Maintaining the efficiency of small engines requires a thorough comprehension of their essential components. Knowledge of how these elements interact is crucial for troubleshooting and repair, ensuring optimal performance over time.

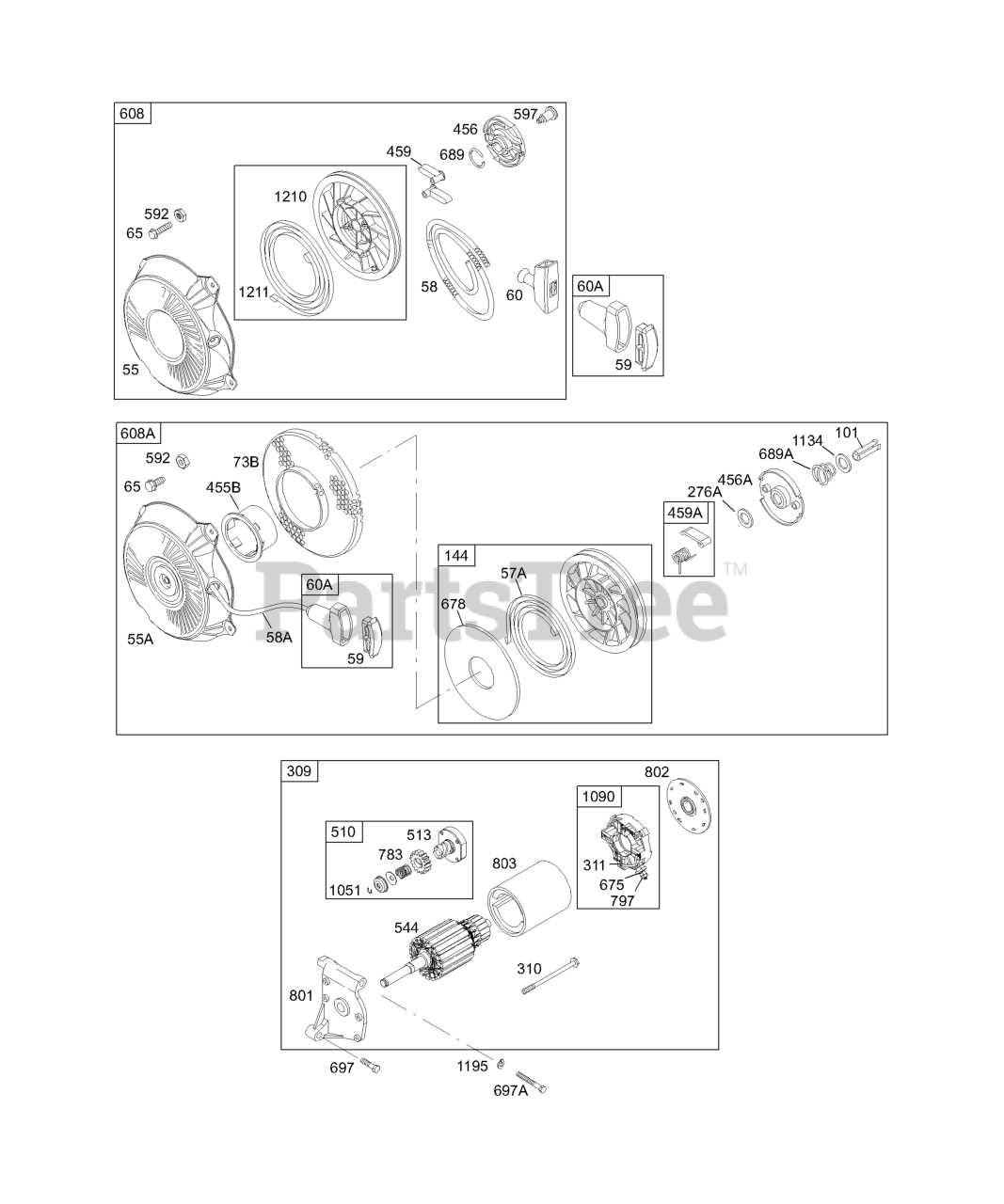

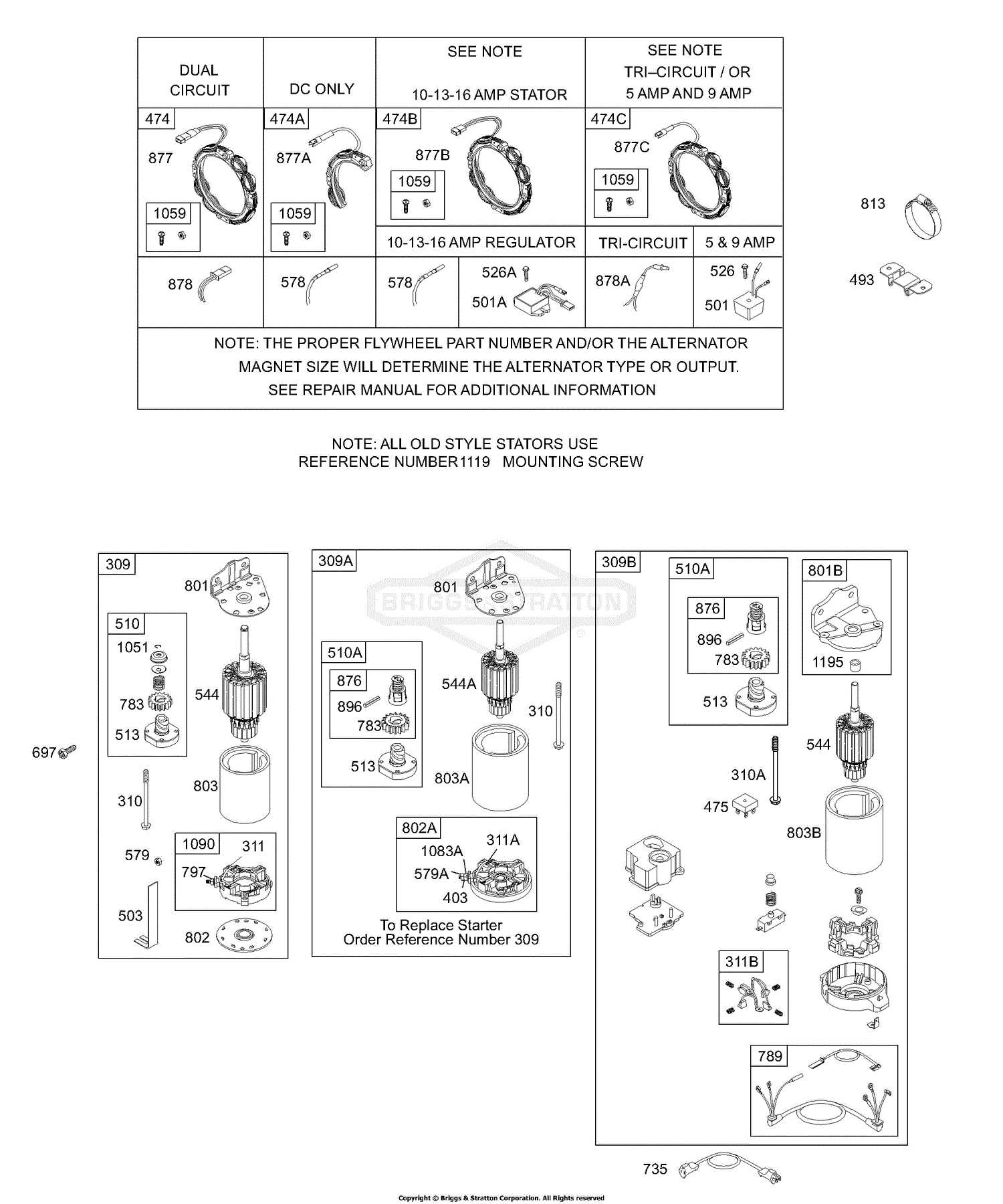

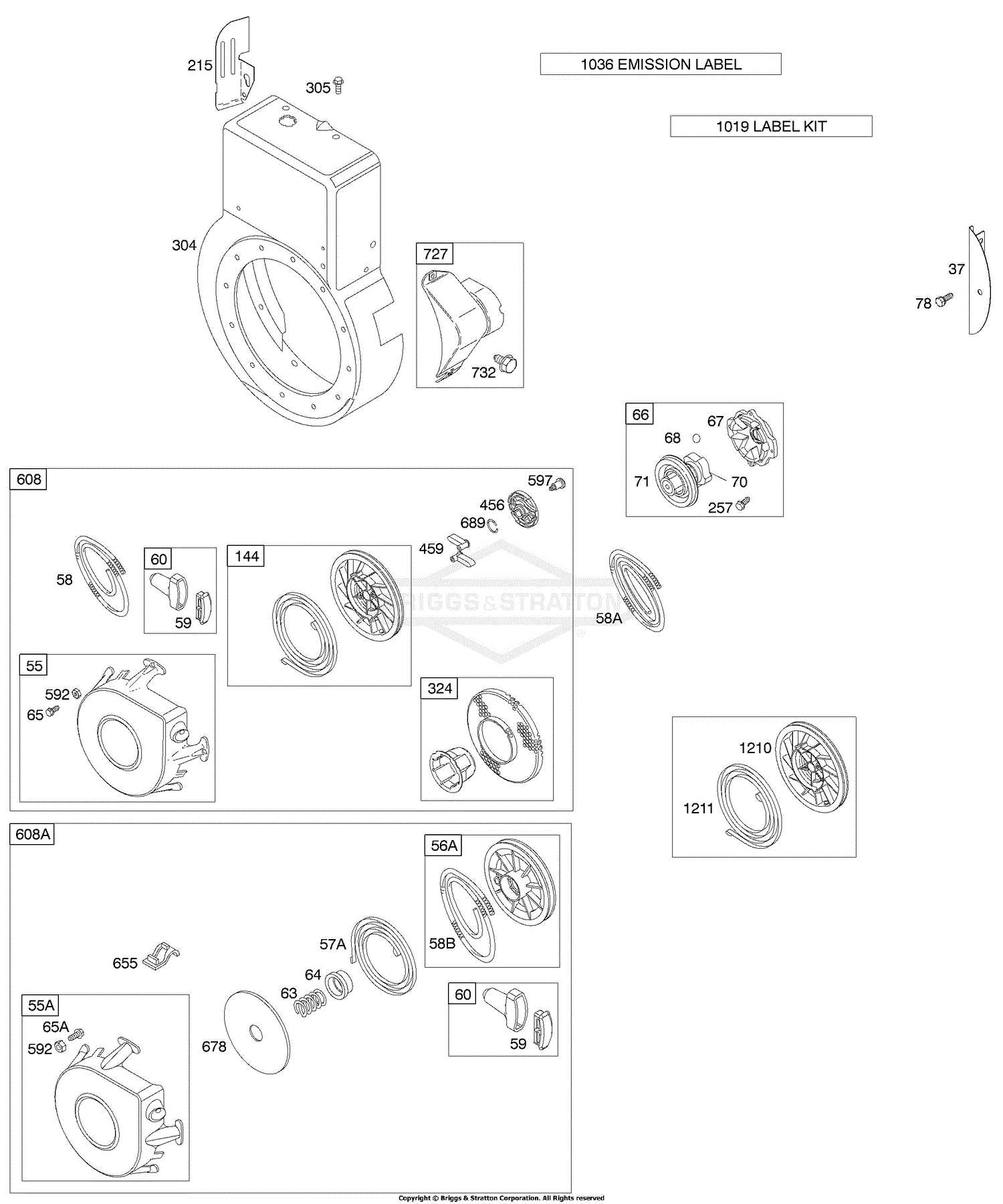

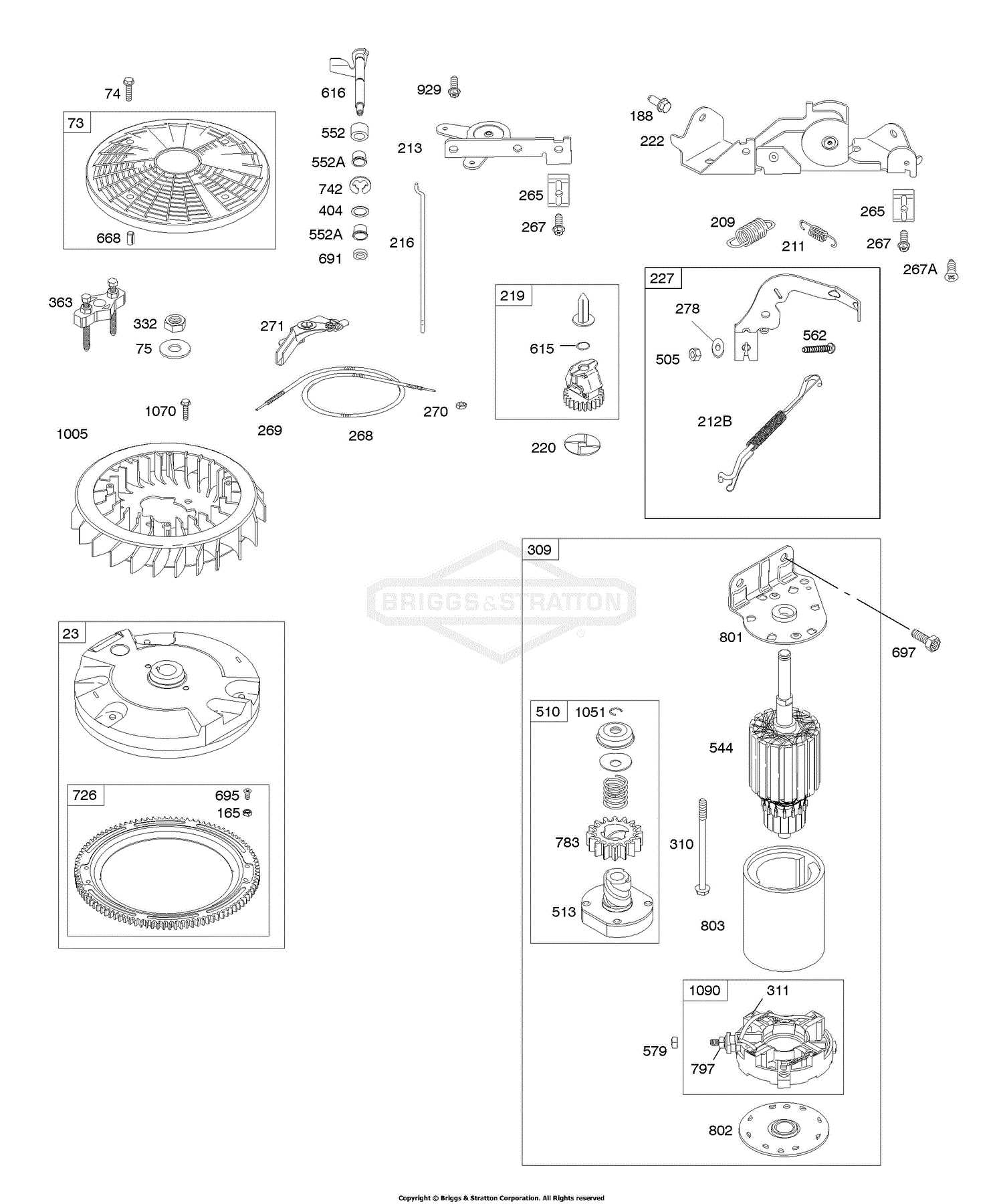

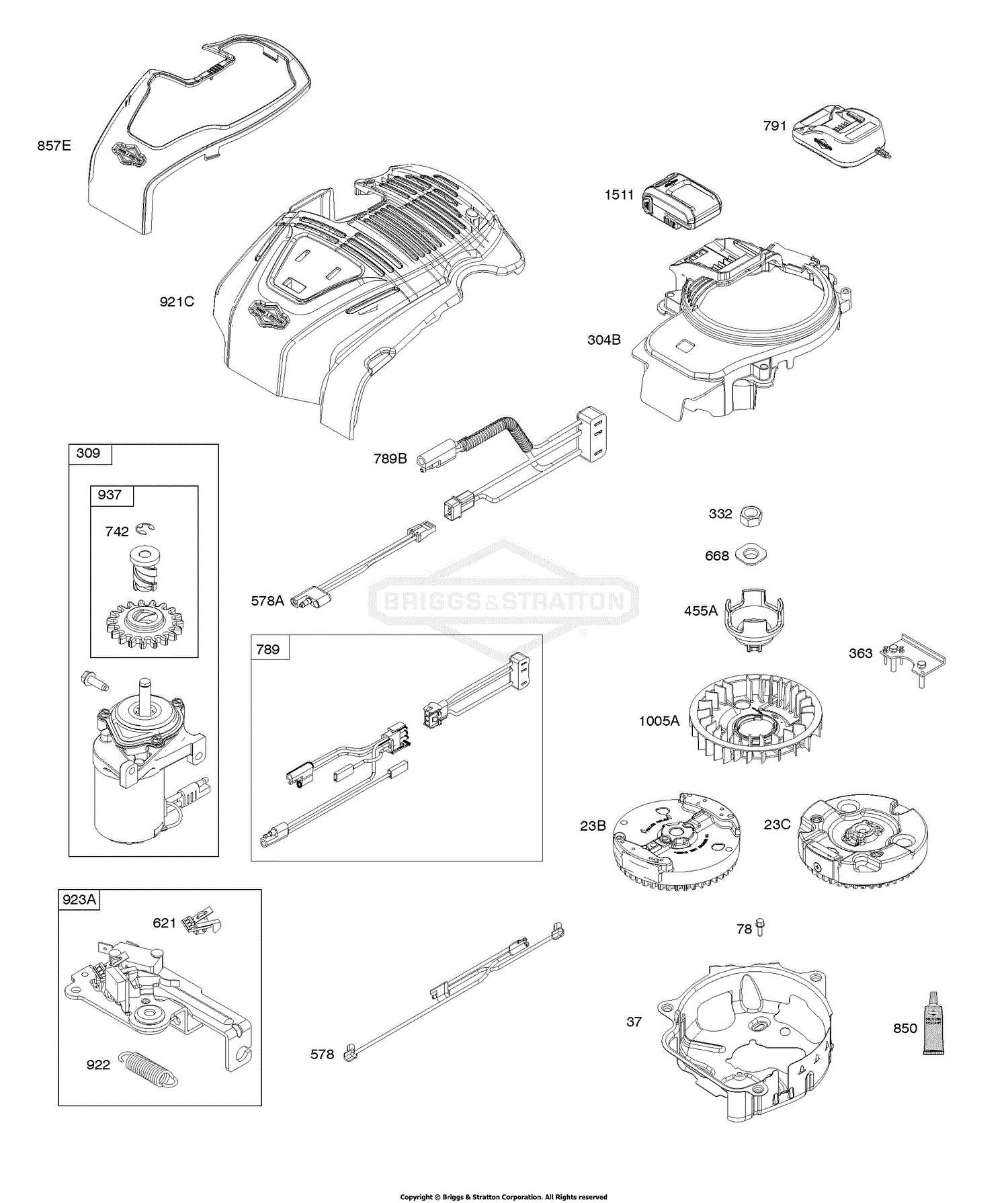

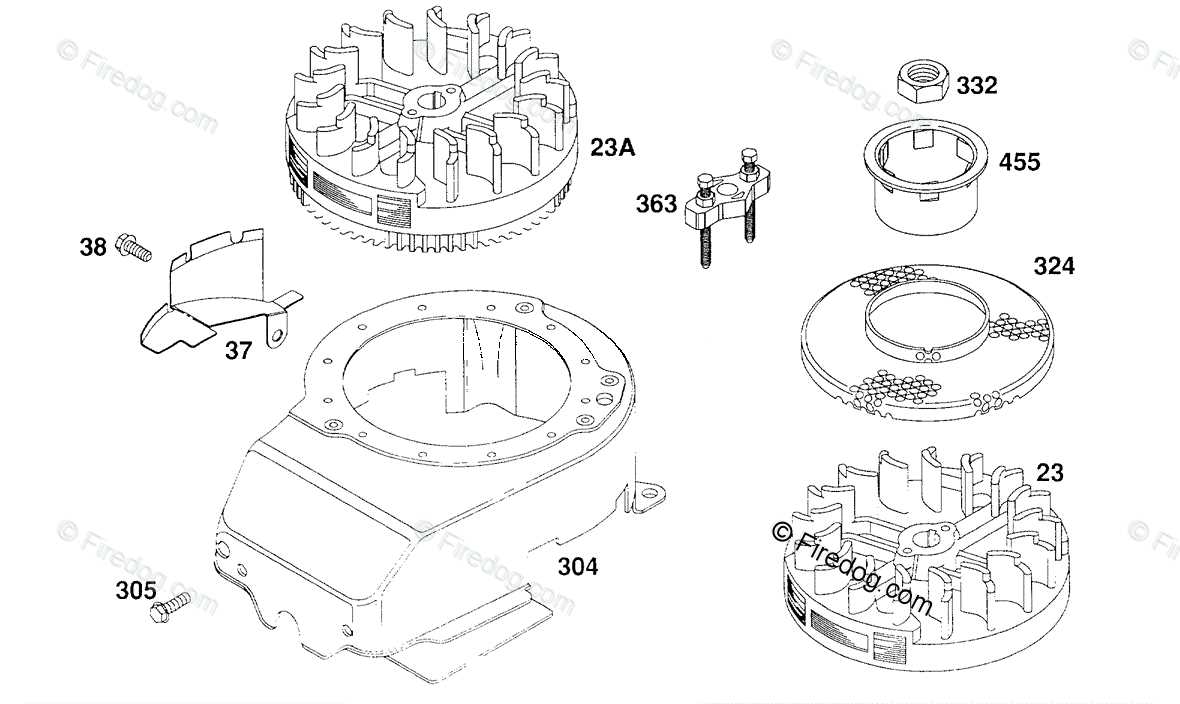

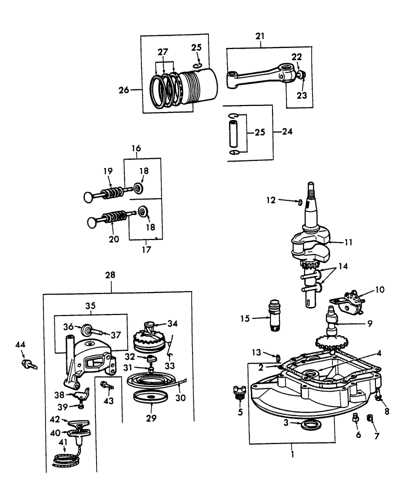

Visual representation of these critical elements can significantly aid in identifying issues and understanding assembly. By examining illustrations, users can grasp the relationship between various components, enabling informed decisions during repairs.

Moreover, having access to detailed schematics can enhance your ultimate maintenance strategy. This resource not only demystifies complex mechanisms but also empowers individuals to engage confidently with their equipment.

Understanding Starter Components for Briggs and Stratton

Comprehending the key elements involved in the ignition mechanism is essential for ensuring optimal performance in small engines. These components work in unison to facilitate the initiation of the engine, providing the necessary energy to start the combustion process. A thorough knowledge of these parts can significantly enhance maintenance and troubleshooting efforts.

The main component typically includes a motor that converts electrical energy into mechanical force. This energy is crucial for engaging the flywheel, which subsequently propels the engine into action. Additionally, gear systems play a vital role, allowing the motor to transmit power effectively while minimizing wear and tear on the parts involved.

Moreover, solenoids are integral to the operation, acting as electrical switches that control the flow of current to the motor. Understanding their function can aid in diagnosing issues related to starting failures. Regular inspection of these elements can prevent complications, ensuring reliable operation during critical moments.

Ultimately, familiarity with these essential components leads to better maintenance practices, prolonging the lifespan of the engine and enhancing overall efficiency. Recognizing signs of wear or failure can empower users to address issues promptly, maintaining the integrity of their equipment.

Key Parts of the Starter System

The initiation mechanism of an engine comprises several critical components that work harmoniously to ensure smooth operation. Understanding these elements is essential for efficient maintenance and troubleshooting.

Solenoid plays a pivotal role by acting as a relay that transmits electrical current to the motor. When engaged, it connects the battery to the engine’s cranking unit.

Motor is the heart of the system, responsible for generating the rotational force needed to initiate the engine’s combustion process. Its efficiency directly impacts the overall functionality.

Gear assembly connects the motor to the flywheel, facilitating the transfer of energy. A well-functioning gear mechanism ensures proper engagement and disengagement during operation.

Switch is the user interface that allows activation of the system. Its reliability is crucial for a seamless start, as it triggers the entire sequence of events.

Regular inspection and understanding of these key components can ultimately enhance performance and longevity of the engine’s initiation system.

How to Read a Starter Diagram

Understanding the layout and function of components in a mechanical system is crucial for effective troubleshooting and maintenance. A visual representation of these elements provides a clear guide, allowing users to identify parts and their relationships. Familiarity with these schematics can simplify repair processes and enhance overall knowledge of the machinery.

Key Components to Identify

- Motor: The primary unit that drives the mechanism.

- Solenoid: Acts as a switch to engage the motor.

- Battery: Provides the electrical power necessary for operation.

- Wiring: Connects various components, facilitating electrical flow.

- Connections: Points where parts join, often marked for clarity.

Steps to Interpret the Visual

- Examine the Legend: Many schematics include a key that explains symbols and color codes.

- Trace the Flow: Follow lines to see how energy moves through the system.

- Identify Connections: Look for junctions to understand how parts interact.

- Note Specifications: Pay attention to any labeled voltages or current ratings for safety.

- Consult Documentation: Use manuals or online resources for additional information if needed.

Common Issues with Starter Parts

When it comes to the ignition system of small engines, several challenges can arise that may hinder performance. These complications often stem from wear and tear, environmental factors, or improper maintenance. Understanding these issues is crucial for effective troubleshooting and ensuring smooth operation.

Electrical Failures: One of the most frequent problems is related to electrical components. Corroded terminals, damaged wires, or weak connections can prevent the system from functioning properly, leading to starting difficulties. Regular inspections can help identify these issues early.

Mechanical Wear: Over time, moving elements may experience significant wear. This deterioration can lead to misalignment or reduced efficiency, making it essential to check for any signs of physical damage. Replacing worn components can restore optimal performance.

Fuel Blockages: Another common issue involves fuel delivery. Clogged filters or lines can disrupt the flow of fuel, resulting in starting problems. Ensuring a clean fuel system is vital for consistent ignition.

Environmental Factors: Conditions such as extreme temperatures can also impact the functionality of the ignition system. Cold weather, for example, can affect battery performance and overall responsiveness. Taking appropriate precautions can mitigate these effects.

Improper Maintenance: Neglecting routine checks can lead to cumulative problems. Regular maintenance, including cleaning and lubrication, is essential for preventing issues and extending the lifespan of the system.

Tools Needed for Repairs

To effectively conduct maintenance or repairs on your machinery, having the right instruments is crucial. A well-equipped toolkit not only simplifies the process but also ensures precision and safety. Below are essential implements you should consider having on hand.

Wrenches are vital for loosening and tightening various components. A set of adjustable wrenches will provide versatility for different sizes of fasteners.

Screwdrivers are necessary for removing or securing screws. A selection of both flathead and Phillips head types will cover most needs.

Pliers, including needle-nose and slip-joint varieties, offer the ability to grip and manipulate small objects or wires effectively.

Torque Wrench is important for applying the correct amount of force to nuts and bolts, preventing damage to the parts being worked on.

Safety Gear, such as gloves and goggles, is essential to protect yourself during any repair activities, ensuring that you can work safely and efficiently.

Lastly, having a good quality flashlight or work light will help illuminate dark areas, allowing you to see what you are doing clearly. With these tools, you will be well-prepared to tackle any repair job with confidence.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. Implementing simple maintenance practices can significantly extend the life of your machinery, enhance performance, and reduce the likelihood of unexpected breakdowns. A proactive approach to upkeep is essential for optimal functionality.

Regular Inspections

Conduct routine checks to identify potential issues before they escalate. Look for signs of wear, leaks, or unusual noises. This early detection can prevent costly repairs and keep your device operating smoothly. Make it a habit to inspect key components, ensuring they are free from debris and functioning correctly.

Proper Cleaning

Keeping your equipment clean is crucial for preventing buildup that can impair performance. Use a soft cloth to wipe down surfaces, and ensure that air vents remain unobstructed. Regular cleaning not only improves efficiency but also contributes to a longer lifespan by reducing the risk of overheating or other damage.

In summary, consistent inspections and cleaning are vital for maintaining equipment in peak condition. By adopting these practices, you can enjoy reliable operation and extend the overall lifespan of your machinery.

Identifying Compatible Replacement Parts

Ensuring the right fit for your machinery components is crucial for optimal performance. Selecting the correct replacements not only enhances efficiency but also extends the lifespan of your equipment.

Here are key considerations when identifying suitable alternatives:

- Consult manufacturer specifications for compatibility details.

- Examine the model number of your equipment to find matching items.

- Check online resources and forums for recommendations from other users.

Ultimately, investing time in thorough research will save you from potential issues down the line.

Safety Precautions During Repairs

When undertaking mechanical maintenance, prioritizing safety is essential to prevent accidents and ensure effective repairs. Adhering to specific guidelines can safeguard both the technician and the equipment.

- Always wear protective gear, including gloves and goggles.

- Ensure the engine is cool and the equipment is turned off before beginning work.

- Disconnect the power source to avoid unintentional activation.

- Keep your workspace tidy to minimize hazards.

- Use tools properly and inspect them regularly for wear.

By following these precautions, individuals can create a secure environment conducive to effective maintenance.

Step-by-Step Starter Assembly Guide

This section provides a comprehensive guide to assembling the essential components needed for the ignition mechanism of your engine. By following these detailed instructions, you can ensure a smooth and efficient assembly process, leading to optimal performance.

Gathering Necessary Tools and Components

Before beginning the assembly, collect all required tools and components. Ensure you have a reliable screwdriver, wrenches, and any specific items necessary for your model. Having everything at hand will streamline the process and prevent interruptions.

Assembly Process

Start by aligning the main housing with the drive mechanism. Secure each piece carefully, ensuring that all connections fit snugly. Next, install the electrical connections, verifying they are properly attached to prevent any power issues. Once everything is in place, conduct a thorough check to confirm that all components are securely fastened and functioning correctly.

Frequently Asked Questions on Starters

This section addresses common inquiries related to ignition mechanisms in outdoor power equipment. Understanding these components can help users troubleshoot issues and maintain their machinery effectively.

What are the signs of a failing ignition mechanism?

Typical indicators include unusual noises when attempting to initiate the device, a complete lack of response, or slow cranking. If the mechanism seems sluggish or struggles to engage, it may need inspection or replacement.

How can I maintain my ignition system?

Regular maintenance is crucial for longevity. Keep the area clean, check connections for corrosion, and lubricate moving parts. Periodically testing the mechanism can help catch potential issues before they escalate.

Pro tip: Always refer to the user manual for specific maintenance guidelines tailored to your equipment model.

Resources for Further Learning

Exploring additional materials can enhance your understanding and skills related to engine mechanisms. Various sources provide insights and practical guidance for enthusiasts and professionals alike.

Online Tutorials and Courses

- Video platforms offering step-by-step guides

- Online educational websites with structured courses

- Forums where experts share knowledge and tips

Books and Manuals

- Technical manuals detailing specific engine models

- Guides on maintenance and repair techniques

- Reference books covering broader mechanical concepts