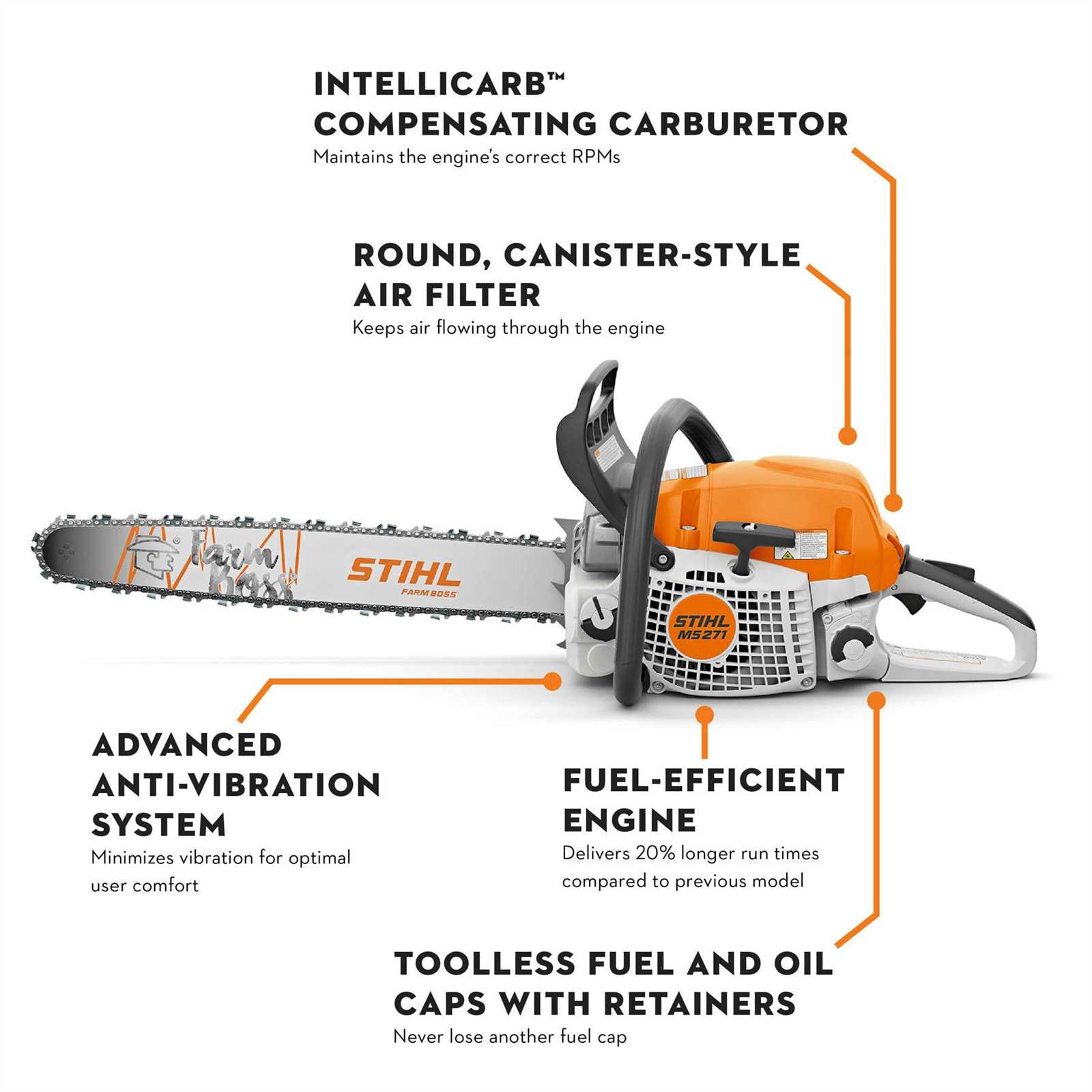

For any avid user of chainsaws, knowing the essential components of the tool is crucial for maintaining its performance and extending its lifespan. This particular model, known for its reliability, features a variety of intricate mechanisms that work together seamlessly. By familiarizing yourself with these elements, you’ll be able to address common issues and keep your machine in optimal condition.

The mechanical structure of this chainsaw includes several key elements that each play a distinct role. Whether you’re dealing with the engine, cutting system, or safety features, every piece has a specific purpose. Understanding how these elements interact can help you troubleshoot effectively and perform necessary adjustments when needed.

In this guide, we’ll explore the core elements of this well-regarded chainsaw, offering you an in-depth look into the assembly and its functionality. Knowing where each part fits and how it operates will ensure smoother operation and better care for your equipment.

Exploring the Essential Components of Stihl MS 025

The intricate design of this well-crafted chainsaw includes a variety of elements that ensure optimal performance. Each part plays a vital role in its operation, working together to deliver efficiency and precision during use. Understanding these critical elements helps to maintain and extend the tool’s life, while also ensuring its proper functionality in demanding conditions.

One of the key components is the engine, which powers the entire system. Alongside it, the cutting mechanism ensures sharp and accurate performance, providing clean cuts through various types of material. The fuel system, with its efficient delivery process, keeps the motor running smoothly, while other internal elements help regulate temperature and maintain balance during operation.

Additionally, the safety features are designed to protect the user during intense tasks. These include mechanisms to prevent kickback and ensure a secure grip, making the tool both powerful and reliable. Together, these parts form a cohesive unit, working seamlessly to handle tough outdoor tasks with ease.

Key Elements for Optimal Chainsaw Performance

Ensuring efficient operation requires attention to several important aspects of the tool’s overall functionality. From the engine to the cutting mechanism, each component must work together seamlessly to deliver peak performance. When all elements are maintained properly, the tool operates smoothly and cuts through material with precision and ease.

Engine Efficiency

A well-maintained engine is the heart of any cutting tool. Regular care and timely adjustments ensure that the engine runs at its highest capacity. Clean fuel and proper lubrication also contribute to a more reliable and longer-lasting engine, allowing for sustained power output during prolonged use.

Cutting Chain and Bar Alignment

The alignment between the chain and the bar is crucial for effective cutting. Proper tension and sharpness of the chain are key to reducing wear and tear, ensuring faster cuts, and improving the overall lifespan of the tool. Routine sharpening and adjustment help maintain optimal alignment, enhancing both safety and performance.

Understanding the Role of the Stihl MS 025 Chain

The chain plays a critical role in ensuring the effectiveness of a chainsaw, directly influencing its cutting performance. As one of the key moving elements, its proper function is vital for smooth operation and precise cuts. The durability and sharpness of the chain can significantly affect both the speed and efficiency of any cutting task, making it essential for users to maintain and understand its importance.

- Responsible for efficient wood cutting and overall performance

- Directly affects cutting speed and smoothness

- Proper maintenance increases longevity and reduces wear

- A dull or damaged chain can cause overheating and poor performance

Understanding how this element operates is crucial for maximizing efficiency and ensuring safe operation during use.

Guide Bar Specifications for Stihl MS 025

The guide bar plays a crucial role in the cutting performance of a chainsaw. It’s essential to understand its key dimensions and characteristics, as these factors greatly influence how well the tool operates in different conditions. Having the right bar ensures optimal handling and longevity for both the equipment and the chain.

Length and Compatibility: The guide bar length varies based on user needs and the task at hand. Choosing the correct size allows for better control during cutting and reduces strain on the machine. It’s important to ensure that the bar length matches the power of the unit for smooth operation.

Material and Durability: Guide bars are constructed from high-grade materials designed to withstand intense pressure. Durability is enhanced through reinforced structures, ensuring that the bar endures heavy use while maintaining cutting precision over time.

Maintenance: Regular care of the guide bar ensures its longevity. Keeping it clean and free from debris, alongside proper lubrication, helps avoid unnecessary wear and extends its operational life. Maintenance practices are vital to ensuring that the bar functio

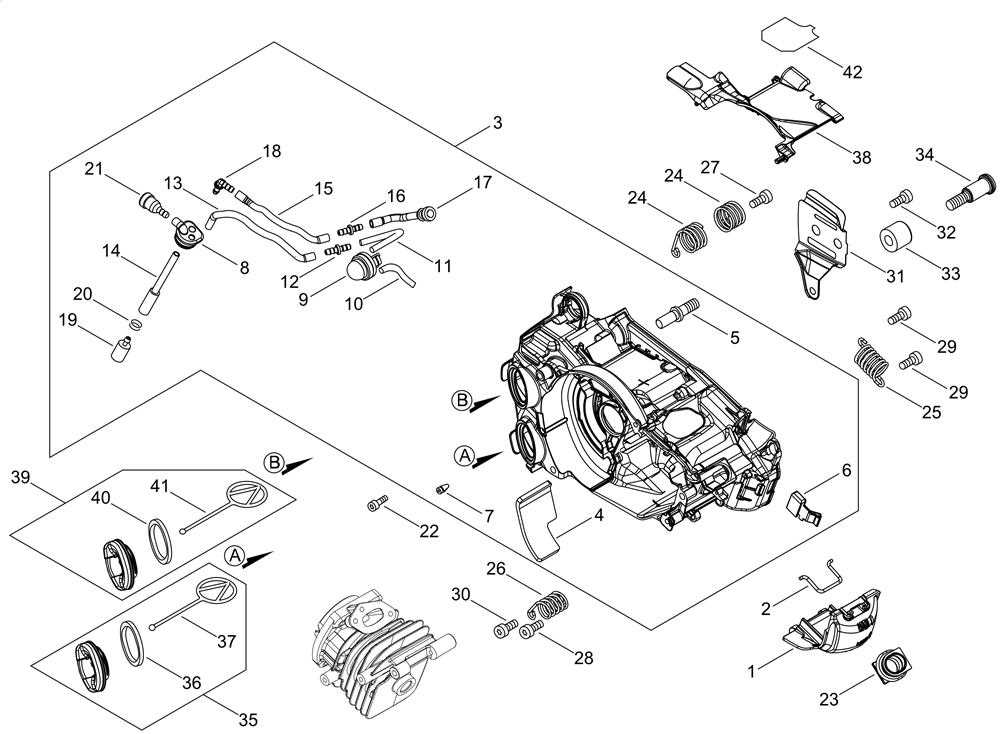

Analyzing the Function of the Clutch Assembly

The clutch system plays a vital role in the efficient operation of various equipment. Its primary function is to connect and disconnect the engine’s power from the cutting mechanism, ensuring controlled movement and safety during usage. Understanding how this component operates helps in maintaining the device’s performance and preventing unnecessary wear.

Main Purpose of the Clutch

The clutch assembly is responsible for engaging the drive system only when needed. This engagement allows the engine to run without spinning the chain or blade when the tool is idling, making it easier to control and preventing unintended activation. By managing the flow of power, it ensures smooth transitions between idle and active states.

How the Clutch Engages and Disengages

At lower speeds, the clutch remains disengaged, allowing the tool to rest. When the engine accelerates, the centrifugal force causes the clutch to engage, transferring power to the cutting mechanism. This design ensures that the system operates only when the user increases the speed, providing better control and reducing unnecessary strain on the machine.

Air Filter Maintenance for Improved Longevity

Proper upkeep of the air filtration system is essential for enhancing the lifespan and performance of outdoor power tools. By ensuring that the air intake remains unobstructed and clean, users can prevent engine damage and maintain optimal functionality. Regular attention to the air filtration component can lead to more efficient operation and reduced wear over time.

To effectively maintain the air filter, it’s important to follow a few straightforward steps. These include regular inspection, cleaning, and replacement when necessary. The following table summarizes key maintenance practices that can be applied:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect air filter | Every 5 hours of operation | Look for dirt and debris accumulation. |

| Clean air filter | Every 10 hours of operation | Use compressed air or a soft brush to remove particles. |

| Replace air filter | Every 25 hours of operation | Change if damaged or excessively dirty. |

Following these guidelines will contribute to a longer operational life and enhanced efficiency of your equipment, ensuring it performs reliably for many seasons.

Fuel System Overview for Stihl MS 025

The fuel mechanism is crucial for optimal performance and efficiency of outdoor power equipment. Understanding the components and their interactions can enhance the maintenance and operation of your device, ensuring it runs smoothly and reliably. This overview will delve into the essential elements that comprise the fuel system.

Key Components

This section highlights the primary elements involved in the fuel delivery process, illustrating their functions and significance.

| Component | Description |

|---|---|

| Fuel Tank | Holds the fuel necessary for the operation of the engine, designed for easy filling and secure closure. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine, protecting it from potential damage. |

| Fuel Lines | Transport the fuel from the tank to the carburetor, ensuring a steady flow under various operating conditions. |

| Carburetor | Mixes the appropriate amount of fuel with air, facilitating efficient combustion in the engine. |

| Primer Bulb | Helps to eliminate air from the fuel lines, making it easier to start the engine by delivering fuel directly to the carburetor. |

Maintenance Tips

Proper upkeep of the fuel system is essential for longevity and performance. Regularly check for leaks, replace the fuel filter as needed, and ensure that the fuel used is fresh and clean to prevent clogs and starting issues.

Ignition Module and Its Importance

The ignition module plays a crucial role in the operation of small engines, acting as the brain behind the spark generation necessary for combustion. This essential component ensures that the engine starts efficiently and runs smoothly, contributing to overall performance and reliability. Understanding its function and significance can help users maintain their equipment effectively.

Functionality of the Ignition Module

This component is responsible for controlling the timing and strength of the spark produced by the engine’s spark plug. By receiving signals from various sensors, the module adjusts the ignition timing, optimizing the combustion process. A properly functioning ignition module leads to improved fuel efficiency and reduced emissions, making it a vital element in modern engine design.

Common Issues and Maintenance

Failures in the ignition module can lead to various operational problems, including difficulty starting the engine or erratic running. Regular maintenance and timely replacement of this component can prevent such issues, ensuring that the engine operates at peak performance. Monitoring the module’s condition is essential for prolonging the life of the engine.

| Issue | Symptoms | Solution |

|---|---|---|

| Faulty Ignition Module | Engine won’t start | Replace ignition module |

| Incorrect Timing | Rough idling | Adjust timing settings |

| Overheating | Engine misfires | Inspect for air blockages |

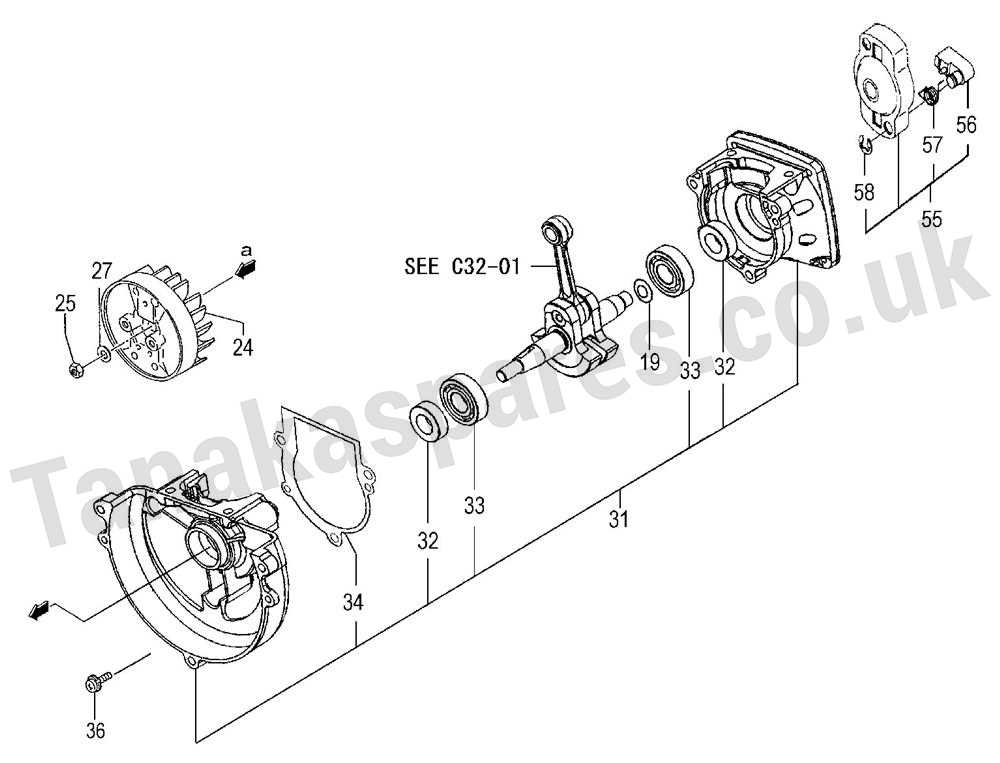

How the Recoil Starter Mechanism Works

The recoil starter mechanism is a crucial component in small engine systems, facilitating the initial ignition process. This system allows users to effortlessly start the engine with a single pull of a cord, ensuring a smooth and reliable operation. Understanding its functionality helps users appreciate its significance in the overall performance of the machine.

Components of the Recoil Starter

The recoil starter consists of several essential parts that work in unison:

- Starter Rope: A durable cord that, when pulled, initiates the engine’s start.

- Recoil Spring: This component stores energy as the rope is pulled, enabling a quick return to its original position.

- Pulley: A circular mechanism that guides the starter rope and engages with the flywheel.

- Starter Handle: The grip that users pull to activate the starting process.

How It Operates

The operation of the recoil starter is a straightforward process:

- The user pulls the starter handle, which extends the rope from the pulley.

- As the rope is pulled, the recoil spring is wound tightly, storing potential energy.

- Once the rope reaches its limit, the energy stored in the spring is released, causing the pulley to spin rapidly.

- This motion engages the flywheel, prompting the engine to turn over and start.

- After the engine fires, the pulley returns to its resting position, ready for the next start.

Through this simple yet effective mechanism, starting small engines becomes a hassle-free experience, making it an indispensable feature in various outdoor power equipment.

Sprocket System and Its Role in Efficiency

The sprocket mechanism is a crucial component in many mechanical systems, contributing significantly to their overall functionality. This intricate assembly facilitates the transfer of motion and power, ensuring that various parts work in harmony. By optimizing the connection between the engine and the cutting elements, it plays a vital role in enhancing operational performance and longevity.

Mechanics of the Sprocket Assembly

The design of the sprocket system allows for precise movement and energy distribution. Each cog is engineered to mesh seamlessly with the chain, providing a reliable link between the motor and the working components. This connection minimizes energy loss and improves the overall torque delivery, which is essential for maintaining high efficiency during operation.

Impact on Performance and Longevity

A well-functioning sprocket assembly not only boosts efficiency but also extends the lifespan of the equipment. By reducing friction and wear, it ensures smoother operation and less frequent maintenance. Consequently, users benefit from enhanced productivity and reduced downtime, making the sprocket system a pivotal element in the reliability of any mechanical setup.

Examining the Muffler and Exhaust Components

The muffler and exhaust system play a crucial role in the overall functionality of a small engine, significantly impacting performance and emissions. Understanding how these components interact can enhance maintenance practices and prolong the lifespan of the equipment. In this section, we will explore the structure and function of the exhaust components, highlighting their importance in ensuring optimal operation.

Muffler Design and Functionality

The design of the muffler is pivotal in controlling engine noise and redirecting exhaust gases. Typically composed of various chambers and baffles, it dissipates sound while allowing gases to flow efficiently. A well-functioning muffler not only minimizes noise pollution but also enhances engine performance by ensuring that exhaust gases exit smoothly, thereby improving fuel efficiency.

Exhaust Pipe and Connector Analysis

The exhaust pipe serves as the pathway for exhaust gases to exit the engine. Its diameter, length, and material can influence the overall performance of the system. Additionally, connectors between the muffler and exhaust pipe must be secure to prevent leaks, which can lead to decreased efficiency and increased emissions. Regular inspection of these components ensures that the exhaust system operates effectively, contributing to the machine’s longevity.