The intricate design of a well-known chainsaw model showcases a variety of essential elements that contribute to its functionality and performance. Each component plays a significant role in ensuring the device operates smoothly, making it crucial for users to have a clear understanding of how these parts interact. From the power system to the cutting mechanisms, every piece has been meticulously engineered to work in harmony.

Familiarity with the individual elements can greatly enhance the maintenance and repair processes. Whether you are a professional user or a hobbyist, grasping the layout and function of these components can lead to improved efficiency and longevity of the equipment. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions when replacing or upgrading specific parts.

In this section, we will delve into the specific arrangements and functionalities of the various elements within this popular chainsaw. By breaking down the key components, we aim to provide valuable insights that will assist users in navigating their maintenance tasks with confidence and ease.

Understanding Stihl MS 362 Components

Familiarizing oneself with the essential elements of a power tool is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring the device operates smoothly and efficiently. This section delves into the various integral parts of this specific model, highlighting their functions and significance.

- Engine Assembly: The heart of the machine, responsible for converting fuel into mechanical energy.

- Bar and Chain: The cutting mechanism, which determines the tool’s effectiveness in slicing through wood.

- Fuel Tank: Holds the fuel required for operation, designed for easy refueling and monitoring.

- Air Filter: Prevents dirt and debris from entering the engine, ensuring clean air intake.

- Handlebar: Provides a grip for the user, allowing for better control and maneuverability during operation.

Understanding these fundamental components not only enhances the user’s experience but also aids in troubleshooting and repair. Regular maintenance of these elements contributes significantly to the longevity and reliability of the equipment.

- Safety Features: Incorporate mechanisms to prevent accidental starts and ensure user protection.

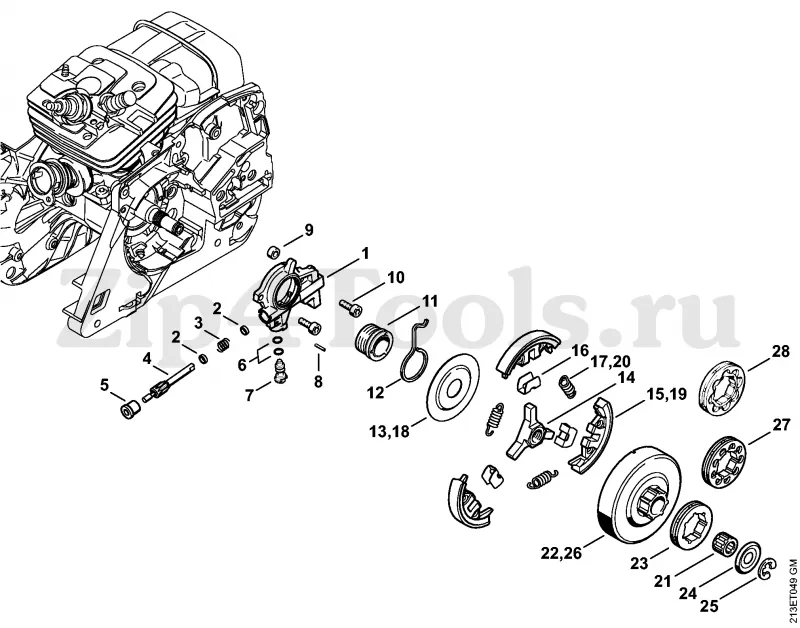

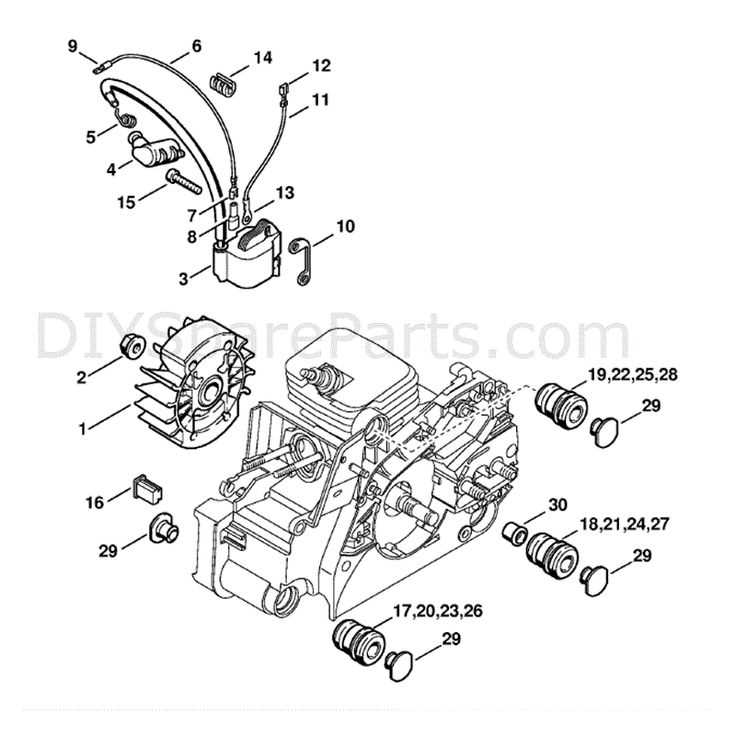

- Starter Mechanism: Facilitates the initial ignition of the engine, often including a recoil starter.

- Oil Pump: Ensures the chain is adequately lubricated, reducing wear and tear during use.

Grasping the intricacies of these components can empower users to make informed decisions regarding upkeep and repairs, ensuring the tool remains in peak condition.

Key Features of Stihl MS 362

This model boasts a range of impressive attributes designed to enhance performance and usability for users. Its engineering focuses on delivering reliable operation while maintaining ease of handling, making it suitable for various applications in outdoor work.

One notable aspect is the advanced engine technology that optimizes fuel efficiency while reducing emissions, aligning with modern environmental standards. The lightweight construction allows for prolonged usage without excessive fatigue, ensuring that even lengthy tasks can be completed with minimal strain.

Additionally, this unit incorporates a well-designed cutting system that provides swift and precise performance. Features such as an adjustable oil pump contribute to the overall functionality, allowing users to customize the lubrication according to their needs, ensuring longevity and reliability.

Lastly, safety mechanisms are integral to its design, promoting user protection during operation. The combination of these characteristics makes this model a preferred choice for both professional and casual users alike.

Common Parts Breakdown and Functions

Understanding the various components of a cutting tool is essential for efficient operation and maintenance. Each element plays a specific role in ensuring that the machine runs smoothly and effectively. By familiarizing oneself with these components, users can enhance performance and troubleshoot potential issues more effectively.

Key Components and Their Roles

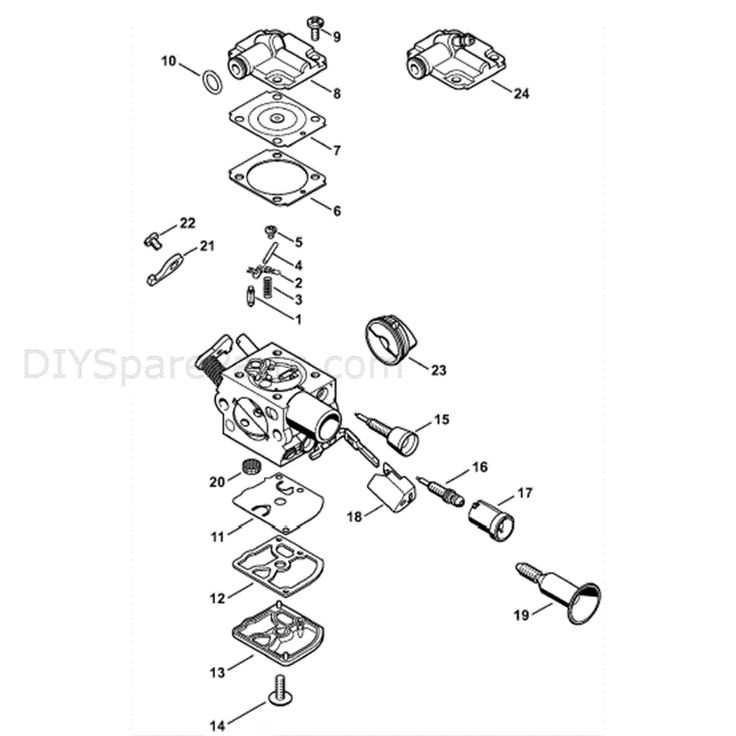

Among the primary elements, the engine serves as the powerhouse, providing the necessary energy for operation. The fuel system, including the tank and lines, ensures that the engine receives the right mixture for optimal combustion. Additionally, the cutting assembly, featuring the chain and guide bar, is crucial for achieving precise cuts, making it vital for users to maintain these parts regularly.

Maintenance Tips for Longevity

Regular inspections and upkeep of the crucial elements can significantly prolong the lifespan of the tool. Ensuring that the air filter is clean allows for proper airflow, while lubricating the chain reduces friction and wear. Additionally, checking the tension of the chain can prevent slippage and improve cutting efficiency, making routine maintenance a key aspect of reliable operation.

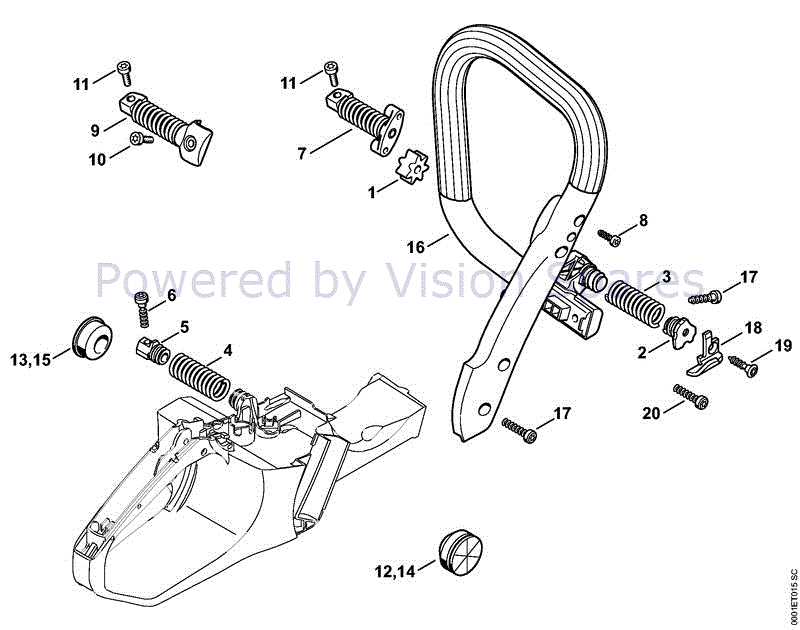

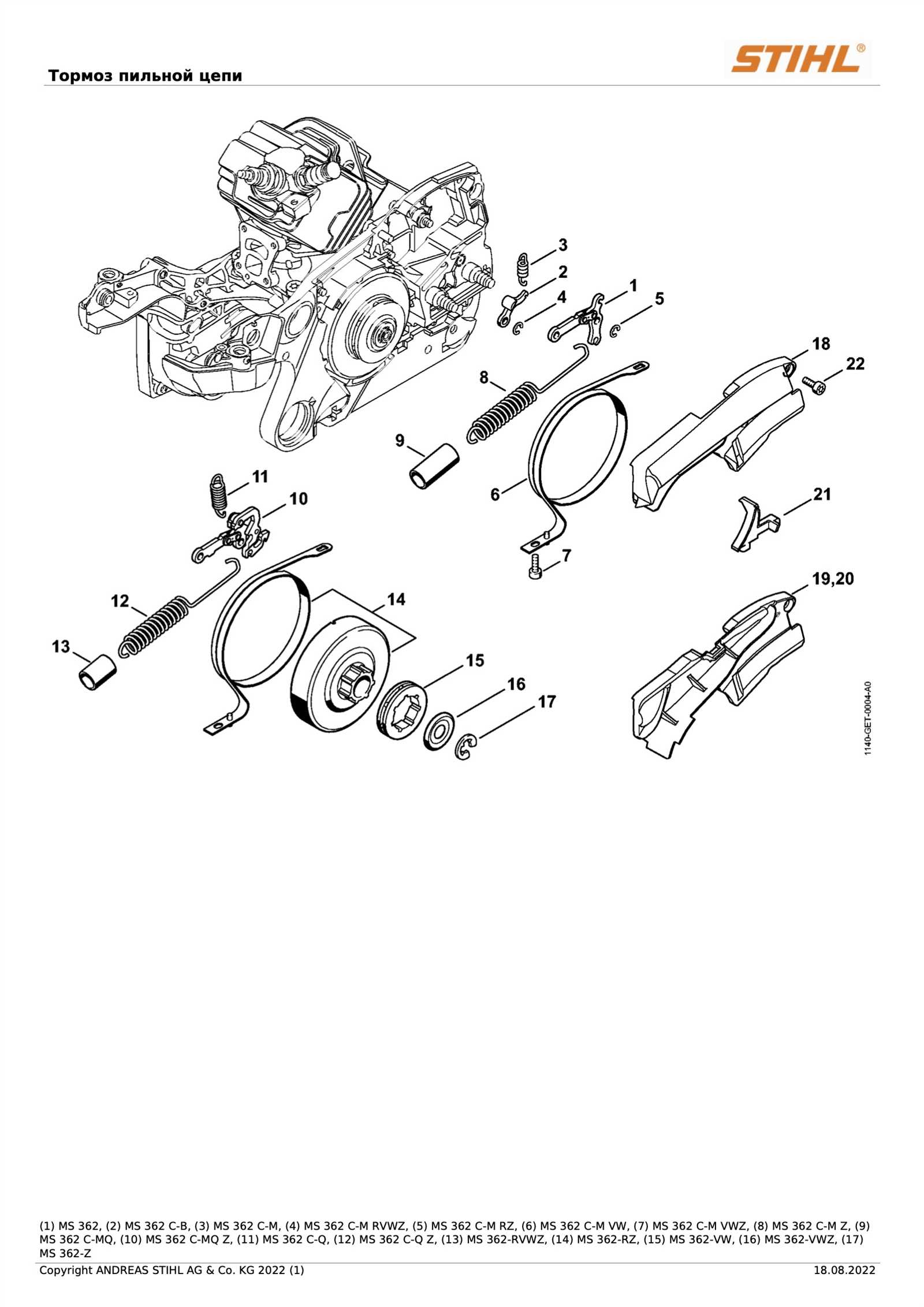

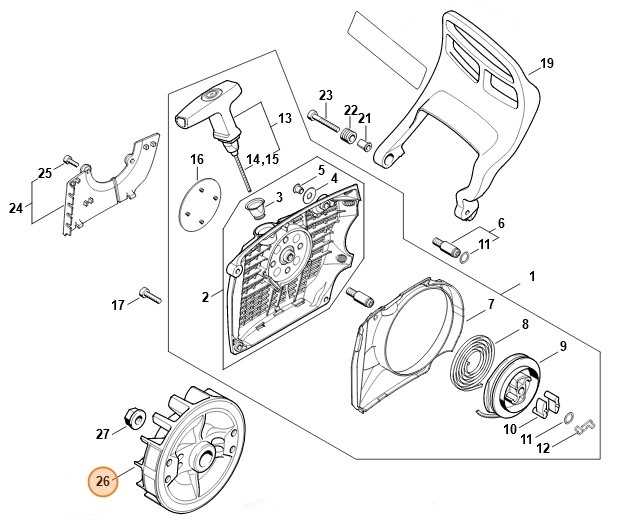

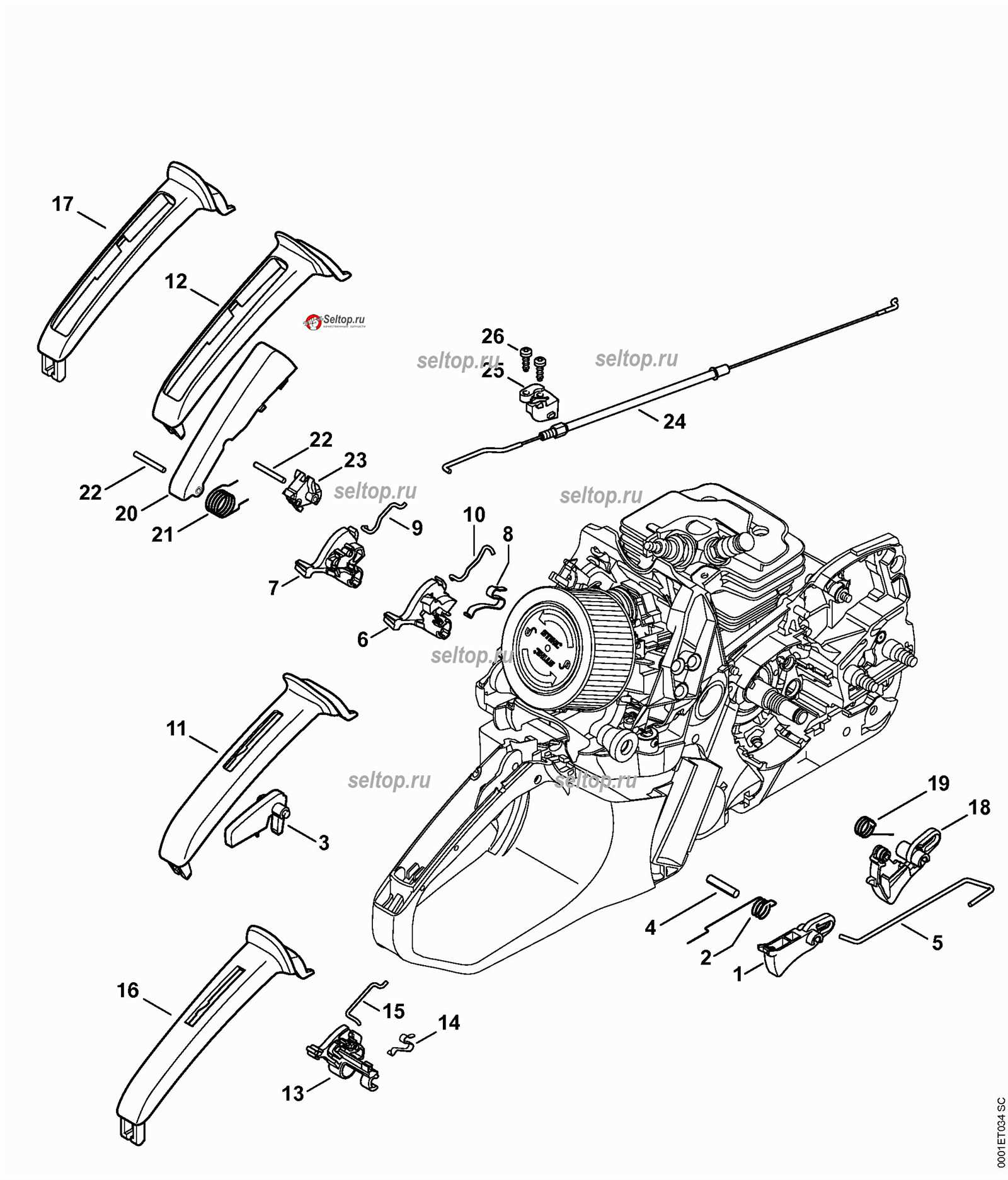

Identifying Stihl MS 362 Assembly Parts

Understanding the various components of a particular machinery is essential for efficient operation and maintenance. This section will explore the individual elements that make up the assembly of this specific tool, highlighting their functions and importance in the overall mechanism.

Every piece plays a critical role in ensuring optimal performance. From the power unit to the cutting mechanism, recognizing each component allows users to troubleshoot issues effectively and perform necessary repairs or replacements. Familiarity with these elements not only aids in maintenance but also enhances the user’s ability to operate the equipment safely and efficiently.

When disassembling or assembling the equipment, it is crucial to follow the correct sequence and ensure that all elements are properly aligned. This attention to detail can prevent potential malfunctions and extend the lifespan of the tool. Whether you are a seasoned professional or a novice user, grasping the intricacies of the assembly can significantly improve your experience and outcomes.

Maintenance Tips for Essential Components

Regular upkeep of crucial elements in your equipment is vital for ensuring longevity and optimal performance. By implementing consistent maintenance practices, you can enhance efficiency, reduce the likelihood of malfunctions, and extend the lifespan of your machinery. Focusing on specific areas during your maintenance routine will yield significant benefits and keep your tools operating smoothly.

Regular Cleaning

Maintaining cleanliness is paramount. Debris and residues can accumulate over time, affecting performance and leading to potential damage. It is advisable to routinely clean the air filters and other accessible areas to ensure that the engine receives adequate airflow. Using a soft brush or compressed air can effectively remove dust and dirt, promoting better operation.

Lubrication of Moving Parts

Proper lubrication of moving components plays a crucial role in reducing friction and wear. Utilizing the appropriate lubricants as recommended in your equipment’s manual helps to ensure smooth functionality. Pay special attention to pivot points, bearings, and chains, as these areas are prone to wear. Regular application of lubricant will enhance performance and prevent premature failure.

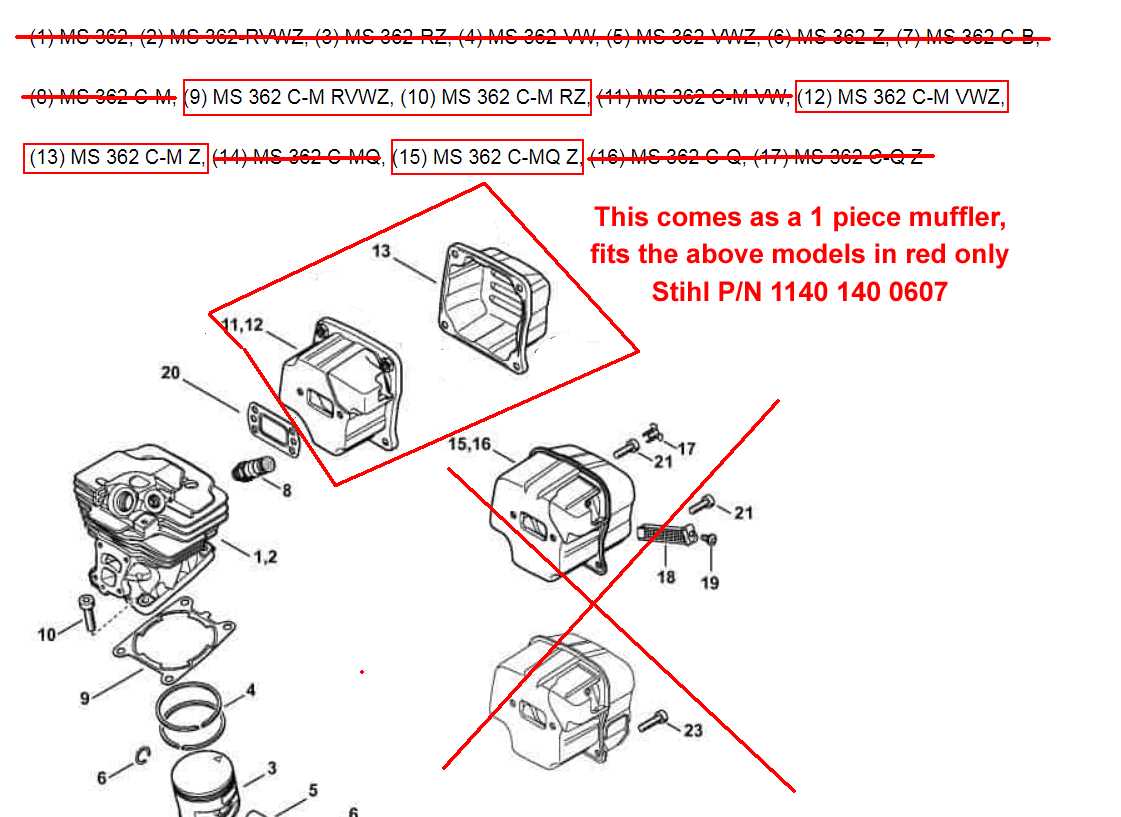

Replacement Parts for Stihl MS 362

Maintaining optimal performance of your chainsaw often requires the replacement of specific components. Understanding the essential elements that contribute to the overall functionality can ensure your equipment operates efficiently and reliably. Below are key components that may need to be replaced over time.

- Air Filter: Essential for keeping dirt and debris from entering the engine.

- Spark Plug: Crucial for ignition; replacing it can improve starting and engine performance.

- Fuel Filter: Helps to ensure a clean fuel supply, preventing clogs that can hinder performance.

- Guide Bar: Worn or damaged bars can affect cutting efficiency and require timely replacement.

- Chain: A dull or broken chain can lead to unsafe operation and should be replaced regularly.

- Piston Rings: Maintaining proper compression is vital; worn rings can decrease power.

By regularly checking and replacing these components, users can enhance the longevity and effectiveness of their equipment, ensuring that it remains in top condition for all cutting tasks.

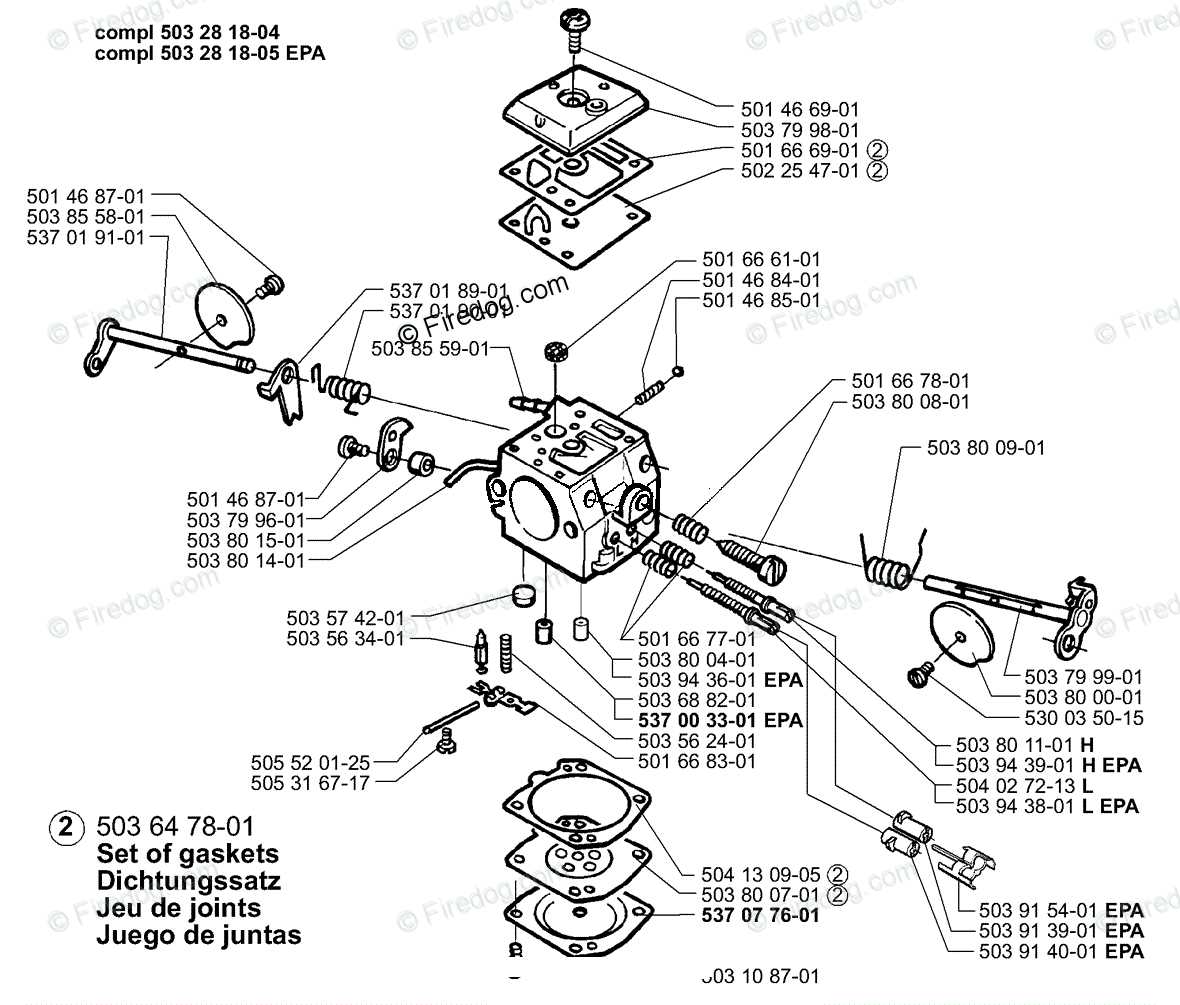

Exploring the Parts List and Diagram

Understanding the components of a power tool is essential for efficient maintenance and operation. A detailed overview of the various elements can provide valuable insights into the machine’s functionality and potential troubleshooting options. This section delves into the essential components, highlighting their roles and interconnections to enhance your familiarity with the tool.

Key Components Overview

Each element within the assembly plays a crucial role in ensuring smooth operation. From the cutting mechanism to the power source, every part contributes to the overall efficiency and performance. Familiarizing yourself with these elements allows for better upkeep and informed decision-making during repairs.

Importance of Visual References

Utilizing visual aids offers a clearer understanding of the arrangement and relationship between components. These references not only assist in identifying parts but also simplify the reassembly process after maintenance. A well-organized visual guide is invaluable for both novice users and experienced operators, ensuring that all elements are correctly aligned for optimal performance.

How to Access Stihl MS 362 Parts

To effectively reach the components of your chainsaw, it’s essential to follow a structured approach. Knowing where to locate each section can simplify maintenance and repairs, enhancing the overall performance of your equipment. This guide will help you understand the steps to access the critical elements of your tool efficiently.

Begin by ensuring the device is powered off and disconnected from any power source. Next, gather the necessary tools such as screwdrivers and wrenches. Carefully examine the outer casing for screws or clips that may need removal. Taking your time to identify each fastening point will prevent damage during disassembly.

Once the outer casing is removed, you will gain visibility into the internal mechanisms. Familiarize yourself with the layout of the components to identify any parts that may need attention. Regular inspection can help in early detection of wear and tear, allowing you to maintain optimal functioning.

Upgrading Components for Better Performance

Enhancing machinery’s efficiency can significantly improve overall functionality and user experience. By focusing on specific elements, users can achieve greater power, responsiveness, and durability. Whether it’s optimizing fuel delivery, increasing air flow, or enhancing cutting performance, each upgrade contributes to a more effective operation.

Improving Fuel and Air Systems

One effective way to boost performance is by refining the fuel and air systems. Upgrading the carburetor can lead to more precise fuel delivery, while a high-performance air filter can enhance airflow. Together, these modifications allow for more efficient combustion, resulting in improved power output and responsiveness.

Enhancing Cutting Equipment

Upgrading cutting tools is another vital aspect of enhancing performance. Selecting a sharper, high-quality blade can drastically improve cutting speed and precision. Additionally, considering a lightweight bar can reduce fatigue, allowing for longer use without sacrificing effectiveness.

Where to Buy Stihl MS 362 Parts

Finding quality components for your equipment can significantly enhance its performance and longevity. Whether you’re looking to replace worn-out items or upgrade certain features, there are several reliable sources available that can meet your needs. This section provides guidance on where to locate the necessary components effectively.

Authorized Dealers

One of the most dependable options is to purchase from authorized retailers. These locations typically carry a comprehensive selection of original components, ensuring compatibility and quality. Visiting a nearby dealer allows you to receive expert advice and assistance in selecting the right items for your equipment.

Online Marketplaces

For convenience and variety, online marketplaces are an excellent choice. Websites dedicated to outdoor equipment often offer a wide range of options at competitive prices. Be sure to check customer reviews and ratings to ensure that you’re buying from a reputable seller. Additionally, look for sellers that provide clear return policies and warranty information for added peace of mind.

DIY Repair Tips for Owners

Maintaining your outdoor equipment can be a rewarding experience, allowing you to save money and ensure optimal performance. By familiarizing yourself with essential components and common issues, you can tackle minor repairs and upkeep tasks confidently. Here are some practical suggestions to help you successfully handle repairs and enhance the longevity of your machinery.

1. Understand the Basics: Before diving into any repairs, take the time to learn about the fundamental elements of your device. Familiarizing yourself with the key features and their functions will empower you to diagnose issues more effectively. Consider referring to user manuals or online resources that provide detailed information on assembly and functionality.

2. Gather the Right Tools: Having the appropriate tools at hand is crucial for a smooth repair process. Invest in high-quality equipment that is specifically designed for your type of machinery. This will not only make repairs easier but also help prevent damage to sensitive components.

3. Regular Maintenance: To prevent costly repairs down the line, implement a routine maintenance schedule. Clean air filters, sharpen blades, and inspect all moving parts regularly. Addressing wear and tear before it escalates can significantly extend the lifespan of your machine.

4. Seek Guidance When Needed: Don’t hesitate to reach out for help if you encounter a challenging repair. Online forums, instructional videos, and community groups can offer valuable insights and tips from experienced users. Engaging with fellow enthusiasts can also provide a sense of camaraderie and support.

5. Document Your Repairs: Keep a log of any maintenance and repairs you perform. This record can be invaluable for tracking performance and identifying recurring issues. It will also assist you in communicating with professionals if you decide to seek external help in the future.