The functionality of a cutting tool relies heavily on its individual components and their interconnections. Each element plays a vital role in ensuring the smooth operation and efficiency of the equipment. Gaining insight into these elements allows users to appreciate the intricacies involved in maintaining and operating such machinery.

In this section, we will explore the various components that contribute to the performance of this powerful equipment. Recognizing how each piece fits together enhances not only understanding but also aids in troubleshooting and repair tasks. This knowledge empowers users to make informed decisions regarding maintenance and replacements.

Ultimately, comprehending the layout and function of these essential parts is crucial for anyone looking to optimize their use of the cutting tool. By familiarizing oneself with the arrangement and purpose of each element, users can ensure their equipment remains in top condition and continues to perform effectively.

The following section provides a comprehensive overview of a specific model of a cutting tool, highlighting its essential components and their functions. Understanding these elements is crucial for proper maintenance and efficient operation, ensuring longevity and optimal performance.

Key Features and Specifications

This segment outlines the notable attributes and technical specifications that distinguish this model, including its power output and operational capabilities.

Design and Build Quality

Here, the focus shifts to the construction and materials used in the tool, discussing how they contribute to durability and user experience.

Maintenance Essentials

In this part, important maintenance practices are detailed, providing insights into how to care for the tool effectively.

Common Issues and Solutions

This section addresses frequently encountered problems users might face, along with practical solutions and troubleshooting tips.

Accessories and Add-ons

A look into the various accessories that can enhance the functionality of the tool, offering users the chance to customize their experience.

User Manual Overview

This part summarizes the critical information found in the user manual, guiding users on how to utilize the tool safely and effectively.

Comparative Analysis

Here, comparisons with similar models are made, helping potential buyers to understand the advantages and disadvantages of this particular choice.

Customer Reviews and Feedback

This section compiles user reviews and feedback, providing insight into the real-world performance of the tool and user satisfaction.

Final Recommendations

The concluding part offers recommendations for prospective buyers, highlighting factors to consider when making a purchase decision.

Essential Components of the Chainsaw

Understanding the key elements of a power saw is crucial for both maintenance and effective operation. Each component plays a vital role in the overall functionality and efficiency of the machine. Familiarizing oneself with these essential parts can enhance the user experience and ensure safe handling.

Core Elements

- Engine: The powerhouse of the tool, converting fuel into mechanical energy.

- Guide Bar: A metal plate that provides support and guides the cutting chain.

- Cutting Chain: A loop of linked metal segments designed for cutting through wood.

- Chain Brake: A safety feature that stops the chain quickly to prevent accidents.

- Air Filter: Prevents dust and debris from entering the engine, ensuring smooth operation.

Additional Components

- Fuel Tank: Holds the mixture of fuel and oil needed for the engine to operate.

- Oil Tank: Supplies lubrication to the cutting chain, reducing friction and wear.

- Starter Mechanism: A system that enables the user to start the engine with minimal effort.

- Throttle Trigger: Controls the speed of the engine and the cutting action.

- Handlebar: Provides grip and maneuverability, allowing for precise control during operation.

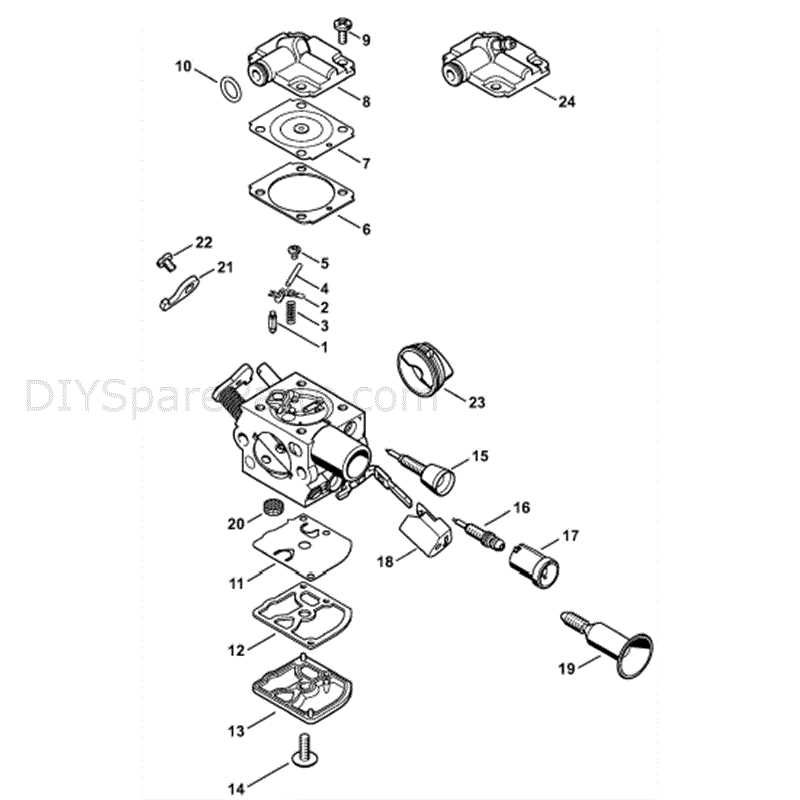

Understanding the Parts Diagram

Gaining insight into the assembly representation of a power tool is essential for effective maintenance and repair. This illustration provides a visual guide that simplifies the identification of various components, facilitating a better understanding of their functions and relationships.

Key aspects to consider when examining the assembly representation include:

- Component Identification: Each element is labeled clearly, allowing users to recognize specific parts easily.

- Functional Relationships: Understanding how different components interact is crucial for troubleshooting and repairs.

- Maintenance Guidance: The representation often highlights service points, indicating areas that require regular attention.

By familiarizing yourself with this representation, you enhance your ability to perform repairs effectively and maintain the longevity of your equipment.

Common Replacement Parts Explained

Understanding the key components of a cutting tool is essential for maintaining its performance and longevity. Regular wear and tear can necessitate the replacement of certain elements to ensure efficient operation. In this section, we will delve into the most frequently replaced components, offering insights into their functions and importance.

Bar and Chain

The bar and chain are crucial for effective cutting. The bar provides the surface for the chain to move along, while the chain consists of sharp links that engage with the material being cut. Over time, both components can wear down, requiring replacement to maintain optimal performance. A dull chain not only makes cutting more difficult but can also increase the risk of accidents.

Air Filter

The air filter plays a vital role in keeping the engine clean and functioning properly. It prevents dirt and debris from entering the engine, ensuring a steady supply of clean air. A clogged air filter can lead to reduced efficiency and increased fuel consumption. Regular inspection and replacement of the air filter can significantly enhance the performance and lifespan of the tool.

Maintenance Tips for Longevity

To ensure optimal performance and extend the lifespan of your cutting equipment, regular upkeep is essential. Implementing a few simple maintenance practices can prevent potential issues and enhance overall efficiency.

Regular Cleaning: After each use, thoroughly clean the exterior and components to remove debris and residue. This practice helps prevent the buildup of dirt that can impede functionality.

Proper Lubrication: Ensure that moving parts are adequately lubricated to reduce friction and wear. This step is crucial in maintaining smooth operation and minimizing the risk of damage.

Check and Replace Filters: Inspect air and fuel filters regularly. Clean or replace them as needed to ensure optimal airflow and fuel delivery, which contribute to efficient performance.

Inspect and Sharpen Blades: Dull blades can lead to excessive strain on the machine and poor cutting results. Regularly inspect and sharpen blades to maintain cutting efficiency.

Storage Practices: When not in use, store the equipment in a dry, protected area. Proper storage prevents rust and damage from environmental factors.

By following these guidelines, you can significantly enhance the durability and functionality of your cutting equipment, ensuring it serves you well for years to come.

Identifying Faulty Parts Easily

Understanding how to recognize malfunctioning components is essential for maintaining the functionality of any equipment. By familiarizing yourself with the signs of wear and tear, you can efficiently troubleshoot issues and ensure optimal performance. This section aims to provide insights into spotting problematic elements without requiring specialized knowledge.

Visual Inspection: Begin with a thorough examination of the exterior. Look for any visible damage, such as cracks or unusual wear patterns. Pay attention to components that show signs of discoloration or rust, as these may indicate deeper issues.

Performance Indicators: Listen for unusual sounds during operation. A machine that produces excessive noise or vibrations may signal that something is amiss. Additionally, observe any changes in performance, such as reduced power or responsiveness, which could point to a malfunctioning element.

Consulting the Manual: Refer to the user manual for guidance on identifying specific issues. The manual often includes troubleshooting tips and visual references that can aid in recognizing faulty components. Regularly reviewing the manual can enhance your understanding of the equipment.

By following these steps, you can simplify the process of identifying malfunctioning components, ensuring your equipment remains in top condition.

How to Use the Parts Diagram

Understanding the components of a tool is essential for effective maintenance and repair. A visual representation of these elements can significantly simplify the process, enabling users to identify and access each piece with ease. This guide will help you navigate the layout and utilize it for troubleshooting or replacement tasks.

Identifying Key Components

Begin by familiarizing yourself with the different sections of the visual layout. Each area corresponds to specific functionalities, which are crucial for optimal operation. Pay attention to the following:

- Examine the labeled sections carefully.

- Note the groupings of related elements.

- Look for any color coding that might indicate functionality.

Applying the Information

Once you have a grasp of the components, you can effectively use the representation for various purposes:

- Assess which elements may need replacement or repair.

- Cross-reference your findings with the manufacturer’s guide for specifications.

- Gather the necessary tools and replacement items based on your analysis.

Using this visual guide empowers you to maintain and restore your equipment with confidence, ensuring its longevity and performance.

Ordering Parts for Your Chainsaw

When maintaining your cutting tool, obtaining the right components is essential for optimal performance. Understanding how to effectively order the necessary items can simplify the process and ensure your equipment remains in excellent condition.

Before placing an order, it’s crucial to identify the specific components needed. Familiarize yourself with the model of your equipment and refer to the manufacturer’s guidelines. This information will help you find the exact replacements required for smooth operation.

Here’s a quick reference table to assist you in the ordering process:

| Item | Description | Recommended Supplier |

|---|---|---|

| Fuel Filter | Ensures clean fuel delivery to the engine. | Local hardware store |

| Air Filter | Prevents debris from entering the engine. | Online retailer |

| Bar and Chain | Essential for cutting through wood. | Specialized equipment supplier |

| Starter Rope | Allows for the engine to be started manually. | Authorized dealer |

Utilizing reputable sources for ordering will not only guarantee the quality of the items but also enhance the lifespan of your equipment. Always check for compatibility and consider reaching out to customer service for assistance if needed.

Safety Precautions When Replacing Parts

Ensuring safety during maintenance and component replacement is crucial for effective operation and to prevent accidents. By following specific guidelines, individuals can minimize risks and ensure a secure working environment.

Before beginning any maintenance task, it is important to take several precautions:

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Make sure the equipment is turned off and disconnected from any power source before starting work.

- Familiarize yourself with the user manual to understand the correct procedures for replacing components.

- Work in a well-lit and clean environment to avoid any mishaps.

Additionally, consider the following tips to enhance safety:

- Double-check all tools and equipment to ensure they are in good condition before use.

- Keep the workspace organized to prevent clutter that could lead to accidents.

- Never rush the replacement process; take your time to ensure accuracy and safety.

- After replacing components, perform a thorough inspection to confirm everything is secure and functioning correctly.

By adhering to these safety measures, individuals can ensure a safer experience during maintenance activities.

Upgrades and Aftermarket Options

Enhancing the performance and functionality of your equipment can significantly improve your overall experience. Various alternatives available on the market cater to different needs, enabling users to customize their tools according to specific preferences and requirements. These enhancements can range from improved efficiency to added durability, making them valuable investments.

When exploring upgrades, consider options such as high-performance blades, advanced filters, and ergonomic handles. These components not only boost efficiency but also contribute to user comfort during extended use. Additionally, aftermarket kits often provide specialized features that original models may lack, enhancing versatility for various tasks.

Investing in quality aftermarket parts can lead to notable improvements in longevity and overall performance. Researching reputable suppliers and reading reviews can help ensure that you choose the best components for your needs. Ultimately, the right upgrades can transform your equipment, making it more effective and enjoyable to use.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding various components of outdoor power equipment. Understanding these elements can enhance your knowledge and help maintain optimal functionality.

What should I consider when replacing a component? It’s essential to ensure compatibility with your specific model. Verify the specifications and consult the manufacturer’s guidelines for proper selection.

How do I know if a part needs replacement? Signs of wear, unusual noises, or decreased performance often indicate that a component may require attention. Regular maintenance checks can help identify issues early.

Are there alternatives to original components? Yes, aftermarket options are available. However, it’s crucial to research the quality and compatibility of these alternatives to avoid potential problems.

Where can I find reliable information about components? Manufacturer websites, authorized dealers, and user manuals are excellent resources for accurate details and updates on specific items.