The intricate world of fluid transportation systems involves a multitude of elements working in harmony. Each component plays a vital role in ensuring efficiency and reliability, making it essential to comprehend how they interconnect and function.

In this section, we will explore a comprehensive overview of various essential elements, shedding light on their design and operational significance. By examining the intricacies, one can delve into the ultimate purpose they serve within the overall mechanism.

Familiarity with these components not only enhances practical knowledge but also aids in troubleshooting and maintenance tasks. A deeper understanding empowers users to make informed decisions regarding performance optimization and longevity.

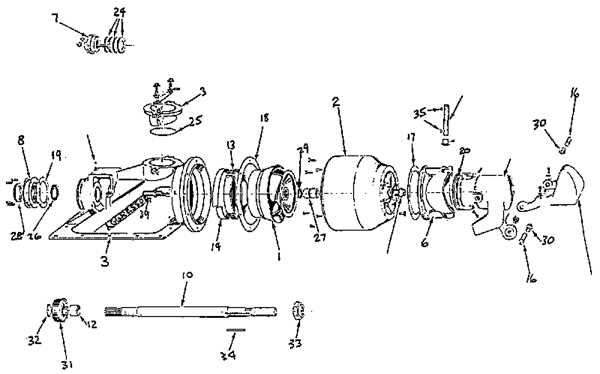

Understanding Berkeley Pump Components

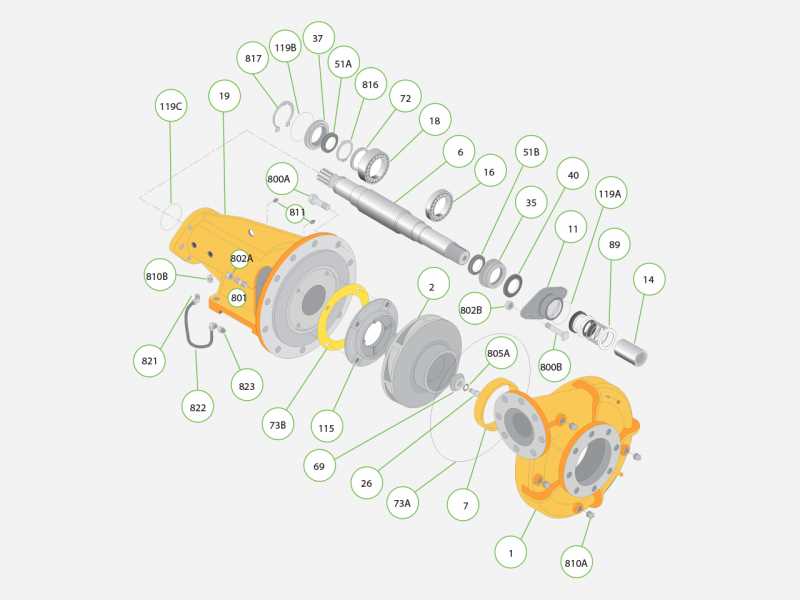

Grasping the various elements that contribute to the functionality of a fluid-moving system is essential for effective operation and maintenance. Each component plays a crucial role in ensuring efficiency and reliability, allowing the system to perform optimally under varying conditions. This overview delves into the main components, their functions, and how they interact within the overall assembly.

Main Elements

The core components of a fluid-moving system include the motor, casing, impeller, and seals. Each part serves a distinct purpose that collectively enhances the system’s performance. Understanding these elements is vital for troubleshooting and upgrades.

| Component | Function |

|---|---|

| Motor | Provides the necessary power to drive the system. |

| Casing | Encases and protects internal elements while directing fluid flow. |

| Impeller | Transforms mechanical energy into fluid energy to enhance movement. |

| Seals | Prevent leakage and maintain pressure within the assembly. |

Importance of Component Interaction

The interaction between these elements is vital for achieving optimal performance. Any malfunction in one part can significantly impact the entire system, leading to decreased efficiency and potential failure. Regular inspection and maintenance of each component are essential to ensure longevity and reliability.

Importance of Accurate Diagrams

Clear and precise illustrations play a crucial role in various technical fields. They serve as essential tools for conveying complex information in an easily understandable format. When representations are accurate, they enhance communication, reduce misunderstandings, and facilitate smoother operations within teams and projects.

Detailed visuals help users quickly grasp essential components and their relationships, leading to more efficient assembly, maintenance, and troubleshooting processes. In industries where precision is paramount, the absence of accurate representations can result in costly errors and delays.

Moreover, well-constructed illustrations support training and educational efforts, allowing newcomers to familiarize themselves with systems more effectively. By investing in high-quality visuals, organizations can ensure safety, reliability, and overall effectiveness in their operations.

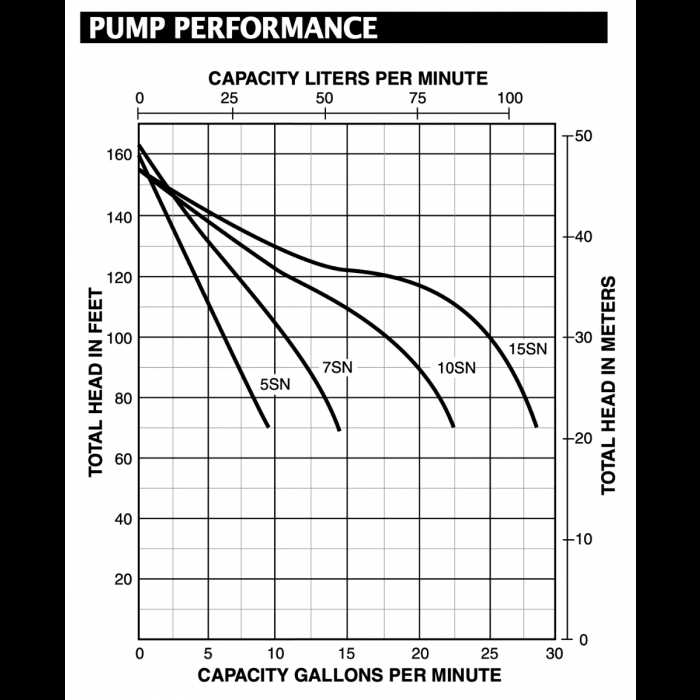

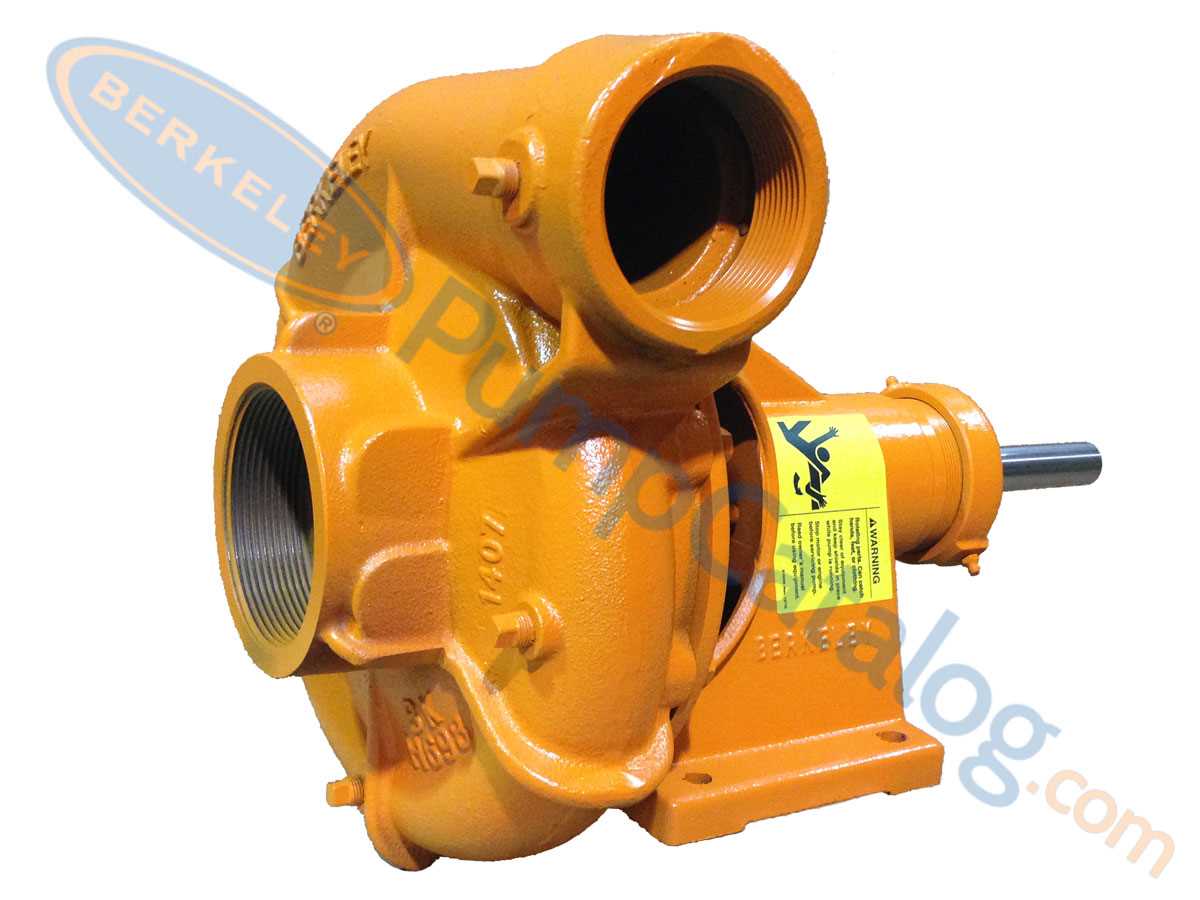

Types of Berkeley Pumps Explained

This section provides an overview of various models designed for fluid movement, highlighting their unique characteristics and functionalities. Understanding these variations is essential for selecting the appropriate system for specific applications, ensuring efficiency and reliability in operations.

Centrifugal Models

Centrifugal systems utilize rotational energy to propel liquids, making them ideal for high-flow applications. Their design features a rotating impeller that enhances fluid velocity, facilitating swift transport across different environments.

Positive Displacement Variants

Positive displacement designs function by trapping a fixed volume of fluid and forcing it through the system, providing consistent flow rates regardless of pressure changes. This reliability is crucial in applications requiring precise control over fluid dynamics.

Common Parts and Their Functions

This section explores the essential components that contribute to the overall functionality of hydraulic systems. Understanding these elements is crucial for effective operation and maintenance, as each plays a specific role in ensuring efficiency and reliability.

Motor: The driving force behind the system, converting electrical energy into mechanical power to initiate the flow of fluids.

Impeller: A key element responsible for increasing fluid velocity, thus facilitating movement through the system.

Volute: This component directs the flow of liquid from the impeller, helping to maintain pressure and ensure smooth operation.

Seal: Essential for preventing leaks, seals maintain the integrity of the system by ensuring that fluids do not escape.

Strainer: This part filters out debris and particulates, protecting the internal components from damage and ensuring optimal performance.

Discharge Outlet: The exit point for the fluid, allowing it to flow into the designated system or application.

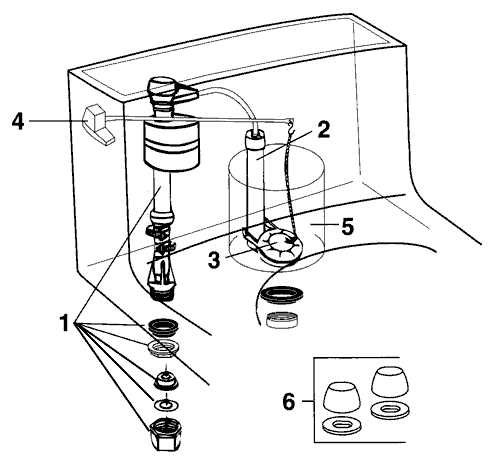

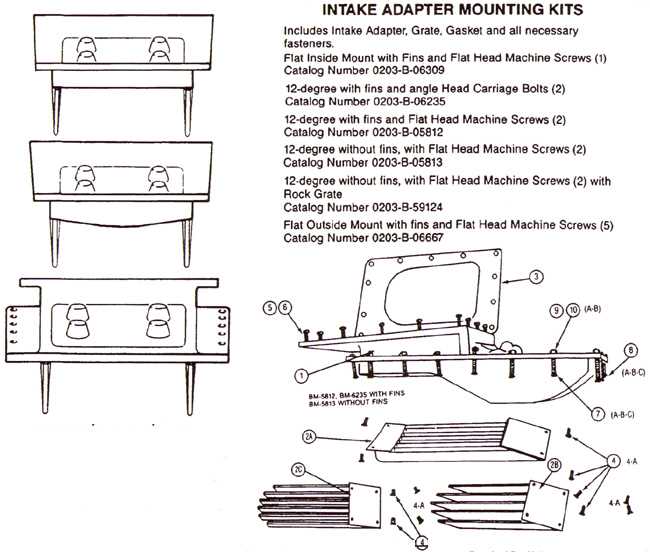

Assembly Process of Pump Components

The assembly process of mechanical devices involves a systematic approach to integrating various elements into a cohesive unit. This procedure ensures that each component fits together perfectly, contributing to the overall functionality and efficiency of the system.

Typically, the assembly process can be broken down into several key stages. Each stage plays a crucial role in achieving a reliable and high-performing assembly. Below is a detailed overview of these stages:

| Stage | Description |

|---|---|

| Preparation | Gather all necessary components and tools, ensuring that everything is clean and ready for use. |

| Alignment | Carefully position the main elements to ensure they are aligned correctly before fastening them together. |

| Fastening | Use appropriate methods to secure the components, such as bolts, screws, or welding, depending on the design specifications. |

| Sealing | Apply seals or gaskets as needed to prevent leaks and ensure optimal performance of the assembled unit. |

| Testing | Conduct a thorough examination to verify that the assembly operates smoothly and meets all required standards. |

Each of these stages must be executed with precision to ensure the integrity and longevity of the final product. Attention to detail throughout the assembly process is essential for optimal performance and reliability.

Maintenance Tips for Long Lifespan

Ensuring the durability and efficiency of your equipment requires regular attention and care. Implementing a systematic maintenance routine can significantly extend its operational life and performance.

1. Regular Inspections: Conduct periodic checks to identify any wear or damage. Early detection can prevent more significant issues.

2. Clean Components: Keep all surfaces free from debris and build-up. Cleanliness is crucial for optimal functioning.

3. Lubrication: Apply appropriate lubricants to moving elements to reduce friction and wear. This practice enhances performance and prevents overheating.

4. Monitor Performance: Keep track of operational metrics. Any deviation from normal performance can signal potential problems.

5. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and procedures. This ensures you are using best practices for longevity.

6. Store Properly: When not in use, store equipment in a dry, sheltered location to protect it from environmental factors.

By following these essential tips, you can help maximize the lifespan of your machinery, ensuring it remains efficient and reliable for years to come.

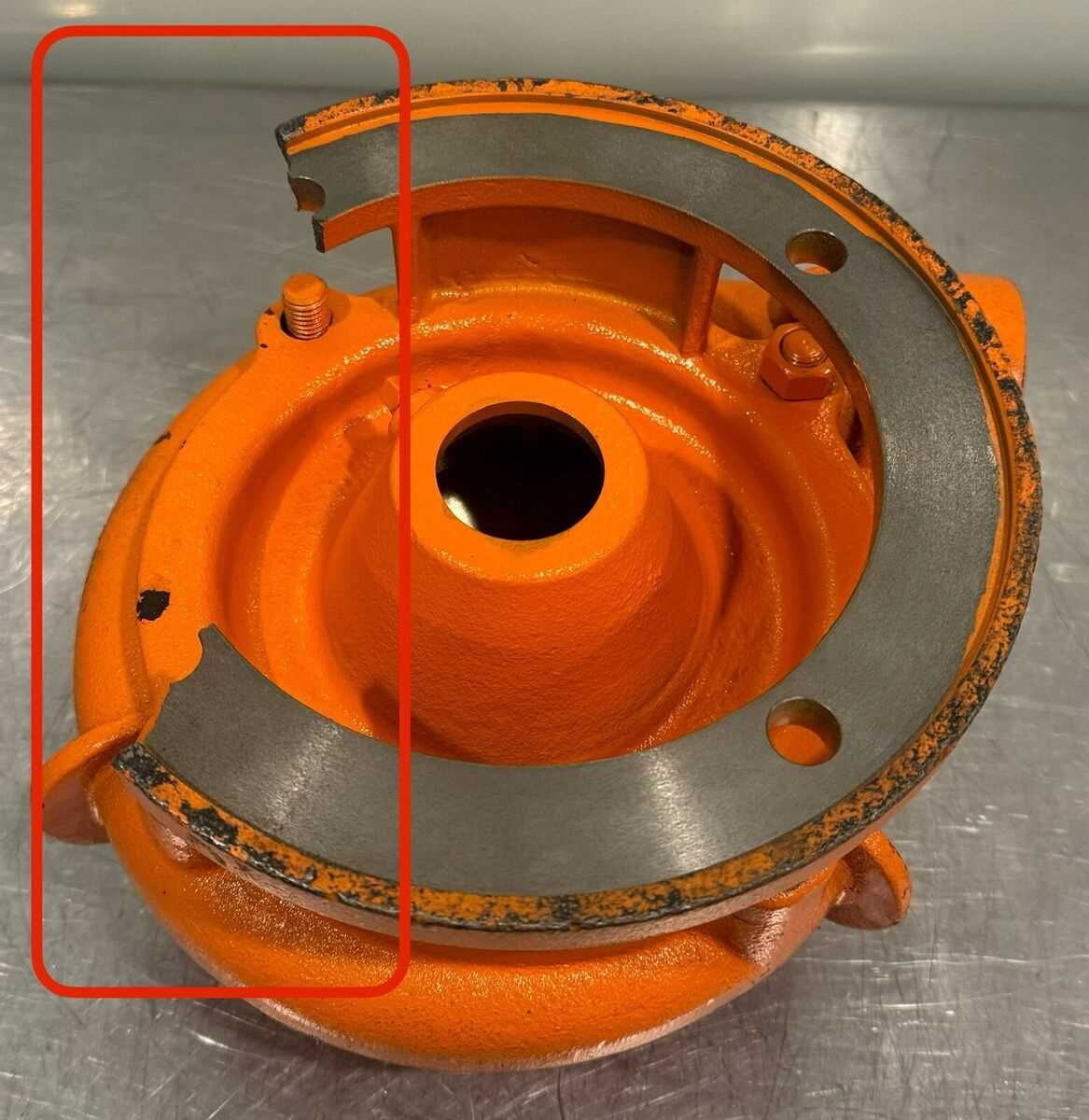

Identifying Wear and Tear Signs

Recognizing signs of deterioration is crucial for maintaining equipment functionality and extending its lifespan. Various indicators can signal that components are not performing optimally, which could lead to more significant issues if not addressed promptly. Understanding these symptoms helps in timely interventions and prevents unexpected failures.

Common Indicators

Several visible and functional signs can point to wear and tear. Observing these aspects can guide users in taking necessary actions to ensure optimal operation.

| Indicator | Description |

|---|---|

| Unusual Noises | Sounds such as grinding, squeaking, or rattling can indicate internal issues. |

| Leakage | Visible fluid escaping from seals or joints often signifies degradation. |

| Vibration | Excessive shaking during operation may suggest misalignment or imbalance. |

| Discoloration | Color changes in components can indicate overheating or material degradation. |

Maintenance Recommendations

To mitigate issues arising from wear and tear, regular inspections and maintenance are essential. Establishing a routine can help in identifying problems early, ensuring that components function effectively for an extended period.

Upgrading Your Pump System

Enhancing your fluid transfer system can lead to significant improvements in efficiency and performance. By carefully selecting and integrating modern components, you can optimize operations, reduce energy consumption, and extend the lifespan of your setup. This section explores essential considerations and steps for an effective upgrade.

Key Considerations

- Performance Needs: Assess the specific requirements of your system, including flow rates and pressure demands.

- Component Compatibility: Ensure that new elements are compatible with existing infrastructure to avoid unnecessary complications.

- Energy Efficiency: Look for solutions that offer lower energy consumption while maintaining or enhancing output.

Upgrade Steps

- Conduct a thorough evaluation of your current system to identify weaknesses and areas for improvement.

- Research advanced components that align with your performance goals.

- Plan the installation process, considering any necessary modifications to existing setups.

- Implement the upgrades while adhering to safety regulations and best practices.

- Test the updated system to ensure optimal functionality and efficiency.

By following these guidelines, you can successfully modernize your fluid handling infrastructure and achieve better results.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is paramount to prevent accidents and injuries. Proper precautions help to create a secure working environment, allowing for efficient and effective repairs while safeguarding both the technician and the equipment.

Essential Safety Measures

Before commencing any repair work, it is crucial to adopt specific safety protocols. These measures include wearing appropriate personal protective equipment and ensuring that all tools are in good condition. Regular inspections of the work area also play a vital role in minimizing hazards.

Tool and Equipment Safety

Utilizing tools correctly is essential for avoiding accidents. Make sure all equipment is suitable for the task at hand and follow manufacturer guidelines for usage.

| Safety Measure | Description |

|---|---|

| Protective Gear | Use gloves, goggles, and helmets as needed. |

| Tool Inspection | Check tools for damage before use. |

| Work Area Cleanliness | Keep the workspace free of debris and clutter. |

| Emergency Procedures | Be familiar with emergency exits and first aid protocols. |

Tools Needed for Assembly

When embarking on an assembly project, having the right tools is essential for achieving optimal results. Each task may require a specific set of instruments to ensure efficiency and accuracy during the process. Proper preparation can significantly streamline the entire operation, allowing for a smoother workflow.

Essential Instruments

To begin, you’ll need a variety of hand tools. A wrench set is crucial for securing and adjusting components. Additionally, a screwdriver set, which includes both flathead and Phillips options, will be necessary for fastening different types of fasteners. A hammer may also come in handy for tapping parts into place without causing damage.

Measuring and Safety Tools

Accurate measurements are vital, so having a reliable tape measure and a level will help ensure everything is aligned correctly. Don’t overlook safety; equip yourself with gloves and safety goggles to protect against potential hazards during assembly. Lastly, consider a workbench or stable surface to keep your workspace organized and efficient.

Resources for Further Learning

Exploring the intricacies of mechanical systems requires a blend of theoretical knowledge and practical skills. To deepen your understanding and enhance your expertise, a variety of resources are available that cater to different learning styles and preferences.

- Books: Look for titles focused on fluid dynamics, machinery design, and maintenance practices.

- Online Courses: Platforms like Coursera and Udemy offer courses tailored to various aspects of engineering and mechanical design.

- Tutorials and Webinars: Many websites provide step-by-step guides and live sessions led by industry professionals.

- Technical Journals: Subscribing to engineering journals can keep you updated on the latest research and innovations.

- Forums and Community Groups: Engaging with online communities can offer practical advice and shared experiences.

Utilizing these resources will enhance your knowledge and skills, enabling you to approach projects with greater confidence and insight.