In the realm of automotive engineering, the intricacies of fuel management are crucial for optimal performance. A comprehensive exploration of the mechanisms involved reveals the complexity behind the seamless operation of engines. This section focuses on various components that work in harmony to ensure efficient fuel flow and combustion.

By examining the configuration and functionality of these essential elements, one can grasp how they contribute to the overall effectiveness of the system. Each segment plays a vital role, impacting everything from energy efficiency to emissions control.

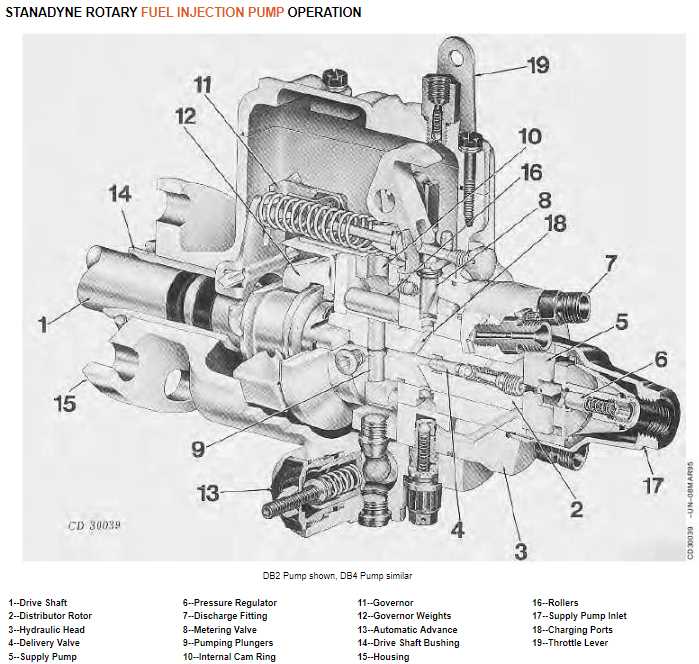

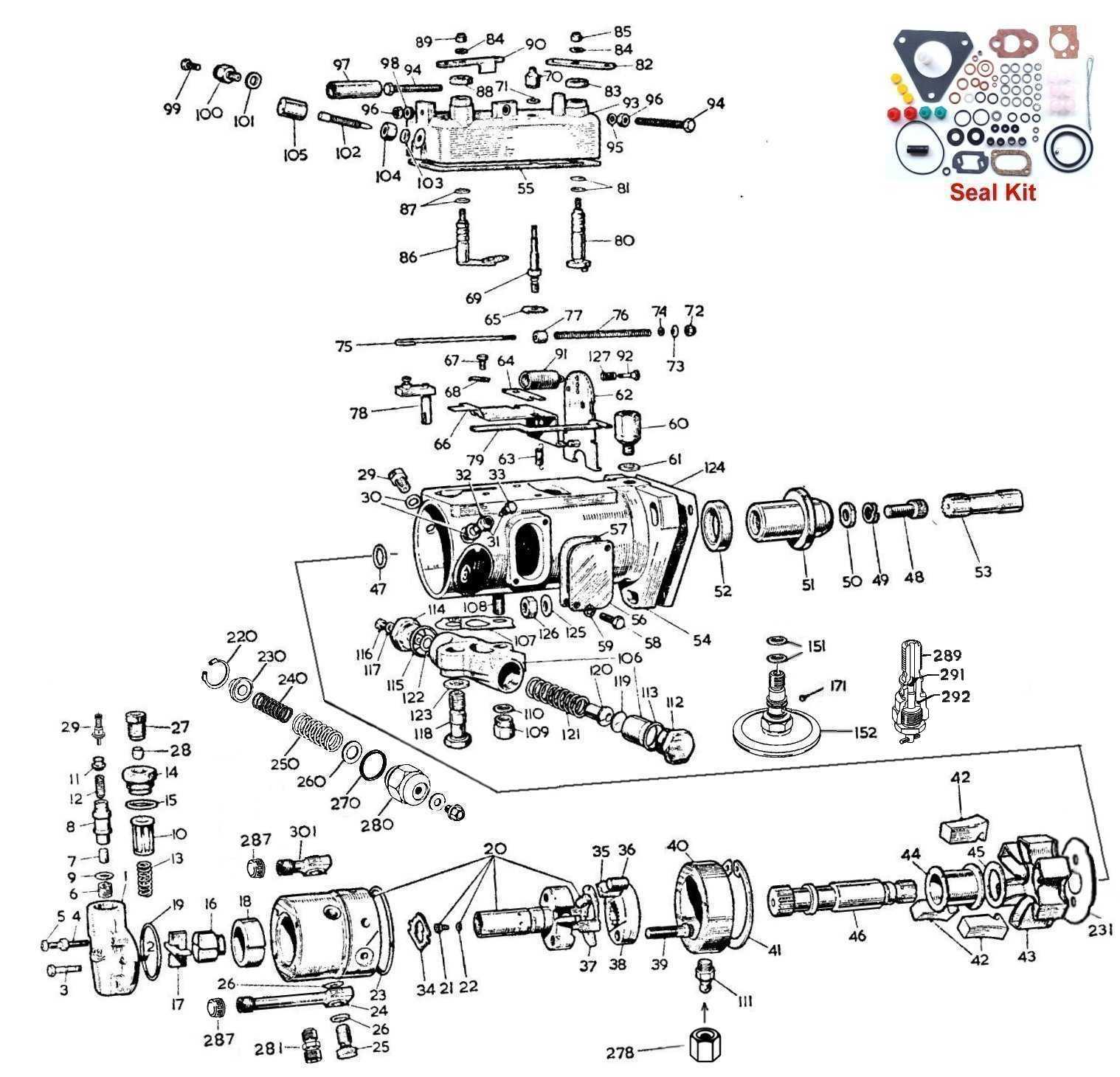

Furthermore, detailed schematics provide invaluable insight into the interconnectivity of these components, enhancing our understanding of how they operate together. This analysis will delve into the specifications and arrangements that define this crucial aspect of automotive technology.

Understanding Cav Injector Pump Functionality

The intricacies of fuel delivery mechanisms are essential for optimizing engine performance. By examining how these systems operate, one can gain insights into their efficiency and reliability. This section aims to explore the fundamental principles behind the functionality of these critical components.

Mechanics of Fuel Delivery

At the core of this system lies a series of precisely engineered elements that work in unison to regulate the flow of fuel. These components ensure accurate timing and pressure, enabling a seamless transfer of energy to the engine. Understanding their roles enhances the overall comprehension of the mechanism.

Importance of Maintenance

Regular upkeep is vital to maintaining the efficacy of these systems. Neglecting the maintenance of individual components can lead to diminished performance and increased wear. A proactive approach not only extends the lifespan of the mechanism but also ensures optimal engine operation.

Key Components of Cav Injectors

This section explores the essential elements that contribute to the functionality and efficiency of fuel delivery systems. Understanding these components is crucial for maintenance and performance optimization.

Major Elements

- Fuel Delivery Mechanism

- Control Unit

- Pressure Regulator

- Timing Device

- Connecting Hoses

Functionality Overview

- Ensures precise fuel distribution.

- Regulates pressure for optimal performance.

- Coordinates timing for effective combustion.

- Facilitates connection to various fuel sources.

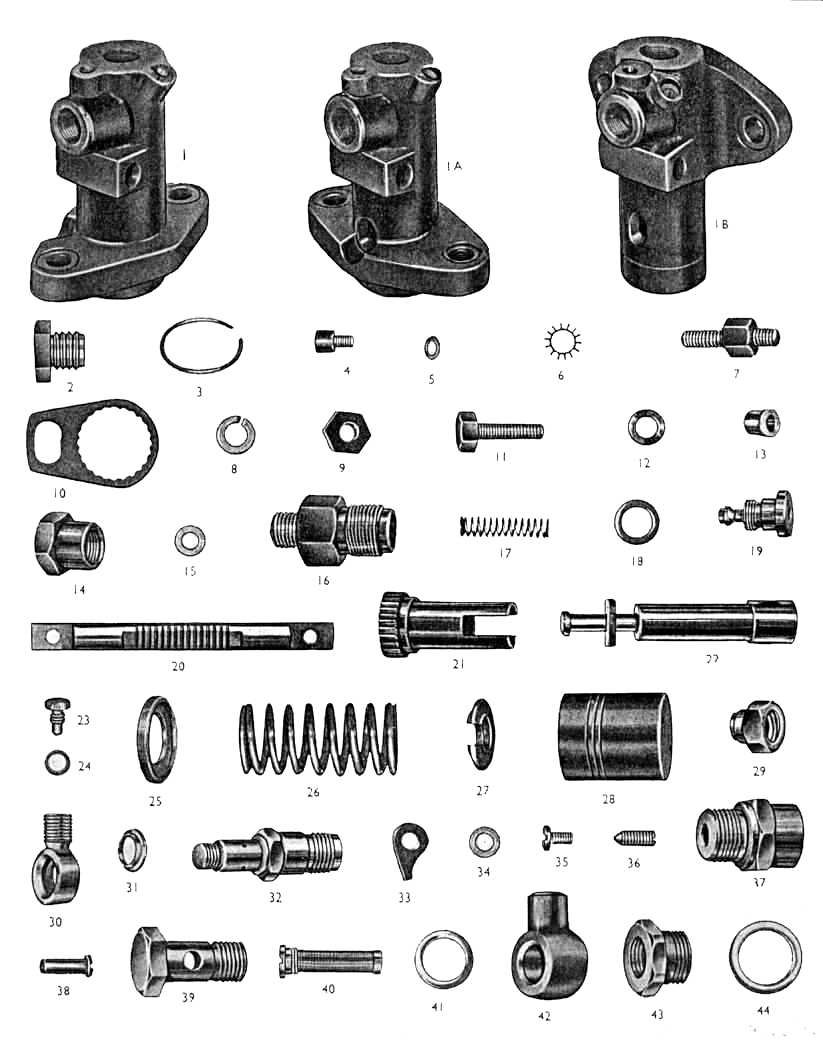

Importance of Injector Pump Diagrams

Understanding the intricacies of fuel distribution systems is crucial for maintenance and efficiency. Visual representations of these mechanisms provide clarity, enabling technicians to diagnose issues swiftly and accurately.

Benefits of Visual Representations

- Enhanced comprehension of complex systems.

- Facilitated troubleshooting and repairs.

- Streamlined training for new personnel.

Key Features to Consider

- Identification of various components.

- Clear flow paths for fuel and pressure.

- Connections and assembly instructions.

Common Issues with Cav Pumps

Understanding the typical challenges associated with fuel delivery systems can significantly enhance maintenance practices. Various components within these systems can experience malfunctions, leading to performance issues and inefficiencies. Identifying these common problems early can prevent extensive damage and costly repairs.

1. Fuel Leakage

One of the most prevalent issues is leakage, which can arise from worn seals or damaged connections. Leakage not only diminishes performance but also poses safety risks. Regular inspections are essential to identify signs of fluid loss, ensuring that all seals and fittings are in good condition.

2. Performance Degradation

Over time, systems may exhibit reduced efficiency due to wear and tear. Decreased performance can manifest as inconsistent flow rates or difficulty starting engines. Factors contributing to this decline include contamination from impurities in the fuel and inadequate maintenance. Regular cleaning and timely replacements of critical components can help mitigate these issues.

Awareness of these potential problems enables proactive measures, fostering better operational reliability and longevity of the system.

How to Read Injector Pump Diagrams

Understanding technical illustrations is essential for effective maintenance and troubleshooting. These visuals convey intricate details about various components and their interrelations, making it easier to grasp their functionality and role in the system.

Key Elements to Observe

- Labels: Pay attention to the annotations that indicate different elements. Each label provides critical information.

- Symbols: Familiarize yourself with common symbols used to represent specific functions or parts.

- Connections: Note the lines indicating how components interact. This helps in visualizing the flow of operations.

Steps to Follow

- Start by identifying the main components illustrated.

- Examine the flow paths marked, as they indicate the sequence of operation.

- Cross-reference with a manual or guide to clarify any unfamiliar symbols.

- Practice reading multiple illustrations to enhance your understanding.

Maintenance Tips for Cav Injector Parts

Regular upkeep is essential for optimal performance and longevity of your fuel delivery system components. Proper care ensures efficient operation, reduces wear and tear, and minimizes the risk of costly repairs.

| Tip | Description |

|---|---|

| Clean Regularly | Remove debris and contaminants to prevent blockages and maintain flow efficiency. |

| Check Seals | Inspect seals frequently for wear or damage to avoid leaks and ensure tight fittings. |

| Monitor Performance | Regularly assess the system’s functionality to identify issues early and address them promptly. |

| Use Quality Fluids | Utilize high-grade fuel and lubricants to enhance performance and reduce wear. |

| Follow Manufacturer Guidelines | Adhere to recommended service intervals and procedures for best results. |

Comparing Cav and Other Brands

When exploring the landscape of fuel delivery systems, it’s essential to understand the differences among various manufacturers. Each brand offers unique features, engineering solutions, and reliability standards that cater to diverse needs in the automotive and agricultural sectors. This section delves into the strengths and weaknesses of one prominent brand compared to its competitors, emphasizing performance, durability, and serviceability.

Performance and Efficiency

One key area of comparison is the efficiency of the mechanisms involved. Many brands tout enhanced performance through advanced technology, which can lead to improved fuel economy and reduced emissions. However, it’s important to consider real-world testing and user feedback, as theoretical advantages do not always translate into practical benefits.

Durability and Maintenance

Durability is another critical aspect that sets brands apart. Some manufacturers focus on robust materials and design, ensuring longer life spans under strenuous conditions. In contrast, others may prioritize ease of maintenance, which can significantly reduce downtime and repair costs. Understanding these trade-offs helps consumers make informed decisions based on their specific applications.

Ultimately, evaluating these brands involves looking beyond specifications and understanding how they align with individual requirements and preferences.

Diagnosing Injector Pump Problems

Identifying issues within the fuel delivery system is essential for maintaining optimal engine performance. Various symptoms can indicate malfunctions, from poor fuel efficiency to rough idling. Understanding these signs is the first step in troubleshooting and ensuring smooth operation.

Common Symptoms of Malfunction

Common indicators include unexpected stalling, difficulty starting, or noticeable drops in power. If the engine struggles to maintain RPM or emits excessive smoke, these may signal underlying problems. Regular observation can help in pinpointing these discrepancies early.

Steps for Troubleshooting

Begin by inspecting fuel quality and ensuring there are no blockages in the system. Check connections for leaks and examine the functionality of the delivery components. Using diagnostic tools can also assist in evaluating performance metrics, leading to a more precise resolution.

Upgrading Cav Injector Systems

Enhancing fuel delivery systems is essential for improving performance and efficiency in modern machinery. Upgrading these systems can lead to better fuel atomization, increased power output, and reduced emissions. This section will explore various strategies for elevating the functionality and reliability of these vital components.

Key Benefits of Upgrading

- Improved fuel efficiency, resulting in lower operational costs.

- Enhanced engine responsiveness and performance under load.

- Reduction in harmful emissions, contributing to environmental sustainability.

- Increased lifespan of engine components due to optimized operation.

Steps for Successful Upgrades

- Assess the current system’s performance and identify areas for improvement.

- Research and select high-quality alternatives that offer advanced technology.

- Ensure compatibility with existing engine specifications to avoid malfunctions.

- Follow best practices during installation to maintain system integrity.

- Conduct regular maintenance checks to ensure ongoing optimal performance.

Resources for Injector Pump Repair

When it comes to restoring fuel delivery systems, having access to reliable information and quality components is crucial. Proper maintenance and repair require a combination of expert guidance and the right materials to ensure optimal functionality. This section provides valuable resources to assist in the repair process.

Online Forums and Communities

Engaging with online communities can be incredibly beneficial. These platforms often host discussions where experienced technicians share tips, troubleshooting techniques, and solutions to common issues. Participating in forums allows you to ask questions and receive advice tailored to your specific situation, making it an invaluable resource for both novice and seasoned mechanics.

Manufacturer Websites and Manuals

Consulting the official websites of component manufacturers is essential. They typically offer technical manuals and detailed guides that outline specifications, assembly instructions, and maintenance recommendations. Utilizing these resources ensures that repairs are conducted according to industry standards, enhancing the reliability and performance of the system.

In summary, leveraging online communities and manufacturer resources can significantly improve the repair process, ensuring that your fuel delivery system operates efficiently and effectively.