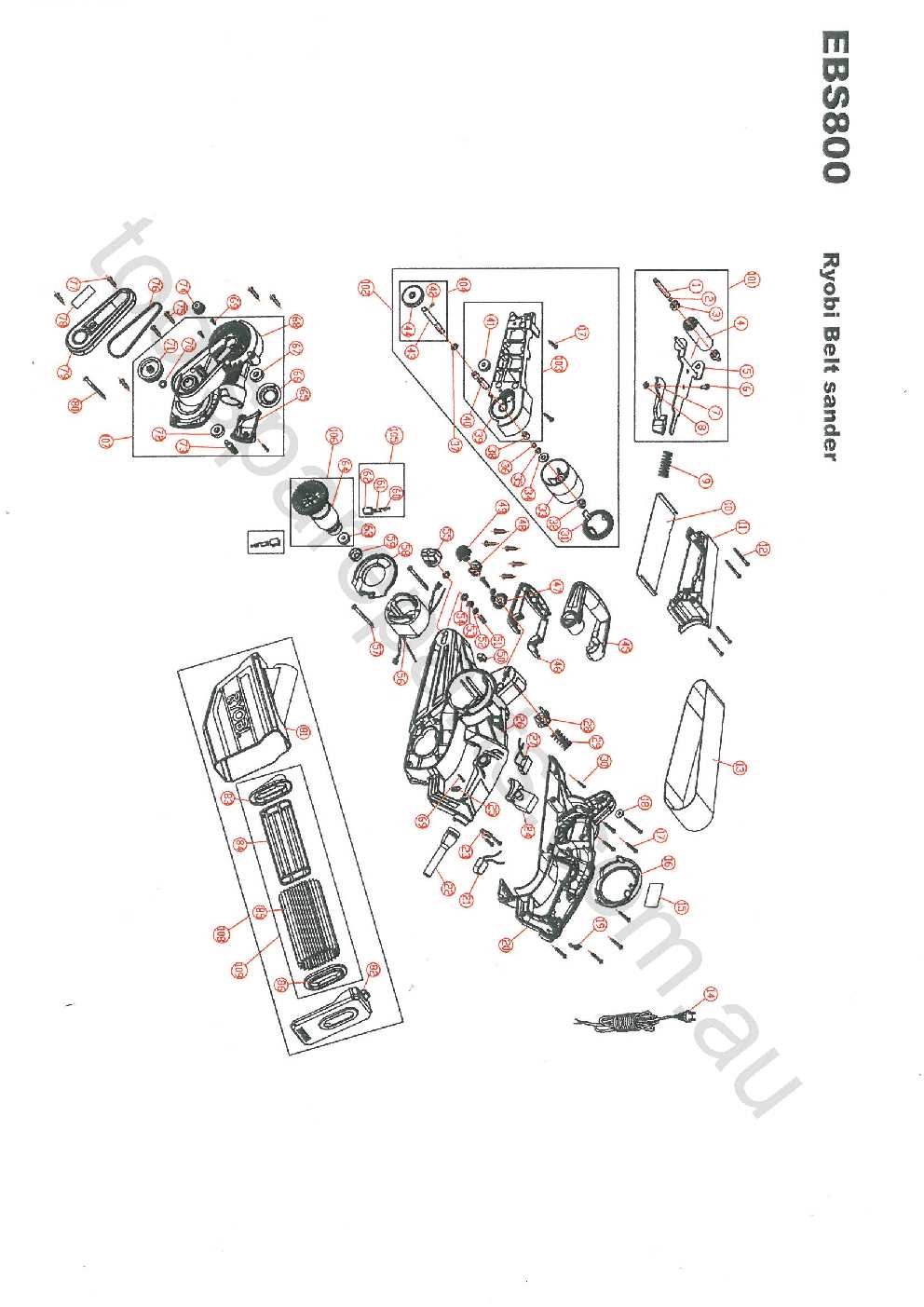

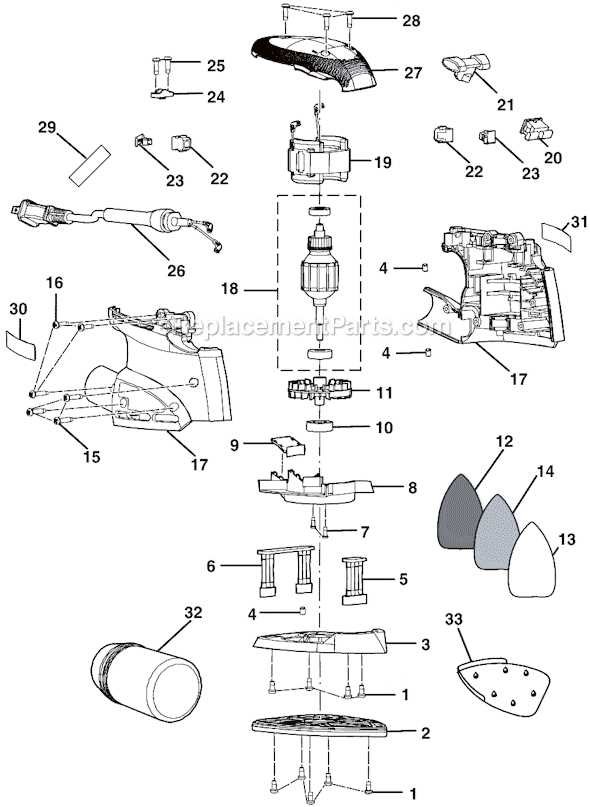

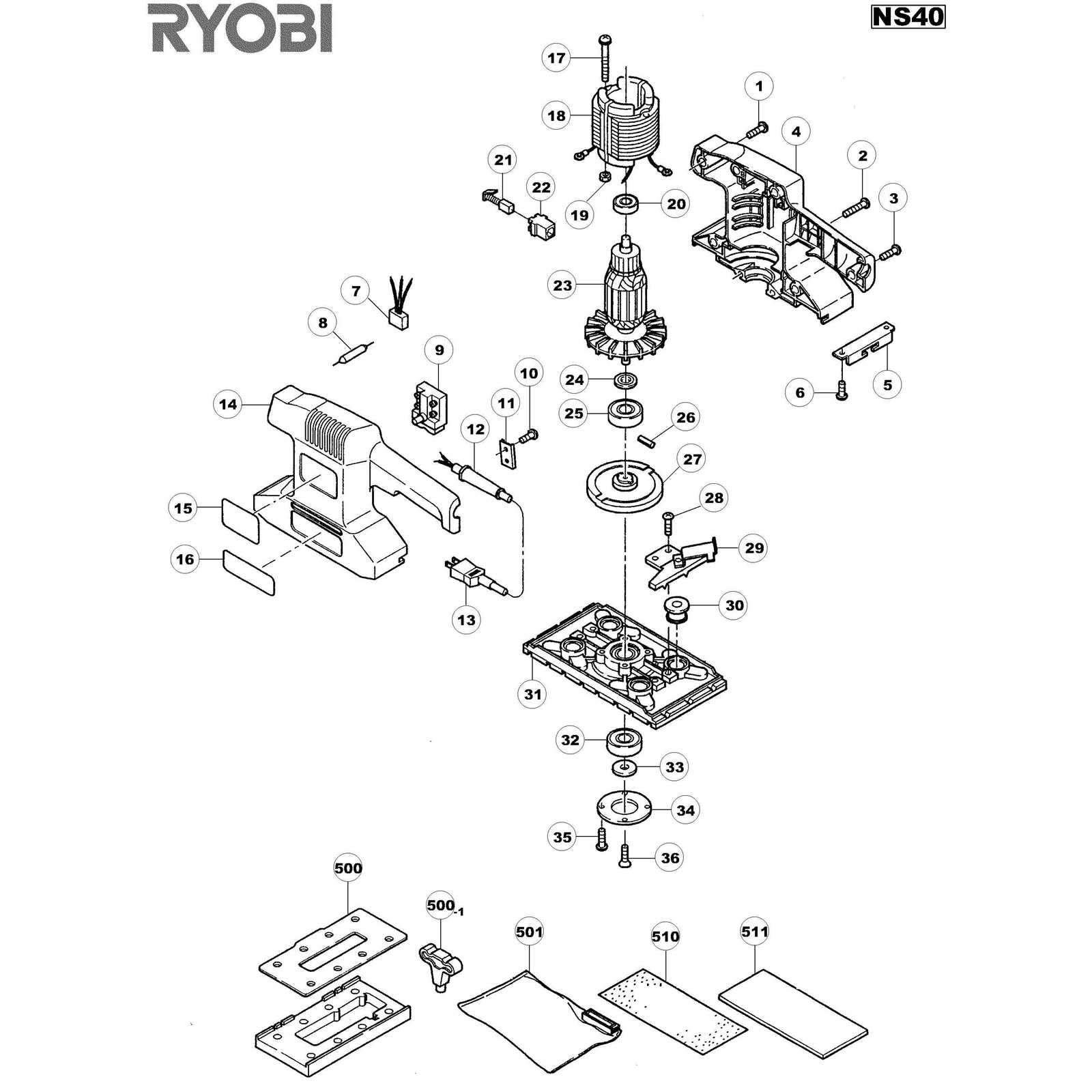

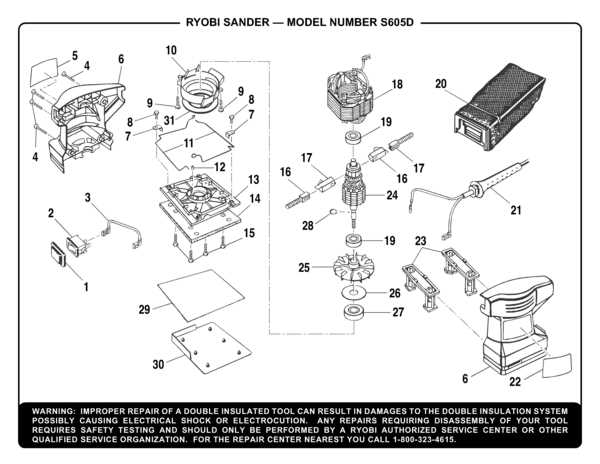

When it comes to maintaining and optimizing the functionality of your handheld finishing tool, having a clear understanding of its individual components is essential. This knowledge not only enhances your ability to troubleshoot issues but also empowers you to perform effective repairs and upgrades. A well-functioning device relies on the harmony between its various elements, making it crucial to familiarize yourself with their roles and interconnections.

Identifying the key elements within your device can greatly improve your overall user experience. Each component plays a specific role, contributing to the tool’s efficiency and performance. By learning about these parts, you can ensure that your equipment operates smoothly and meets your expectations in various projects.

In this section, we will explore a comprehensive overview of the essential components of your finishing device. This guide will serve as a valuable reference, helping you navigate through the intricacies of your tool and understand how each part functions within the whole. Whether you’re a novice or a seasoned user, this information will enhance your confidence in managing your equipment effectively.

Understanding Ryobi Orbital Sanders

In the world of power tools, certain devices stand out for their efficiency and versatility in finishing surfaces. These tools are essential for achieving a smooth and polished appearance on various materials. They employ a unique mechanism that allows for a combination of speed and precision, making them ideal for both professionals and DIY enthusiasts alike.

Components and Functionality

The key elements of these devices work in harmony to deliver outstanding results. At the core, a robust motor drives the sanding surface, enabling rapid rotation and effective abrasion. The design of the backing pad plays a significant role, as it determines the compatibility with different sanding sheets. Proper attachment ensures that the tool functions at its best, allowing users to achieve the desired finish without hassle.

Maintenance and Care

To ensure longevity and optimal performance, regular upkeep is essential. Keeping the sanding surface clean and replacing worn sheets can greatly enhance the tool’s effectiveness. Additionally, periodically checking the motor and electrical components for any signs of wear can prevent more significant issues down the line. By following these simple maintenance tips, users can maximize the efficiency of their finishing tools and achieve professional-quality results consistently.

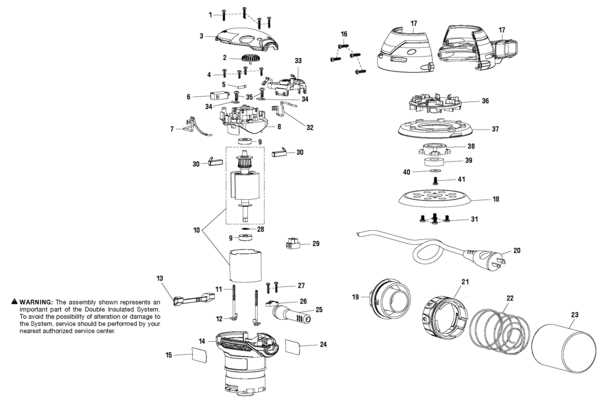

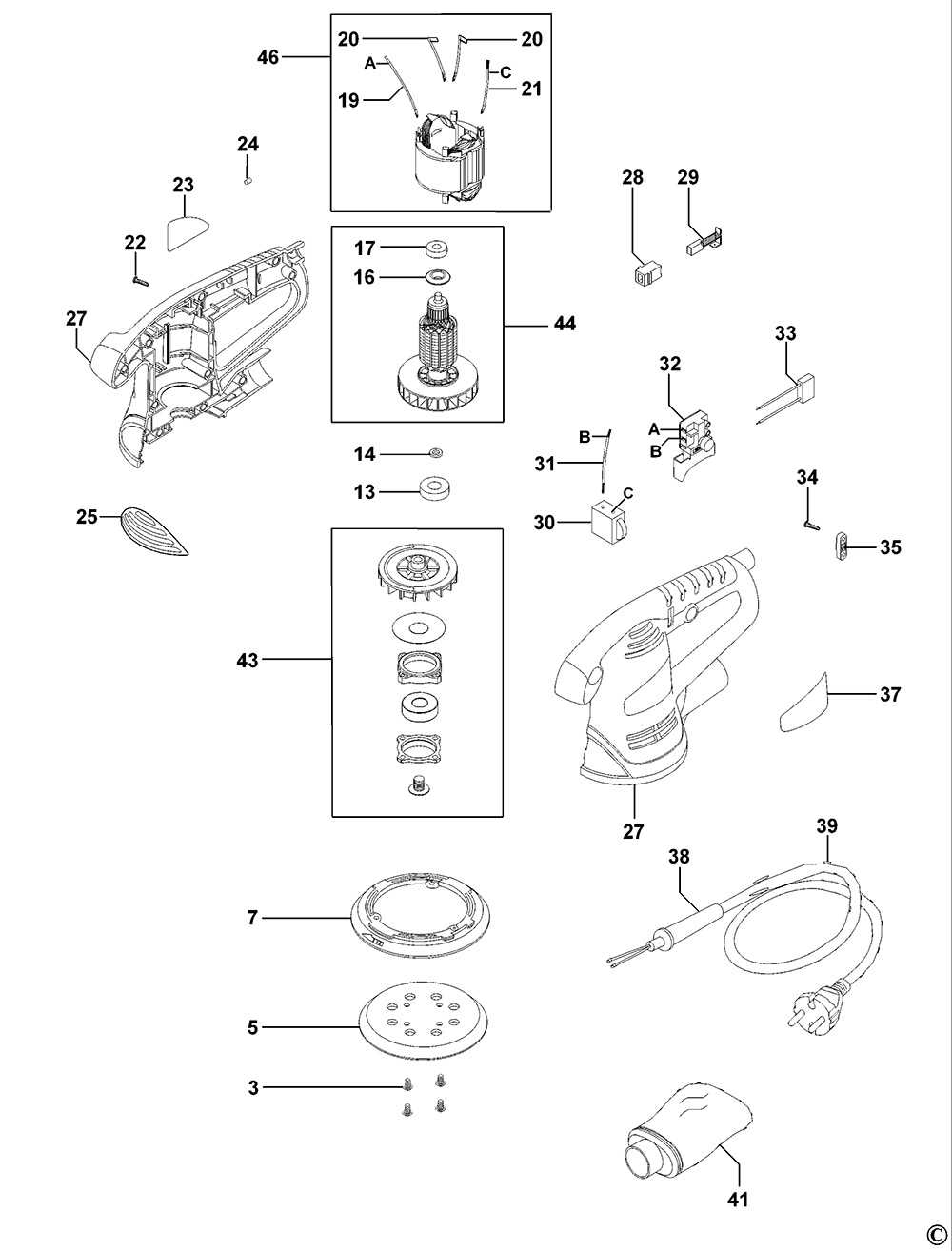

Key Components of Orbital Sanders

Understanding the essential elements of sanding tools is crucial for effective operation and maintenance. Each component plays a significant role in achieving smooth finishes and optimal performance, ensuring that users can tackle various tasks with ease and efficiency.

- Motor: The driving force behind the tool, responsible for powering the sanding motion. A high-quality motor enhances efficiency and durability.

- Sanding Pad: This is the surface that holds the abrasive material. It is available in various sizes and materials, tailored to different sanding requirements.

- Dust Collection System: An essential feature for maintaining a clean workspace. This system captures dust and debris generated during sanding, improving visibility and reducing cleanup time.

- Base Plate: The flat surface that connects to the sanding pad, ensuring even pressure distribution and stability during operation.

- Speed Control: Many models include adjustable speed settings, allowing users to modify the sanding speed according to the material and desired finish.

Familiarity with these key elements will empower users to select the right tool for their needs and perform necessary maintenance, ultimately enhancing their woodworking or DIY projects.

Functionality of Sanding Mechanisms

The sanding mechanisms are essential components in various power tools, designed to enhance the efficiency of surface preparation. These systems utilize a combination of rotational and oscillating motions to effectively smooth out surfaces, remove imperfections, and prepare materials for finishing. Understanding how these mechanisms operate can greatly impact the quality of work produced.

Types of Smoothing Actions

There are different types of smoothing actions employed in these devices. Circular motions allow for quick material removal, making them suitable for rough sanding tasks. In contrast, oscillating movements provide a gentler approach, ideal for fine finishing. The choice of motion directly influences the final surface texture, making it crucial to select the appropriate mechanism for specific applications.

Importance of Dust Extraction

Effective dust extraction is another critical aspect of these systems. The ability to minimize dust production not only creates a cleaner workspace but also improves visibility during operation. Integrated dust collection systems help to capture debris, ensuring that users can work efficiently and safely. This functionality enhances overall productivity and contributes to better results.

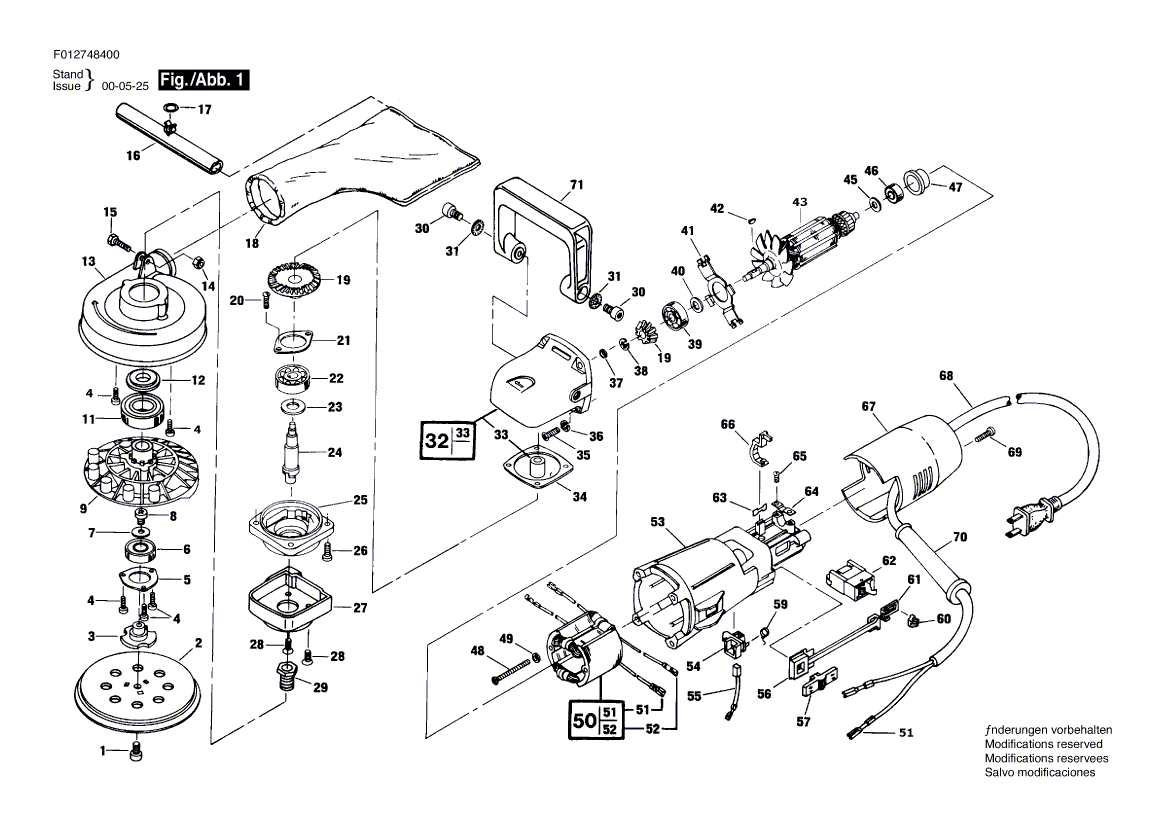

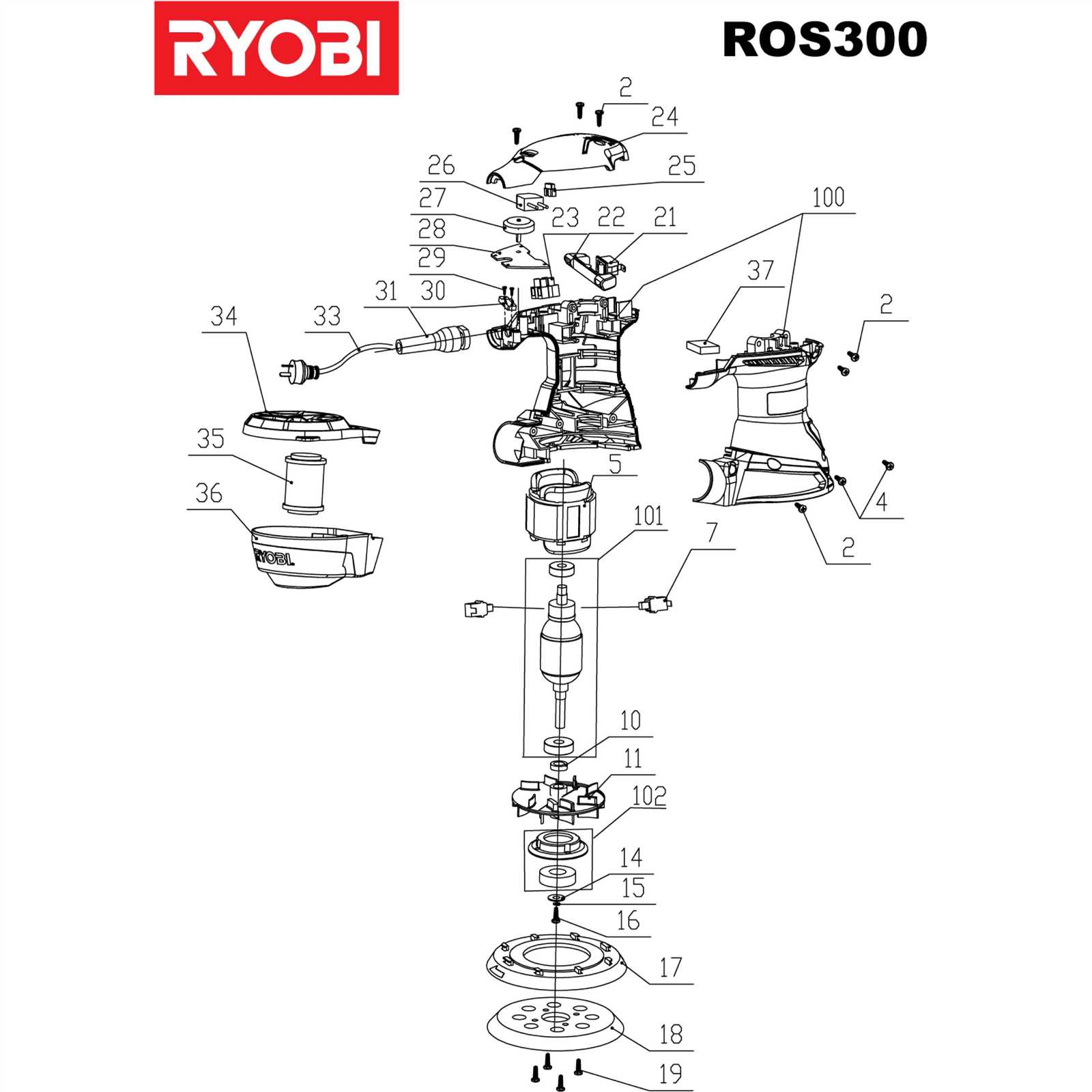

Identifying Wearable Parts

Understanding the components that experience regular usage and require periodic replacement is essential for maintaining optimal performance of your tool. Recognizing these elements helps in ensuring efficiency and prolonging the lifespan of the equipment.

Common Components Subject to Wear

Numerous elements within power tools may become worn over time, impacting their functionality. Key components to monitor include those that directly interact with materials during operation. Below is a table summarizing the frequently replaced items and their significance.

| Component | Description |

|---|---|

| Sandpaper | The abrasive surface that removes material from the workpiece; varies in grit to suit different tasks. |

| Backing Pad | The cushion that holds the abrasive material in place; may wear down with prolonged use. |

| Motor Brushes | Components that conduct electricity to the motor; can degrade and cause performance issues when worn. |

| Dust Bag | Collects debris generated during operation; should be checked regularly for blockages and wear. |

Importance of Regular Inspections

Regularly inspecting these components is vital for ensuring smooth operation. Identifying wear early on can prevent potential malfunctions and enhance the overall efficiency of the tool. Keeping a checklist for routine evaluations can be beneficial in maintaining your equipment in optimal condition.

Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of your tool, regular upkeep is essential. Proper care not only enhances functionality but also minimizes the likelihood of breakdowns. By following some straightforward maintenance practices, you can keep your device running smoothly and achieve the best results in your projects.

Regular Cleaning

One of the most important aspects of maintenance is keeping the equipment clean. After each use, remove any dust and debris from the surface and the vents. This prevents the accumulation of particles that can hinder performance. Utilize a soft brush or compressed air to effectively clear out hard-to-reach areas.

Inspection and Replacement of Components

Routine inspection of all components is crucial. Check for signs of wear or damage, particularly on surfaces that experience friction. Replace worn-out elements promptly to maintain optimal functionality. Additionally, lubricate moving parts as recommended in the user manual to ensure smooth operation.

Common Issues and Solutions

When working with power tools designed for surface finishing, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their corresponding solutions can greatly enhance the overall experience and extend the lifespan of the equipment.

One frequent issue is excessive vibration during operation, which may lead to reduced accuracy and discomfort. This can often be remedied by ensuring that all components are securely fastened and that the sanding medium is appropriate for the task at hand. Regular maintenance checks to tighten loose screws and replace worn-out pads can also help mitigate this problem.

Another common concern involves inadequate power or sluggish performance. This can result from a clogged dust collection system or a worn-out motor. Cleaning the dust container and ensuring that the airflow is unobstructed can restore optimal functionality. If the problem persists, it may be necessary to inspect the motor and replace any damaged components to improve power output.

Finally, uneven sanding results can be a source of frustration for users. This issue can arise from using the wrong sanding grit or applying uneven pressure during use. To achieve a smoother finish, it’s essential to select the appropriate grit for the material and maintain consistent pressure throughout the sanding process.

Choosing the Right Sandpaper

Selecting the appropriate abrasive material is crucial for achieving optimal results in various projects. The right type of grit and backing can significantly influence the efficiency and quality of the work. Understanding the different options available is essential for both novice and experienced users.

When considering your choices, it’s important to recognize the various grit levels and their specific applications. Finer grits are typically used for finishing touches, while coarser grits are more suitable for heavy material removal. Below is a table summarizing the different grit levels and their typical uses:

| Grit Level | Typical Use |

|---|---|

| 60-80 | Heavy material removal, rough shaping |

| 100-120 | Surface preparation, initial sanding |

| 150-180 | Fine sanding, preparing for finishing |

| 220+ | Final finishing, smoothing surfaces |

In addition to grit size, the material of the sandpaper backing can also impact performance. Options like cloth, paper, or film can provide varying levels of durability and flexibility, depending on the task at hand. Selecting the right combination of grit and backing material will enhance your results and extend the life of your abrasive tools.

Exploring Dust Collection Features

The efficiency of any sanding tool greatly depends on its ability to manage dust and debris effectively. A well-designed collection system plays a crucial role in maintaining a clean workspace, enhancing visibility, and reducing health risks associated with inhaling fine particles. This section delves into the various aspects of dust management systems integrated into modern sanding devices.

Key Components of Dust Collection

Most tools come equipped with a vacuum attachment or a built-in dust bag that captures particles as they are generated. These components work together to minimize mess and streamline the sanding process. The vacuum system often features a filter to trap fine dust, ensuring that the air remains clean and breathable.

Benefits of Effective Dust Management

Utilizing an efficient dust collection system not only enhances the user’s experience but also extends the life of the tool. Reduced debris accumulation prevents overheating and wear, contributing to better overall performance. Furthermore, a cleaner workspace allows for greater focus on the task at hand, improving the quality of the finished product.

Maintenance Considerations

Regular maintenance of the dust collection components is essential for optimal performance. This includes checking filters for clogs and ensuring that bags are emptied regularly. Proper care helps maintain suction power and prevents dust from escaping back into the environment, safeguarding the health of the user.

In summary, understanding the significance of dust collection features is vital for maximizing the effectiveness of any sanding tool. By investing in quality dust management systems and maintaining them properly, users can enjoy a cleaner, safer, and more efficient working experience.

Upgrading Accessories for Better Results

Enhancing the effectiveness of your finishing tool involves selecting the right enhancements to optimize performance. By upgrading components, you can achieve superior results in your projects, improving both efficiency and the quality of your work. Whether it’s changing the sanding discs or modifying the attachments, each adjustment can make a significant impact.

Choosing the Right Accessories

When it comes to upgrading, consider the following options that can transform your experience:

| Accessory Type | Description | Benefits |

|---|---|---|

| Sanding Discs | Different grits and materials for varied surfaces. | Improved smoothness and finish quality. |

| Dust Collection Bags | Specialized bags designed for efficient dust management. | Cleaner workspace and enhanced visibility. |

| Ergonomic Handles | Upgraded grips for better comfort and control. | Reduced fatigue during prolonged use. |

| Adapters for Different Attachments | Compatibility tools to connect various accessories. | Increased versatility for multiple tasks. |

Maximizing Performance

By thoughtfully selecting and implementing new enhancements, you can not only elevate the quality of your work but also streamline your processes. Evaluate your current needs and invest in accessories that align with your goals to experience a noticeable difference in your results.

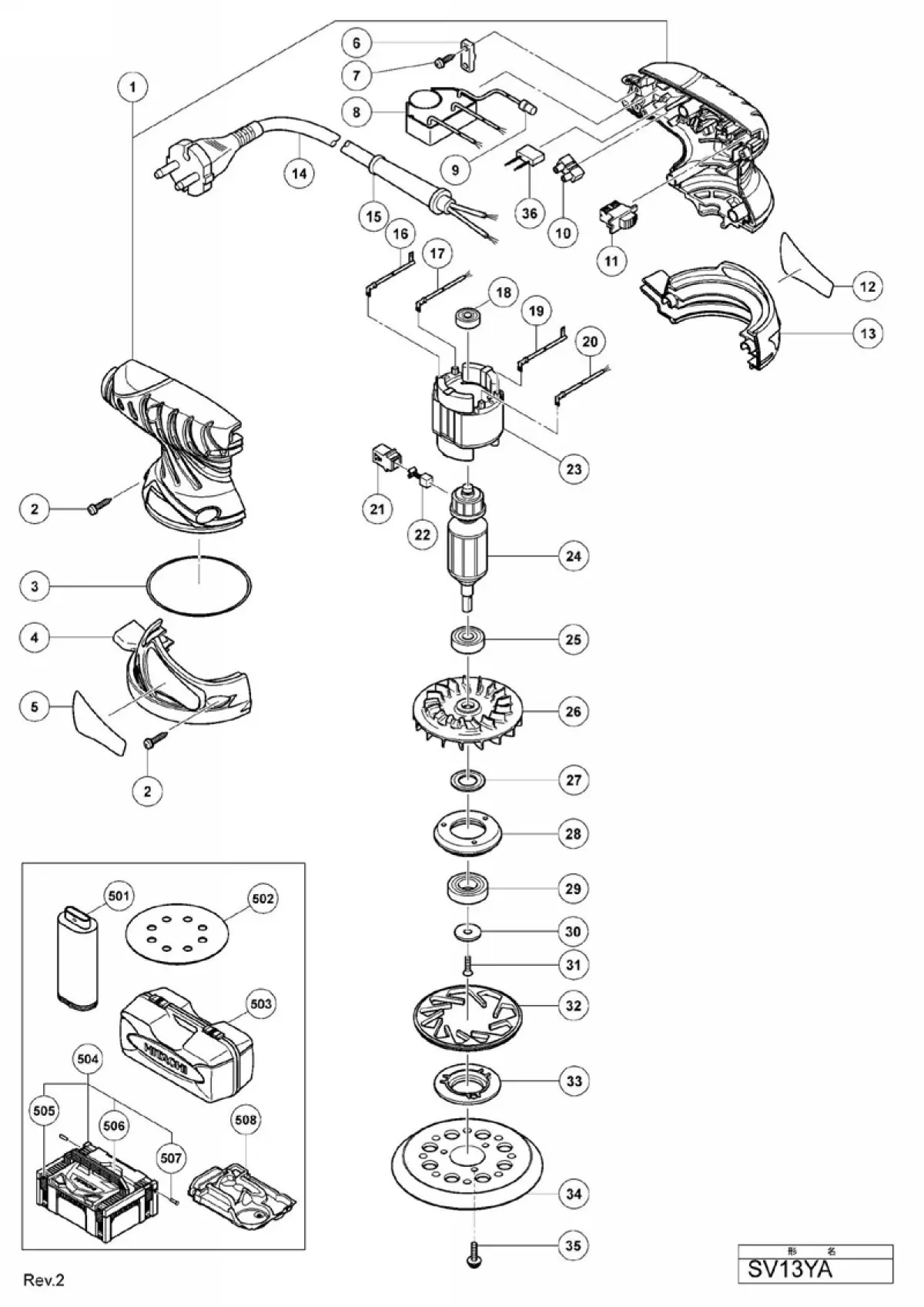

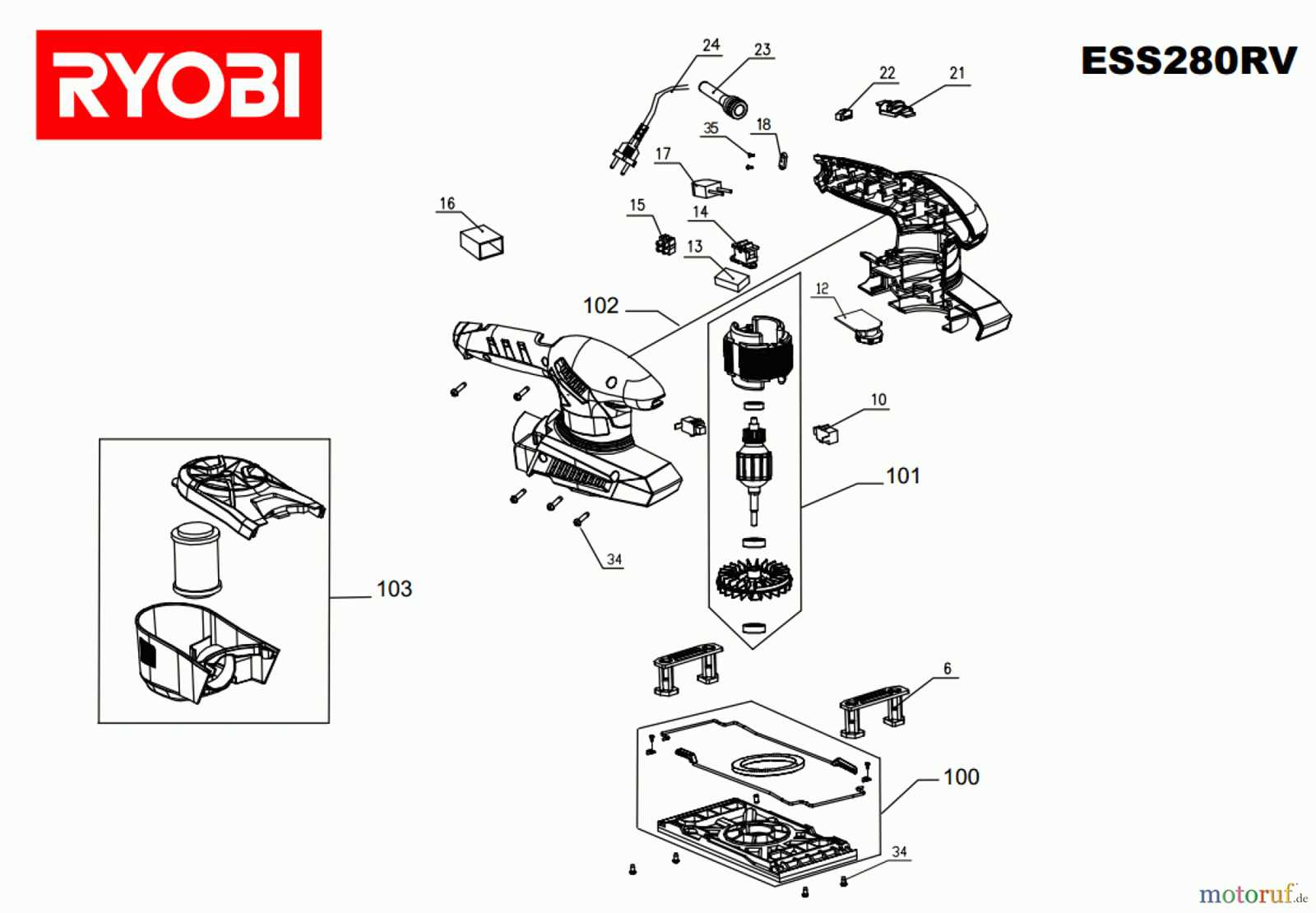

Comparing Different Ryobi Models

This section focuses on the analysis of various models within a popular line of power tools designed for sanding applications. By examining their unique features and specifications, users can make informed choices that best suit their projects and preferences.

One of the key factors to consider is the power of each tool. Some models are equipped with more robust motors, allowing for faster material removal and greater efficiency. In contrast, lighter variants may be better suited for delicate tasks, providing a gentle touch without compromising control.

Another significant aspect is ergonomics. Different designs cater to user comfort, with some featuring soft grips and balanced weights for extended use without fatigue. Evaluating the handle configurations can help determine which model will feel most comfortable during prolonged sanding sessions.

Dust collection systems also vary across the range. While some tools include advanced mechanisms for minimizing mess and improving visibility, others may rely on basic collection bags. Assessing the effectiveness of these systems can greatly influence the overall sanding experience.

Finally, examining the accessories and compatibility with different sandpaper types can provide insight into the versatility of each model. Some units may offer greater adaptability, allowing users to tackle a wider range of tasks with ease.

Resources for Repair and Replacement

When it comes to maintaining and fixing your power tools, having access to the right resources is essential for effective troubleshooting and efficient replacements. Whether you are a professional tradesperson or a DIY enthusiast, understanding where to find the necessary components and support can greatly enhance your repair experience.

Manufacturer’s Website: The official website of the manufacturer is often the best place to start. It typically offers detailed information about available components, repair guides, and user manuals that can assist you in identifying the right parts for your equipment.

Online Retailers: Numerous online platforms specialize in tool supplies, providing a vast selection of replacement items. Websites like Amazon or specialized tool retailers can be valuable resources for locating specific components quickly and conveniently.

Local Hardware Stores: Visiting nearby hardware or home improvement stores can be beneficial as well. Many of these establishments carry a range of accessories and spare parts for common tools, and staff members may offer insights on suitable replacements or repair tips.

Community Forums: Online forums and communities dedicated to tool enthusiasts often share invaluable advice and experiences regarding repairs. Engaging with other users can lead to discovering alternative solutions and reliable resources for sourcing parts.

Repair Services: If the task feels overwhelming, consider professional repair services. Many local technicians specialize in power tool repairs and can source genuine parts on your behalf, ensuring that the maintenance is performed correctly and efficiently.