In the realm of nautical navigation, precision and reliability are paramount. Effective management of vessel movement is facilitated by a complex interplay of mechanisms designed to provide optimal handling and responsiveness. This section delves into the intricate elements that contribute to efficient directional control, highlighting the significance of each component in ensuring smooth operation.

As boat enthusiasts and professionals alike seek to enhance their maritime experience, a comprehensive grasp of these systems becomes essential. Familiarity with the various mechanisms and their functions not only aids in effective maintenance but also empowers users to troubleshoot potential issues. Through an examination of key elements and their interrelationships, one can appreciate the sophistication inherent in modern marine technology.

Moreover, understanding these components enables vessel operators to make informed decisions regarding upgrades and replacements, ultimately enhancing safety and performance on the water. This exploration serves as a valuable resource for anyone looking to deepen their knowledge of essential control mechanisms in maritime environments.

Understanding Baystar Hydraulic Steering Systems

This section explores the intricacies of a specific system designed for precision navigation and control in aquatic environments. These mechanisms are crucial for ensuring smooth maneuverability and enhancing overall performance, allowing vessels to respond effectively to operator input.

Components and Functionality

The system comprises various essential elements that work in unison to facilitate efficient operation. Each component plays a vital role, from the actuators that convert user commands into movement, to the fluid reservoirs that enable seamless motion. Understanding how these pieces interact is key to mastering the overall functionality.

Benefits of Advanced Systems

Implementing sophisticated systems offers numerous advantages, including improved responsiveness and reduced effort during operation. Such enhancements not only elevate the user experience but also contribute to the longevity and reliability of the entire mechanism, making it an ultimate choice for enthusiasts and professionals alike.

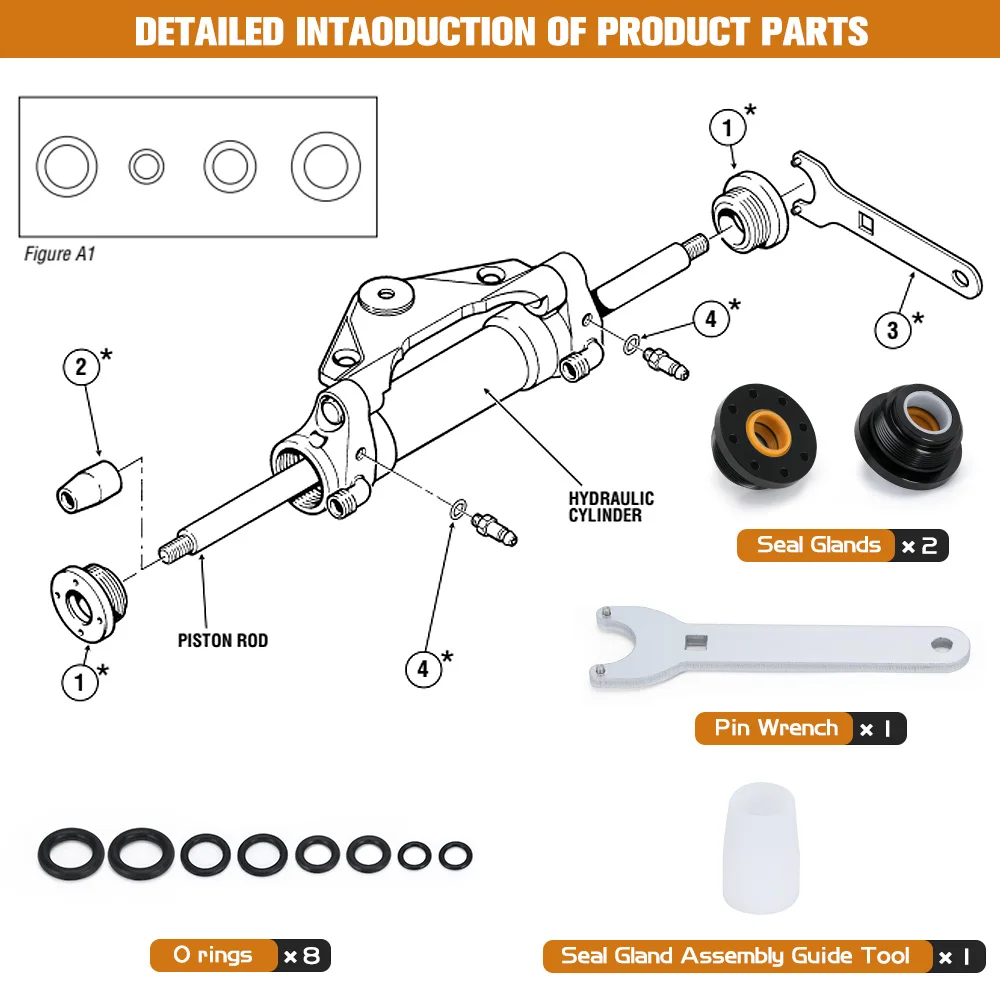

Components of Baystar Steering Assemblies

This section explores the essential elements that make up the hydraulic control system, emphasizing their roles in achieving smooth maneuverability and stability. Understanding each component is crucial for effective maintenance and troubleshooting.

1. Helm Unit: This is the primary control mechanism that enables the operator to direct the vessel. It translates the user’s input into hydraulic pressure.

2. Actuator: This device converts hydraulic pressure into mechanical motion, allowing for the adjustment of the vessel’s angle with precision.

3. Hoses: Flexible tubes transport hydraulic fluid between the helm and actuator, ensuring efficient transmission of power without leaks.

4. Fluid Reservoir: A container that holds the hydraulic fluid necessary for operation, maintaining adequate levels for optimal function.

5. Fittings: Connectors that secure the hoses to the helm unit and actuator, providing leak-free joints to withstand high pressure.

6. Filters: These components help maintain fluid cleanliness, preventing contaminants from damaging the system.

Understanding these crucial elements allows for better maintenance practices and enhances overall performance.

Benefits of Hydraulic Steering Mechanisms

Utilizing advanced control systems in vehicles offers numerous advantages that enhance overall performance and user experience. These mechanisms provide smooth operation and greater responsiveness, making navigation effortless even in challenging conditions. The design facilitates optimal weight distribution, contributing to improved handling and stability.

One of the primary benefits is the reduction of physical effort required from the operator. This ease of use minimizes fatigue during long journeys, allowing for more enjoyable travel. Additionally, precision in maneuvering is significantly enhanced, resulting in increased safety for both the vehicle and its occupants.

| Advantage | Description |

|---|---|

| Effortless Control | Reduces the physical strain on the operator, making driving less tiring. |

| Increased Precision | Offers better handling and maneuverability, especially in tight spaces. |

| Enhanced Stability | Promotes a balanced feel, contributing to safer driving experiences. |

| Improved Durability | Typically designed for longevity, minimizing maintenance needs over time. |

In summary, these sophisticated systems not only make driving more manageable but also elevate safety and performance, making them a preferred choice in modern vehicle design.

How to Read a Parts Diagram

Understanding a schematic can greatly enhance your ability to identify components and their relationships. Each illustration is designed to convey specific information, making it essential to grasp its layout and symbols.

First, familiarize yourself with the key or legend, which explains the symbols used throughout the illustration. This is crucial for interpreting what each icon represents.

Next, observe the arrangement of elements. Components are often grouped according to function, allowing you to quickly locate related items. Pay attention to lines or arrows that indicate connections or flow between parts.

Finally, take note of any annotations or notes that provide additional context. These insights can clarify the purpose of specific elements and guide you in understanding their role within the overall system.

Common Issues with Baystar Systems

Understanding typical challenges that arise with marine control mechanisms is essential for maintaining optimal performance. Users often encounter various difficulties that can affect functionality, safety, and overall experience on the water.

Frequent Problems

Several issues frequently reported include leaks, responsiveness inconsistencies, and component wear. Recognizing these symptoms early can help in implementing timely solutions.

Table of Common Issues

| Issue | Description |

|---|---|

| Leaks | Fluid leaks can occur from seals or connections, leading to reduced performance. |

| Delayed Response | Systems may exhibit lag in reaction time, impacting maneuverability. |

| Wear and Tear | Components may degrade over time, requiring replacement to ensure safety. |

Maintenance Tips for Hydraulic Steering

Proper upkeep of your vessel’s directional control system is essential for safe and efficient navigation. Regular checks and timely interventions can significantly extend the lifespan of your equipment.

- Regular Fluid Checks: Monitor the fluid levels frequently to ensure optimal performance.

- Inspect for Leaks: Examine hoses and connections for any signs of leakage that may compromise functionality.

- Clean Components: Keep the system free from debris and contaminants that can affect operation.

- Check for Wear: Regularly assess components for signs of wear or damage that may require replacement.

- Follow Manufacturer Guidelines: Adhere to maintenance schedules and recommendations provided by the manufacturer.

By following these tips, you can ensure a smoother and safer experience while on the water.

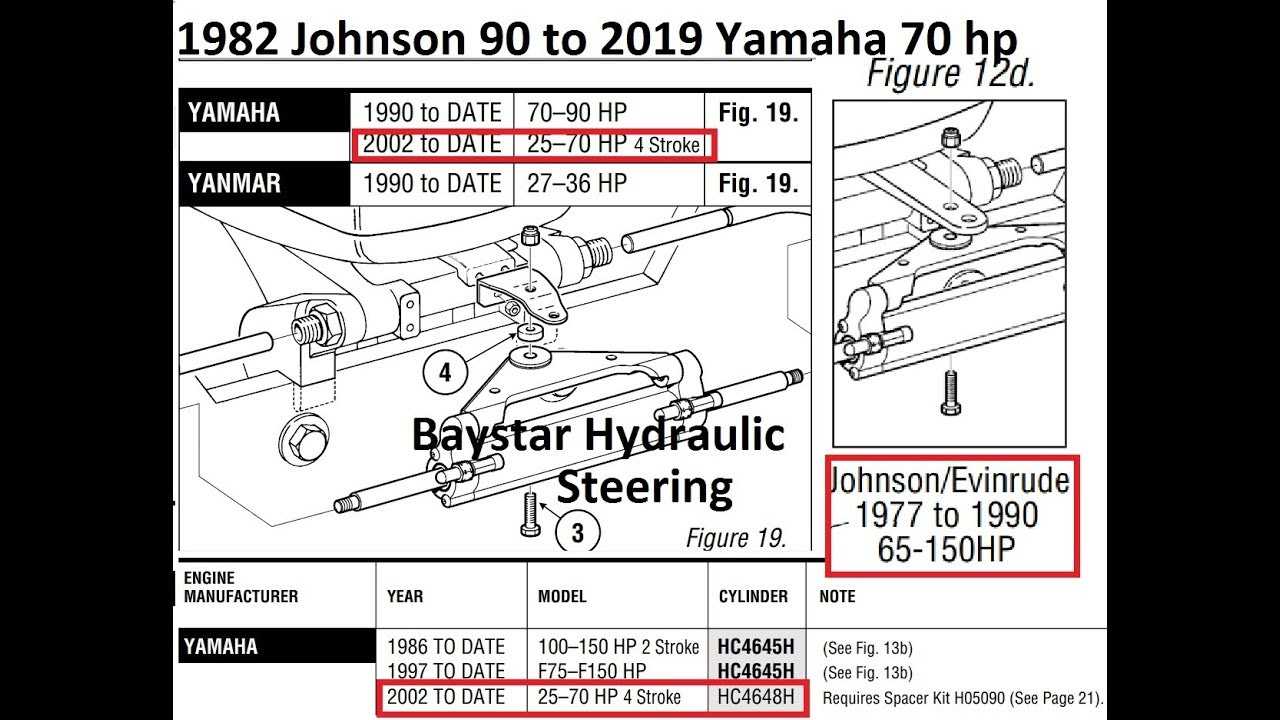

Installation Guide for Baystar Parts

This section provides a comprehensive overview of the steps involved in the setup and assembly of crucial components for a reliable control system. Following these instructions carefully will ensure optimal performance and longevity of your equipment.

Preparation Steps

Before commencing installation, gather all necessary tools and components. Ensure you have a clean workspace and refer to the provided manual for detailed specifications.

Installation Process

The following table outlines the essential steps and required tools for each stage of the setup:

| Step | Description | Tools Required |

|---|---|---|

| 1 | Identify the mounting location for the main unit. | Level, Marker |

| 2 | Secure the primary unit using appropriate fasteners. | Wrench, Screwdriver |

| 3 | Connect the auxiliary components as per the layout. | Cable Ties, Wire Strippers |

| 4 | Check all connections for stability and integrity. | Inspection Tool |

| 5 | Test the system for proper functionality before finalizing. | Testing Device |

By following this guide, you will ensure that each component is installed correctly, paving the way for a seamless operational experience.

Choosing the Right Steering Fluid

When it comes to ensuring optimal performance and longevity of your vessel’s control system, selecting the appropriate fluid is crucial. The right liquid not only facilitates smooth operation but also protects critical components from wear and damage.

Types of Fluids Available

There are various formulations on the market, each designed to meet specific requirements. It’s essential to consider factors such as viscosity, temperature range, and compatibility with existing systems. Many manufacturers recommend using fluids that meet particular industry standards to ensure reliability and efficiency.

Compatibility and Performance

Always check the manufacturer’s guidelines for compatibility. Using the wrong liquid can lead to serious malfunctions or degrade performance. A quality product should provide excellent lubrication, resist foaming, and offer protection against corrosion, enhancing the overall functionality of your system.

In summary, choosing the correct fluid is vital for maintaining the integrity and performance of your control mechanisms. Taking the time to select the right product will ultimately save you from costly repairs and ensure a smoother operation.

Upgrading Your Baystar System

Enhancing your vessel’s maneuverability can significantly improve your overall experience on the water. Upgrading components not only boosts performance but also ensures a smoother and more responsive handling. This section explores various enhancements to elevate your marine experience.

Benefits of Modernization

Implementing newer technologies can lead to increased reliability and safety. Advanced systems often feature improved materials and engineering, resulting in reduced maintenance needs and enhanced longevity. These upgrades also provide more precise control, making navigation easier and more enjoyable.

Choosing the Right Components

Selecting compatible upgrades is crucial for optimal performance. Research various options and consult with professionals to identify the best components for your specific needs. Prioritize high-quality products that align with your vessel’s requirements to ensure seamless integration and outstanding results.

Comparing Baystar to Other Brands

This section explores the distinctions between one popular system and its competitors in the market. By examining various features, performance metrics, and overall reliability, we can gain insight into how each option stands up to scrutiny. Understanding these differences is crucial for users looking to make informed decisions tailored to their specific needs.

While many brands offer similar functionalities, nuances in design and user experience can significantly impact effectiveness. Some alternatives may prioritize ease of installation, while others focus on advanced technology or superior durability. Analyzing these factors allows consumers to identify the ultimate solution that meets their expectations.

Additionally, customer feedback and reviews play a pivotal role in shaping perceptions of these systems. Real-world experiences can highlight both strengths and weaknesses, providing valuable information for prospective buyers. Ultimately, comparing these offerings can guide individuals towards a choice that balances quality, performance, and value.

Frequently Asked Questions About Baystar

This section addresses common inquiries related to a specific marine control system, providing clarity on various aspects that users may encounter. Whether you are new to this technology or seeking advanced knowledge, the following questions will help you navigate your concerns effectively.

What are the key components of this control system?

The main elements include the actuator, pump, and hoses, each playing a vital role in ensuring smooth operation.

How do I know if my system needs maintenance?

Signs include difficulty in maneuvering, unusual noises, or fluid leaks, indicating it’s time for a check-up.

Can I install this system myself?

While some individuals may handle installation, it’s recommended to consult a professional for optimal results.

What should I do if I encounter a malfunction?

First, check for obvious issues like fluid levels. If problems persist, seek expert assistance to diagnose and resolve the issue.

Are replacement components readily available?

Yes, many suppliers offer a range of replacement items, ensuring you can maintain the system effectively.