functionality and performance of a specific outdoor power tool. Understanding these core parts can enhance maintenance and repair efforts, ensuring longevity and efficiency.

Engine Assembly

The heart of any machinery, the engine assembly provides the necessary power for operation. It consists of various parts such as the cylinder, piston, and ignition system, which work in unison to deliver optimal performance.

Cutting Mechanism

The cutting mechanism is crucial for achieving precise results. This includes components like the chain, bar, and drive system, which together facilitate smooth and efficient cutting action.

Finding Replacement Parts

When maintaining or restoring equipment, locating suitable components is essential for ensuring optimal performance. This process often involves exploring various sources to secure the necessary items, from retailers to specialized online platforms.

| Source | Description |

|---|---|

| Authorized Dealers | Official distributors offer genuine components with reliable warranties. |

| Online Marketplaces | Websites provide a vast selection, often at competitive prices, with user reviews. |

| Local Repair Shops | These establishments can provide insights and sometimes have stock of parts. |

| Salvage Yards | Used components may be available, often at a fraction of the cost. |

Utilizing these various avenues can lead to successful discoveries, ultimately enhancing the longevity and functionality of your equipment.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in ensuring effective assembly, maintenance, and troubleshooting of machinery. They provide users with clear visual guidance, minimizing the risk of errors and enhancing overall efficiency.

Benefits of Detailed Visuals

- Facilitates comprehension of complex systems.

- Reduces the likelihood of misinterpretation during repairs.

- Enhances communication among technicians and users.

Impact on Efficiency

- Speeds up the repair process by providing a clear reference.

- Helps in identifying components quickly and accurately.

- Contributes to prolonged equipment lifespan through proper maintenance.

Common Issues with Poulan 3400

Many users encounter various challenges with their outdoor power equipment, which can hinder performance and efficiency. Understanding these frequent problems can help in troubleshooting and maintaining optimal functionality.

- Starting Difficulties:

It is common for machines to experience trouble starting due to:

- Old or contaminated fuel

- Clogged air filters

- Defective spark plugs

- Overheating:

Equipment may overheat for several reasons, including:

- Lack of proper ventilation

- Dirty cooling fins

- Inadequate lubrication

- Chain Problems:

Issues with the cutting mechanism can manifest as:

- Chain derailing

- Excessive wear

- Inconsistent tension

- Fuel Leakage:

Leaks can occur, leading to potential hazards. Common causes include:

- Worn gaskets

- Cracked fuel lines

- Loose connections

- Vibration Issues:

Excessive vibration can be caused by:

- Unbalanced components

- Loose bolts or screws

- Deteriorated dampers

lessCopy code

Addressing these common challenges promptly can prolong the life of the equipment and enhance overall performance.

Maintenance Tips for Longevity

Proper care and attention can significantly enhance the lifespan of your outdoor equipment. By adhering to a few essential practices, you can ensure optimal performance and reliability over time.

- Regular Cleaning: Remove dirt and debris after each use to prevent buildup that can cause wear and tear.

- Lubrication: Apply appropriate oils to moving parts to reduce friction and prevent rusting.

- Inspect Components: Frequently check for any signs of damage or wear. Early detection can prevent further issues.

- Replace Filters: Clean or replace air and fuel filters periodically to maintain efficiency and performance.

Following a consistent maintenance routine not only boosts efficiency but also saves you from costly repairs down the line.

- Check Fuel Quality: Always use fresh fuel and store it properly to avoid contamination.

- Sharpen Blades: Keep cutting edges sharp for better performance and to reduce strain on the motor.

- Winter Storage: Prepare your equipment for off-season storage by draining fluids and keeping it in a dry place.

Investing time in these simple maintenance tasks will pay off, ensuring your equipment remains in top condition for years to come.

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to identify and source necessary elements for maintenance or repair tasks. These illustrations typically include numbered references and descriptive labels, guiding users in locating specific items effectively.

Interpreting Symbols and Numbers

Each illustration contains unique symbols and numeric codes that correspond to various components. Familiarizing yourself with these indicators is essential, as they provide a direct link to the corresponding parts list, making it easier to find what you need.

Utilizing Reference Lists

Alongside the visual guide, a reference list is usually provided. This list details each component’s specifications and availability, enabling you to delve deeper into purchasing or replacement options. Ensuring that you have the correct identifiers will streamline the process significantly.

Sources for Authentic Parts

Finding reliable suppliers for genuine components is crucial for maintaining equipment performance and longevity. Authentic materials not only enhance efficiency but also ensure safety during operation.

Start by checking with the original manufacturer’s official website or authorized dealers. These sources often provide a comprehensive catalog of available items and detailed specifications.

Additionally, reputable online marketplaces can offer a wide range of options. Look for sellers with verified ratings and reviews to ensure the quality of the components.

Local repair shops may also stock genuine materials or can order them on your behalf. Establishing a relationship with a knowledgeable technician can provide insights into the best sources for your needs.

Lastly, online forums and community groups dedicated to similar equipment can be valuable resources. Members often share their experiences and recommendations for trustworthy suppliers.

Upgrading Your Poulan 3400

Enhancing the performance of your chainsaw can significantly improve efficiency and reliability. By focusing on key components and implementing thoughtful upgrades, you can elevate your tool’s capabilities. This not only extends its lifespan but also ensures optimal operation in various conditions.

One effective approach is to replace the original cutting mechanism with a more advanced version. Upgrading to a sharper, high-quality chain can reduce friction and improve cutting speed. Additionally, investing in a better guide bar can enhance stability and precision, making your tasks smoother.

Fuel efficiency can also be addressed by optimizing the engine components. Consider upgrading the air filter and spark plug to enhance combustion efficiency. This change can lead to better power output and reduced emissions, ultimately benefiting both performance and the environment.

For those who use their equipment frequently, ergonomics play a vital role. Upgrading the handle grips and vibration dampeners can significantly improve comfort during prolonged use. Such modifications not only make the tool more user-friendly but also help reduce fatigue.

Finally, keeping an eye on accessory compatibility can allow for further enhancements. Additional features, such as protective covers and advanced lubrication systems, can be easily integrated to provide added convenience and protection.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and repair components for various models of outdoor equipment. Whether you’re seeking clarification on specific elements or general troubleshooting tips, you’ll find valuable insights here.

What should I do if I can’t find the right component?

If you’re having difficulty locating a particular item, consider checking multiple retailers or online platforms that specialize in outdoor machinery. It may also be helpful to consult the manufacturer’s website for additional resources.

How can I ensure compatibility with my equipment?

To ensure proper fit, always reference the model number and specifications when searching for replacement items. Cross-referencing with user manuals can provide crucial information.

Are there alternatives to original components?

Yes, many aftermarket options are available, which can often provide the same quality at a lower price. However, be cautious and verify that these alternatives meet necessary standards.

What are the signs that a part needs replacement?

Common indicators include decreased performance, unusual noises, or visible wear and tear. Regular inspections can help identify issues early.

Where can I find repair guides?

Numerous online resources, including forums and video tutorials, can assist you in learning the repair process step-by-step. These platforms often share experiences and tips from other users.

Expert Insights on Performance

Understanding the intricacies of machine performance can significantly enhance user experience and longevity. Experts emphasize the importance of regular maintenance and the right components to ensure optimal functionality.

- Regular inspections can prevent major issues.

- Using high-quality replacements boosts efficiency.

- Adjustments to settings may enhance power delivery.

Incorporating expert recommendations can lead to remarkable improvements:

- Ensure all moving parts are lubricated to reduce friction.

- Check for any wear and tear that could affect performance.

- Regularly clean air filters to maintain airflow.

Ultimately, focusing on these insights can transform how equipment operates, ensuring reliability and peak performance.

Resources for Further Research

This section aims to provide valuable references and tools for those seeking deeper insights into specific components and their functionality. Whether you’re a seasoned enthusiast or a novice, these resources can enhance your understanding and assist with maintenance tasks.

Online Databases

Many websites host extensive libraries of technical manuals and guides. These platforms often include diagrams, specifications, and troubleshooting tips that can be invaluable.

Community Forums

Engaging with fellow enthusiasts through online forums can yield practical advice and personal experiences. These discussions often cover common issues and innovative solutions.

| Resource Type | Example |

|---|---|

| Technical Manuals | Service Manuals Online |

| Discussion Boards | Small Engine Repair Forum |

| Video Tutorials | YouTube Repair Channels |