The functionality and efficiency of modern cooking equipment rely heavily on the precise arrangement and interaction of various internal components. Knowing how these elements work together can greatly enhance the user’s ability to maintain, troubleshoot, and optimize performance. Each element plays a crucial role in ensuring smooth operation and long-lasting reliability.

In this overview, we will delve into the structure of a popular commercial kitchen unit, highlighting the key sections that require attention. By familiarizing yourself with the core features and how they interconnect, you can ensure consistent results in everyday use while minimizing potential breakdowns.

We’ll guide you through a closer look at the major elements, offering insights into their specific roles and how they contribute to the overall operation. Whether you are seeking to improve your technical knowledge or looking for guidance in upkeep, this comprehensive exploration will provide the clarity needed for effective management.

Overview of Components in Cooking Equipment

Modern kitchen equipment is made up of various interconnected parts, each designed to perform a specific role in the preparation of food. These elements are crucial for ensuring efficiency, safety, and high performance in professional and home kitchens alike. Understanding how these components interact and function together can help maintain optimal cooking conditions and prolong the life of the appliance.

Primary Functional Elements

- Heating Components: These include elements responsible for generating the necessary heat to cook food. They vary depending on whether the equipment uses gas, electricity, or another heat source.

- Control Systems: These components manage the regulation of temperature and operational settings, ensuring precise cooking conditions are met for various culinary tasks.

- Ventilation and Safety Mechanisms: Proper ventilation is essential to maintain a safe cooking environment, while safety systems prevent overheating or gas leaks.

Supportive Structures

- Framework and Housing: The external structure holds all internal parts in place, providing stability and protecting sensitive elements from external damage.

- Insulation and Sealing: Designed to

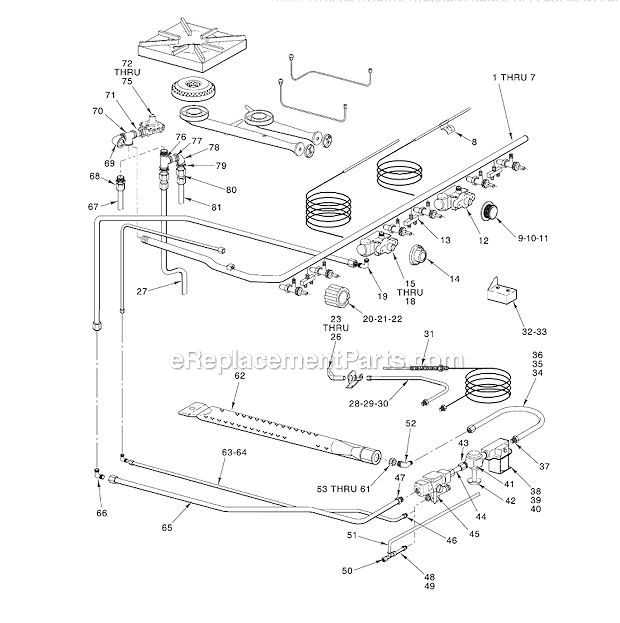

Key Elements in Gas Control Systems

Gas control mechanisms are essential for regulating the flow, pressure, and safety of heating appliances. They work to ensure that the system operates efficiently and securely, balancing heat output while preventing hazards. Understanding the key components involved helps to maintain consistent performance and troubleshoot issues more effectively.

Flow Management

The flow regulation aspect of the system includes valves and pressure regulators that precisely control how much fuel enters the heating unit. These elements are vital in maintaining consistent heat levels, preventing overflows, and ensuring optimal energy use.

Safety Features

In addition to controlling flow, safety elements like thermocouples and shut-off systems act as protective measures. They detect irregularities in temperature or fuel levels and can automatically stop the supply in case of malfunction, enhancing the

Understanding Burner Functionality and Structure

The burner is a crucial component in cooking appliances, responsible for generating the necessary heat to prepare food. Its design and operation are engineered to ensure efficient combustion, resulting in even heat distribution. Understanding how this element works and the principles behind its structure is essential for both maintenance and troubleshooting.

Key Elements of Burner Operation

At the core of the system lies a combination of fuel and air, which mix in precise proportions to produce a flame. The efficiency of this process directly affects the heat output. Burner jets regulate the flow of gas, ensuring a steady flame, while the ignition system provides the initial spark to ignite the mixture. Proper ventilation and combustion chambers guide the heat to the appropriate surface for optimal cooking results.

Structural Aspects for Efficiency

The design of the burner typically includes features like perforations or orifices, which allow for controlled gas release. The material used in construction, often metal, is selected for its durability and ability to withstand high temperatures. Heat distribution plates or covers are incorporated to spread

Exploring Ignition Mechanisms for Safety

Ensuring proper activation methods is essential for maintaining a secure and efficient environment in any heat-producing system. The ignition setup plays a critical role in initiating and controlling the energy source, making it vital to understand how these mechanisms contribute to overall system safety.

Reliable ignition control is a key factor in preventing hazardous conditions. By carefully monitoring and managing the energy activation process, these systems minimize risks related to gas or fuel leaks. Furthermore, modern designs often include fail-safe features that enhance protection in case of malfunctions, ensuring the user remains safe throughout operation.

Overall, by prioritizing secure ignition methods, energy systems not only improve functionality but also significantly reduce potential dangers, ensuring safe and reliable performance.

Temperature Regulation and Control Features

Maintaining precise thermal conditions is essential for ensuring optimal performance in various cooking environments. Advanced systems designed for thermal management ensure that the desired level of heat is maintained consistently throughout the process. This enhances both efficiency and consistency, crucial factors in food preparation. The ability to fine-tune and stabilize temperatures allows for greater control over cooking results, reducing the risk of over- or under-cooking.

Key Components of Temperature Control

The core of the regulation system includes various elements working together to provide accuracy in heat management. These components are responsible for sensing, adjusting, and maintaining heat levels in real-time. They include the main control unit, sensors, and adjustment mechanisms, each playing a specific role in achieving the desired thermal balance.

Component Function Thermal Sensor Monitors internal temperature and sends data to the control unit. Control Unit Detailed Look at Heat Distribution

The efficient management of thermal energy is crucial in cooking appliances, ensuring uniform heating and optimal performance. Understanding how heat is transferred within the system can significantly impact food preparation outcomes.

Heat distribution refers to the way thermal energy is spread across cooking surfaces and components. This process involves conduction, convection, and radiation, each playing a vital role in achieving desired cooking results. Effective heat management allows for even cooking, reducing the chances of hot or cold spots that can affect food quality.

Conduction occurs when heat moves through solid materials, directly transferring energy from the heat source to the cooking surface. This is essential for achieving high temperatures quickly. Convection, on the other hand, involves the movement of air or liquid, distributing heat throughout the cooking environment. This method enhances overall temperature consistency, which is especially important for larger dishes. Finally, radiation provides direct heat transfer through electromagnetic waves, offering a unique cooking method that can be utilized in specific applications.

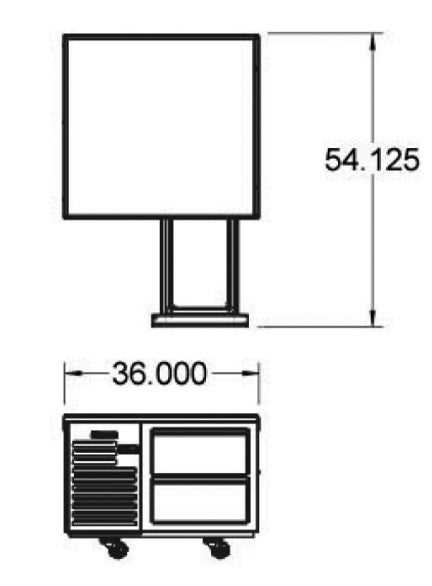

Material and Build Quality of Parts

The quality of materials and construction plays a crucial role in the overall performance and longevity of any assembly. Understanding the components used in manufacturing can provide insights into their durability, reliability, and efficiency in various applications.

High-grade materials often enhance the functional capabilities of these assemblies. Here are some key aspects to consider:

- Durability: The choice of materials significantly impacts the lifespan and resilience against wear and tear.

- Weight: Lighter components can improve handling and efficiency, while heavier materials may offer added stability.

- Resistance: Various materials exhibit different levels of resistance to environmental factors such as heat, moisture, and corrosion.

Furthermore, the construction techniques utilized during assembly can also influence performance:

- Precision Engineering: Components manufactured with high precision ensure a better fit and function.

- Assembly Methods: The techniques employed, whether welding, bolting, or other methods, can affect overall strength and integrity.

- Quality Control: Rigorous testing and inspection protocols help maintain consistent quality across the production line.

By focusing on both the materials and the methods of construction, users can better appreciate the craftsmanship behind these assemblies, leading to more informed decisions in their selection and usage.

Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of your cooking appliance, regular upkeep is essential. By implementing a few straightforward practices, you can maintain peak functionality and enhance the overall experience in your kitchen. This section provides useful insights into effective maintenance strategies that will keep your equipment in top shape.

Regular Cleaning

Keeping surfaces and components clean is vital for optimal operation. Residue buildup can hinder performance and lead to unnecessary wear. Consider the following cleaning schedule:

Frequency Task Daily Wipe down exterior surfaces and remove food debris. Weekly Clean the interior and check for any signs of wear. Monthly Inspect and clean burners and heating elements thoroughly. Regular Inspections

Routine inspections play a crucial role in identifying potential issues before they escalate. Ensure that you check key components for wear or damage. Make a habit of examining:

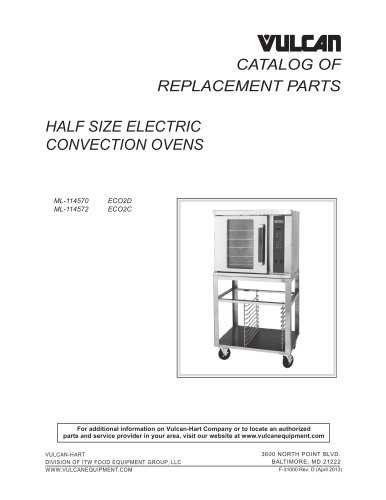

Component Inspection Tips Electrical Connections Look for frayed wires and ensure connections are secure. Gas Lines Check for leaks and ensure fittings are tight. Control Knobs Ensure they function smoothly and do not stick. Common Replacement Parts and Their Roles

In the realm of kitchen appliances, certain components are essential for maintaining optimal performance and efficiency. Understanding the functions of these elements can significantly enhance the longevity and reliability of the equipment. This section focuses on various critical components that are often replaced due to wear and tear or malfunction.

Heating Elements

Heating elements are vital for generating the necessary heat required for cooking. They come in various forms, including coil and radiant types, and are responsible for evenly distributing heat across the cooking surface. Regular checks can help ensure that these elements are functioning correctly, as failure to do so can result in inconsistent cooking results.

Thermostats

Another crucial component is the thermostat, which regulates temperature by monitoring the heat levels within the unit. It plays a significant role in maintaining the desired cooking temperature and can directly affect the quality of the prepared dishes. If the thermostat malfunctions, it may lead to overheating or underheating, necessitating its replacement for proper operation.

Assembly and Disassembly Procedures Explained

This section provides a comprehensive overview of the methods used for putting together and taking apart various components within a cooking appliance. Understanding these procedures is crucial for effective maintenance and repair, ensuring the appliance operates smoothly and safely.

Before initiating the assembly or disassembly process, it is important to gather all necessary tools and familiarize oneself with the components involved. Below are the key steps and considerations for each procedure:

Disassembly Procedure

- Ensure the appliance is completely turned off and unplugged from the power source.

- Remove any external attachments or accessories to gain better access to internal components.

- Using the appropriate tools, carefully unscrew or unclip the fasteners holding the outer casing.

- Gently detach the outer casing to expose the internal structure.

- Take note of the arrangement of components for easier reassembly, possibly using a diagram or photograph as a reference.

- Proceed to disconnect any wiring harnesses or plugs, ensuring to label them for reinstallation.

- Remove individual parts in the sequence outlined, starting from the top to prevent damage to other components.

Assembly Procedure

- Begin with a clean workspace to ensure no foreign objects interfere with the assembly.

- Refer to the notes or visual references taken during disassembly for guidance on the proper arrangement.

- Reconnect any wiring harnesses or plugs, ensuring they are secure and correctly aligned.

- Reattach internal components, securing them with the appropriate fasteners.

- Carefully place the outer casing back, ensuring all clips or screws align properly.

- Double-check all connections and fasteners to confirm everything is securely in place.

- Plug the appliance back in and conduct a brief test to verify it operates correctly.

Following these procedures diligently will help maintain the integrity of the appliance and prolong its lifespan. Regular maintenance through proper assembly and disassembly can prevent issues and enhance performance.

Enhancing Durability with Proper Care

Maintaining the longevity of equipment requires attention and diligence. Regular maintenance not only ensures optimal performance but also extends the lifespan of components. By adhering to recommended practices, users can significantly enhance the durability of their devices.

Key Maintenance Practices

- Regular Cleaning: Remove dust and debris to prevent buildup that can hinder functionality.

- Routine Inspections: Check for wear and tear to identify potential issues before they escalate.

- Timely Repairs: Address any malfunctions promptly to avoid further damage.

Proper Usage Guidelines

- Follow Manufacturer Instructions: Adhere to guidelines for usage and maintenance as outlined in the manual.

- Avoid Overloading: Ensure that the equipment is used within its specified limits to prevent excessive strain.

- Utilize Protective Covers: Use appropriate coverings when the equipment is not in use to shield it from environmental factors.

Implementing these strategies will not only promote longevity but also enhance the overall efficiency of the apparatus. Investing time in proper care yields significant returns in performance and durability.