Every machinery enthusiast knows the importance of familiarizing oneself with the intricate workings of their equipment. Having a comprehensive grasp of each individual element not only enhances the user experience but also aids in effective maintenance and repairs. When a machine’s components are well-understood, it empowers users to troubleshoot issues more efficiently and prolong the lifespan of their tools.

In the realm of power tools, recognizing how various pieces interact is crucial for optimal performance. This understanding allows for better decision-making when it comes to replacements and upgrades. Visual representations can serve as invaluable resources, simplifying the identification of necessary elements and ensuring that users are equipped with the right knowledge for any task.

Whether you are a seasoned professional or a novice, mastering the details of your equipment fosters confidence. Accessing clear, detailed illustrations of the components involved can illuminate the complexity of your tool, guiding you through assembly, disassembly, and everything in between. Embracing this knowledge ultimately leads to a more rewarding and efficient experience.

Understanding the Stihl 440 Chainsaw

This section provides a comprehensive look into a popular model of a handheld cutting tool, exploring its essential components and functionality. Whether you’re a novice user or a seasoned professional, grasping the intricacies of this equipment can enhance your operational efficiency and maintenance practices.

| Component | Description |

|---|---|

| Engine | Power source that drives the cutting mechanism. |

| Guide Bar | Metal blade that supports the chain during cutting. |

| Chain | Sharp links that rotate around the guide bar to cut through wood. |

| Handle | Provides grip and control during operation. |

| Air Filter | Prevents debris from entering the engine, ensuring optimal performance. |

Overview of Stihl 440 Features

This segment delves into the exceptional characteristics of a renowned power tool designed for heavy-duty tasks. Its engineering reflects a perfect balance between power and precision, making it a favorite among both professionals and enthusiasts in various fields. Users can expect durability and efficiency, along with an array of features that enhance usability and performance.

Key Attributes

The device boasts several standout attributes that contribute to its popularity:

| Feature | Description |

|---|---|

| Powerful Engine | Offers impressive cutting capability, handling tough materials with ease. |

| Ergonomic Design | Ensures comfort during extended use, reducing fatigue for the operator. |

| Low Emissions | Environmentally friendly operation with reduced carbon footprint. |

| Easy Maintenance | Streamlined access to components simplifies servicing and upkeep. |

Performance and Efficiency

This tool is engineered for high performance, providing reliable operation in demanding situations. Its efficiency is complemented by features designed to maximize output while minimizing resource consumption, ensuring that users achieve their goals effectively and sustainably.

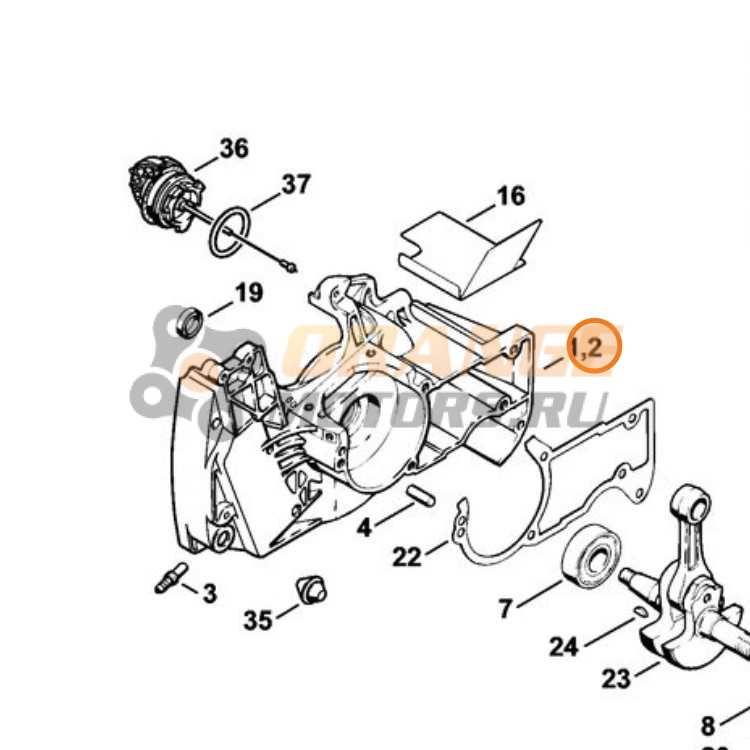

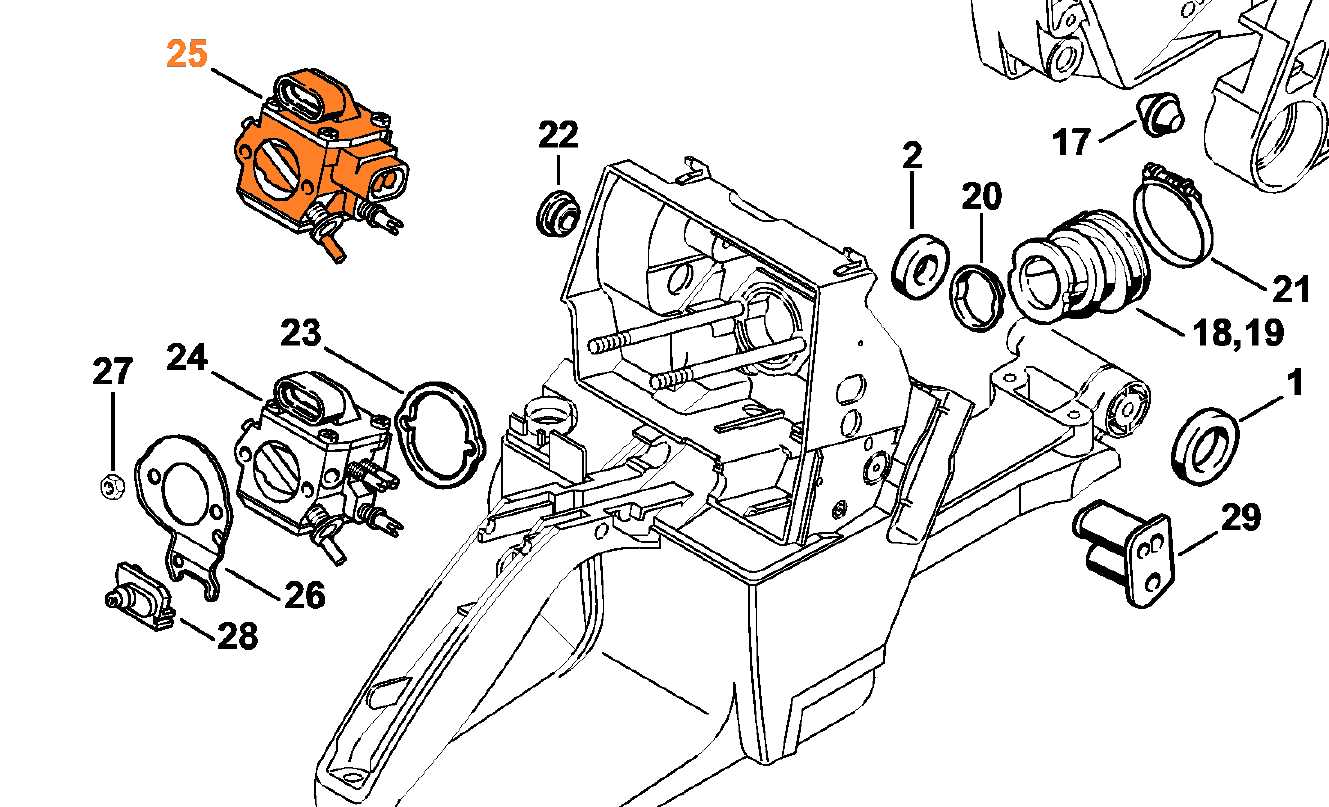

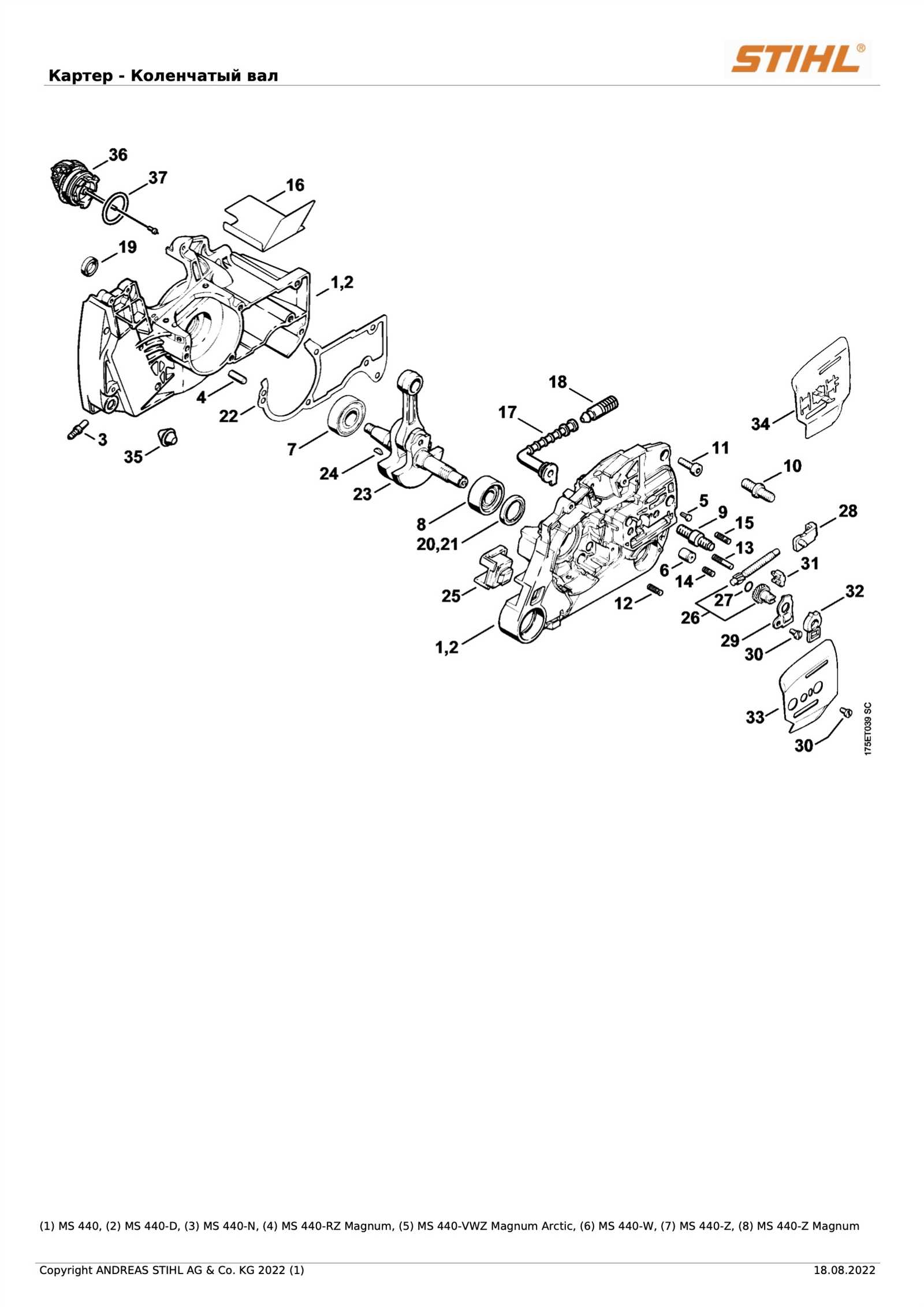

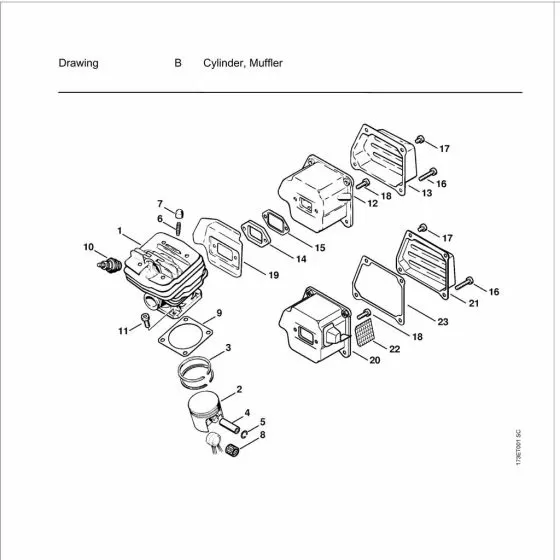

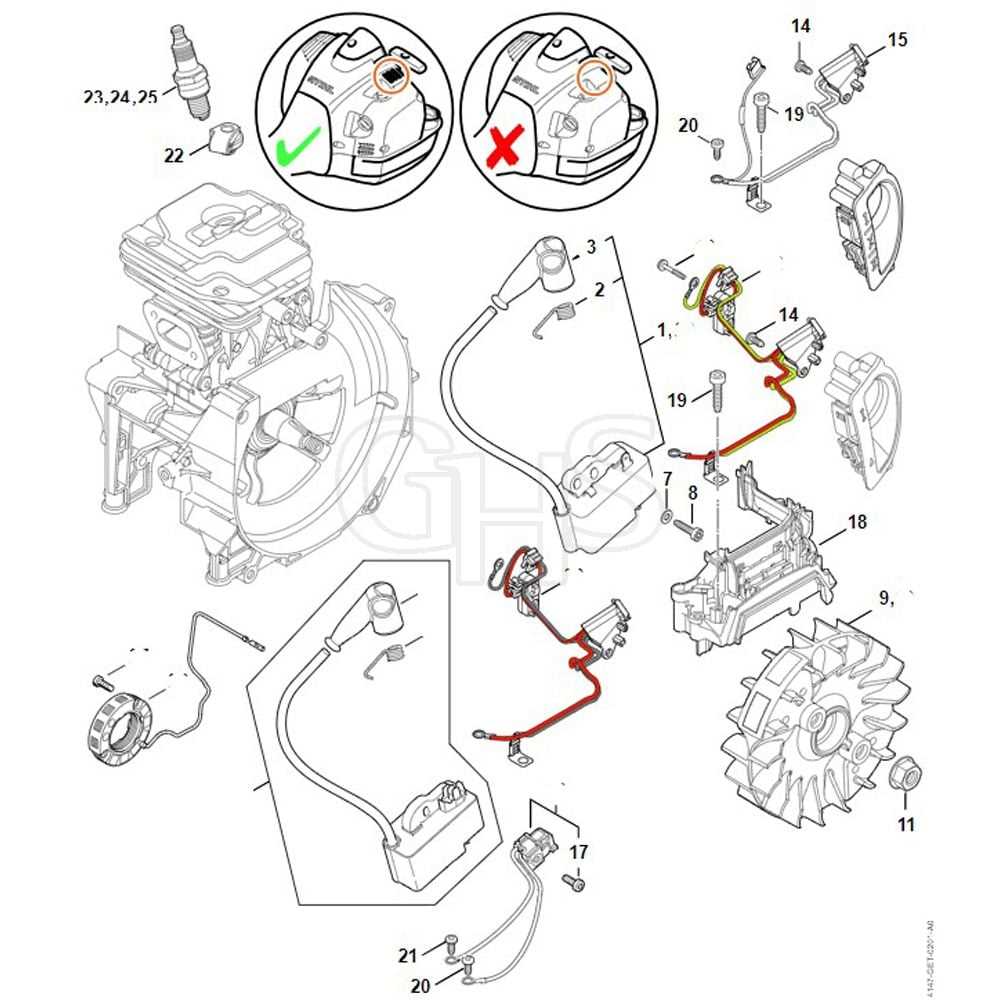

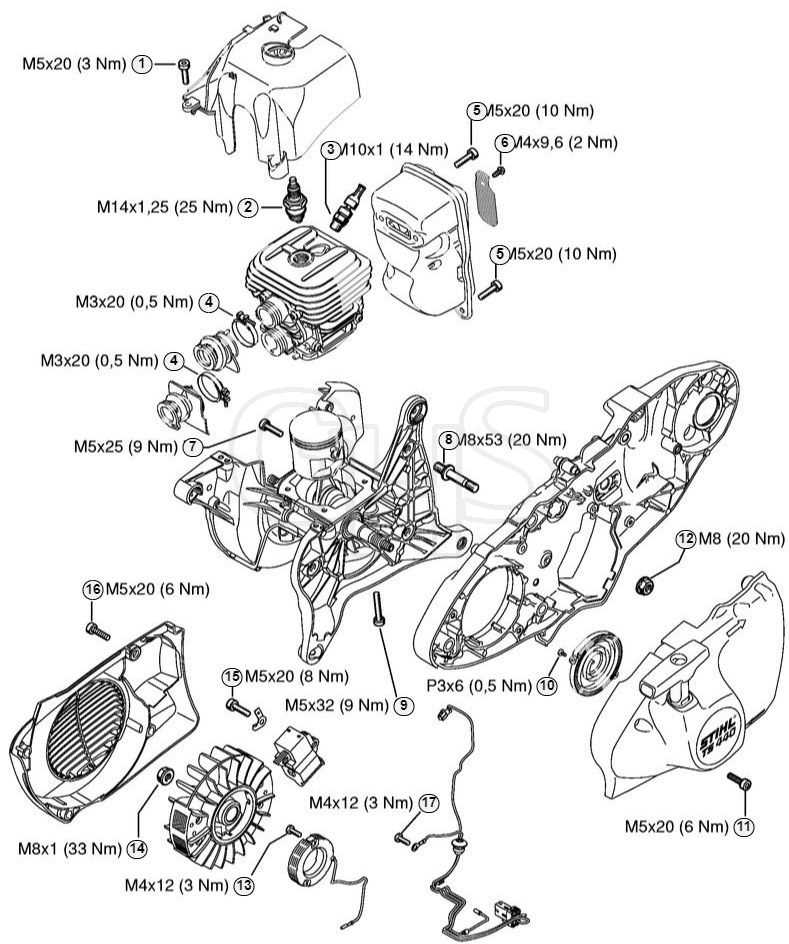

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable tools, allowing users to identify each element, its function, and its relationship to other parts.

Clear visuals aid technicians in troubleshooting, ensuring that they can quickly locate issues and determine the necessary replacements. This ultimately enhances efficiency and reduces downtime.

Furthermore, illustrations facilitate communication between users and suppliers, making it easier to order the correct components. Accurate references not only simplify the repair process but also help in extending the lifespan of the equipment.

Key Components of Stihl 440

This section explores the essential elements that contribute to the functionality and efficiency of this powerful outdoor tool. Understanding these components is crucial for effective maintenance and optimal performance.

Core Elements

- Engine: Provides the necessary power for operation.

- Chain: Critical for cutting, requiring regular inspection.

- Guide Bar: Supports the chain and ensures precise cutting.

Supportive Features

- Air Filter: Ensures clean airflow to the engine.

- Fuel System: Facilitates proper fuel delivery for combustion.

- Ignition System: Responsible for starting and running the engine efficiently.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will help you interpret such illustrations, enabling you to identify and manage various elements accurately.

- Familiarize Yourself with Symbols: Different icons represent specific parts. Recognizing these will streamline your understanding.

- Check the Numbering System: Often, each element is numbered, corresponding to a list. This assists in locating replacements easily.

- Identify Groupings: Components may be organized into sections based on function or assembly. Pay attention to these groupings for a clearer perspective.

- Consult the Key: Many illustrations include a legend or key. This explains symbols and codes used throughout the image.

By mastering these elements, you can effectively navigate and utilize the visual guide for your repair needs.

Common Replacement Parts Explained

Understanding essential components can enhance the longevity and performance of your equipment. Knowing which elements frequently require replacement allows for efficient maintenance and smoother operation.

- Filters: Vital for maintaining clean air and fuel flow, filters should be regularly inspected and swapped out when necessary.

- Chains: These wear down over time due to friction and should be replaced to ensure optimal cutting efficiency.

- Spark Plugs: Crucial for ignition, worn spark plugs can lead to poor performance, making timely replacements essential.

- Drive Belts: These components are subject to wear and should be checked periodically for signs of damage or fraying.

Regularly assessing these key elements can prevent unexpected breakdowns and extend the life of your machinery.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention to detail. Adopting good maintenance practices not only extends the lifespan of your machine but also enhances its performance. Here are some essential tips to keep in mind for effective care.

Regular Cleaning

- After each use, remove dirt and debris from the exterior to prevent buildup.

- Check and clean air filters periodically to ensure optimal airflow.

- Inspect the spark plug and clean it as necessary to maintain efficient ignition.

Routine Inspections

- Conduct visual inspections of all components for signs of wear or damage.

- Regularly check fluid levels, including oil and fuel, and replenish as needed.

- Monitor the condition of belts and chains, replacing them if they show signs of deterioration.

By following these maintenance tips, you can significantly enhance the performance and lifespan of your machinery, ensuring it operates efficiently for years to come.

Identifying Genuine Stihl Parts

Ensuring the reliability and longevity of outdoor power equipment hinges on the use of authentic components. Recognizing these original items is crucial for maintaining optimal performance and safety standards. Counterfeit alternatives can compromise functionality and lead to costly repairs, making it essential for users to distinguish between genuine and imitation offerings.

One of the primary indicators of authenticity is the packaging. Original items are typically presented in high-quality, branded boxes with clear labeling. Inspecting the packaging for signs of wear or poor print quality can help in identifying fakes.

Another important aspect to consider is the price. If an offer seems too good to be true, it likely is. Genuine components are priced competitively but reflect their quality and durability. Unusually low prices can be a red flag for counterfeit products.

Additionally, examining the item itself is vital. Authentic components feature precise manufacturing details, such as clear logos, consistent color schemes, and specific model numbers. Any discrepancies in these features should raise suspicion.

Finally, purchasing from reputable dealers is one of the best ways to ensure authenticity. Authorized retailers are more likely to stock genuine items and can provide the necessary documentation for verification. When in doubt, checking online resources or contacting the manufacturer can provide further confirmation.

Where to Find Parts Diagrams

Locating visual representations of components for machinery can be crucial for maintenance and repairs. Understanding how each piece fits together aids in troubleshooting and ensures the longevity of your equipment. There are several reliable sources to explore when seeking these illustrations.

Manufacturer Websites

Official websites of equipment manufacturers often provide comprehensive resources, including visual guides. These platforms typically offer downloadable materials that are updated regularly, ensuring you have access to the latest information.

Online Retailers and Forums

Numerous online retailers and specialized forums host a wealth of user-generated content. These communities frequently share diagrams, experiences, and tips, creating a valuable resource for both novice and experienced users alike.

Step-by-Step Repair Process

Repairing machinery can seem daunting, but breaking the process into manageable steps can make it much more accessible. Whether you’re addressing a minor issue or a more complex malfunction, following a structured approach will help you achieve the desired results efficiently and effectively. The key is understanding the components involved, ensuring you have the necessary tools, and proceeding with a clear plan in mind.

Preparation

Before starting any repair work, it is essential to gather the necessary materials and tools. Make sure the machine is completely powered off and safely positioned to prevent any accidents. Take note of the specific components that might need attention and assess their condition. Always work in a well-lit and organized environment.

- Gather tools such as screwdrivers, pliers, and wrenches.

- Ensure you have access to replacement parts, if required.

- Wear safety equipment like gloves and goggles to protect yourself.

Disassembly

The next step involves disassembling the unit. Carefully remove any outer covers or panels that may obstruct access to the internal components. Keep track of all screws, bolts, and fasteners in an organized manner to avoid confusion when reassembling the unit later. It is often helpful to take notes or photos during this stage for reference.

- Loosen and remove the screws or bolts securing the outer panels.

- Gently remove any covers to expose the internal parts.

- Inspect the internal components for signs of wear or damage.

Identifying and Replacing Faulty Components

Once you have access to the machine’s internal structure, identify any worn-out or damaged components. Whether it’s a broken part or a worn-out element, replacing them promptly will prevent further damage and ensure proper functioning. Compare the faulty components with the new ones to confirm compatibility.

- Remove the defective components carefully using the appropriate tools.

- Install the new components in the correct position, ensuring a secure fit.

- Check the alignment and positioning before proceeding with reassembly.

Reassembly and Testing

After replacing the necessary parts, it’s time to reassemble the machine. Start by replacing the covers and panels, securing them with the previously removed screws and bolts. Once the machine is fully reassembled, conduct a series of tests to ensure that everything functions correctly. Test the unit at a low power setting to verify that all parts are working properly before full operation.

- Reattach the covers and secure them tightly.

- Ensure all fasteners are properly tightened.

- Perform a test run to check the functionality of the repaired machine.

FAQs About Stihl 440 Parts

This section addresses common inquiries regarding components and accessories related to a popular model. Here, you’ll find essential information that can help users navigate maintenance and repair tasks effectively.

- What are the most common issues with the components?

Users often encounter wear and tear on specific elements, such as the engine and chain assembly. Regular maintenance can mitigate these problems.

- How can I identify the right components for my equipment?

Refer to the model’s manual or consult authorized dealers to ensure you obtain compatible replacements.

- Where can I purchase reliable replacements?

Reputable retailers, online marketplaces, and authorized service centers are excellent sources for high-quality replacements.

- What maintenance practices should I follow?

- Regularly check and clean air filters.

- Inspect the chain for damage and ensure proper tension.

- Change lubricants as recommended in the user manual.

- Are there any specific tools needed for repairs?

Basic hand tools like wrenches and screwdrivers are typically sufficient, though specialized tools may be necessary for certain tasks.

Resources for Stihl Users

For enthusiasts and professionals alike, accessing the right tools and information is essential for maintaining and optimizing outdoor equipment. Whether you are looking for repair guidance, maintenance tips, or component specifications, a variety of resources are available to enhance your experience and ensure your machines operate at peak performance.

Online Forums and Communities provide a platform for users to exchange ideas, seek advice, and share experiences. Engaging with fellow owners can yield practical solutions and insights into common challenges faced during operation and upkeep.

Official Manufacturer Websites often feature comprehensive support sections, including user manuals, troubleshooting guides, and detailed descriptions of various models. These resources are invaluable for understanding specific features and requirements of your equipment.

Video Tutorials on platforms like YouTube offer step-by-step instructions for repairs and maintenance tasks. Visual guides can simplify complex processes, making it easier for users to follow along and complete projects with confidence.

Local Dealers and Service Centers serve as essential points of contact for parts and professional assistance. Establishing a relationship with a trusted dealer can ensure you have access to quality components and expert advice tailored to your specific needs.

Utilizing these resources can significantly enhance your ownership experience, empowering you to tackle maintenance tasks with ease and keep your equipment running smoothly.