When it comes to maintaining outdoor machinery, having a clear understanding of its components is essential. A thorough examination of each part not only enhances the performance of the device but also extends its lifespan. This section aims to provide a detailed exploration of how these elements function together to achieve optimal results.

Visual aids play a crucial role in this understanding, offering a clear representation of how different segments interact. By dissecting the assembly, users can pinpoint specific areas that may require attention or replacement. This approach empowers individuals to tackle maintenance tasks with confidence and precision.

Furthermore, familiarity with the various components contributes to informed decision-making when sourcing replacements or upgrades. By recognizing the significance of each piece, users can ensure that their equipment operates smoothly and efficiently, leading to a more enjoyable experience in the great outdoors.

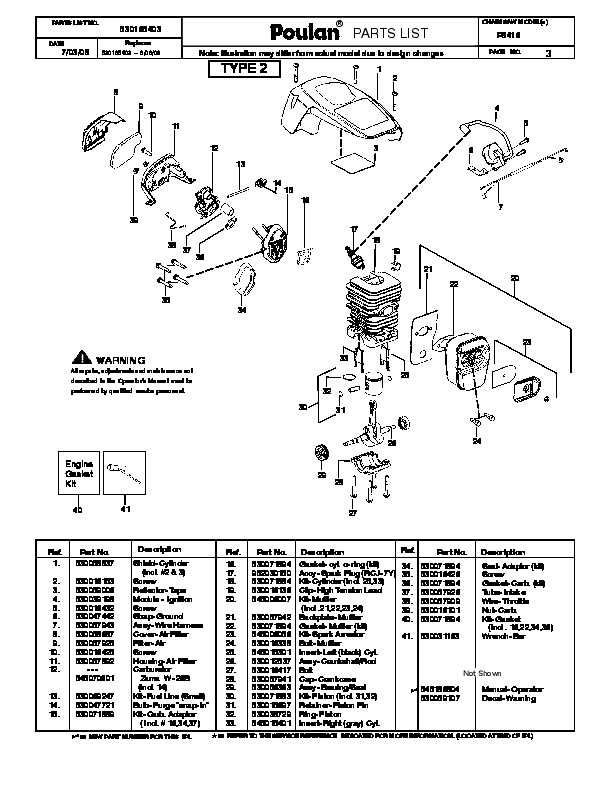

Poulan P3416 Overview

This section provides a comprehensive examination of a versatile outdoor power tool designed for efficiency and performance. With a focus on functionality and user experience, the device serves as an essential aid for various landscaping tasks.

Key Features

The tool boasts a robust engine, enabling it to handle demanding jobs with ease. Its lightweight design ensures portability, while ergonomic elements enhance user comfort during extended use. Additionally, the combination of innovative technology and durability makes it suitable for both amateur and professional users.

Maintenance and Care

Proper upkeep is crucial for optimal performance and longevity. Regular inspections and timely replacements of essential components can significantly enhance efficiency. Following the manufacturer’s guidelines for maintenance will ensure the tool remains in peak condition.

Importance of Parts Diagrams

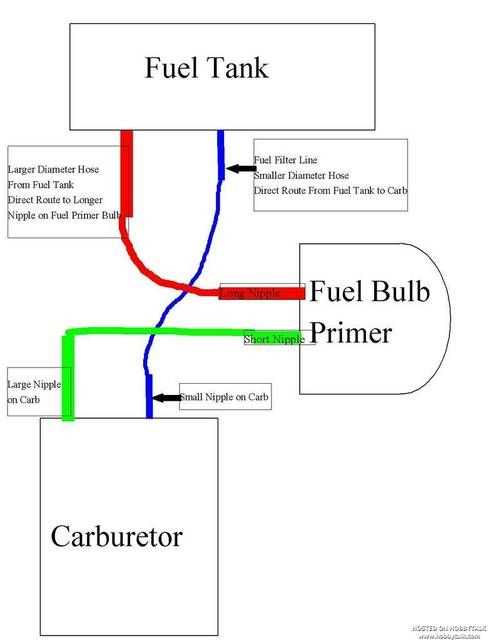

Understanding the layout of components within a machine is crucial for effective maintenance and repair. These visual representations serve as essential tools, enabling users to identify and locate specific elements swiftly, ultimately enhancing the efficiency of any task.

Enhanced Troubleshooting

By utilizing these illustrations, technicians can pinpoint issues with greater accuracy. Recognizing each segment’s function aids in the diagnosis of malfunctions, allowing for a more focused approach to resolving problems.

Streamlined Reassembly

When disassembling equipment, having a clear visual guide ensures that reassembly is done correctly. This not only saves time but also minimizes the risk of overlooking critical components, which could lead to future complications.

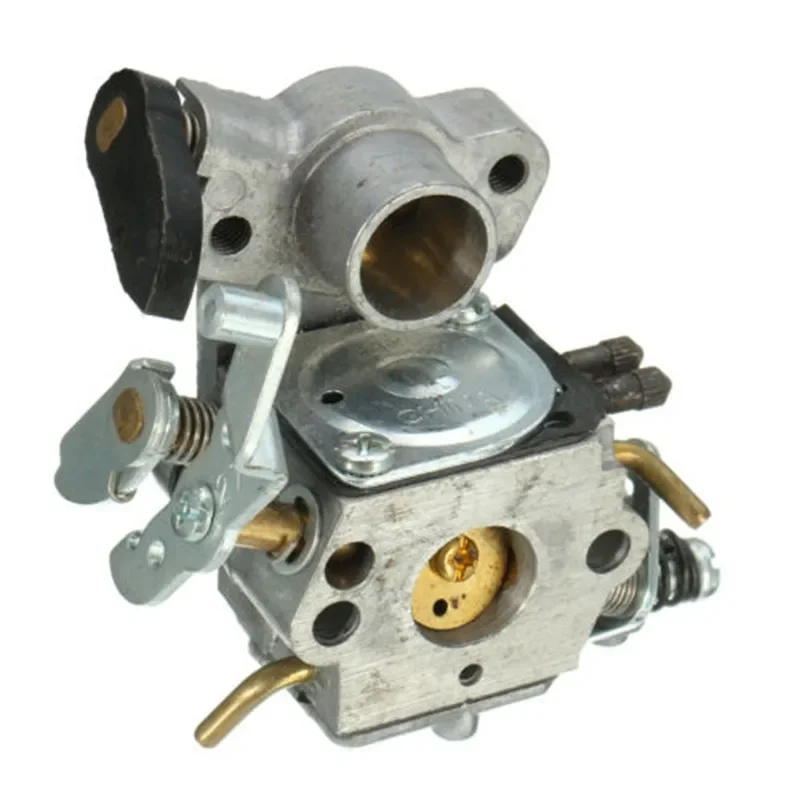

Key Components of Poulan P3416

Understanding the essential elements of this cutting tool is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency and reliability during operation.

- Engine: The power source that drives the entire mechanism.

- Chain: The cutting element that interacts with the material.

- Guide Bar: Supports and directs the chain for precise cutting.

- Throttle Trigger: Controls the engine’s power output.

- Air Filter: Ensures clean air enters the engine for combustion.

- Fuel Tank: Stores the necessary fuel for operation.

- Handle: Provides grip and control during use.

Each of these parts contributes to the tool’s overall functionality, making familiarity with them vital for effective handling and maintenance.

Understanding Chain Saw Mechanics

Chain saws are powerful tools that combine mechanical engineering with cutting-edge technology to facilitate efficient tree cutting and wood processing. Understanding the inner workings of these machines is essential for both operators and technicians, as it ensures optimal performance and longevity.

Key Components of a Chain Saw

Every chain saw consists of several critical parts, each serving a specific function. Familiarity with these components can enhance maintenance practices and troubleshooting skills.

- Engine: The heart of the machine, converting fuel into mechanical energy.

- Guide Bar: The metal bar that supports and guides the cutting chain.

- Cutting Chain: The loop of sharp teeth that performs the actual cutting.

- Throttle Control: Regulates engine speed and cutting power.

- Chain Brake: A safety feature that stops the chain quickly in case of kickback.

Mechanics in Action

The operation of a chain saw is a fine balance of various mechanical processes working together. Here’s how they interact:

- The engine ignites fuel, generating power.

- This power drives the crankshaft, which spins the sprocket.

- The sprocket moves the cutting chain along the guide bar.

- The chain’s sharp teeth cut through wood as the operator maneuvers the saw.

Understanding these mechanics not only aids in efficient operation but also plays a pivotal role in ensuring safety and effectiveness in cutting tasks.

Finding Replacement Parts Online

Locating suitable components for your equipment can be a straightforward process if you know where to look. The internet offers a vast array of resources, making it easier to source the necessary items without the hassle of traditional shopping. From specialized retailers to large e-commerce platforms, you can find what you need with just a few clicks.

Start by identifying the specific item you require, along with its model and specifications. This information is crucial for ensuring compatibility. Utilize search engines effectively, incorporating relevant keywords related to the component and your equipment type. This strategy will yield numerous options across various websites.

Many manufacturers provide official online stores, which can be a reliable source for authentic components. Additionally, consider checking user reviews and ratings on different platforms to gauge the quality and reliability of the suppliers. Online forums and communities can also offer valuable insights and recommendations from fellow users who have navigated similar searches.

Once you find potential suppliers, compare prices and shipping options. Some sites may offer discounts or bundle deals, which can lead to significant savings. Finally, ensure that the vendor has a clear return policy, should the item not meet your expectations. By following these steps, you can efficiently find and order the components you need for your equipment.

Common Issues and Solutions

When operating outdoor equipment, various challenges may arise that can hinder performance. Understanding these common problems and their remedies can help users maintain their tools effectively. Below is a summary of frequent issues and suggested solutions to enhance functionality and extend the lifespan of your equipment.

| Issue | Solution |

|---|---|

| Engine won’t start | Check the fuel level and ensure it is fresh. Inspect the spark plug for wear and replace if necessary. |

| Loss of power | Clean or replace the air filter. Ensure the fuel line is clear and free of blockages. |

| Unusual vibrations | Tighten loose screws and check for damaged components. Replace worn parts as needed. |

| Overheating | Allow the machine to cool down. Check for debris around the engine and clean the cooling fins. |

| Excessive smoke | Inspect oil levels; too much oil can cause smoke. Use the recommended oil type and quantity. |

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires a combination of regular upkeep and mindful usage. By adhering to a few essential practices, you can significantly enhance performance and reduce the risk of premature wear and tear. Implementing these strategies will help maintain efficiency and reliability over time.

Regularly inspecting your machine for signs of damage or wear is crucial. Check for loose components, frayed cables, or any abnormal noises during operation. Addressing minor issues promptly can prevent more significant problems down the line.

Keep the equipment clean, as debris can lead to overheating and mechanical failure. After each use, remove any dirt or buildup, especially from air vents and moving parts. This simple step promotes optimal functionality and prevents blockages.

Lubrication is vital for the smooth operation of mechanical parts. Use the recommended oils and greases to keep moving components well-maintained. This practice reduces friction and helps to avoid unnecessary strain on the machinery.

Lastly, always follow the manufacturer’s guidelines for storage and operation. Proper handling, including temperature considerations and secure storage, will further enhance durability and longevity. By integrating these maintenance tips into your routine, you can ensure that your equipment remains reliable for years to come.

Exploring Aftermarket Options

When maintaining or repairing outdoor power equipment, considering alternative components can significantly enhance performance and longevity. These options often provide a cost-effective solution without compromising quality. By exploring aftermarket alternatives, users can find a variety of products that may offer improved functionality and durability.

Quality and Compatibility are key factors to consider when selecting non-original replacements. Many manufacturers produce components that meet or exceed original specifications, ensuring a reliable fit and performance. Researching brands and reading customer reviews can guide you in making informed choices.

Cost savings is another compelling reason to look beyond standard parts. Aftermarket options often come at a lower price point, allowing users to allocate their budget more effectively. This financial advantage does not necessarily imply a loss in quality, as many aftermarket manufacturers prioritize performance and longevity.

Lastly, exploring a range of suppliers can lead to discovering unique innovations and enhancements that may not be available through original manufacturers. This exploration can result in a tailored solution that best meets individual needs and preferences, ultimately improving the overall experience with your equipment.

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for anyone looking to repair or maintain equipment. These visual representations provide detailed insights into the various components and their arrangement within the machine. By familiarizing yourself with how to interpret these visuals, you can streamline your repair process and ensure that you have the necessary items for any project.

Identifying Components

Begin by locating the key sections within the illustration. Each part is usually labeled with a unique identifier, such as a number or letter, which corresponds to a list of items. Pay attention to the orientation of the components, as this often indicates their correct positioning during reassembly.

Understanding Relationships

Next, observe how the various elements interact with one another. Look for connecting lines or arrows that show how parts fit together or how they function in relation to each other. This can help you grasp the overall mechanics and pinpoint areas that may need adjustment or replacement.

Safety Precautions When Repairing

When undertaking maintenance or repair tasks on outdoor equipment, adhering to safety measures is essential to prevent accidents and ensure a successful outcome. Proper precautions not only protect the individual performing the repairs but also help safeguard others in the vicinity.

Firstly, always wear appropriate personal protective equipment (PPE). This includes safety goggles to protect your eyes from debris, gloves to shield your hands from sharp objects, and sturdy footwear to provide support and protect against falling items.

Secondly, it is crucial to disconnect the power source before beginning any work. This simple step can prevent unexpected starts or electrical hazards, reducing the risk of injury. Additionally, ensure that the work area is well-lit and free from clutter, as a clean space promotes focus and minimizes the chances of accidents.

Furthermore, familiarize yourself with the equipment’s manual and specifications. Understanding how the machinery operates and the functions of different components can prevent errors during repairs. Always use the correct tools for the job, as using improvised instruments can lead to damage or personal injury.

Lastly, maintain a clear communication line with anyone nearby. Inform others about your activities, and ensure that they stay at a safe distance to avoid distractions or potential hazards. Following these guidelines will create a safer environment for both the technician and those around them.