Maintaining optimal performance in your cutting tool requires a clear comprehension of its individual elements. Each component plays a crucial role in ensuring efficiency and safety during operation. This section aims to guide users through the intricate assembly of their machine, highlighting essential pieces and their functions.

Knowledge of the inner workings can significantly enhance your ability to troubleshoot issues and perform necessary repairs. By familiarizing yourself with the various sections and their interconnections, you can approach maintenance tasks with confidence. A detailed exploration of these elements will empower you to make informed decisions regarding your equipment.

Whether you’re looking to replace a worn-out piece or simply wish to understand your tool better, this resource provides valuable insights. By examining the layout of components, you can streamline your maintenance process and ensure your device remains in peak condition.

Understanding the Stihl MS290 Chainsaw

This section provides insight into a popular model of cutting equipment, known for its reliability and efficiency. Whether you’re a professional or a casual user, knowing the components and functionality of this tool is essential for optimal performance and maintenance.

Key features of this chainsaw include:

- Robust engine performance

- User-friendly design

- Efficient fuel consumption

- Variety of attachments for different tasks

When utilizing this device, it’s important to familiarize yourself with the following components:

- Engine: The heart of the chainsaw, providing the necessary power.

- Guide bar: Supports the chain and helps direct the cutting process.

- Chain: The component that performs the actual cutting.

- Fuel system: Essential for the operation and efficiency of the engine.

- Safety features: Crucial for preventing accidents during use.

Regular maintenance can prolong the lifespan of this cutting tool. Essential maintenance tasks include:

- Cleaning the air filter

- Checking the chain tension

- Inspecting the guide bar for wear

- Regularly changing the oil

By understanding these aspects, users can enhance their experience and ensure the longevity of their cutting equipment.

Key Features of the MS290 Model

This model stands out in the world of power tools due to its exceptional performance and reliability. Designed for both professionals and hobbyists, it combines power, efficiency, and user-friendly features that enhance productivity in various cutting tasks.

Power and Performance

- Robust engine offering impressive torque for demanding tasks.

- Optimized cutting speed, enabling faster work completion.

- Effective anti-vibration system for improved comfort during extended use.

User-Centric Design

- Lightweight structure allowing for easy maneuverability.

- Ergonomic handle ensuring a secure grip and reducing fatigue.

- Simple starting mechanism for quick and hassle-free operation.

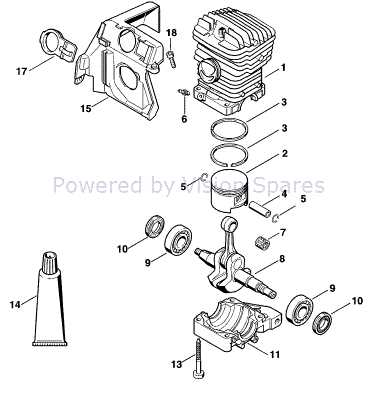

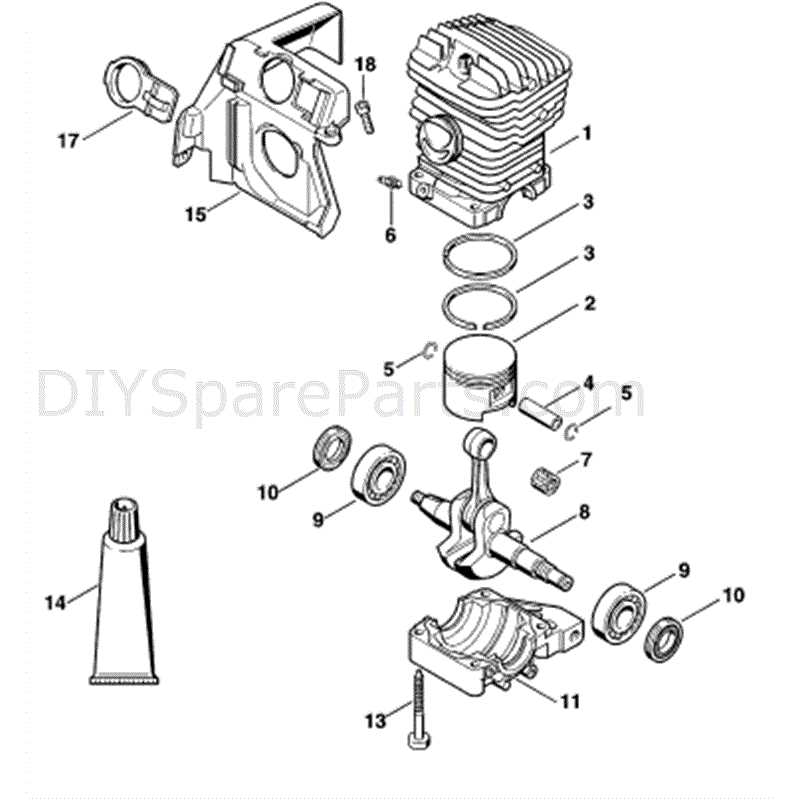

Importance of Parts Diagrams

Understanding the components of any machine is crucial for effective maintenance and repair. Visual representations of these elements offer clarity, enabling users to identify each piece and comprehend its function within the overall system. Such resources serve as valuable tools for both professionals and enthusiasts alike, facilitating informed decision-making and enhancing troubleshooting skills.

These visual aids not only simplify the assembly and disassembly processes but also help in sourcing the correct replacements when needed. By providing a detailed overview, they reduce the likelihood of errors during repairs, ultimately leading to improved efficiency and extended lifespan of the equipment. Furthermore, they foster a deeper understanding of the machinery, empowering users to perform tasks with confidence and accuracy.

In essence, having access to clear and informative illustrations is an indispensable aspect of equipment maintenance, ensuring that every user can engage with their tools effectively and safely. This knowledge is vital for optimizing performance and achieving longevity in the equipment’s operation.

How to Access the Manual

Accessing the instructional guide for your equipment is essential for understanding its components and ensuring proper maintenance. This resource provides detailed insights into assembly, operation, and troubleshooting, making it invaluable for both novice and experienced users.

Online Resources

Many manufacturers offer digital versions of their guides on official websites. To locate the necessary documentation, follow these steps:

| Step | Description |

|---|---|

| 1 | Visit the manufacturer’s official website. |

| 2 | Navigate to the support or resources section. |

| 3 | Search for your specific model or product. |

| 4 | Download the PDF or view it online. |

Physical Copies

If you prefer a tangible reference, many retailers provide printed versions. Additionally, you can request a copy directly from the manufacturer. This ensures you have a comprehensive resource at hand for any repairs or maintenance tasks.

Identifying Common Replacement Parts

Understanding the essential components of a cutting tool is crucial for effective maintenance and operation. Many users encounter the need for replacements due to wear and tear, which can impact performance. Recognizing these elements can help ensure optimal functionality and longevity.

One of the most frequently replaced items is the cutting chain. Over time, it can become dull or damaged, necessitating a new one for efficient operation. Regular inspection can help detect signs of wear early.

Another critical component is the air filter. A clogged filter can lead to decreased engine performance and increased fuel consumption. Replacing it periodically ensures proper airflow and efficiency.

The spark plug also plays a vital role in starting and running the machine smoothly. A worn spark plug can lead to misfires or difficulty starting, so it’s wise to check and replace it as needed.

Finally, the fuel line should not be overlooked. Cracks or blockages can lead to fuel leaks or insufficient fuel delivery, impacting overall operation. Regular maintenance and timely replacements can significantly enhance the tool’s performance.

Step-by-Step Maintenance Guide

Regular upkeep is essential for the longevity and performance of your equipment. This section outlines a comprehensive procedure to ensure that every component is in optimal condition. By following these steps, you can enhance efficiency, prevent issues, and extend the lifespan of your machine.

The maintenance process involves several key tasks that should be performed systematically. Below is a table summarizing these tasks along with their recommended frequency and a brief description.

| Task | Frequency | Description |

|---|---|---|

| Air Filter Cleaning | Every 10 hours | Remove and clean the air filter to ensure proper airflow and engine performance. |

| Chain Lubrication | After each use | Apply chain oil to reduce wear and maintain smooth operation. |

| Spark Plug Inspection | Every 25 hours | Check and replace if necessary to ensure reliable starting and combustion. |

| Fuel System Check | Monthly | Inspect fuel lines and filter for clogs or leaks to maintain fuel delivery. |

| Bar and Chain Inspection | Every 20 hours | Examine for wear and damage; replace if necessary to ensure safety. |

Adhering to this guide will not only promote safety but also improve the overall functionality of your machinery. Regular attention to these details can prevent minor issues from escalating into costly repairs.

Safety Precautions During Repairs

When undertaking maintenance or repair work, ensuring safety should always be the top priority. Proper precautions can prevent accidents and injuries, creating a secure environment for both the individual performing the repairs and those nearby. Adhering to guidelines and using appropriate protective gear are essential steps in this process.

Essential Protective Gear

Before starting any repair tasks, it is crucial to equip yourself with the right protective equipment. This includes gloves to shield your hands from sharp objects and goggles to protect your eyes from debris. Additionally, wearing sturdy footwear can help prevent injuries from heavy components or tools that may fall.

Safe Work Environment

Creating a safe workspace is vital. Ensure that the area is well-lit and organized, with all necessary tools within reach to avoid unnecessary movement. Remove any clutter or obstacles that could cause trips or falls. Furthermore, it’s advisable to have a first aid kit readily available in case of emergencies.

Tools Needed for Assembly

When assembling your equipment, having the right tools is essential for a smooth and efficient process. This section outlines the necessary instruments that will aid in putting everything together correctly, ensuring optimal functionality and safety.

| Tool | Description |

|---|---|

| Wrench Set | Used for tightening bolts and securing components. |

| Screwdriver | Essential for fastening screws in place. |

| Pliers | Helpful for gripping and bending parts as needed. |

| Torque Wrench | Ensures proper tightening to avoid damage. |

| Allen Keys | Ideal for hex screws and certain fittings. |

Troubleshooting Common Issues

Identifying and resolving frequent problems is essential for maintaining the efficiency of your equipment. Many users encounter similar challenges that can be addressed with a systematic approach. This section provides guidance on diagnosing and fixing common malfunctions, ensuring optimal performance.

Engine Won’t Start

If the engine refuses to start, consider the following potential causes:

- Check the fuel level and ensure it’s not stale or contaminated.

- Inspect the ignition system for faulty spark plugs or connections.

- Examine the air filter for clogs that could restrict airflow.

- Verify that the choke is properly set.

Excessive Vibration

Excessive vibration can lead to wear and tear. Address this issue by checking:

- The condition of the blade or chain for damage.

- All mounting screws and bolts to ensure they are tightened.

- The balance of the cutting tool; unbalanced components can cause instability.

- The damping system, which should be intact and functional.

By following these troubleshooting tips, you can maintain the longevity and reliability of your equipment. Regular inspections and maintenance will help prevent many common issues from arising.

Comparing MS290 with Other Models

This section explores the differences and similarities between a specific model and its contemporaries in the chainsaw market. Understanding these distinctions can help users make informed choices based on their needs and preferences.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 2.8 HP | 3.0 HP | 2.5 HP |

| Weight | 12 lbs | 11 lbs | 13 lbs |

| Bar Length | 16 inches | 18 inches | 16 inches |

| Fuel Efficiency | Excellent | Good | Average |

Evaluating these characteristics allows potential buyers to delve into the ultimate performance expectations based on their specific applications, ensuring they choose the most suitable option.

Where to Buy Genuine Parts

Finding authentic components for your outdoor equipment is essential for maintaining performance and longevity. Ensuring that you source these items from reputable suppliers can make a significant difference in the functionality of your machinery. Authentic parts are designed to fit perfectly and work seamlessly with your equipment, reducing the risk of damage and enhancing efficiency.

One of the best places to start your search is through authorized dealers. These retailers specialize in genuine components and often provide expert advice on compatibility and installation. You can also explore official online platforms where manufacturers sell their products directly, ensuring you receive original items with verified quality.

Additionally, visiting local hardware stores can be beneficial. Many of these establishments stock a range of genuine components and can assist in locating the specific items you need. Online marketplaces may offer a wide selection, but it’s crucial to verify the seller’s reputation to avoid counterfeit goods.

Consider joining community forums or groups dedicated to outdoor equipment. Members often share valuable recommendations on where to find authentic components at competitive prices. This collaborative approach can lead to discovering trusted sources that you may not have considered initially.

Tips for Long-lasting Performance

Ensuring the longevity and efficiency of your equipment requires attention to several key factors. By following best practices for maintenance and operation, you can enhance performance and extend the lifespan of your tools.

Regular upkeep is essential for preventing wear and tear. This includes routine cleaning, timely oil changes, and the inspection of vital components. Adhering to these practices helps maintain optimal functionality and reduces the risk of breakdowns.

| Tip | Description |

|---|---|

| Routine Cleaning | Remove debris and dirt after each use to prevent build-up that can cause damage. |

| Oil Changes | Regularly replace the oil to ensure smooth operation and reduce engine friction. |

| Component Inspection | Check for wear in critical parts and replace them promptly to avoid larger issues. |

| Proper Storage | Store equipment in a dry, secure place to protect it from environmental factors. |

| Use Quality Fuel | Utilize high-quality fuel to prevent clogging and maintain performance standards. |

By implementing these strategies, you can ensure that your tools operate efficiently and remain reliable for years to come.

Community Resources and Forums

Engaging with fellow enthusiasts can significantly enhance your understanding and maintenance of outdoor equipment. Online communities provide a platform for sharing knowledge, troubleshooting issues, and exchanging tips. These resources foster collaboration, making it easier to tackle challenges and improve skills.

Online Discussion Boards

Discussion boards are invaluable for connecting with other users who face similar challenges. Participants often share their experiences, solutions, and insights, creating a rich repository of information that can aid in resolving technical problems.

Social Media Groups

Social media platforms host numerous groups dedicated to outdoor tools and equipment. These groups allow for real-time interactions and updates, helping users stay informed about best practices, new products, and innovative techniques.