For anyone engaged in outdoor work or maintenance, familiarity with the individual elements of a reliable cutting tool is essential. These machines are designed for efficiency, and knowing how each component functions can greatly enhance user experience and performance. This guide aims to provide clarity on the various segments of this well-known device, ensuring users can easily identify and understand each part’s role.

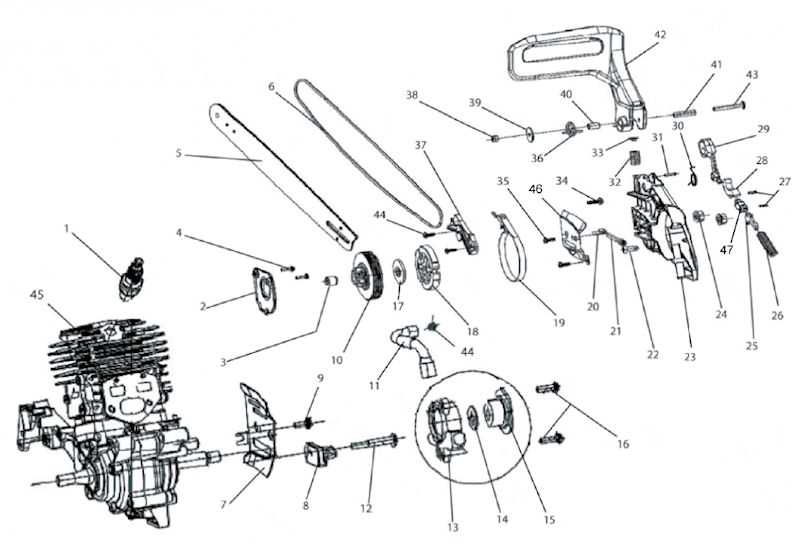

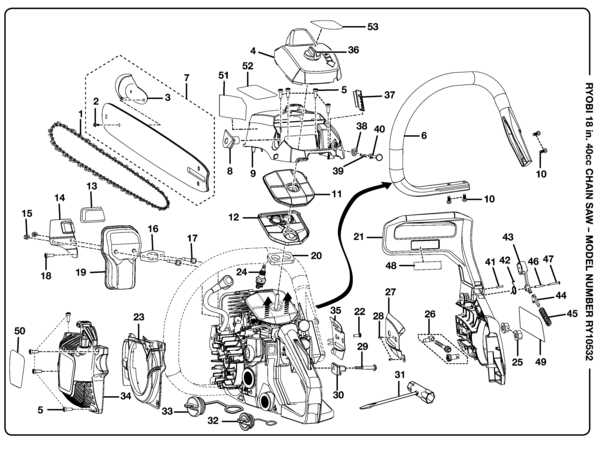

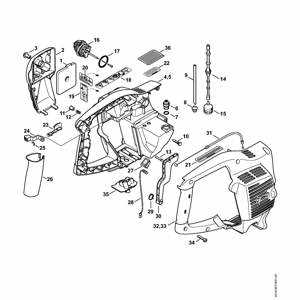

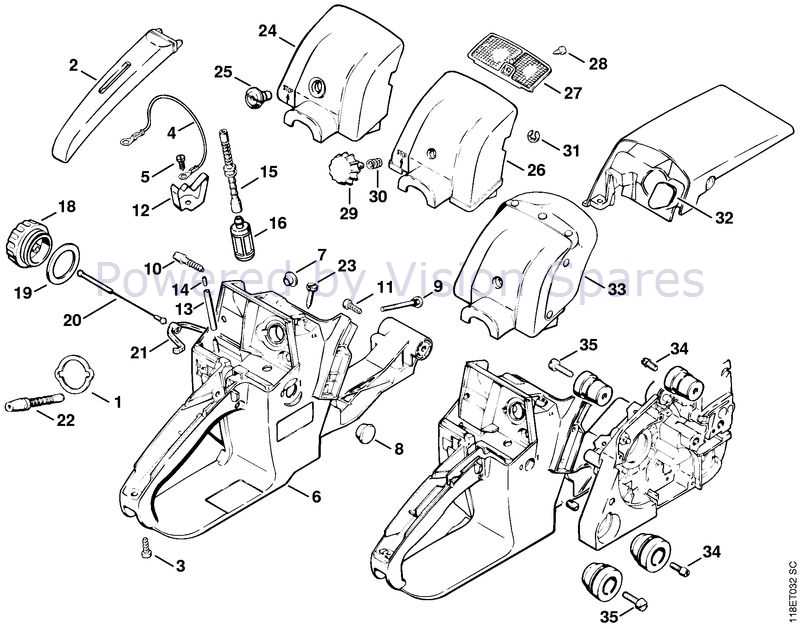

When dealing with mechanical tools, visual representations play a crucial role in comprehending their construction. A detailed illustration can serve as an invaluable reference for both novices and seasoned users alike. This resource offers a comprehensive look at the assembly, allowing for better insights into maintenance, repair, or modification processes.

By gaining a deeper understanding of the inner workings, operators can not only troubleshoot issues more effectively but also appreciate the craftsmanship behind the design. Whether you’re a hobbyist or a professional, mastering the intricacies of your equipment is key to maximizing its potential and ensuring longevity.

Understanding Stihl 028 Components

The effective operation of any outdoor power tool relies on a comprehensive understanding of its various elements. Each component plays a crucial role in the overall functionality and performance, contributing to the machine’s efficiency and longevity. By familiarizing oneself with these essential parts, users can better appreciate their importance and enhance maintenance practices.

Key elements within this equipment include the power unit, which generates the necessary energy for operation, and the cutting mechanism, designed to ensure precision and efficiency. Additionally, support structures, such as the frame and housing, provide stability and protection for internal mechanisms. Fuel delivery systems play a vital role in ensuring the proper mixture reaches the engine, while air intake components are essential for optimal combustion. Understanding the interplay between these various elements is vital for effective troubleshooting and maintenance.

Regular inspections and proper care of each individual part can significantly extend the lifespan of the equipment. Familiarity with components not only aids in identifying potential issues but also empowers users to perform basic repairs and adjustments. This knowledge is invaluable for maximizing performance and ensuring reliable operation over time.

Overview of Chainsaw Structure

The internal composition of a cutting tool designed for wood processing is essential for understanding its functionality and efficiency. This article will explore the primary components that make up such a device, highlighting their roles and interactions. Each section will delve into the significance of various elements, ensuring users have a comprehensive grasp of the tool’s construction.

Key Components

To effectively operate, a wood processing instrument consists of several critical components. Each part contributes uniquely to the overall performance, ensuring that the device operates smoothly and efficiently. Below is a brief overview of these essential elements:

| Component | Description |

|---|---|

| Engine | The power source that drives the cutting mechanism, typically a two-stroke engine known for its lightweight and high power output. |

| Guide Bar | A metal bar that supports the cutting chain and determines the length of the cut; its design is crucial for stability. |

| Cutting Chain | A loop of metal links equipped with sharp teeth, responsible for slicing through wood with precision and speed. |

| Handle | Provides grip and control for the user, often designed ergonomically for comfort during extended use. |

| Throttle Trigger | Regulates the engine speed and cutting power, allowing users to adjust performance according to the task at hand. |

Functional Interactions

The interplay between the various components enhances the effectiveness of the tool. For instance, the engine’s power directly influences the speed of the cutting chain, while the guide bar’s length affects maneuverability and cutting capacity. Understanding these interactions is vital for optimal operation and maintenance.

Key Parts of the Stihl 028

This section focuses on the essential components that make up a well-known power tool designed for cutting and trimming tasks. Understanding these elements is crucial for maintenance, repairs, and enhancing performance. Each component plays a significant role in the overall functionality and efficiency of the machine.

Main Components

The main components of this equipment are critical for its operation. Below is a table that outlines the key components along with their respective functions:

| Component | Function |

|---|---|

| Engine | Powers the tool, providing the necessary energy for cutting. |

| Bar | Supports the chain and guides it during operation. |

| Chain | Designed with sharp teeth for efficient cutting through wood. |

| Air Filter | Prevents debris from entering the engine, ensuring smooth operation. |

| Fuel Tank | Holds the fuel needed to power the engine. |

Additional Features

Besides the main components, there are various additional features that enhance usability and safety. These include vibration dampening systems, safety guards, and adjustable tensioners. Each feature contributes to a better user experience and prolongs the lifespan of the tool.

Importance of Proper Maintenance

Regular upkeep of equipment is essential to ensure optimal performance and longevity. Neglecting maintenance can lead to decreased efficiency, increased wear and tear, and potentially costly repairs. By implementing a systematic maintenance routine, users can significantly enhance the reliability and lifespan of their tools.

Benefits of Regular Upkeep

- Enhanced Performance: Consistent maintenance helps maintain the efficiency of the equipment, ensuring it operates at peak performance.

- Increased Safety: Well-maintained tools are less likely to malfunction, reducing the risk of accidents and injuries during operation.

- Cost Savings: Preventative care can minimize the need for expensive repairs or replacements, saving money in the long run.

Key Maintenance Practices

- Regularly clean and inspect the equipment for any signs of wear or damage.

- Keep all components lubricated to reduce friction and prevent overheating.

- Replace worn or damaged parts promptly to maintain optimal function.

- Store the equipment properly to protect it from environmental factors.

Common Issues with Stihl 028

Many users of this popular cutting tool encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems can help users maintain their equipment effectively and ensure longevity. Here are some frequently reported concerns:

- Starting Difficulties: Users often experience trouble getting the device to start, which can stem from issues such as a clogged air filter or improper fuel mixture.

- Inefficient Cutting: A tool may struggle to cut through wood effectively. This can be caused by dull blades or incorrect tension on the cutting chain.

- Excessive Vibration: Noticing heightened vibration levels during operation can indicate problems with the balance of the cutting system or worn components.

- Fuel Leaks: Fuel leaks are a significant issue that can arise from damaged seals or fuel lines, leading to performance setbacks and safety hazards.

- Overheating: Continuous use without adequate cooling can lead to overheating, often resulting from restricted airflow or a malfunctioning cooling system.

Addressing these concerns promptly can greatly improve the functionality and safety of the tool. Regular maintenance checks and following operational guidelines are essential for preventing these issues from becoming more severe.

Replacing Worn Out Parts

Over time, machinery components can degrade, impacting overall performance and efficiency. Regular maintenance and timely replacement of these worn elements are crucial for optimal functioning. Understanding which components require attention can help extend the lifespan of the equipment and ensure reliable operation.

Identifying Wear: Signs of wear may include unusual noises, decreased power, or visible damage. It is essential to regularly inspect the equipment to catch issues early. Components such as blades, filters, and spark plugs often exhibit signs of fatigue and should be prioritized during assessments.

Replacement Process: Begin by consulting the manufacturer’s guide for specific instructions on removing and replacing components. It’s important to gather the necessary tools and replacement elements before starting. Ensure the machinery is turned off and disconnected from any power sources to avoid accidents.

Proper Installation: When installing new components, follow the manufacturer’s specifications closely. Ensure that all fasteners are tightened to the recommended torque and that the replacements fit securely. After replacement, conduct a brief test run to ensure everything operates smoothly.

Regular Maintenance: To prevent future wear and tear, establish a routine maintenance schedule. Regularly cleaning, lubricating, and checking components can significantly reduce the frequency of replacements and enhance the overall durability of the equipment.

Identifying Compatible Replacement Parts

When maintaining or repairing a power tool, selecting the right components is crucial for optimal performance and longevity. Understanding the characteristics and specifications of the required elements can significantly impact the efficiency of the tool. Proper identification of compatible replacements ensures a seamless fit and functionality, allowing for effective operation without unexpected disruptions.

Researching Specifications

Begin by gathering detailed information about the tool’s model and features. Consult the user manual or manufacturer’s website to identify key specifications such as size, material, and compatibility requirements. This research will provide a solid foundation for making informed decisions regarding suitable components.

Utilizing Reliable Sources

Turn to reputable suppliers or online marketplaces that specialize in power tool components. Look for listings that include comprehensive descriptions and compatibility charts. Customer reviews can also be beneficial, as they often provide insights into the reliability and performance of the replacements. Consulting forums dedicated to tool enthusiasts may also yield valuable recommendations.

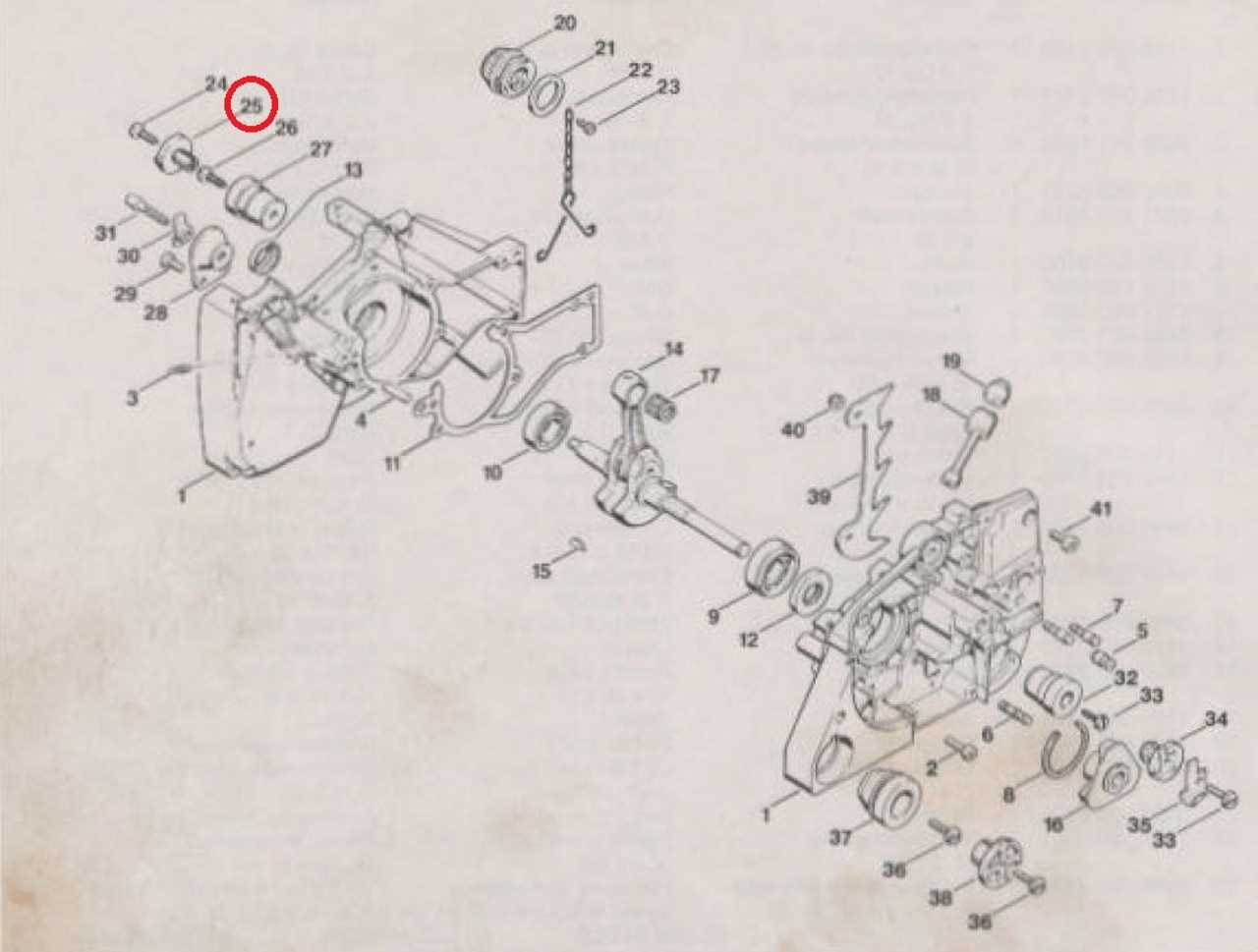

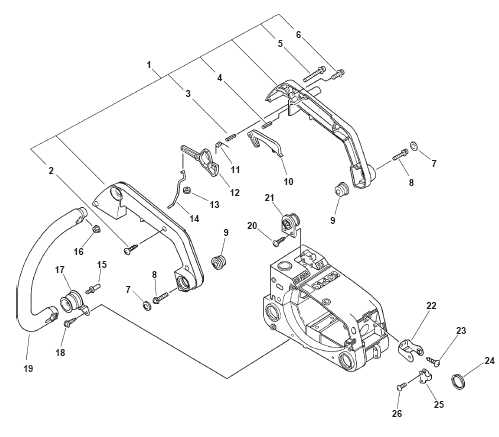

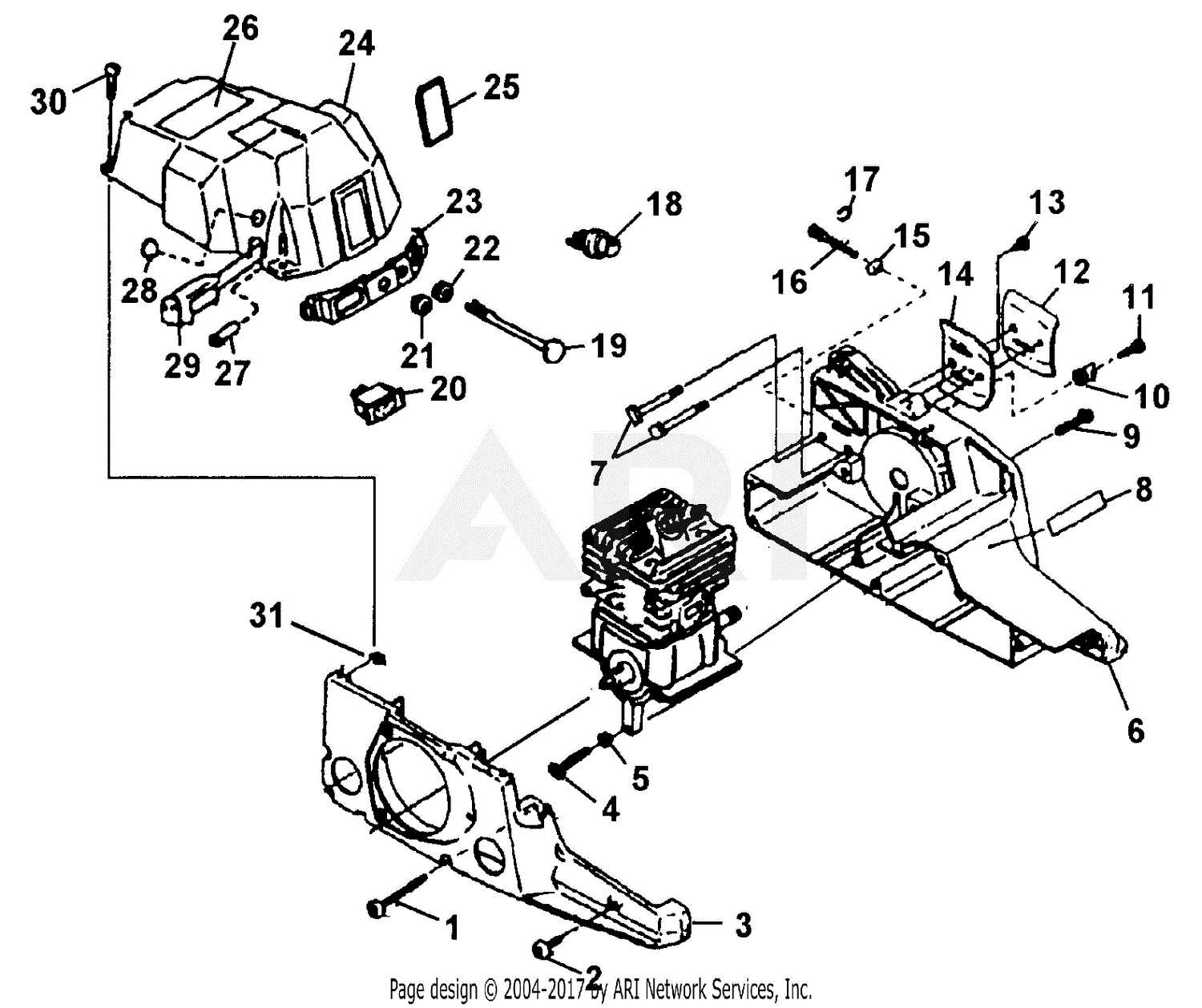

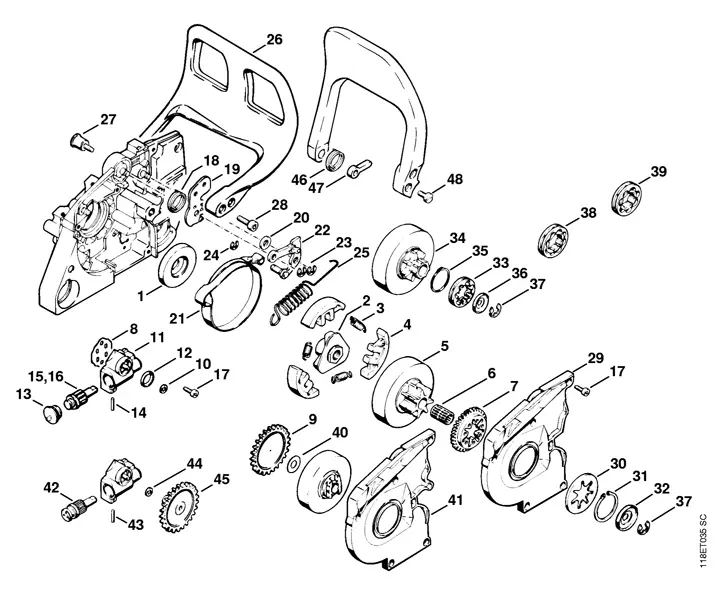

Diagram Interpretation for Users

Understanding the layout of components in machinery is crucial for effective maintenance and repair. Familiarity with how each piece fits and functions within the system allows users to troubleshoot issues efficiently and replace worn or damaged elements without confusion.

When analyzing a visual representation of the assembly, consider the following key aspects:

- Component Labels: Ensure that each part is clearly identified, often accompanied by a reference number. This aids in locating the exact item needed for replacement.

- Groupings: Components are typically organized into sections, which may indicate their function or the area of the machine they belong to. Recognizing these groupings can simplify understanding the overall structure.

- Connection Points: Pay attention to how parts are interconnected. This information is vital for disassembly and reassembly, ensuring that everything is put back in the correct order.

- Maintenance Indicators: Some diagrams include notes on regular upkeep or warning signs that may signal when a part needs inspection or replacement.

By mastering these elements, users can enhance their comprehension of the machinery’s configuration, ultimately leading to improved performance and longevity of the equipment.

Safety Considerations When Disassembling

When undertaking the task of dismantling a mechanical device, it is essential to prioritize safety to prevent accidents and injuries. Ensuring a secure environment and using proper techniques can significantly reduce the risks involved in such activities.

Before beginning the disassembly process, consider the following safety measures:

- Personal Protective Equipment (PPE): Always wear appropriate gear, including safety goggles, gloves, and sturdy footwear to protect against potential hazards.

- Work Area Preparation: Clear the workspace of unnecessary items and ensure adequate lighting to avoid distractions and hazards.

- Secure the Equipment: Make sure the device is turned off and disconnected from any power sources to prevent accidental starts.

- Use Proper Tools: Utilize the correct tools for disassembly to avoid damaging components or causing injury.

- Follow Manufacturer Instructions: Adhere to any guidelines or manuals provided by the manufacturer for safe disassembly procedures.

By implementing these precautions, individuals can enhance their safety and ensure a more efficient disassembly experience.

Tools Required for Repairs

When undertaking maintenance or fixing a mechanical device, having the right tools at your disposal is essential for achieving efficient and effective results. The proper equipment not only streamlines the repair process but also enhances safety and minimizes the risk of damage to the unit. This section will outline the essential tools that are commonly needed for such tasks.

First and foremost, a reliable set of hand tools is crucial. This includes screwdrivers, pliers, and wrenches in various sizes to tackle different fasteners. A torque wrench is particularly important to ensure that components are tightened to the manufacturer’s specifications. Additionally, a socket set can make it easier to access hard-to-reach areas.

Power tools can significantly reduce the effort required during repairs. A cordless drill or impact driver is invaluable for removing stubborn screws and bolts. Furthermore, a good-quality saw may be necessary for cutting through materials when replacing components.

Safety equipment should not be overlooked. Protective gloves and safety goggles are vital for safeguarding against injuries during repair work. Additionally, a sturdy workbench or surface can provide stability while working on the unit.

Finally, having a comprehensive repair manual or guide can be extremely beneficial. This reference material can provide detailed instructions and specifications, ensuring that each step of the process is followed correctly.

Tips for Efficient Repair Processes

Engaging in maintenance and restoration tasks can often be daunting, yet adopting effective strategies can streamline the entire operation. A systematic approach not only enhances productivity but also reduces the likelihood of errors, ensuring a smoother workflow.

1. Organize Your Workspace: A clutter-free environment is essential for efficient repairs. Ensure all tools and components are readily accessible. Group similar items together to minimize search time and enhance focus.

2. Utilize Quality Tools: Investing in reliable equipment can significantly impact the repair process. High-quality tools reduce the risk of damage to components and promote a more accurate and efficient workflow.

3. Follow a Step-by-Step Guide: Familiarizing yourself with a structured manual or reference material is crucial. A detailed guide helps to avoid missing critical steps and allows for a thorough understanding of each task.

4. Keep Track of Components: Assembling and disassembling machinery can lead to misplaced elements. Use containers or labeled bags to keep track of each part, ensuring nothing is lost during the process.

5. Take Breaks When Needed: Working for extended periods without rest can lead to fatigue and decreased focus. Short breaks can help maintain concentration and promote better decision-making throughout the repair.

6. Document Your Progress: Keeping a record of completed tasks can serve as a useful reference for future repairs. Noting any challenges encountered and solutions found can be invaluable for subsequent maintenance efforts.

By implementing these strategies, individuals can significantly improve their efficiency during repair tasks, leading to a more satisfying and successful experience.

Resources for Further Information

For individuals seeking more in-depth knowledge and understanding regarding maintenance and repair of power equipment, numerous sources are available. These resources can enhance your comprehension of components, functionality, and troubleshooting techniques. Engaging with reliable materials will facilitate informed decisions and effective usage of your tools.

Online Platforms

- Manufacturer’s Official Website: Explore the comprehensive resources provided by the manufacturer, including manuals and support documentation.

- Online Forums: Join community forums dedicated to equipment enthusiasts, where you can exchange experiences and gather insights from fellow users.

- YouTube Tutorials: Access a variety of instructional videos that visually demonstrate maintenance procedures and repairs.

Books and Publications

- Maintenance Manuals: Seek specialized manuals that provide detailed information about equipment upkeep and troubleshooting methods.

- Guides on Equipment Repair: Look for comprehensive guides that cover various types of power tools and their functionality.

- Trade Magazines: Subscribe to industry-specific publications that feature articles on the latest innovations and techniques in tool maintenance.