When maintaining a healthy garden, having the right equipment is essential. Among these tools, a specific type of handheld device plays a crucial role in ensuring that vegetation remains well-trimmed and tidy. To optimize the use of such a machine, understanding its various elements is paramount. Each component contributes to its overall functionality and efficiency, making it important for users to familiarize themselves with their roles.

In this section, we will explore the essential components that make up this gardening device. By examining these parts, users can gain insights into how each section works together to enhance performance. Whether you are a novice gardener or an experienced landscaper, having a clear understanding of these elements can aid in proper maintenance and troubleshooting.

Additionally, recognizing the individual functions of these components can assist in making informed decisions regarding repairs and replacements. A well-informed user is better equipped to ensure that their equipment operates at peak performance, leading to more efficient gardening tasks. The following information will provide a comprehensive overview, enabling users to make the most of their gardening endeavors.

This section will provide an overview of the various elements that comprise a specific outdoor equipment model. Understanding these components is essential for effective maintenance and troubleshooting. Each part plays a critical role in the overall functionality and efficiency of the device.

Key Elements of the Equipment

- Engine: The heart of the machine, responsible for power generation.

- Handle: Provides control and comfort during operation.

- Cutting Mechanism: The part responsible for the actual trimming action.

- Fuel Tank: Stores the mixture needed for the engine to operate.

- Air Filter: Keeps contaminants out of the engine for optimal performance.

Importance of Proper Maintenance

Regular upkeep of each component is vital to ensure longevity and reliability. Neglecting any part can lead to reduced performance or failure. Key maintenance tasks include:

- Checking and replacing the air filter as needed.

- Inspecting the cutting mechanism for wear and tear.

- Ensuring the fuel tank is clean and free of debris.

- Lubricating moving parts to prevent friction and damage.

Essential Parts of the FS85 Trimmer

The functionality of any cutting device relies heavily on its fundamental components. Understanding these key elements is crucial for efficient operation and maintenance. Each segment plays a vital role in ensuring the overall performance and longevity of the machine.

Power Unit: This is the heart of the equipment, providing the necessary energy for operation. A robust engine enhances cutting efficiency and reduces downtime.

Cutter Head: This component is responsible for the actual cutting action. Depending on the type of vegetation, various attachments can be used to achieve optimal results.

Handle: A comfortable grip is essential for controlling the device. Ergonomically designed handles reduce user fatigue and improve maneuverability during extended use.

Guard: Safety is paramount when operating cutting equipment. The guard protects the user from debris and ensures safe operation by covering the moving parts.

Fuel System: An efficient fuel delivery system is necessary for optimal engine performance. Regular maintenance of this system ensures reliability and reduces the risk of engine failure.

Starter Mechanism: This component is vital for initiating the engine. A well-functioning starter ensures quick and easy starts, minimizing frustration for the user.

Maintenance Tips for Your Trimmer

Proper upkeep of your gardening equipment is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures safety during operation. Here are some effective practices to keep your equipment in top condition.

1. Regular Cleaning: After each use, clean the exterior thoroughly to remove dirt and debris. Pay special attention to the cutting mechanism, as buildup can hinder performance. Use a brush or compressed air for hard-to-reach areas.

2. Inspect Components: Routinely check all parts for wear and tear. Look for cracks or damage in the casing and inspect the cutting elements for dullness. Replace any worn-out components to prevent further issues.

3. Lubrication: Ensure moving parts are well-lubricated to reduce friction and prevent premature wear. Use a suitable lubricant as specified in the manufacturer’s recommendations.

4. Fuel Maintenance: If your equipment operates on fuel, use fresh fuel and consider adding a fuel stabilizer to prevent degradation. Empty the tank if the equipment will not be used for an extended period.

5. Storage Practices: Store your device in a dry and secure place to protect it from environmental damage. Consider covering it to prevent dust accumulation and potential rust.

Common Issues with Stihl FS85

When operating a popular brush cutting device, users may encounter several frequent problems that can affect performance and efficiency. Understanding these issues is essential for maintaining the equipment in optimal condition and ensuring reliable operation.

Frequent Problems

One common challenge involves difficulty starting the machine, often attributed to fuel or ignition system issues. Users should also be aware of power loss during operation, which can result from dull cutting blades or fuel flow restrictions. Additionally, overheating may occur if the device is used for prolonged periods without sufficient breaks.

Solutions and Maintenance Tips

To address starting problems, ensure that the fuel is fresh and the spark plug is functioning correctly. For power loss, regularly sharpen or replace the cutting components and check the fuel lines for blockages. To prevent overheating, take breaks during prolonged usage and allow the engine to cool down as needed.

| Issue | Possible Cause | Solution |

|---|---|---|

| Difficulty Starting | Old fuel, faulty spark plug | Replace fuel, check spark plug |

| Power Loss | Dull blades, fuel blockage | Sharpen blades, inspect fuel lines |

| Overheating | Continuous use | Take breaks, allow cooling |

How to Replace Trimmer Parts

Replacing components of your gardening equipment is essential for maintaining its performance and longevity. Whether you are dealing with a faulty mechanism or worn-out accessories, understanding the replacement process can ensure your tool operates effectively. This section outlines the steps to efficiently change the necessary elements of your device.

Step-by-Step Guide

Begin by gathering the required tools and new components needed for the task. Make sure to turn off the machine and disconnect it from any power source to ensure safety during the replacement process. Following the manufacturer’s instructions, carefully disassemble the relevant sections of the equipment to access the parts that need to be replaced.

Reassembly and Testing

Once the new components are in place, reassemble the equipment by reversing the disassembly steps. Ensure that everything is secured properly to avoid any operational issues. Finally, conduct a test run to confirm that the device functions as expected. Regular maintenance and timely replacements will enhance the efficiency and reliability of your gardening tools.

Identifying Worn-Out Components

Recognizing components that have reached the end of their lifespan is crucial for maintaining efficiency and performance. By regularly inspecting various parts, users can ensure optimal functionality and prevent further damage. Awareness of signs indicating wear can help in timely replacements and extend the life of the equipment.

Common Signs of Wear

Several indicators can signal that a component may be worn out. These include unusual noises, decreased performance, and visible signs of deterioration. Regular checks can help identify these issues before they escalate.

Inspection Checklist

When assessing components, use the following checklist to streamline the process:

| Component | Signs of Wear |

|---|---|

| Blade | Chips, cracks, or dullness |

| String Head | Uneven wear or excessive fraying |

| Fuel Lines | Cracks or leaks |

| Throttle Trigger | Sticking or sluggish response |

Tools Needed for Repairs

When it comes to maintaining and fixing garden equipment, having the right tools is essential for achieving efficient and effective results. A well-equipped toolkit not only simplifies the repair process but also ensures safety while working with machinery.

Essential Tools

- Screwdrivers: Various sizes and types, including flathead and Phillips, are necessary for loosening and tightening screws.

- Wrenches: Adjustable and socket wrenches help in removing and securing bolts and nuts.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating small components.

- Torque Wrench: This tool is crucial for applying the correct amount of torque to fasteners.

- Measuring Tools: A tape measure or caliper ensures accurate measurements for replacement parts.

Safety Equipment

- Safety Glasses: Protect your eyes from debris while working on equipment.

- Gloves: Wearing gloves can prevent cuts and abrasions during repairs.

- Ear Protection: Use earplugs or earmuffs to safeguard your hearing from loud machinery.

Assembly Process for FS85 Parts

The assembly procedure for the components of this equipment requires careful attention to detail and a methodical approach. Ensuring that each element is correctly positioned and secured is essential for optimal performance and longevity.

Begin by gathering all necessary components and tools required for the assembly process. This preparation will facilitate a smooth and efficient workflow.

- Review the manual or reference guide for assembly instructions.

- Lay out all components in a systematic manner.

- Ensure that all fasteners and connectors are available and in good condition.

Next, follow these steps for the assembly:

- Start by attaching the base component to the main body, ensuring that all locking mechanisms are properly engaged.

- Proceed to install the drive mechanism, making sure it is aligned accurately with the guiding channels.

- Securely fasten any protective coverings, verifying that they are free of debris and aligned correctly.

- Finally, check all connections and fastenings to confirm they are tight and secure before performing any functional tests.

After completing the assembly, conduct a thorough inspection to ensure that everything is in place and functioning correctly. Regular maintenance and checks will help maintain performance and extend the lifespan of the equipment.

Safety Precautions When Servicing

When maintaining equipment, it is essential to prioritize safety to prevent accidents and ensure proper functioning. Adhering to safety guidelines minimizes risks associated with maintenance tasks, allowing for a smoother and more effective servicing experience.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) to safeguard against potential hazards. This includes safety goggles to protect your eyes, gloves to prevent cuts and abrasions, and sturdy footwear to ensure stability. Additionally, using hearing protection can help reduce noise exposure during operation.

Work Environment Considerations

Ensure your workspace is clean and organized to avoid tripping hazards and ensure efficient workflow. Proper lighting is crucial, as it helps you see small components and potential issues clearly. Always work in a well-ventilated area to avoid inhaling fumes or dust that may arise during maintenance.

Where to Buy Replacement Parts

Finding the right components for your gardening equipment can greatly enhance its performance and longevity. There are several avenues to explore when seeking to acquire these necessary items, ensuring that you can keep your machinery operating at its best.

Here are some options to consider:

- Authorized Dealers: Visit local distributors who specialize in outdoor equipment. They often carry a wide range of components and can provide expert advice.

- Online Retailers: Numerous websites offer a vast selection of components. Look for reputable platforms that provide detailed descriptions and customer reviews.

- Manufacturer’s Website: Directly checking the official website can lead to genuine components. Many manufacturers have an online store or a list of authorized sellers.

- Repair Shops: Local repair shops may have spare components available or can order them for you. They can also offer insights into the most reliable options.

When purchasing, ensure that the items are compatible with your specific model to avoid any issues during installation.

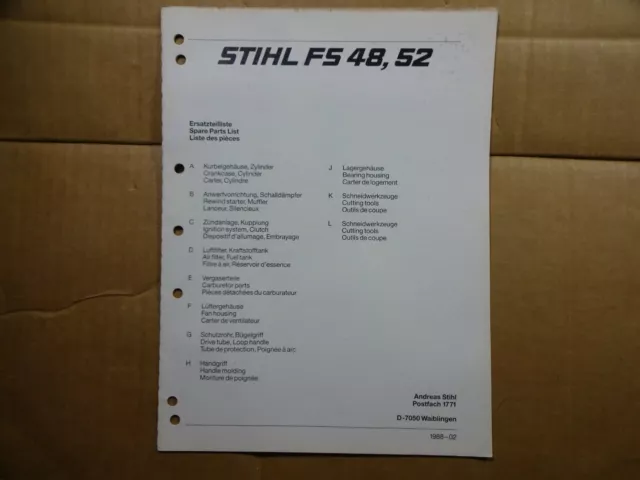

Understanding the Parts Diagram

A visual representation of components is essential for effective maintenance and repair of outdoor equipment. This illustration helps users identify each segment, facilitating a better understanding of how these elements interact within the machine. By grasping the function of each component, users can troubleshoot issues and perform repairs more efficiently.

Each segment of the illustration plays a vital role in the overall functionality. Here’s a breakdown of common elements found in such illustrations:

| Component Name | Description | Function |

|---|---|---|

| Motor | The power unit that drives the machine. | Converts electrical energy into mechanical motion. |

| Cutting Head | The attachment where the cutting line is housed. | Responsible for trimming and cutting grass and weeds. |

| Handle | The grip that allows for maneuverability. | Enables the user to control the device effectively. |

| Fuel Tank | The container that holds the fuel. | Supplies energy to the motor for operation. |

| Throttle Control | The mechanism to adjust engine speed. | Allows users to control cutting power and efficiency. |