In the realm of outdoor tools, clarity regarding individual elements is crucial for effective maintenance and operation. Recognizing the arrangement and interaction of these essential components enhances the overall efficiency of any equipment. A well-structured overview can serve as a valuable resource for both novice users and seasoned professionals alike.

Familiarity with each segment fosters a deeper comprehension of functionality and aids in troubleshooting potential issues. Whether for repair or enhancement, having access to a detailed representation significantly streamlines the process. This knowledge empowers users to optimize performance and ensure longevity.

As we delve into the intricate details, this exploration provides a comprehensive look at the various sections involved. Understanding how each part contributes to the whole not only facilitates effective repairs but also enriches the user experience. Thus, grasping these connections is paramount for anyone engaged with such equipment.

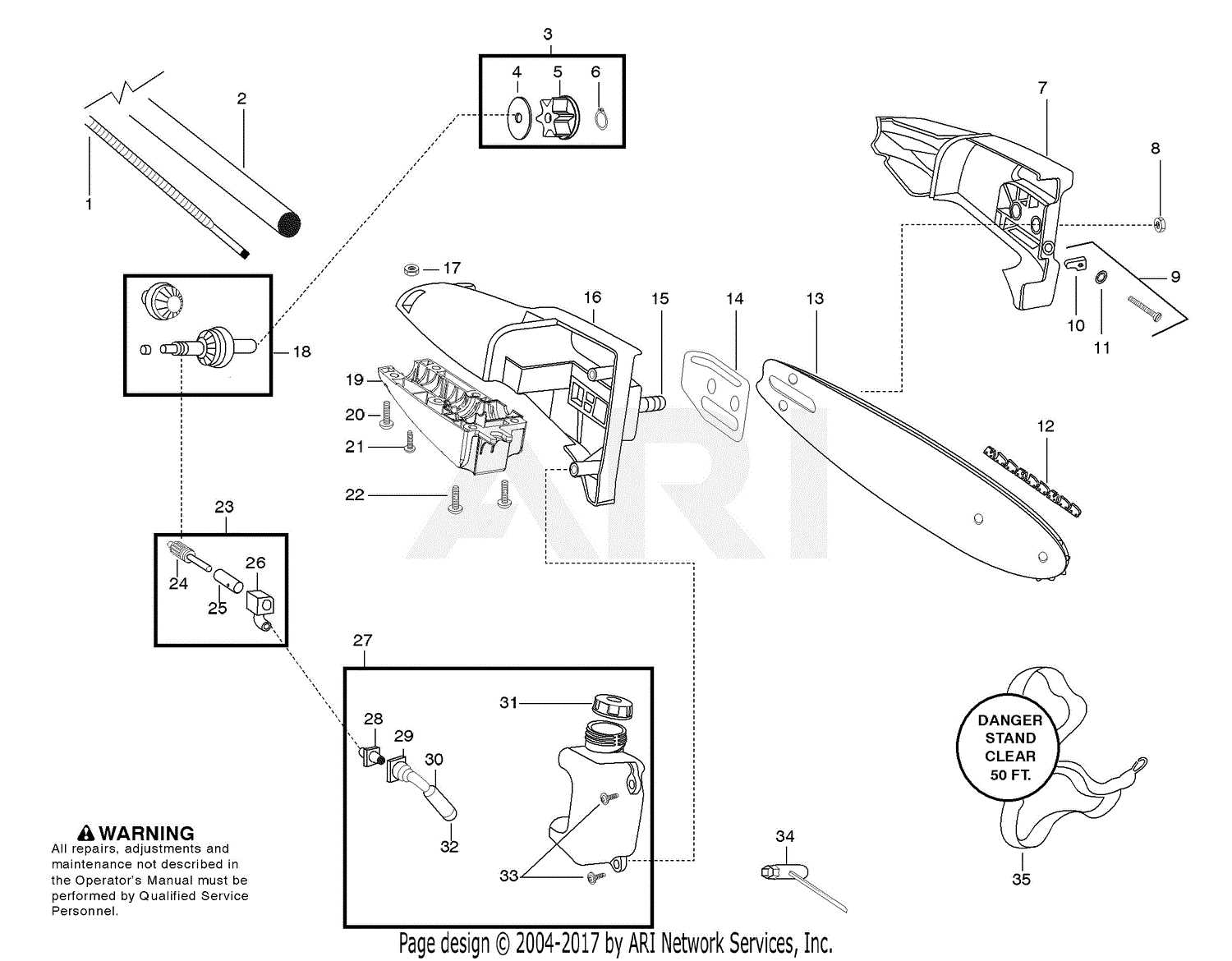

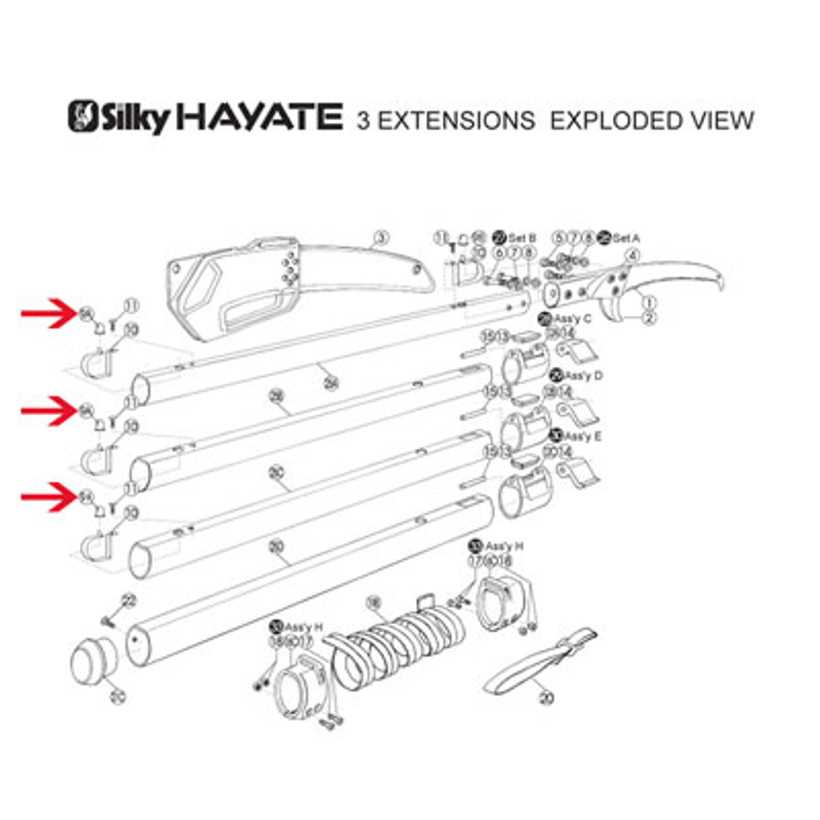

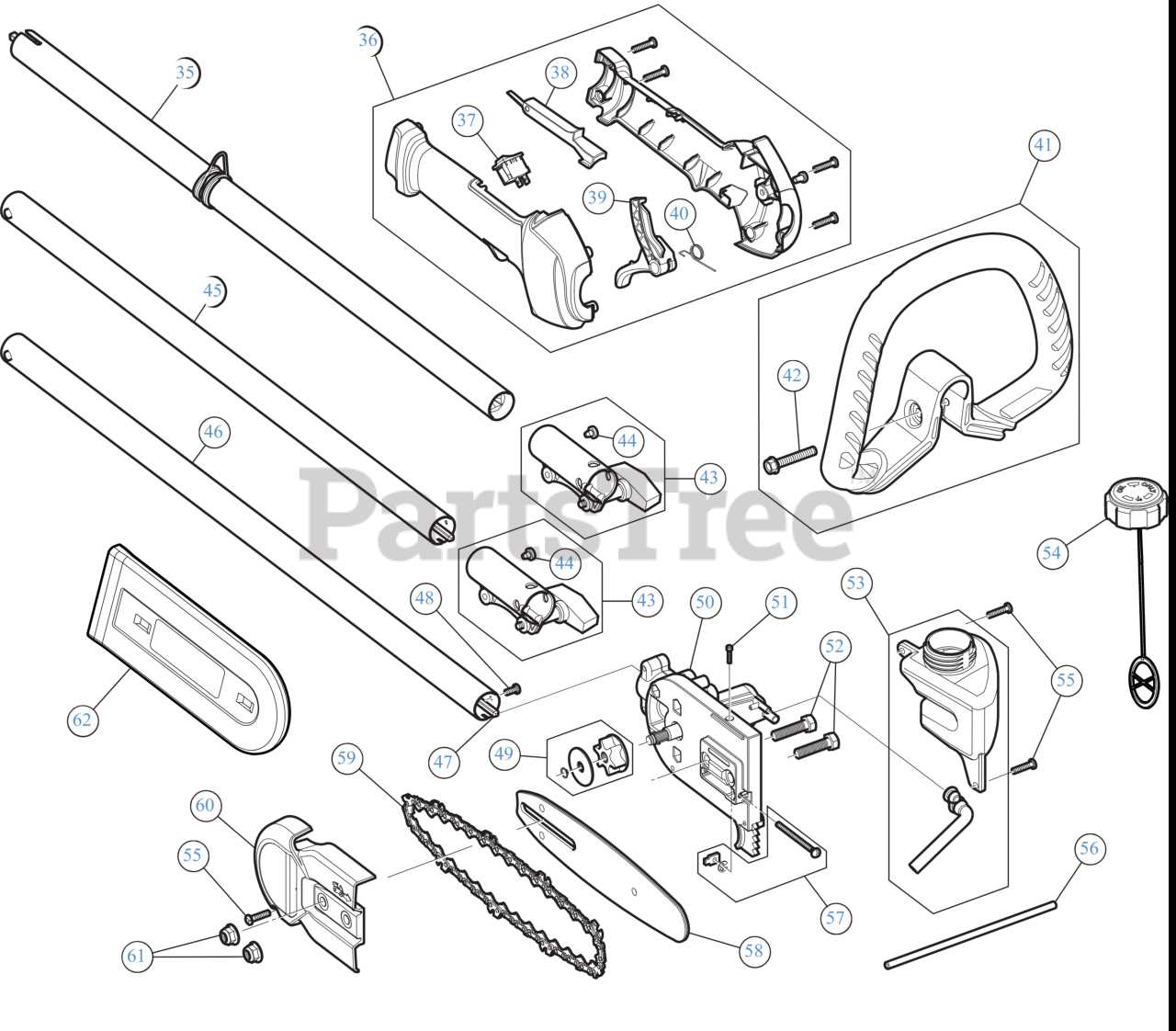

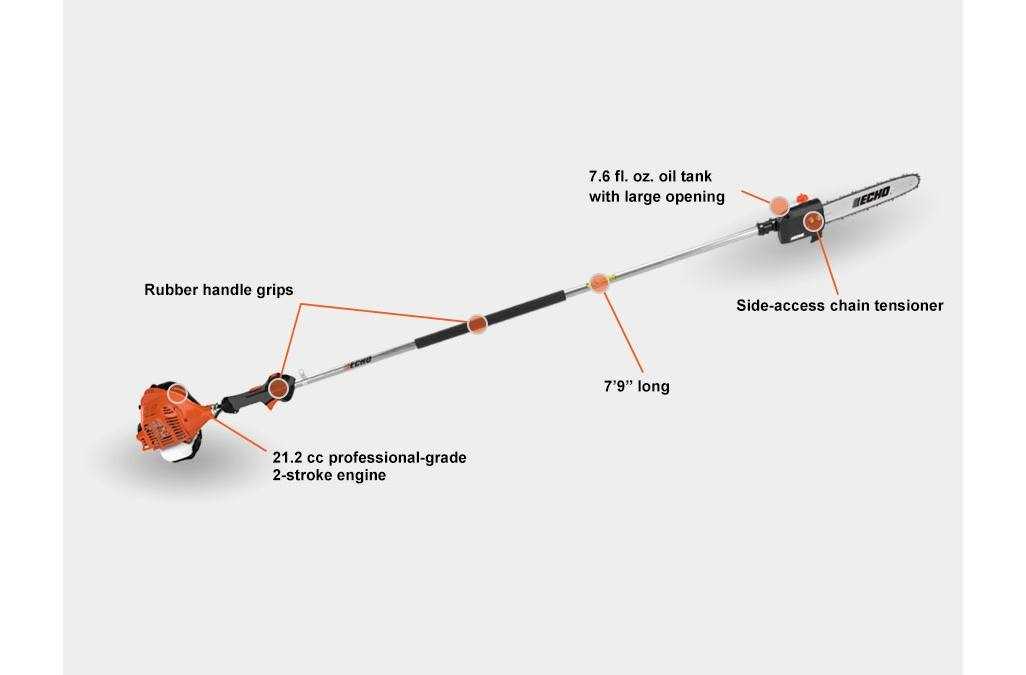

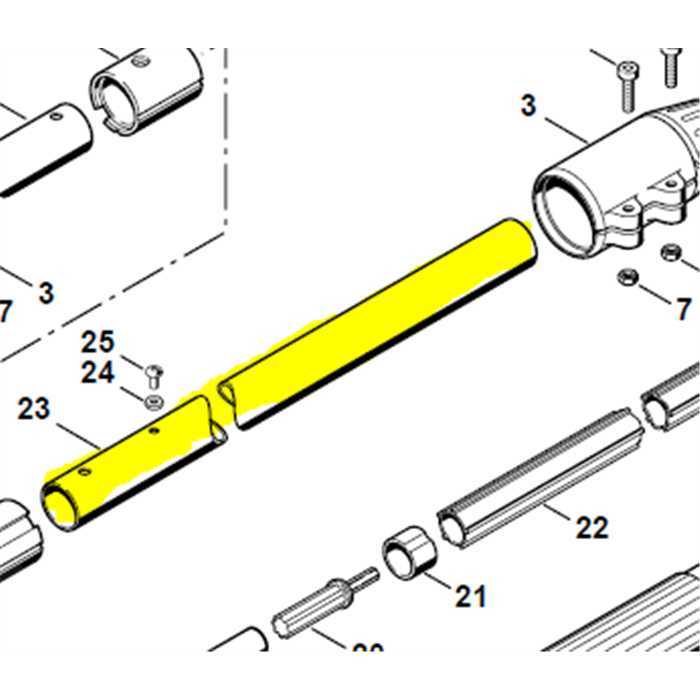

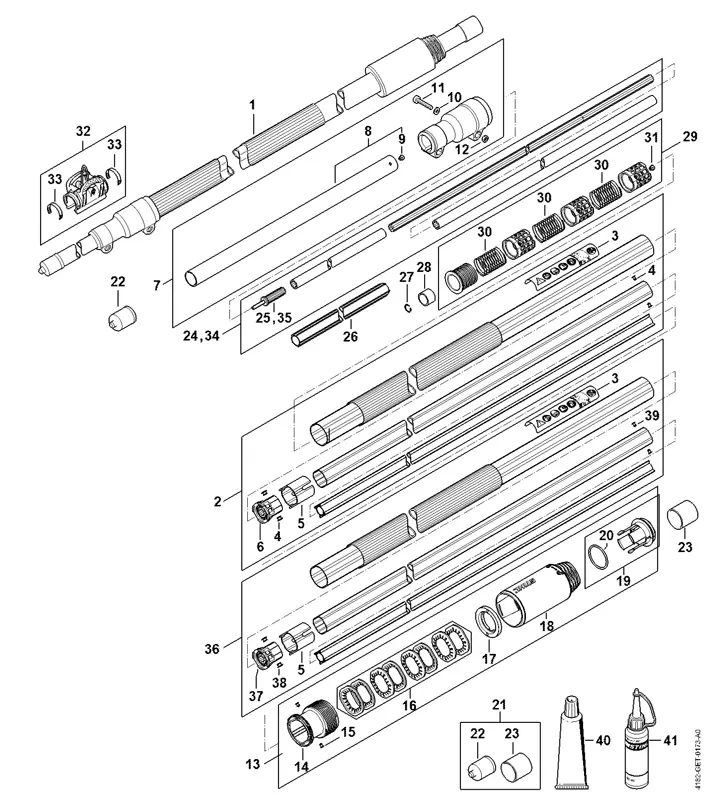

Overview of Pole Saw Components

This section delves into the essential elements that constitute a versatile cutting tool. Understanding the various components enhances the user’s ability to maintain, troubleshoot, and effectively operate the equipment. Each element plays a significant role in the overall functionality, ensuring efficiency during use.

Key Functional Elements

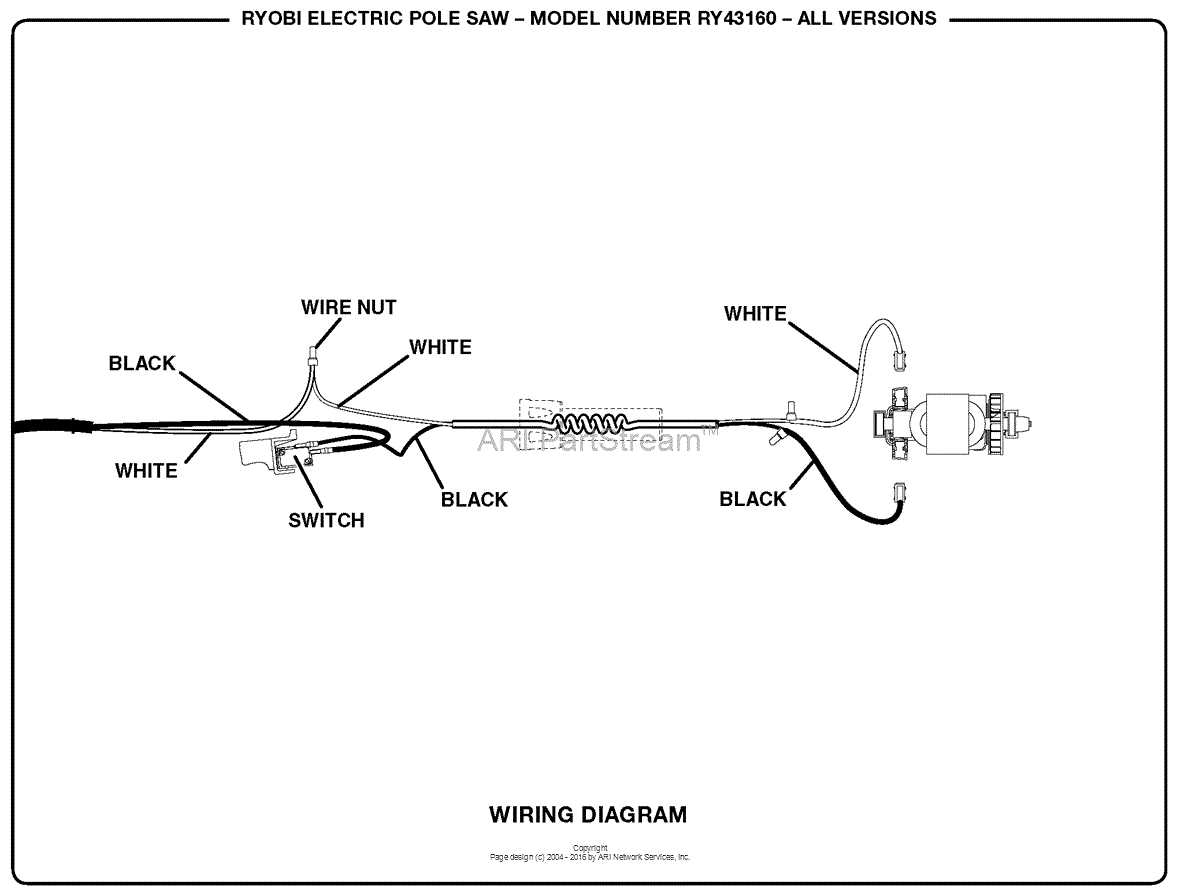

Central to the operation are the driving mechanisms, which provide the necessary power for cutting tasks. These include motors and gears, designed to deliver optimal performance. Additionally, the cutting mechanism is crucial, consisting of blades engineered for precision and durability. Each component’s quality directly impacts the overall efficacy of the device.

Supportive Structures

In addition to the main operational parts, various supportive structures enhance stability and ease of use. Handles are crafted for ergonomic comfort, facilitating better control during operation. Protective covers are also essential, offering safety and shielding vital components from debris. Together, these elements ensure a reliable and safe experience for the user.

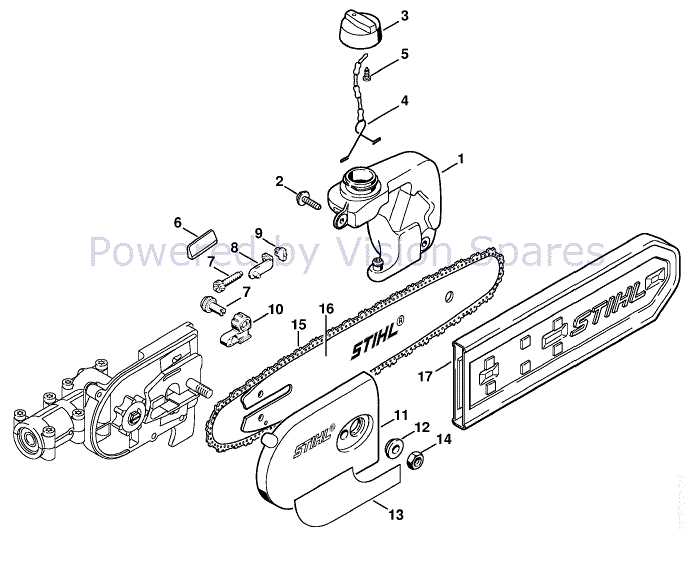

Understanding the Cutting Mechanism

The effectiveness of a cutting tool hinges on its ability to efficiently slice through materials. This section explores the fundamental components and principles that contribute to the overall cutting performance.

Key Components

- Blade Design: The shape and sharpness play a crucial role in how easily the tool penetrates the target material.

- Drive System: This element transmits power from the motor to the blade, influencing cutting speed and efficiency.

- Safety Features: These mechanisms ensure user protection while maintaining optimal functionality.

Operational Principles

- When activated, the motor generates rotational energy.

- This energy is conveyed to the blade through the drive system.

- The blade’s design allows it to cut through various materials with precision.

- Safety mechanisms engage to protect the user from potential hazards during operation.

Essential Safety Features Explained

Ensuring user safety during operation is paramount in any cutting tool. Key attributes designed to protect the operator can significantly reduce the risk of accidents and enhance overall experience. Understanding these features is essential for both novice and experienced users.

Automatic Shutoff Mechanism

This feature helps prevent injuries by immediately halting the equipment when certain safety thresholds are exceeded. Whether due to overexertion or unusual vibrations, this system acts as a critical line of defense against potential harm.

Ergonomic Design

An ergonomically crafted structure minimizes strain on the user, allowing for more comfortable handling. Proper weight distribution and grip design can enhance control, thereby reducing the likelihood of mishaps during operation.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your outdoor tool requires consistent upkeep and attention. Regular maintenance not only enhances performance but also prevents unexpected failures during use.

Here are essential practices to consider:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Clean the Components | After Each Use | Remove debris and residue to prevent buildup that can affect functionality. |

| Inspect for Wear | Monthly | Check for any signs of damage or deterioration on critical components. |

| Lubricate Moving Parts | Every 10 Uses | Apply appropriate lubricant to ensure smooth operation and reduce friction. |

| Sharpen Cutting Edges | As Needed | Maintain optimal cutting performance by sharpening blades regularly. |

By following these guidelines, users can enhance the reliability and efficiency of their equipment, ensuring it remains in peak condition for years to come.

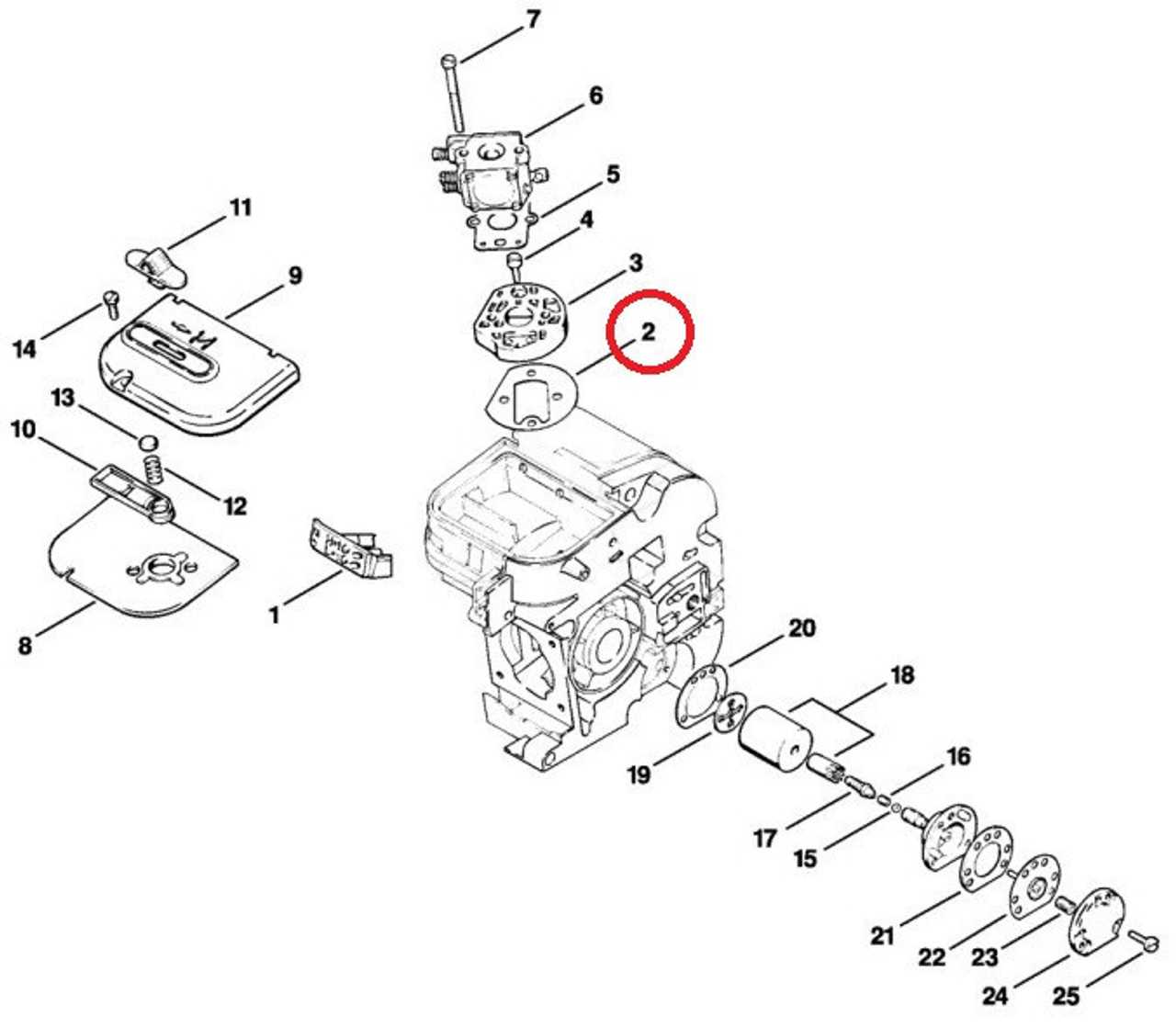

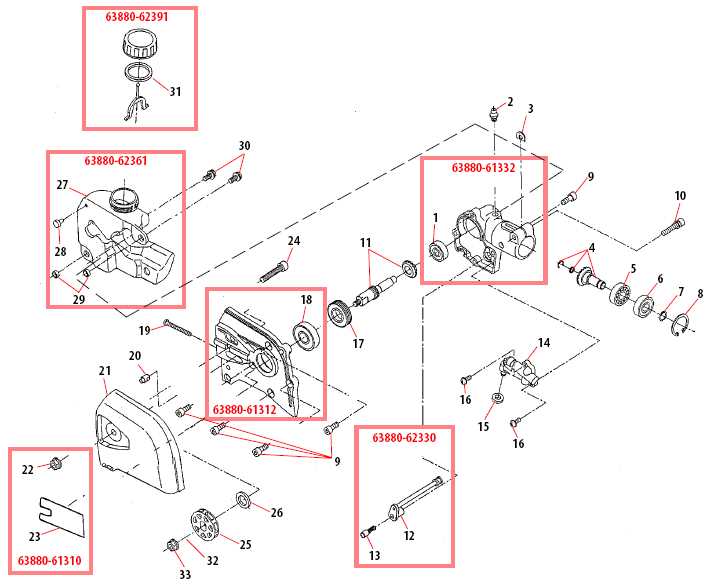

Identifying Replacement Parts Easily

Understanding how to recognize essential components in your tools can significantly enhance maintenance and repair efficiency. Familiarity with the specific elements will ensure you can quickly find what you need when the time comes for replacements.

Here are some effective strategies to simplify the identification process:

- Consult the User Manual: Always refer to the manufacturer’s guide for detailed information on each component.

- Use Online Resources: Many websites provide extensive catalogs and visual references for various components.

- Join Community Forums: Engage with fellow enthusiasts to share insights and tips on identifying specific elements.

- Label Components: When disassembling, label parts for easy reassembly and future reference.

By implementing these techniques, you can streamline the process of locating replacements and ensure your equipment remains in top condition.

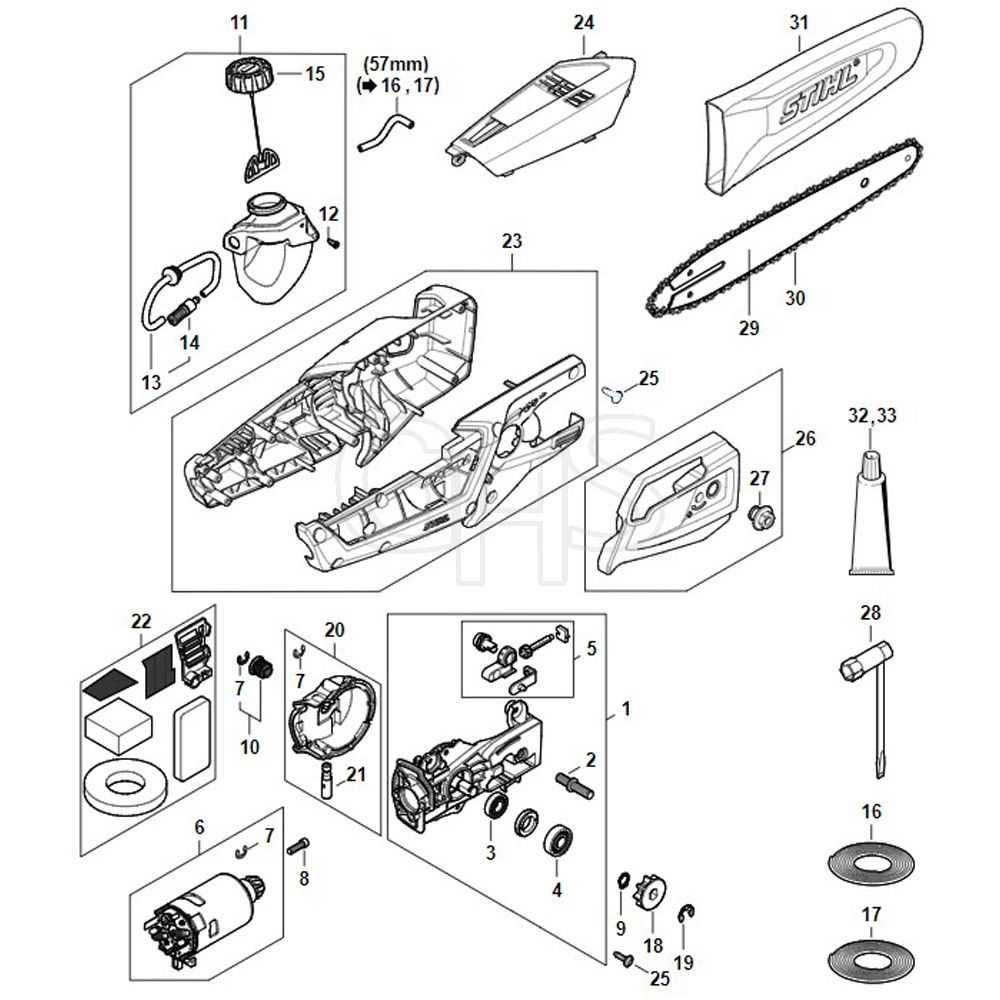

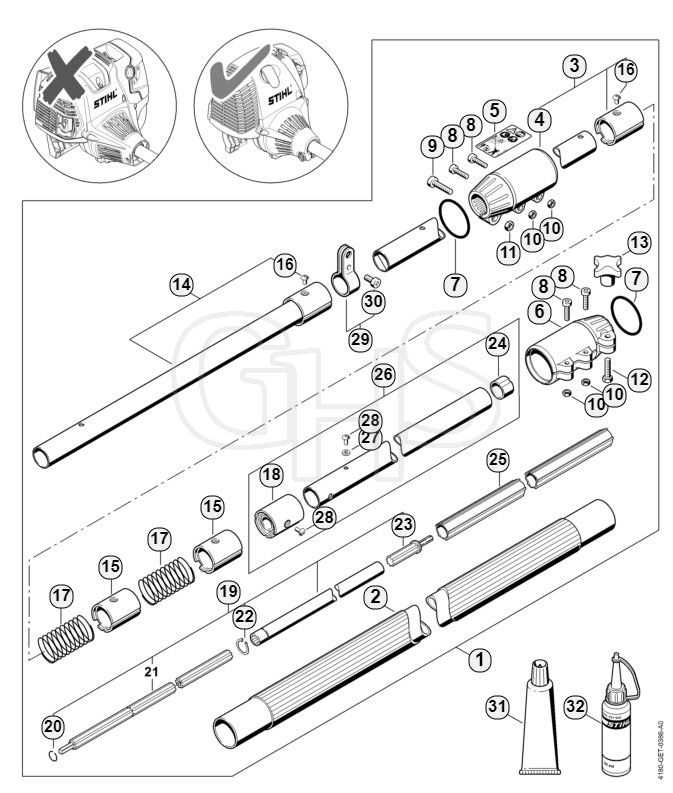

How to Assemble Your Equipment

Putting together your tools can significantly enhance their performance and ease of use. Understanding the components involved and their assembly is crucial for efficient operation. Follow these steps to ensure a smooth setup process.

| Step | Description |

|---|---|

| 1 | Gather all components and tools needed for assembly. |

| 2 | Carefully review the user manual to familiarize yourself with each part’s function. |

| 3 | Begin by connecting the primary segments, ensuring secure fittings. |

| 4 | Attach any additional elements, checking that they align correctly with the main body. |

| 5 | Once assembled, conduct a thorough inspection to confirm stability and safety. |

| 6 | Perform a test operation to ensure everything functions as intended. |

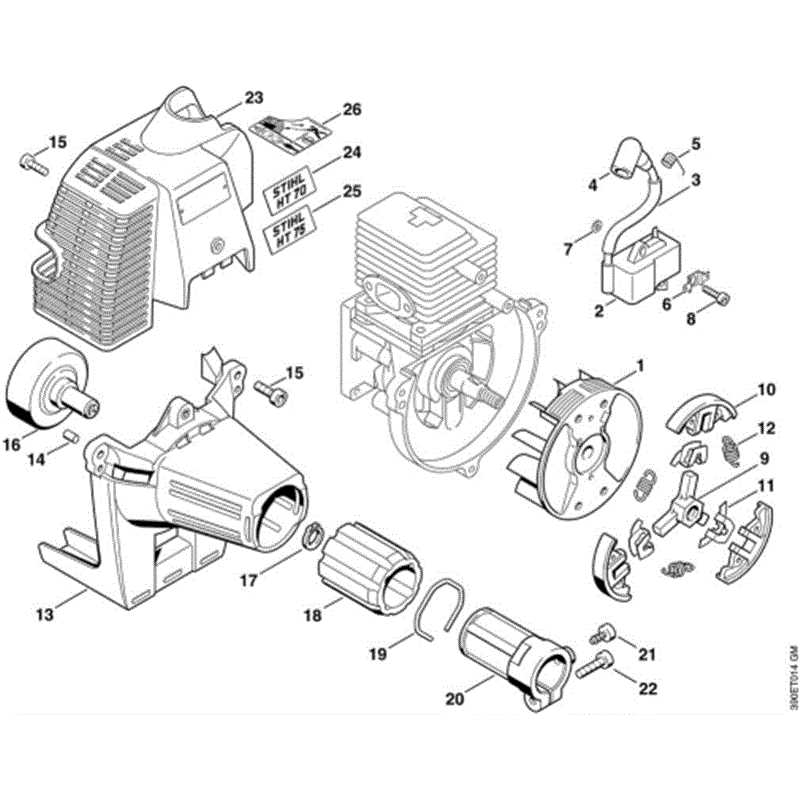

Common Issues and Troubleshooting

When using outdoor cutting equipment, users may encounter various challenges that can affect performance. Identifying and addressing these common issues is crucial for maintaining efficiency and ensuring a smooth operation.

Engine Starting Problems: One of the most frequent complications is difficulty in starting the engine. This may stem from issues such as fuel contamination, air filter blockages, or improper ignition timing. Regular maintenance and checks can help prevent these setbacks.

Power Loss: Users might notice a significant decrease in cutting power during operation. This can result from dull blades, inadequate fuel supply, or obstructed exhaust pathways. Ensuring that all components are clean and in good condition is essential for optimal performance.

Vibration and Noise: Excessive vibration or unusual sounds can indicate underlying problems, such as loose components or misalignment. It’s advisable to inspect the assembly regularly and tighten any loose parts to avoid further damage.

Fuel Leaks: Leaks can pose safety hazards and affect the equipment’s efficiency. Common causes include worn gaskets or damaged fuel lines. Promptly addressing leaks by replacing faulty parts is vital for safe operation.

By recognizing these issues early and following proper troubleshooting techniques, users can enhance the longevity and reliability of their equipment.

Exploring Power Source Options

When considering the functionality of a cutting tool, the type of energy supply plays a crucial role. Various sources offer unique benefits, affecting performance, convenience, and operational duration. Understanding these options helps in making informed decisions tailored to specific tasks.

Electric Energy Supply

Electric models provide a clean and quiet operation, ideal for residential areas. They are often lightweight and easy to maintain, appealing to casual users.

Gasoline-Powered Units

Gasoline-driven alternatives tend to deliver higher power output, suitable for more demanding tasks. While they require more upkeep and can be heavier, their mobility makes them popular among professionals.

| Power Source | Advantages | Disadvantages |

|---|---|---|

| Electric | Quiet, low maintenance, lightweight | Limited range, dependent on outlets |

| Gasoline | High power, portable, longer runtime | Heavier, more maintenance, noisier |

Benefits of Quality Accessories

Investing in high-quality add-ons can significantly enhance the overall performance and longevity of your equipment. These enhancements not only improve functionality but also ensure safer and more efficient operations, leading to better outcomes in various tasks.

Quality accessories contribute to a smoother experience, providing the necessary support for optimal performance. Users often find that these components are designed to fit perfectly, reducing the likelihood of malfunctions.

| Advantage | Description |

|---|---|

| Durability | High-grade materials ensure a longer lifespan and resilience against wear and tear. |

| Compatibility | Precision-engineered components offer seamless integration with existing tools. |

| Efficiency | Enhanced performance leads to quicker task completion and reduced effort. |

| Safety | Reliable accessories minimize risks associated with equipment failure. |

Comparing Different Models Available

When selecting a cutting tool for overhead tasks, it’s essential to consider the variations among the available options. Each model offers distinct features that cater to different user needs, ensuring efficiency and effectiveness in various applications.

Here are some key aspects to compare:

- Power Source: Options range from battery-operated to gas-powered models, each with its advantages in terms of runtime and performance.

- Bar Length: Different lengths are available, affecting the reach and cutting capability suitable for various environments.

- Weight: Lighter models provide ease of use and maneuverability, while heavier units may offer enhanced durability and power.

- Adjustable Features: Some tools come with adjustable angles or extendable shafts, increasing versatility for diverse cutting tasks.

Evaluating these factors will help you choose the right model that aligns with your specific requirements, ensuring a more productive and satisfying experience.

Recommendations for Effective Use

To maximize performance and ensure safety when utilizing trimming equipment, it is essential to follow best practices. Proper handling and maintenance not only enhance efficiency but also prolong the lifespan of the device.

Preparation and Safety Measures

- Always wear appropriate personal protective gear, including gloves, goggles, and hearing protection.

- Inspect the equipment before use to ensure all components are in good condition.

- Familiarize yourself with the user manual to understand operational guidelines and safety warnings.

Operational Tips

- Maintain a firm grip while operating, ensuring stability during use.

- Work in well-lit conditions to improve visibility and accuracy.

- Take breaks to avoid fatigue, which can lead to accidents.

Finding Authorized Repair Services

When it comes to maintaining your outdoor equipment, selecting certified service centers is crucial for ensuring longevity and optimal performance. These professionals possess the necessary expertise and access to genuine components, which guarantees that your tools remain in peak condition.

Benefits of Authorized Centers

Choosing an authorized repair location provides several advantages. Trained technicians have a deep understanding of the specific models, enabling them to diagnose issues accurately. Additionally, they often use original manufacturer components, which can enhance the reliability and efficiency of repairs.

How to Locate Certified Services

To find certified service centers, start by visiting the official website of the manufacturer. They typically provide a directory of authorized locations. Furthermore, local equipment retailers may offer recommendations based on their partnerships with certified repair shops.