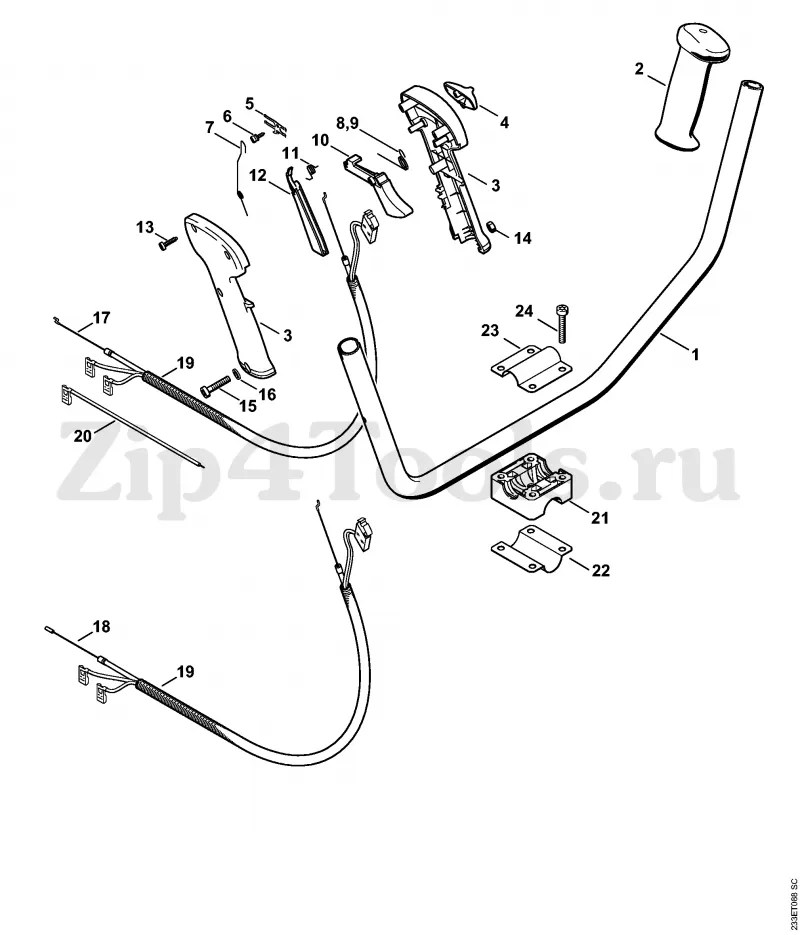

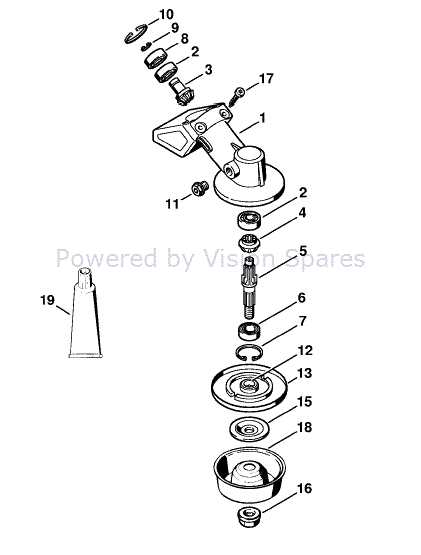

The functionality of trimming tools heavily relies on a variety of essential elements that work in unison. Understanding the layout and interaction of these components is crucial for effective maintenance and repair. Proper familiarity with these individual parts can significantly enhance the longevity and performance of the machinery.

In this section, we will explore a comprehensive representation of the various elements that contribute to the overall operation of these tools. Each component plays a pivotal role, and recognizing their positions and connections will empower users to troubleshoot effectively and carry out necessary adjustments or replacements when needed.

By familiarizing oneself with the intricate network of parts, users can ensure their equipment remains in optimal condition. This knowledge not only aids in resolving issues but also fosters a deeper appreciation for the engineering behind modern trimming devices.

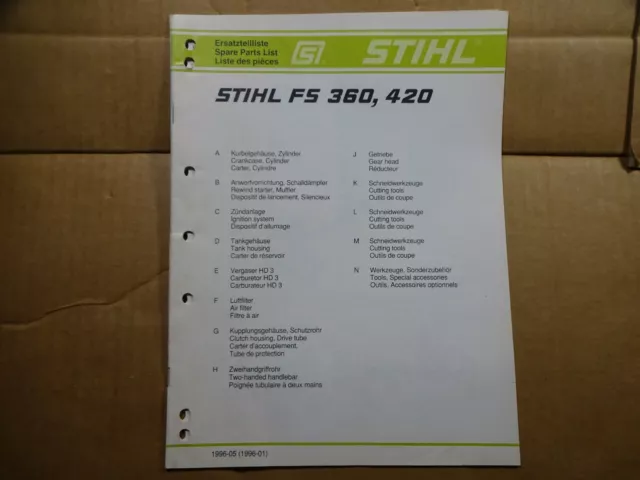

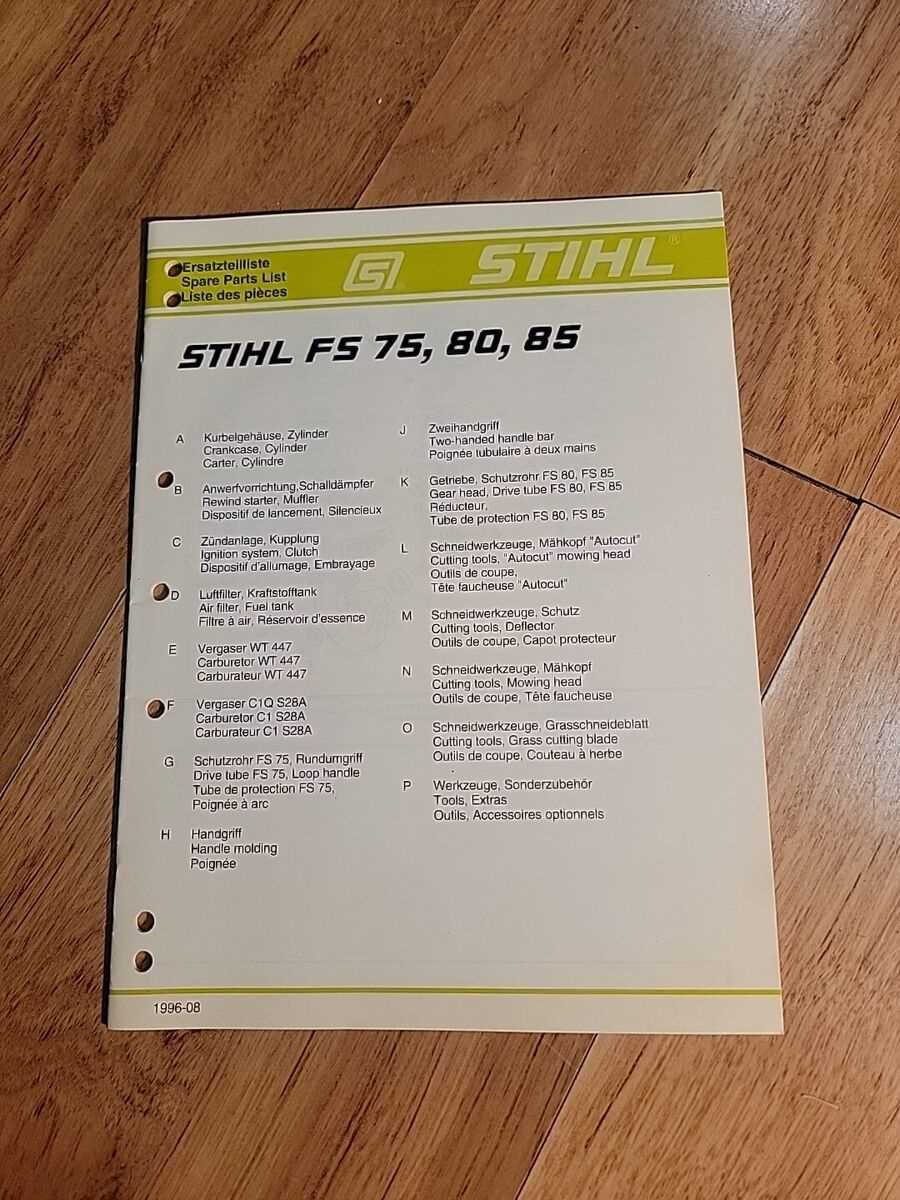

This section aims to provide a comprehensive understanding of the various components associated with a specific outdoor power tool. By exploring the essential elements, users can better appreciate how each part contributes to the overall functionality and performance of the equipment.

Key Components of the Equipment

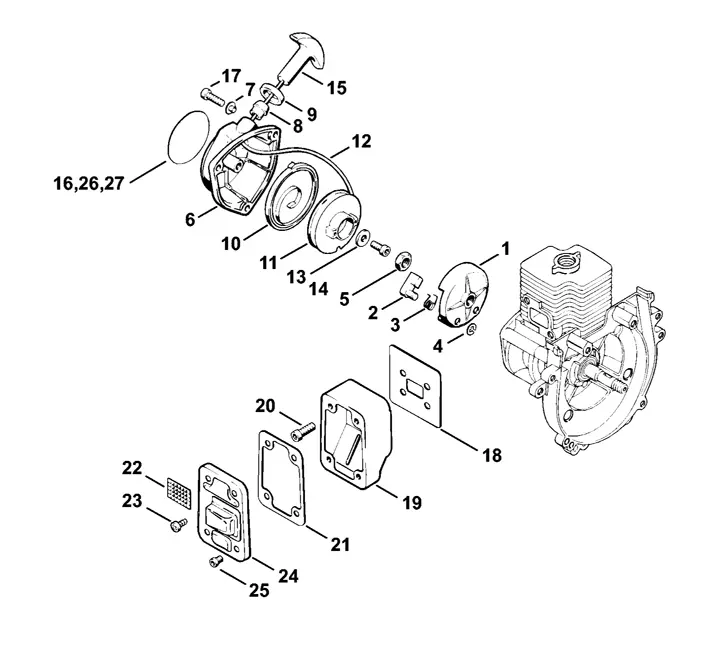

- Engine assembly: The heart of the tool, providing the necessary power for operation.

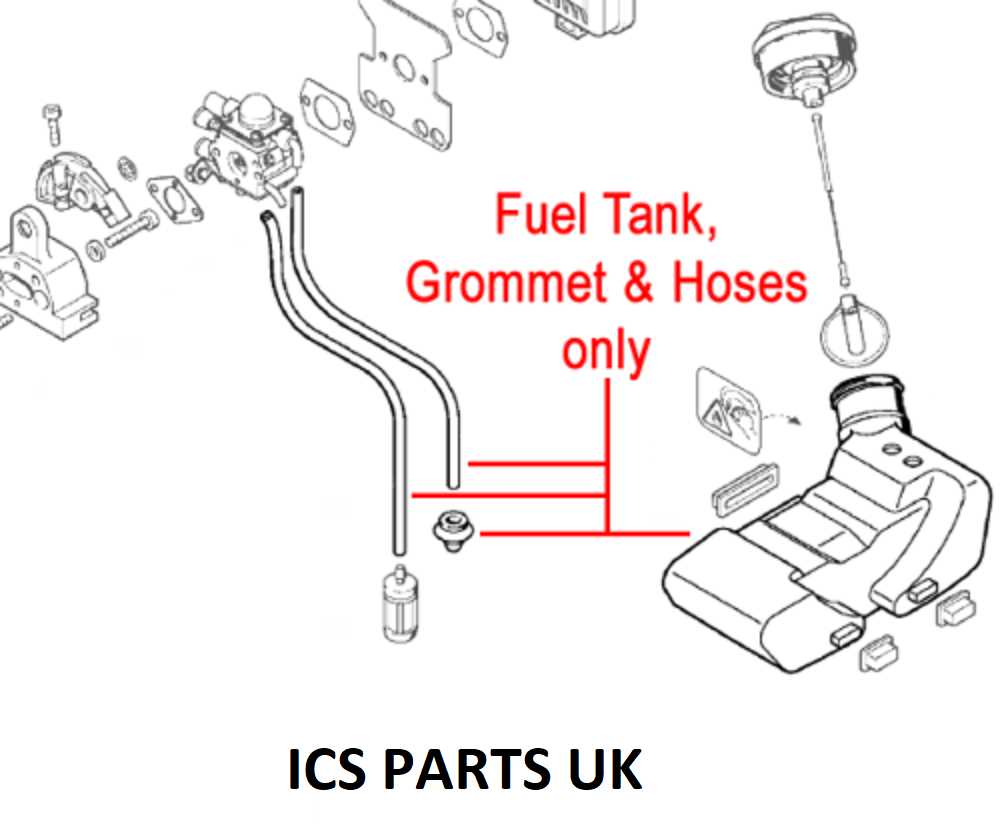

- Fuel system: Ensures the proper delivery of fuel to the engine for optimal performance.

- Cutting attachment: The primary component responsible for executing the intended cutting or trimming tasks.

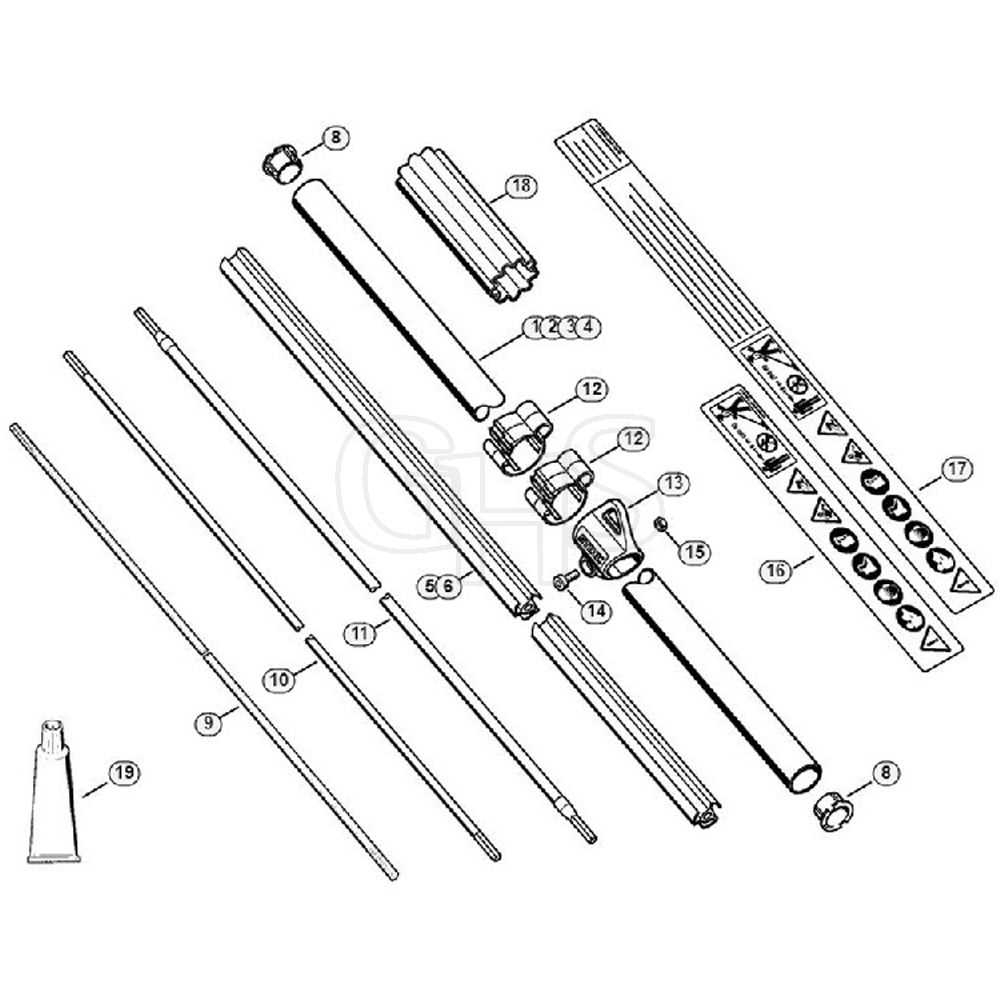

- Handle and shaft: These parts facilitate user control and maneuverability during operation.

Understanding Each Element

Familiarizing oneself with each of these components allows for better maintenance and troubleshooting. Here are some examples:

- Engine assembly: A well-maintained engine ensures reliable performance.

- Fuel system: Regular checks on fuel lines can prevent clogs and leaks.

- Cutting attachment: Choosing the right attachment enhances cutting efficiency.

- Handle and shaft: Ensuring these parts are secure promotes safe operation.

Importance of a Parts Diagram

Understanding the configuration and components of a machine is crucial for effective maintenance and repair. A visual representation of the various elements within the device allows users to identify each part’s role and connection. This knowledge enhances the ability to troubleshoot issues, ensuring that the equipment operates smoothly.

Benefits of Having a Visual Representation

- Facilitates easier identification of components.

- Helps in understanding the assembly process.

- Assists in locating replacement elements quickly.

Enhancing Maintenance Efficiency

When users have access to a clear illustration, they can carry out repairs and maintenance tasks with greater precision. This reduces the risk of errors and ensures that each component is handled appropriately. Moreover, knowing where each part fits can significantly decrease downtime during repairs.

Common Issues and Solutions

When operating outdoor power tools, users often encounter a variety of challenges that can impact performance and efficiency. Understanding these common problems and their respective solutions is crucial for maintaining optimal functionality and extending the lifespan of the equipment.

Engine Starting Problems: One frequent issue is difficulty starting the engine. This can be caused by a faulty ignition system, stale fuel, or a clogged air filter. To resolve this, ensure that the fuel is fresh and check the spark plug for wear or damage.

Power Loss: Another common concern is a noticeable decrease in power during operation. This may stem from a dirty carburetor or a blocked exhaust. Cleaning or servicing the carburetor and ensuring the exhaust is clear can significantly enhance performance.

Excessive Vibration: Excessive vibrations can also pose a problem, potentially indicating an imbalance or worn components. Inspecting the cutting head and ensuring that all parts are securely fastened can help mitigate this issue.

Overheating: Overheating is a serious issue that can lead to engine damage. This often occurs due to insufficient cooling or a lack of lubrication. Regularly checking the cooling fins and ensuring the oil level is adequate can prevent overheating.

By addressing these common issues promptly, users can ensure their equipment operates efficiently and effectively, reducing downtime and enhancing productivity.

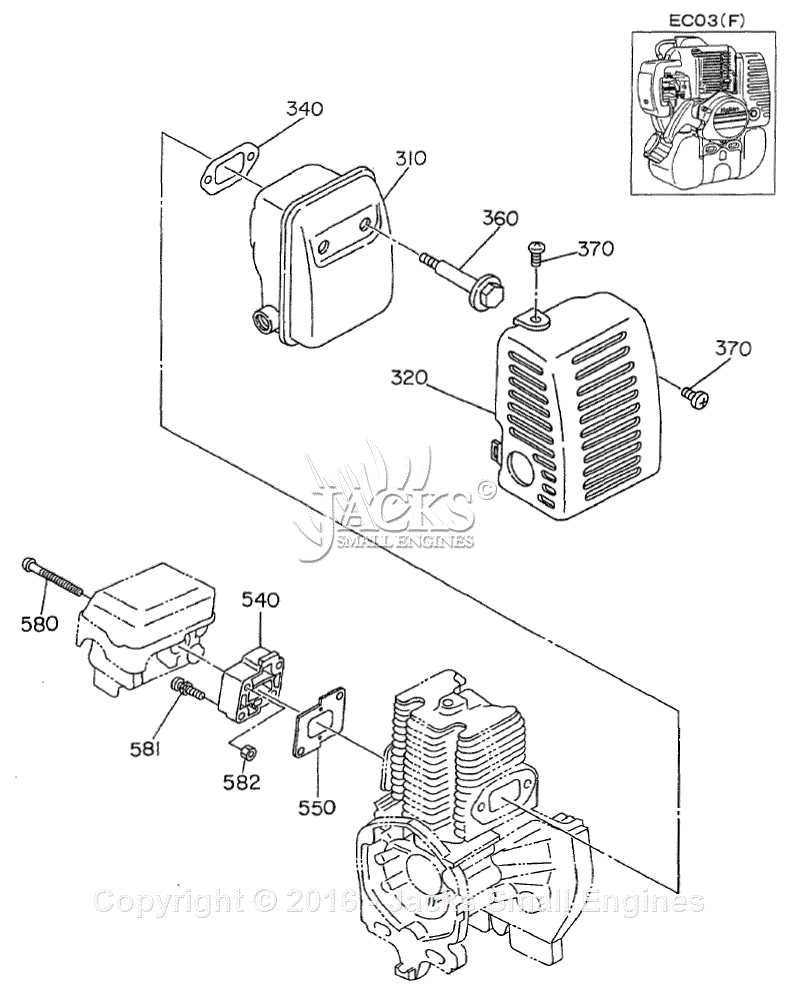

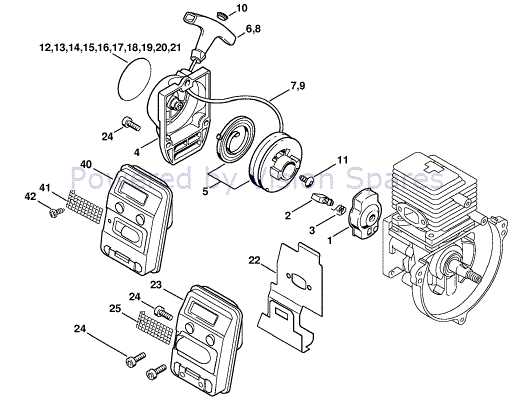

How to Interpret the Diagram

Understanding a technical illustration is essential for effective maintenance and repair of equipment. This visual representation helps users identify components and their functions within the machine, enabling them to make informed decisions during troubleshooting and servicing tasks.

To effectively interpret the visual representation, consider the following key aspects:

- Component Labels: Each part is typically labeled with a unique identifier or number, making it easier to reference in manuals or during repairs.

- Connections: Pay attention to the lines or arrows that indicate how components are connected, as this shows the flow of operation and can highlight potential issues.

- Grouping: Components may be grouped based on their functions, providing a clearer understanding of how they interact with one another.

- Color Coding: Some illustrations use color to differentiate between various types of components, such as electrical parts versus mechanical parts.

By keeping these factors in mind, users can enhance their understanding of the equipment, leading to more efficient maintenance and repair processes.

Essential Tools for Repair

Having the right instruments at your disposal is crucial for effectively maintaining and restoring machinery. A well-equipped workspace not only simplifies the repair process but also enhances precision and efficiency. Whether you’re tackling minor adjustments or comprehensive overhauls, understanding the essential tools can make all the difference in achieving successful outcomes.

Basic Hand Tools

Start with a selection of fundamental hand tools. These include screwdrivers, wrenches, and pliers, which are vital for loosening and tightening various components. Ensuring these tools are of high quality will facilitate better grip and reduce the risk of damage during repairs.

Specialized Equipment

In addition to basic tools, having specialized equipment tailored to specific tasks can greatly enhance your repair capabilities. This may include torque wrenches, socket sets, and alignment tools. Utilizing the right equipment not only saves time but also ensures that all components are assembled correctly.

| Tool Type | Purpose |

|---|---|

| Screwdrivers | For driving screws in various applications. |

| Wrenches | For tightening and loosening nuts and bolts. |

| Pliers | For gripping and manipulating small objects. |

| Torque Wrench | For applying a specific torque to fasteners. |

| Socket Set | For working with nuts and bolts of different sizes. |

| Alignment Tool | For ensuring components are properly aligned. |

Step-by-Step Repair Process

Repairing outdoor power equipment can be a straightforward task if approached methodically. Understanding the assembly and components of the machine is crucial for effective maintenance. This section outlines a systematic approach to troubleshooting and fixing common issues, ensuring your equipment remains in optimal condition.

1. Gather Necessary Tools and Materials: Before starting the repair, assemble all required tools, including wrenches, screwdrivers, and replacement components. Having everything at hand saves time and minimizes frustration.

2. Disconnect the Power Source: Always ensure that the device is powered off and disconnected from any energy sources to prevent accidents during the repair process.

3. Identify the Problem: Assess the equipment to determine the specific issue. Listen for unusual sounds, check for leaks, or inspect for visible damage. Documenting symptoms helps in diagnosing the problem accurately.

4. Disassemble the Relevant Parts: Carefully remove the necessary components to gain access to the faulty area. Keep track of all screws and small parts, organizing them to facilitate reassembly.

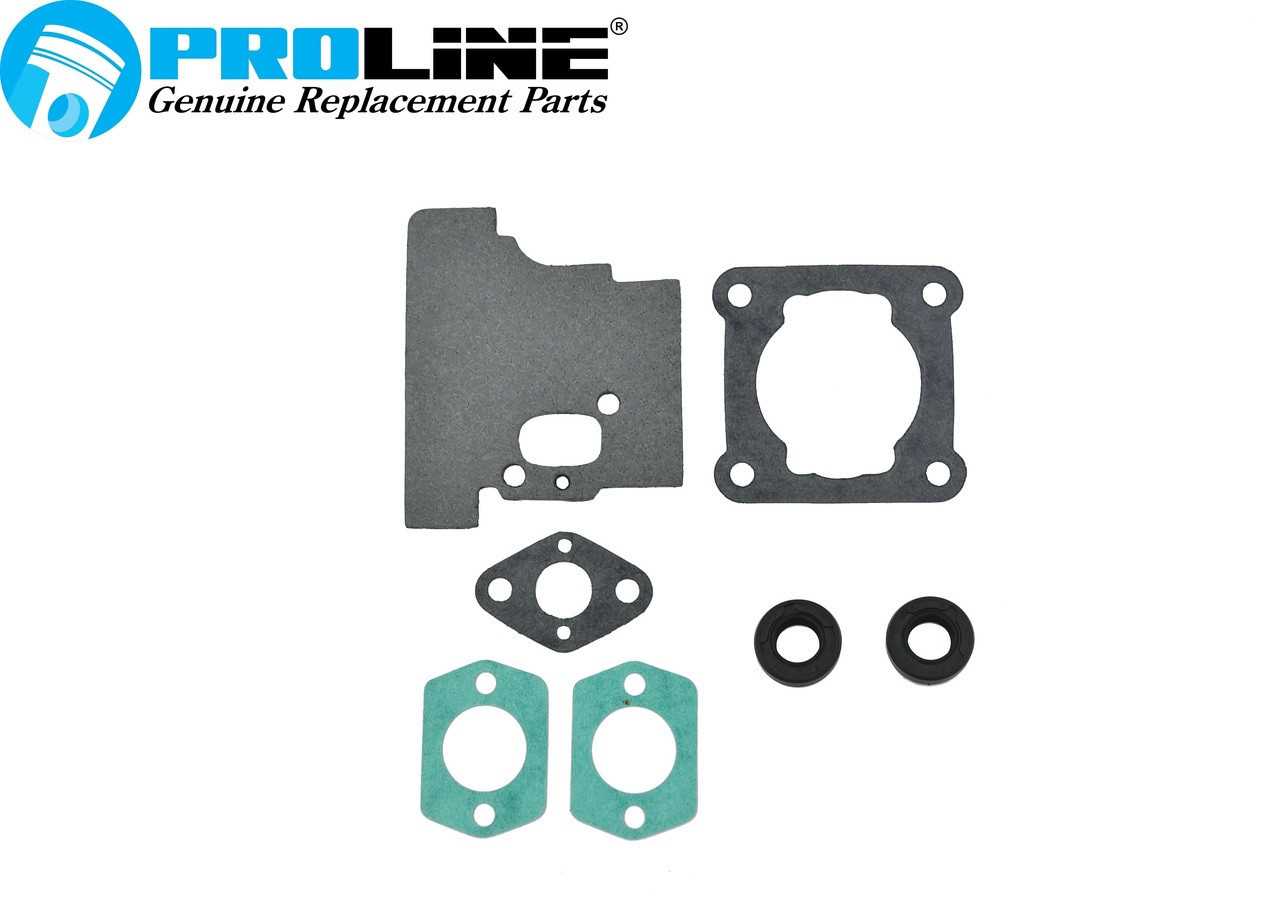

5. Replace or Repair Faulty Components: Once the damaged parts are identified, either replace them with new ones or make the necessary repairs. Ensure all replacements meet the required specifications for compatibility.

6. Reassemble the Equipment: Carefully put the machine back together, reversing the disassembly steps. Ensure all components fit snugly and securely, and avoid over-tightening screws, which may cause damage.

7. Test the Equipment: Once reassembled, reconnect the power source and test the equipment to confirm that the issue has been resolved. Monitor its performance for any remaining problems.

8. Perform Routine Maintenance: After completing the repair, establish a routine maintenance schedule to keep the machine functioning effectively. Regular checks and cleaning can help prevent future issues.

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, locating suitable components is crucial for ensuring optimal performance. Various sources provide options for acquiring the necessary replacements, each with its unique advantages and considerations.

Authorized Dealers: One of the most reliable places to seek replacements is through authorized distributors. These retailers typically offer genuine components that meet the manufacturer’s standards, ensuring compatibility and quality.

Online Retailers: Numerous e-commerce platforms specialize in outdoor equipment, providing a vast selection of components. Shopping online allows for easy comparison of prices and availability, making it a convenient choice for many users.

Local Repair Shops: Local repair shops often stock essential components or can order them on request. This option supports local businesses while providing personalized service and expertise.

Second-Hand Market: Exploring second-hand options can be a cost-effective solution. Platforms that facilitate the sale of used components might offer older or discontinued items that are still functional.

In summary, whether you choose to purchase from authorized dealers, online retailers, local shops, or second-hand markets, each avenue presents opportunities to find the right components for your maintenance needs.

Understanding Parts Compatibility

Ensuring that components work together effectively is crucial in maintaining the efficiency and longevity of your equipment. Compatibility between various elements can significantly impact performance, safety, and overall functionality. This section delves into the significance of selecting compatible pieces for your machinery.

Importance of Component Compatibility

Using interchangeable elements that are designed to work seamlessly can prevent issues such as wear and tear, inefficient operation, and potential damage. Understanding the specifications of each piece can help in making informed choices, thereby optimizing the performance of the device.

Factors to Consider

When evaluating compatibility, consider factors such as size, material, and design specifications. Manufacturer recommendations often provide insights into which components are best suited for specific models. Additionally, exploring aftermarket alternatives may yield viable options that enhance functionality while ensuring reliability.

Maintenance Tips for Longevity

Proper upkeep of equipment is essential to ensure its longevity and optimal performance. Regular maintenance not only extends the life of your tools but also enhances their efficiency, allowing for a smoother operation during use. By following a few key practices, users can significantly reduce wear and tear, leading to fewer repairs and a more reliable experience.

Regular Cleaning

Keeping your equipment clean is one of the simplest yet most effective ways to maintain its functionality. Dirt, debris, and residues can accumulate over time, affecting performance and leading to potential damage. Regularly inspect and clean the exterior and interior components to prevent blockages and ensure smooth operation.

Routine Inspections

Conducting routine checks on various components is crucial for early detection of any issues. Look for signs of wear, loose parts, or any irregularities in performance. Addressing these concerns promptly can prevent minor problems from escalating into major repairs, ultimately saving time and costs.