The intricate design of small engines plays a crucial role in their functionality and efficiency. This section will explore the various elements that contribute to the overall performance of these machines. By examining the essential components, users can gain a deeper understanding of how each piece interacts to create a seamless operation.

For enthusiasts and professionals alike, having access to a visual representation of the internal mechanisms is invaluable. It allows for easier identification of each element, fostering a more effective maintenance routine. A well-structured overview not only aids in repairs but also enhances the overall experience of using the equipment.

In the following segments, we will delve into specific sections of the engine’s layout, highlighting their ultimate importance and functionality. This exploration will empower users to make informed decisions when it comes to repairs and replacements, ensuring their machinery operates at peak efficiency.

Poulan Counter Vibe 3400 Overview

This section provides an insightful look into a specific model of chainsaw, highlighting its key features and functionality. Designed for both efficiency and user comfort, this tool stands out in the competitive landscape of outdoor power equipment.

Key attributes include:

- Robust engine performance

- Vibration dampening technology

- User-friendly design

- Durability and reliability in various conditions

Users can benefit from its:

- Lightweight construction, facilitating ease of handling

- Ergonomic grips, reducing fatigue during prolonged use

- Advanced safety features, ensuring secure operation

Whether for residential use or light commercial applications, this model is engineered to meet a range of cutting needs while maintaining optimal performance. Understanding its components and overall design can greatly enhance user experience and efficiency.

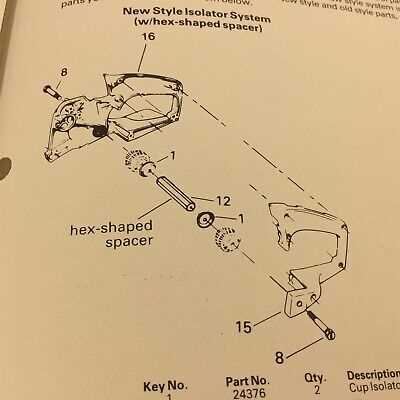

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding machinery and equipment. They serve as a guide for assembly, maintenance, and troubleshooting, enabling users to identify individual elements effectively.

- Enhance clarity by illustrating the relationship between different components.

- Facilitate easy identification of replacement items when repairs are necessary.

- Streamline the assembly process by providing clear instructions.

- Help in diagnosing issues by pinpointing specific areas of concern.

Ultimately, these illustrations support users in achieving efficient operation and maintenance of their equipment, ensuring longevity and optimal performance.

Key Features of the Poulan 3400

This model stands out due to its remarkable combination of efficiency and user-friendly design. Engineered for optimal performance, it is tailored to meet the demands of various tasks while ensuring ease of operation.

Powerful Engine: The heart of this machine is its robust motor, delivering consistent power that enhances cutting efficiency. Users can tackle challenging jobs with confidence, knowing they have a reliable source of energy at their disposal.

Lightweight Construction: Designed with portability in mind, the lightweight frame allows for effortless maneuvering. This feature is particularly beneficial during extended use, reducing fatigue and improving overall user comfort.

Vibration Reduction Technology: Equipped with innovative vibration dampening systems, this tool minimizes user discomfort. This technology not only enhances the overall experience but also promotes longer working sessions without strain.

Durability: Built with high-quality materials, this equipment offers longevity and resilience in various environmental conditions. This durability ensures that users can rely on it for years to come, regardless of the challenges faced.

Easy Maintenance: The design includes components that simplify upkeep, making it accessible for users to perform routine checks and repairs. This focus on maintenance helps extend the lifespan of the tool, ensuring it remains in top condition.

Understanding the Engine Components

Engines are intricate machines composed of various elements that work together to produce power and ensure efficiency. Grasping the function of each component is crucial for optimal performance and maintenance. This section delves into the primary elements that constitute a typical engine, highlighting their roles and interrelationships.

Key Components Overview

Each part plays a significant role in the overall operation, influencing everything from fuel combustion to power delivery. Understanding these components helps in diagnosing issues and performing effective repairs.

Component Functionality

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, where fuel and air mix and ignite. |

| Piston | Moves up and down within the cylinder, converting combustion energy into mechanical motion. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion to drive the machinery. |

| Fuel Injector | Delivers precise amounts of fuel into the combustion chamber for efficient burning. |

| Spark Plug | Ignites the air-fuel mixture, initiating the combustion process. |

Fuel System Breakdown

The fuel system is a crucial component in the performance of small engine machinery. It ensures the proper delivery of fuel to the engine, enabling efficient combustion and optimal functionality. Understanding its various elements is essential for maintenance and troubleshooting.

Key Components

- Fuel Tank: Stores the fuel and provides gravity or pump-fed delivery.

- Fuel Lines: Transport fuel from the tank to the carburetor.

- Carburetor: Mixes air and fuel in the correct ratio for combustion.

- Fuel Filter: Removes impurities from the fuel before it enters the engine.

- Primer Bulb: Aids in starting the engine by drawing fuel into the carburetor.

Common Issues

- Clogged Fuel Filter: Can restrict fuel flow, leading to performance issues.

- Damaged Fuel Lines: May cause leaks or reduce fuel delivery.

- Carburetor Malfunction: Can disrupt the air-fuel mixture, affecting engine start and operation.

Electrical System Insights

The electrical framework of any machinery plays a crucial role in its overall functionality and performance. Understanding the intricacies of this system can significantly enhance maintenance practices and troubleshooting efforts, leading to optimal operation and longevity.

Key Components

Central to the electrical architecture are elements such as wiring harnesses, batteries, and ignition systems. Each component serves a specific function, contributing to the seamless flow of energy necessary for efficient performance.

Maintenance Tips

Regular inspections and timely replacements of worn parts are essential to ensure reliability. Delving into the specifics of your equipment’s electrical components can help identify potential issues before they escalate, ensuring the ultimate efficiency of the entire system.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. By adopting a regular maintenance routine, you can enhance performance and prevent costly repairs.

Regular Cleaning

- Remove debris after each use to prevent clogging.

- Wipe down surfaces to eliminate dust and dirt.

- Inspect air filters regularly and replace when necessary.

Routine Inspections

- Check for wear and tear on moving parts.

- Lubricate components as per the manufacturer’s guidelines.

- Monitor fuel levels and quality to ensure optimal operation.

Common Issues and Solutions

Understanding the frequent challenges encountered with outdoor equipment can significantly enhance performance and longevity. Addressing these problems promptly not only improves functionality but also ensures safety during use.

Issue 1: Difficulty Starting

This problem often stems from a clogged air filter or stale fuel. Solution: Check and replace the air filter if necessary, and use fresh fuel mixed correctly with oil.

Issue 2: Excessive Vibration

Vibration can indicate loose components or wear. Solution: Tighten all screws and inspect the blades for damage; replacing worn parts can alleviate this issue.

Issue 3: Engine Overheating

Overheating is frequently due to inadequate lubrication or blocked cooling fins. Solution: Ensure proper oil levels and clear any debris from the cooling areas.

Issue 4: Poor Performance

This can result from a dirty spark plug or incorrect carburetor settings. Solution: Clean or replace the spark plug and adjust the carburetor as needed.

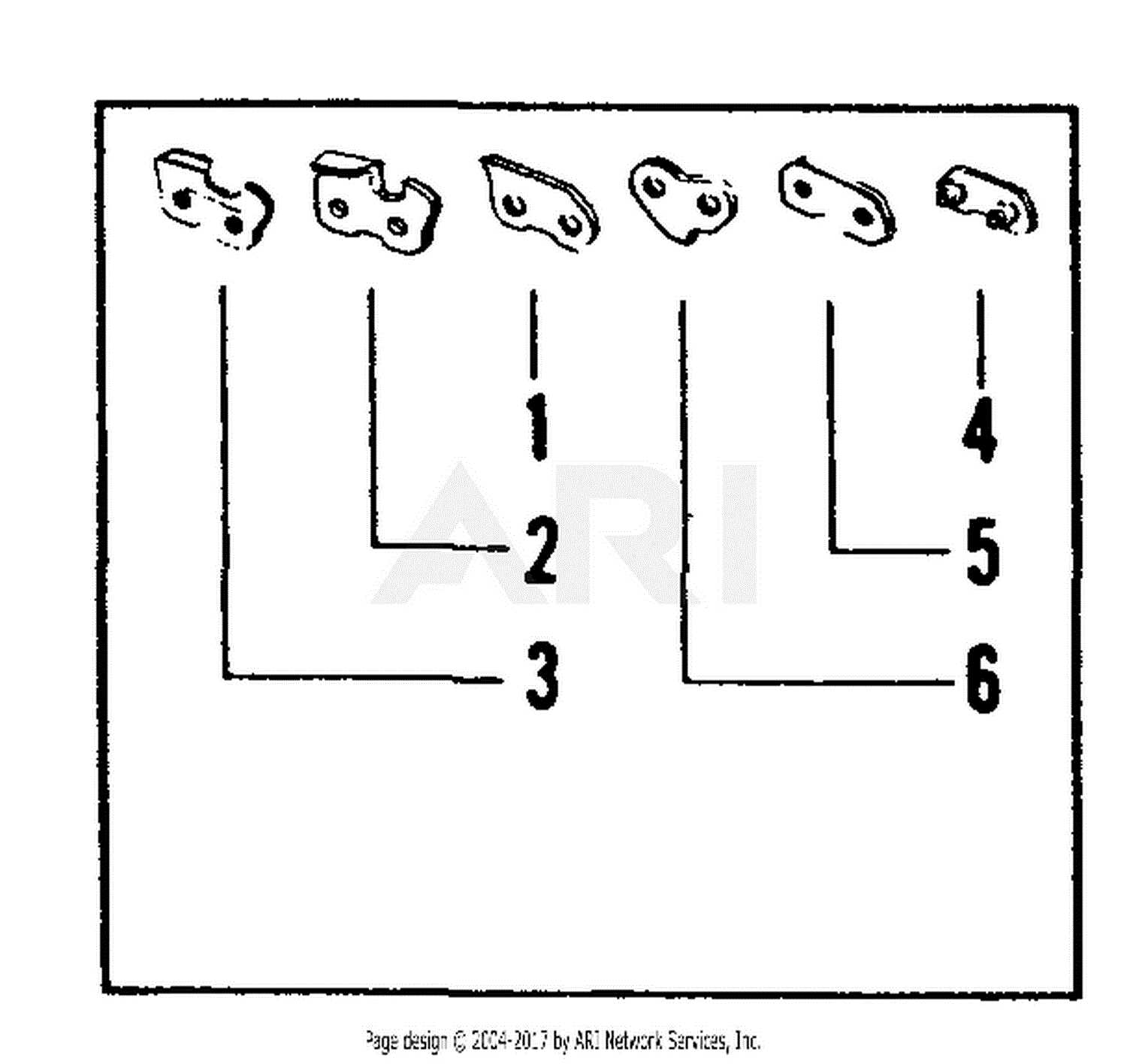

Identifying Replacement Parts

Understanding the essential components of your equipment is crucial for effective maintenance and repair. By recognizing each element, you can ensure optimal performance and longevity. This section aims to guide you through the process of pinpointing the necessary components for your machine.

Common Components Overview

Familiarity with typical elements helps in quickly identifying what needs replacement. Below is a brief overview of standard parts commonly encountered.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire unit. |

| Fuel Tank | Stores the fuel required for operation. |

| Air Filter | Prevents dirt and debris from entering the engine. |

| Spark Plug | Ignites the fuel-air mixture for combustion. |

Steps for Identification

To effectively identify components, begin by consulting the manufacturer’s specifications. Cross-reference with diagrams or manuals to locate and verify the parts required for your repair or replacement needs.

Where to Find Parts Diagrams

Locating illustrations that detail the components of various equipment can be essential for maintenance and repairs. These visual guides help users identify and understand the individual elements required for effective servicing.

Online Resources: Many websites specialize in providing comprehensive visual references for various tools and machinery. Searching on manufacturer websites or authorized retailers often yields accurate and up-to-date information.

Forums and Community Groups: Engaging with online communities can be invaluable. Experienced users frequently share resources, including visual schematics, that can aid in identifying necessary components.

Manuals and Documentation: Checking the original manuals that accompany the equipment is a reliable way to find detailed illustrations. If the original documents are not available, many manufacturers offer downloadable versions on their websites.

Utilizing these resources can ultimately streamline the repair process, ensuring you have the right visuals at your fingertips.

Tools Needed for Repairs

Effective maintenance and restoration of outdoor equipment require a selection of essential instruments. Having the right tools at your disposal can streamline the repair process, ensuring efficiency and precision in each task.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To drive screws into various components. |

| Pliers | For gripping and manipulating small parts. |

| Socket Set | To access hard-to-reach fasteners. |

| Torque Wrench | To ensure proper tightening of bolts. |

| Safety Gear | To protect yourself during repairs. |

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment effectively. Following these guidelines will ensure you navigate the repair process smoothly and efficiently.

- Gather Tools and Materials:

- Wrench set

- Screwdrivers

- Replacement components

- Lubricants

- Disassemble the Unit:

Carefully remove the outer casing and identify the internal parts that need attention.

- Inspect Components:

Look for wear, damage, or any signs of malfunctioning parts that require replacement.

- Replace Damaged Parts:

Install new components as needed, ensuring proper alignment and secure fittings.

- Reassemble the Unit:

Put all parts back together, making sure everything is tightened correctly.

- Test the Equipment:

Run the machine to ensure all repairs were successful and the unit operates smoothly.

By following these steps, you will enhance the longevity and performance of your device, ensuring it runs at its best.

Enhancing Performance of the Poulan

Improving the efficiency and effectiveness of your gardening tool can lead to a more enjoyable and productive experience. By focusing on maintenance and upgrades, users can maximize performance and longevity.

Key Maintenance Tips

- Regularly clean the air filter to ensure optimal airflow.

- Sharpen the blade consistently for precise cutting.

- Check and replace the spark plug as needed.

- Inspect fuel lines for wear and tear to prevent leaks.

Upgrades to Consider

- Invest in a high-quality fuel to improve combustion efficiency.

- Consider aftermarket filters for enhanced air intake.

- Upgrade to a performance spark plug for better ignition.

Implementing these strategies can significantly enhance the functionality and reliability of your equipment, allowing for a seamless gardening experience.