Every modern cooling appliance consists of numerous interconnected elements, each playing a crucial role in its overall functionality. Recognizing how these components are arranged can significantly enhance your ability to troubleshoot issues, perform maintenance, or consider upgrades. This section delves into the intricate arrangement of these essential elements, offering valuable insights for users and technicians alike.

By familiarizing yourself with the layout of these key components, you can better understand how they interact and contribute to the appliance’s efficiency. Whether you are replacing a worn-out element or simply curious about the inner workings, a comprehensive understanding of the configuration can be incredibly beneficial. The information presented here aims to empower you with the knowledge needed to navigate and manage your cooling system effectively.

As you explore the various features and structures within these appliances, you will gain a clearer perspective on their operation and maintenance requirements. This exploration will not only aid in addressing potential malfunctions but also assist in maximizing the longevity and performance of your unit. Embrace the journey into the world of appliance components, where clarity and knowledge pave the way for optimal usage.

This section delves into the essential mechanisms that allow for effective preservation and cooling of various items. Understanding these operations can enhance user knowledge and maintenance of these household appliances.

Key Components

- Compressor: Acts as the heart of the system, circulating refrigerant through the entire setup.

- Condenser: Releases heat from the refrigerant, allowing it to transition from gas to liquid.

- Evaporator: Absorbs heat from the interior, cooling the air and preserving the contents.

- Expansion Valve: Regulates the flow of refrigerant, ensuring the correct pressure is maintained.

Cooling Process

- The compressor compresses the refrigerant gas, raising its temperature and pressure.

- The heated gas flows into the condenser coils, where it releases heat and condenses into a liquid.

- The liquid refrigerant passes through the expansion valve, dropping in pressure and temperature.

- The cold refrigerant enters the evaporator, absorbing heat from the internal environment.

- The cycle repeats as the refrigerant returns to the compressor in gaseous form.

Key Parts of LG Refrigerators

Understanding the essential components of LG cooling appliances is crucial for efficient operation and maintenance. These key elements work together to ensure optimal performance, keeping food fresh and beverages cool.

Among the most significant features is the compressor, which plays a vital role in circulating refrigerant throughout the system. Another important element is the condenser, responsible for dissipating heat and transforming the refrigerant from gas to liquid. Additionally, the evaporator is essential for absorbing heat inside the unit, contributing to the overall cooling process.

Other noteworthy components include the thermostat, which regulates temperature settings, and the fans that facilitate air circulation. The door seals also play a critical role by preventing cold air from escaping, thereby enhancing energy efficiency.

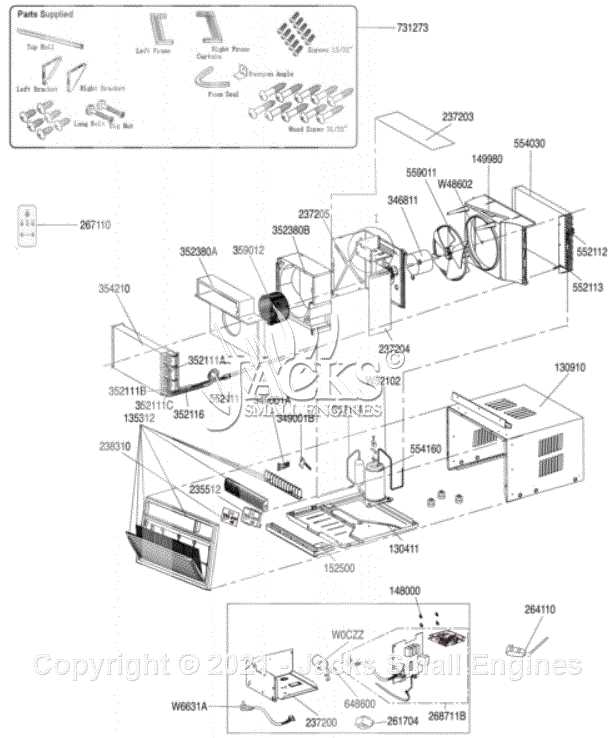

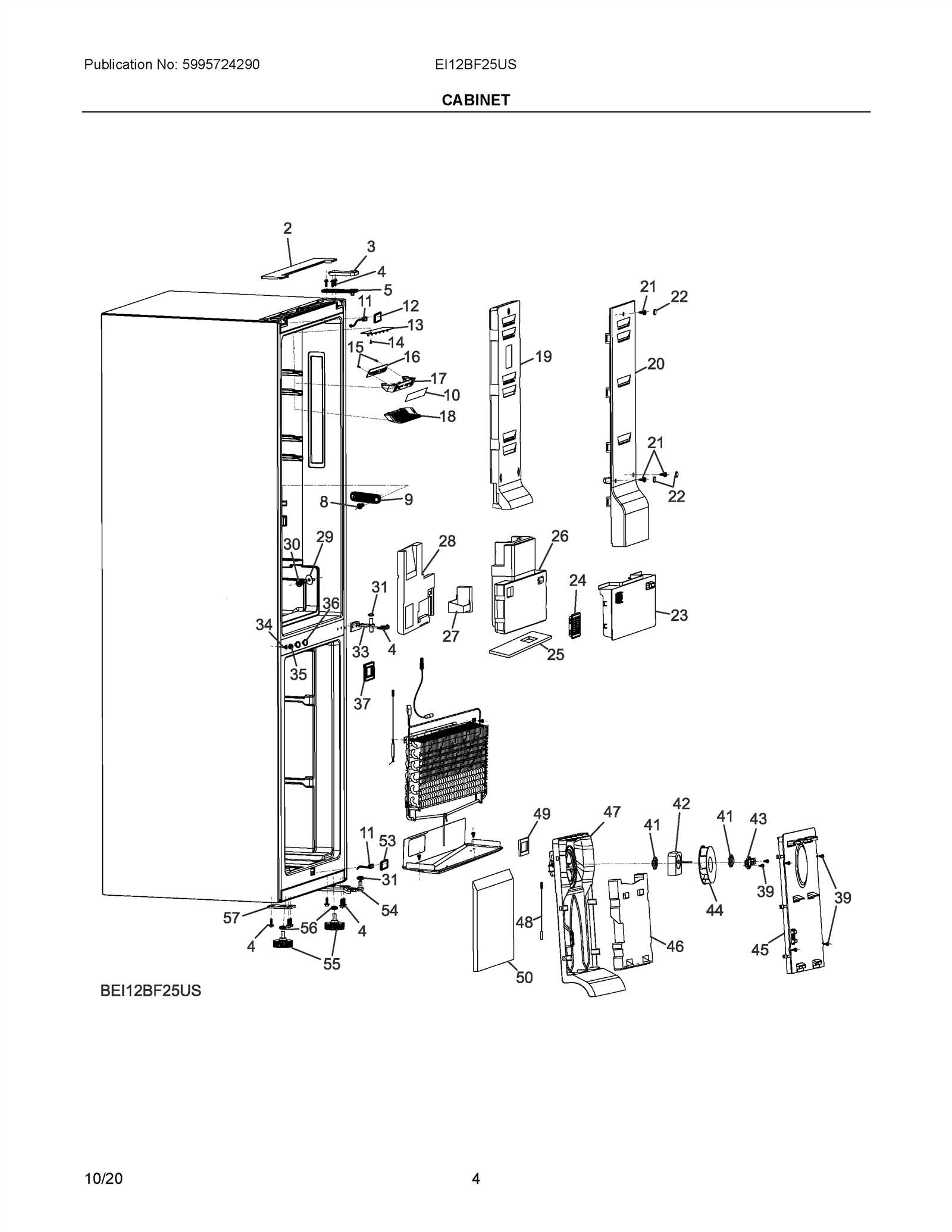

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in the maintenance and repair of complex appliances. These illustrations not only aid in understanding the various components but also facilitate efficient troubleshooting. Without accurate visual guides, users may struggle to identify issues or replace faulty elements correctly, leading to potential further damage or inefficient repairs.

Moreover, having well-defined illustrations enhances communication between technicians and consumers. It allows both parties to discuss problems and solutions more effectively, minimizing misunderstandings that could arise from vague descriptions. Such clarity is essential for ensuring that any repairs or maintenance tasks are performed correctly and promptly.

In addition, accurate representations contribute to safety during repair processes. They provide essential information regarding the placement and connection of each component, reducing the risk of accidents or mishandling. When users are equipped with reliable visual resources, they can approach repairs with greater confidence and competence.

Common Issues with Refrigerator Parts

Understanding typical problems that may arise with various components of cooling appliances is essential for effective maintenance and timely repairs. These issues can significantly impact performance, efficiency, and longevity, making it crucial to recognize the signs of malfunction early on.

Here are some frequent concerns associated with essential elements of cooling systems:

- Temperature Fluctuations: Inconsistent cooling can result from various factors, including faulty thermostats or damaged seals.

- Noisy Operation: Unusual sounds often indicate issues with motors or fans that may require attention.

- Water Leaks: Moisture accumulation can stem from blocked drainage systems or worn-out gaskets.

- Frost Buildup: Excessive ice formation can occur due to malfunctioning defrost heaters or timers.

- Power Failures: Problems with electrical connections or control boards can lead to complete unit shutdowns.

Regular inspections and maintenance can help identify these issues before they escalate, ensuring optimal functionality and preventing costly repairs.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and troubleshooting. These visual representations provide insight into the components of an appliance and their relationships, enabling users to identify and resolve issues more efficiently.

Familiarizing with Symbols and Notations

Before diving into the specifics, it’s crucial to become acquainted with the common symbols and notations used in these visuals. Familiarity with these elements can greatly enhance comprehension and facilitate quicker identification of components.

| Symbol | Description |

|---|---|

| ☐ | Indicates a removable component |

| ⚙️ | Represents a moving part |

| Denotes electrical connections | |

| Signifies areas requiring tools for access |

Interpreting Connections and Layouts

Once the symbols are understood, the next step is to analyze how these components are interconnected. Pay attention to lines that indicate relationships, as they often show how parts interact and contribute to the overall functionality of the device.

Replacing Essential Components

When it comes to maintaining the functionality of your cooling appliance, understanding the process of swapping out key elements is crucial. This section provides insights into the common components that may require replacement over time, ensuring your unit operates efficiently and effectively.

Identifying when to replace an item can save both energy and money. Regular checks can help pinpoint which elements might be worn or malfunctioning, allowing for timely interventions. Here’s a brief overview of the essential components and their respective functions:

| Component | Function |

|---|---|

| Compressor | Circulates refrigerant throughout the system, maintaining temperature. |

| Evaporator Coil | Absorbs heat, allowing the internal environment to stay cool. |

| Condenser Coil | Releases absorbed heat, enabling the refrigerant to cool down. |

| Thermostat | Regulates temperature by controlling the compressor’s operation. |

Understanding the role of each component facilitates better decision-making when it comes to repairs or replacements. Proper maintenance and timely replacements can significantly extend the lifespan of your unit, ensuring it continues to serve its purpose efficiently.

Maintenance Tips for Longevity

Ensuring the prolonged efficiency of your cooling appliance involves regular care and attention. By implementing a few simple practices, you can enhance its performance and lifespan while preventing common issues that arise from neglect.

Regular Cleaning

Maintaining cleanliness is crucial for optimal functioning. Dust and debris can accumulate on coils and vents, leading to reduced efficiency. Regularly clean these areas with a soft brush or cloth to promote proper airflow and cooling efficiency.

Temperature Management

Monitoring and adjusting the internal temperature can greatly impact the functionality of your appliance. Aim to maintain a consistent setting, ideally between 37°F and 40°F. Sudden fluctuations can cause strain and reduce the lifespan of various components.

By following these maintenance tips, you can ensure your cooling unit remains in excellent working condition for years to come.

Finding Replacement Parts Easily

When your appliance encounters issues, locating suitable components can significantly simplify the repair process. Understanding where to find these essential elements not only saves time but also ensures your unit operates efficiently again.

Start by consulting the manufacturer’s website, which often provides a wealth of resources, including detailed illustrations and a comprehensive list of available components. Many brands also have online retailers or authorized dealers where you can purchase genuine elements directly.

Utilizing online marketplaces can be advantageous as well. Websites dedicated to home improvement or appliance repair frequently feature a wide selection of options. Be sure to read reviews and check seller ratings to guarantee quality.

Additionally, consider joining forums or communities focused on appliance maintenance. These platforms offer valuable insights and recommendations from other users who may have faced similar challenges. They can guide you towards reliable sources for acquiring what you need.

Lastly, local hardware stores or specialized shops may carry certain items, providing an opportunity for immediate purchase. Always keep a record of model numbers and specifications to ensure compatibility when seeking replacements.

Identifying Model-Specific Diagrams

Understanding the intricate layout of a household cooling unit is essential for efficient maintenance and repair. Each model possesses its own unique arrangement of components, which can vary significantly from one version to another. Thus, recognizing the specific configuration for a given model is crucial for effective troubleshooting.

To accurately identify the appropriate schematics for your unit, it is advisable to consult the manufacturer’s resources. These documents typically include detailed illustrations that highlight the individual elements and their relationships. Furthermore, they often provide valuable information about compatible accessories and potential upgrade options.

Utilizing online platforms can also enhance your search for specific layouts. Many manufacturers host databases or forums where users share insights and visual aids related to particular models. Engaging with these communities may offer additional perspectives and solutions tailored to your appliance’s requirements.

In summary, familiarizing yourself with the distinctive configurations of various models not only aids in identifying necessary replacements but also empowers you to address potential issues proactively. This knowledge serves as a foundation for ensuring the longevity and optimal performance of your cooling unit.

Common Repairs and Troubleshooting

Maintaining the functionality of your cooling unit can often be achieved through simple repairs and effective problem-solving techniques. Understanding common issues that may arise can save both time and resources, allowing for quick resolutions to ensure optimal performance.

Identifying Common Issues

One of the most frequent challenges users encounter is inconsistent temperature regulation. This can stem from a variety of factors, including blockages in airflow or faulty components. Regularly inspecting the internal environment and ensuring adequate space around the appliance can help mitigate these issues. Additionally, check seals and gaskets for wear and tear, as improper sealing can lead to energy loss and inefficient operation.

Basic Repair Techniques

When faced with minor complications, many individuals can undertake straightforward repairs. For instance, replacing worn-out seals or cleaning coils can significantly enhance performance. Furthermore, monitoring the unit’s drainage system is crucial; clogs can lead to water accumulation and subsequent malfunctions. For more complex issues, consulting a professional technician is advisable to avoid further complications.

When to Call a Professional

There are instances when it is essential to seek the expertise of a skilled technician rather than attempting to address issues independently. Recognizing the right moments to enlist professional help can save time, ensure safety, and prevent further complications.

Signs Indicating Professional Assistance is Needed

- Persistent malfunctions despite troubleshooting efforts

- Unusual noises that could indicate serious internal problems

- Leaking fluids or excessive condensation

- Electrical issues, such as flickering lights or faulty wiring

- Strong, unpleasant odors emanating from the unit

Benefits of Hiring an Expert

- Access to specialized knowledge and tools

- Enhanced safety, reducing the risk of injury or damage

- Assurance of proper diagnosis and effective repairs

- Time savings, allowing for quicker resolution of issues

- Long-term cost efficiency by preventing future problems