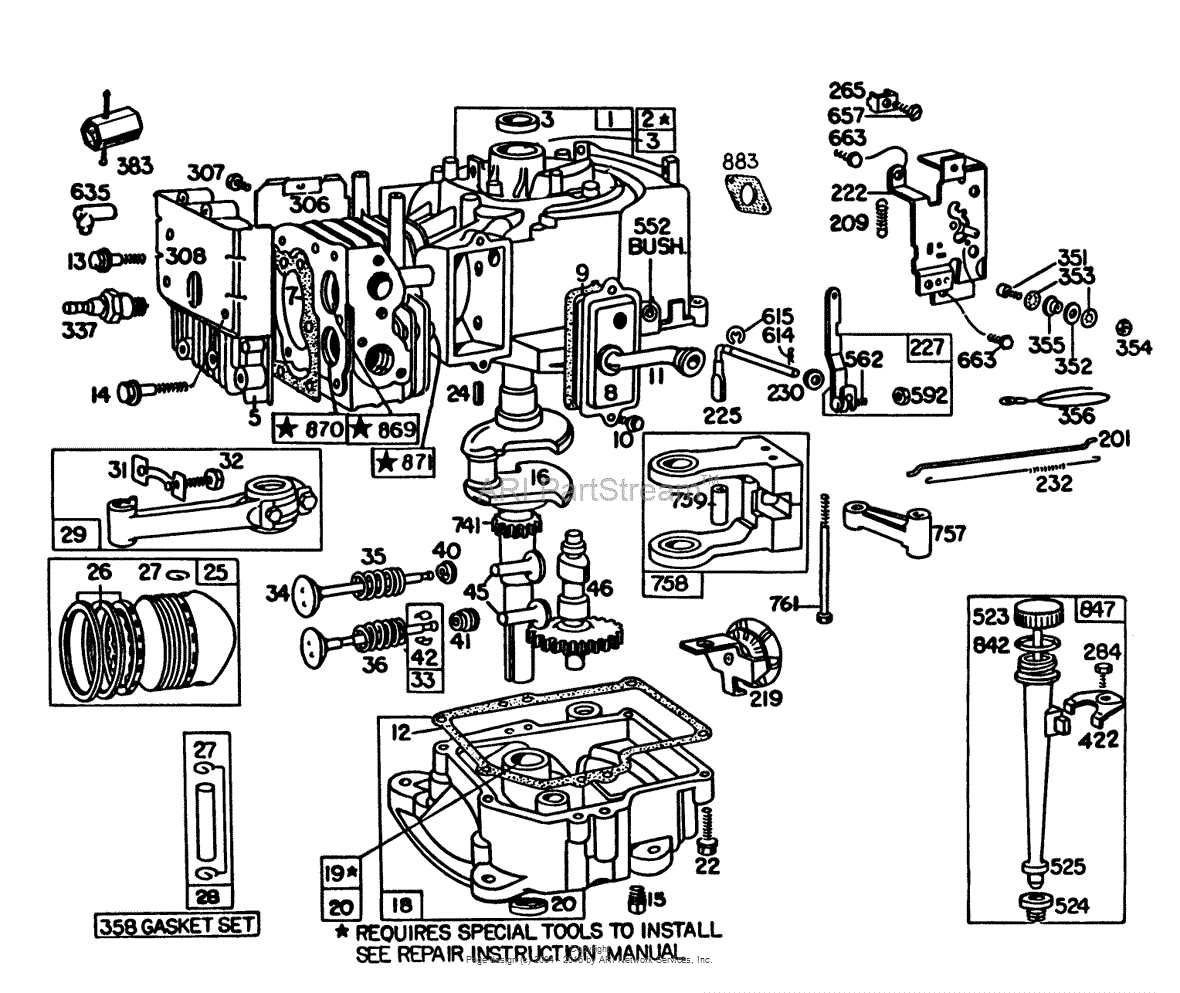

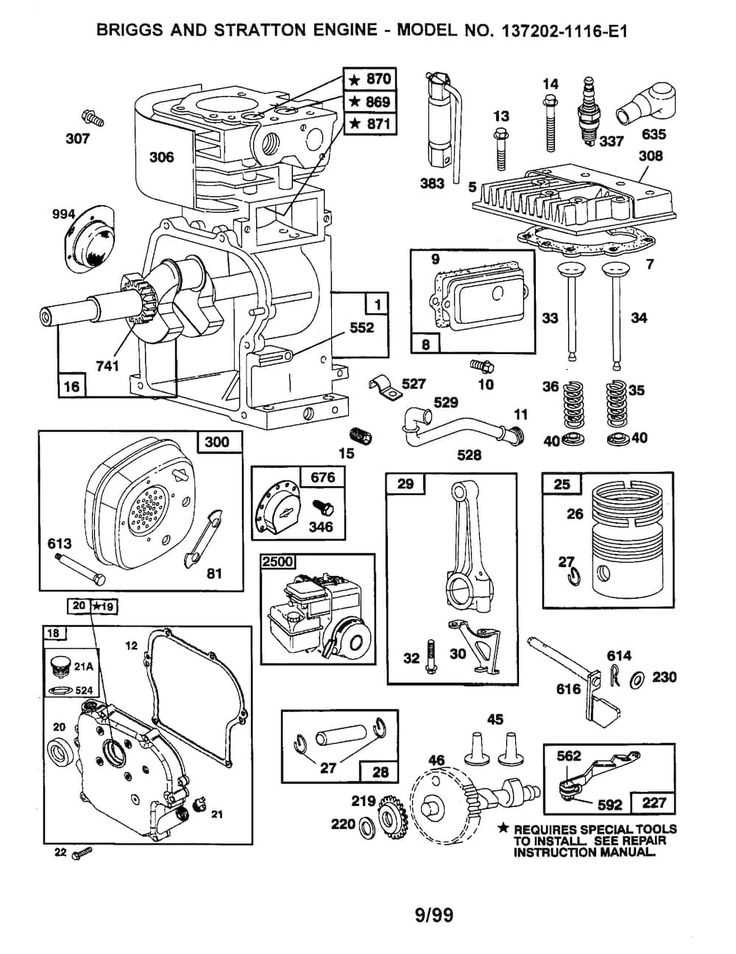

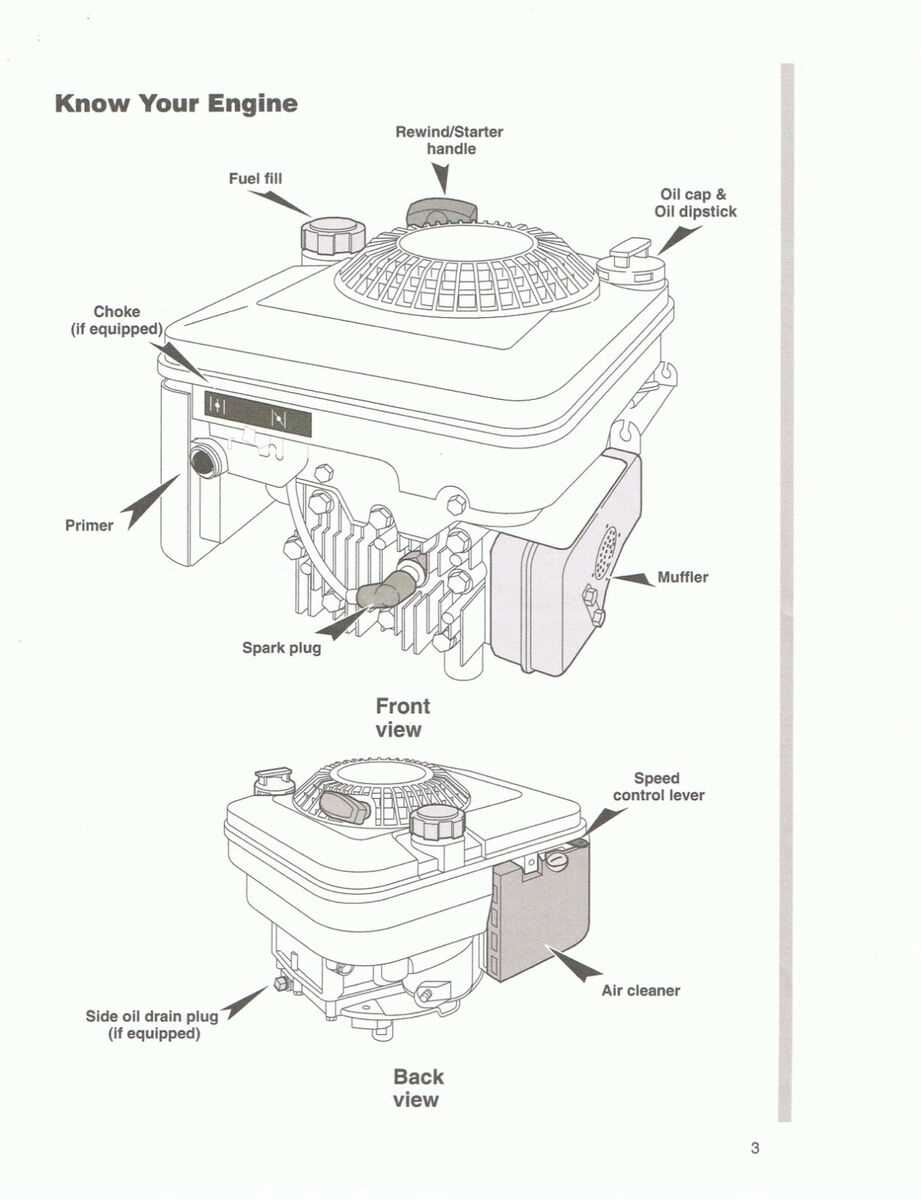

The inner workings of small engines are intricate and require a comprehensive understanding of their various components. Each part plays a vital role in ensuring optimal performance and efficiency. Familiarizing oneself with the layout of these elements can significantly aid in troubleshooting and maintenance tasks.

In this section, we will explore a visual representation of the essential components of a specific small engine model. By analyzing the arrangement and functionality of each element, users can gain valuable insights into the operational mechanics. This knowledge will not only assist in repairs but also enhance the overall user experience.

Whether you are a seasoned technician or a novice enthusiast, having a clear understanding of the configuration of engine elements is paramount. This resource aims to demystify the complexities involved, providing clarity and confidence in managing engine-related tasks effectively.

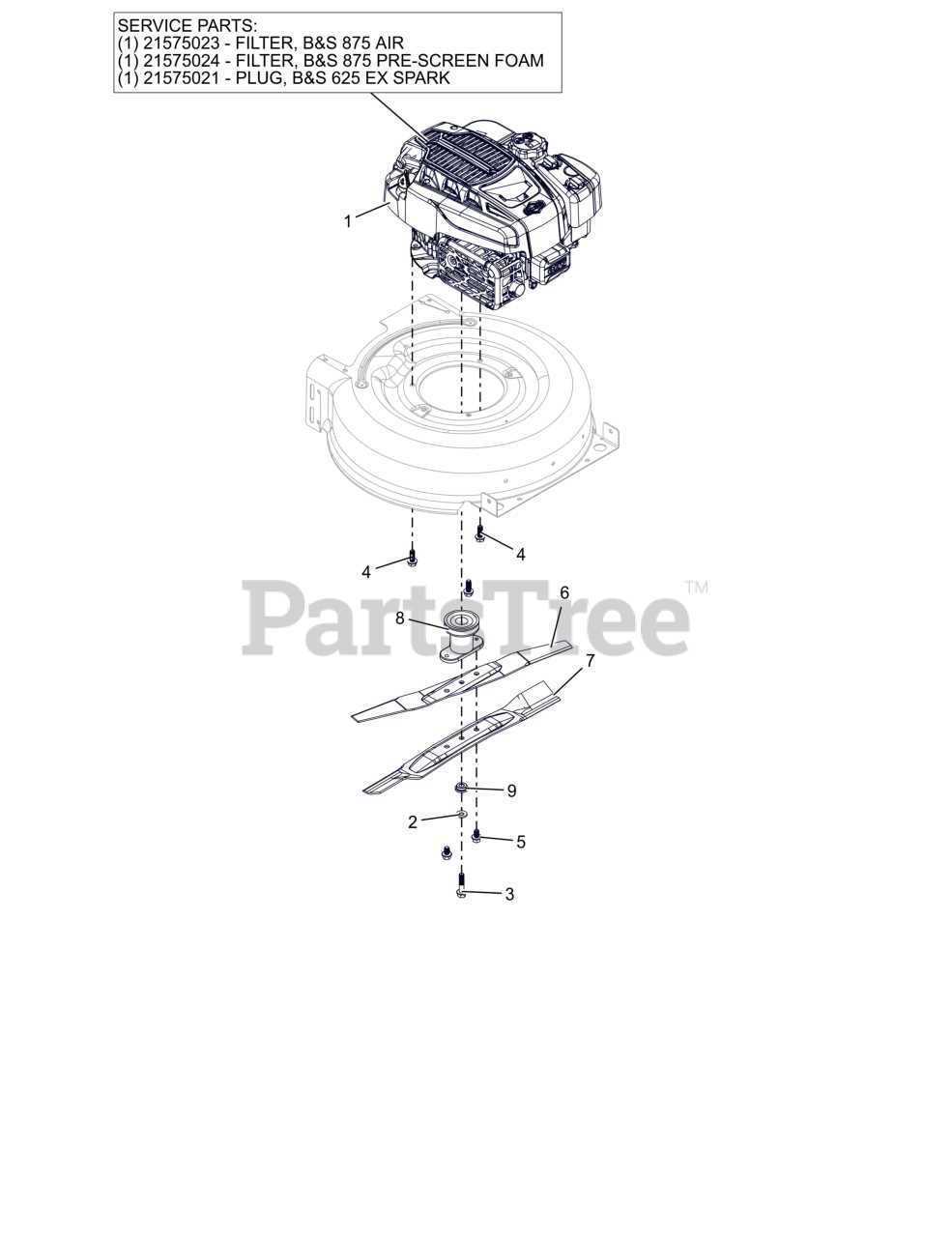

This section outlines a structured approach to exploring the various components associated with a popular engine model. Understanding these elements is crucial for effective maintenance and repairs, ensuring optimal performance and longevity.

- Introduction to Engine Components

- Essential Accessories for Operation

- Common Replacement Items

- Maintenance Tools and Their Uses

- Identifying Key Parts

- How to Properly Maintain Each Component

- Common Issues and Solutions

- Where to Find Quality Components

- Assembly and Disassembly Instructions

- Safety Precautions While Working

Essential Components of 625EX Engine

The efficient operation of a small engine relies on a variety of crucial elements that work together seamlessly. Understanding these fundamental components is vital for anyone looking to maintain or repair their engine. Each part plays a significant role in ensuring optimal performance and longevity.

Fuel System: This system is responsible for delivering the right amount of fuel to the engine, ensuring proper combustion. Key components include the fuel tank, fuel lines, and carburetor, all of which work together to maintain the necessary fuel flow.

Ignition System: A well-functioning ignition system is essential for starting the engine and keeping it running smoothly. This system typically comprises the spark plug, ignition coil, and flywheel magnet, all contributing to the ignition process.

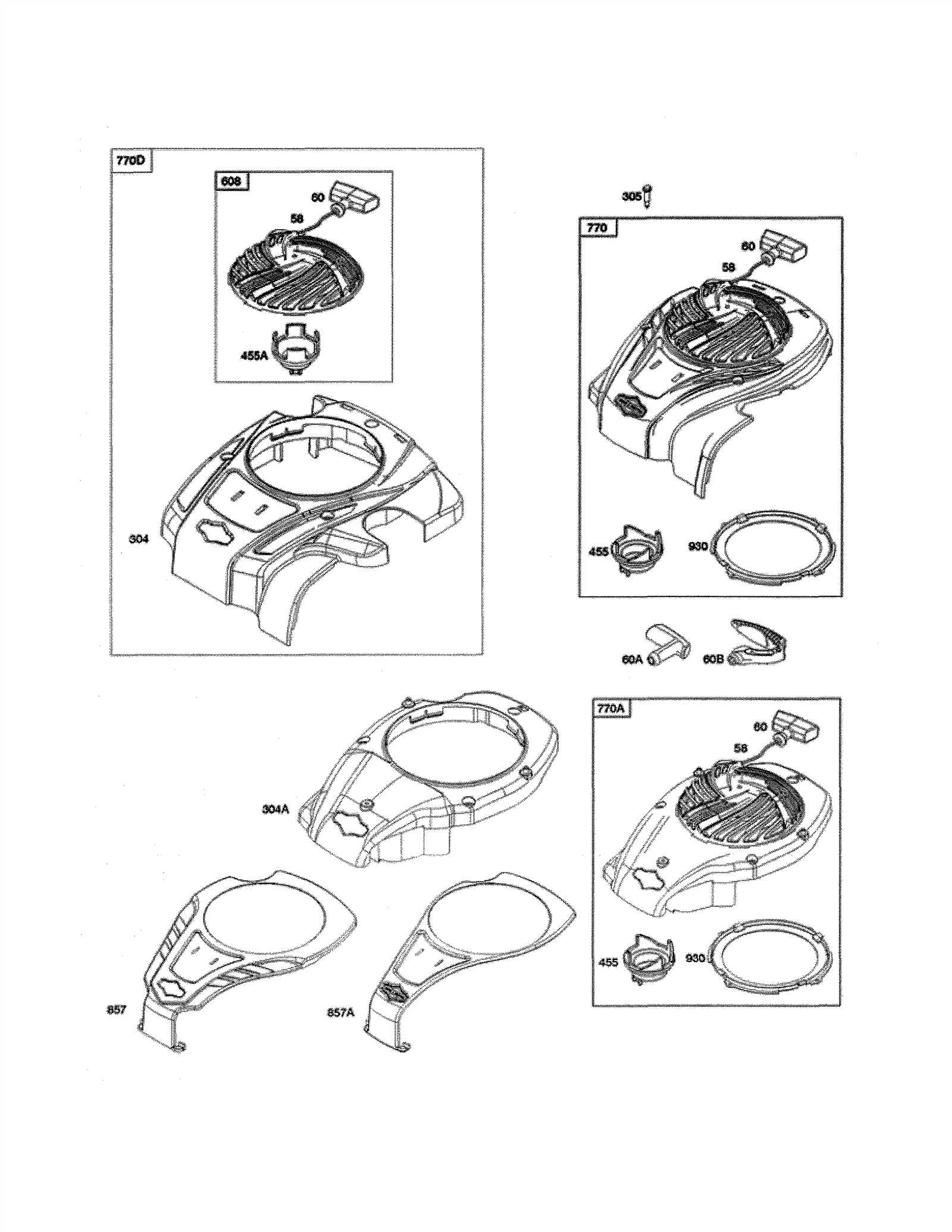

Cooling System: To prevent overheating, the engine utilizes a cooling system that includes a cooling fan and air intake. This system is crucial for maintaining optimal operating temperatures during use.

Crankshaft and Piston: The crankshaft converts the linear motion of the piston into rotational motion, which powers the engine. The piston compresses the fuel-air mixture, playing a vital role in the combustion process.

Exhaust System: After combustion, exhaust gases must be expelled efficiently. The exhaust system includes components like the muffler and exhaust pipe, which work together to reduce noise and direct harmful gases away from the engine.

Common Issues and Solutions

In the realm of small engines, various challenges may arise that can hinder performance and efficiency. Understanding these common problems and their respective solutions is essential for maintaining optimal functionality. This section aims to highlight frequent concerns and provide effective resolutions.

Engine Fails to Start

One of the most prevalent issues encountered is the engine’s failure to start. This can be caused by several factors, including fuel shortages, clogged filters, or spark plug malfunctions. To resolve this, ensure that the fuel tank is filled with fresh gasoline, check and replace any dirty filters, and inspect the spark plug for wear. Cleaning or replacing the spark plug can often restore functionality.

Overheating Problems

Overheating can lead to significant damage if not addressed promptly. This issue may arise from insufficient oil levels or debris obstructing airflow. To remedy overheating, regularly check the oil levels and ensure the engine is adequately lubricated. Additionally, cleaning any dirt or debris from the cooling fins and air intake can improve airflow and help prevent overheating.

Maintenance Tips for Optimal Performance

To ensure the best functionality of your outdoor equipment, regular maintenance is essential. This involves systematic checks and timely interventions to keep your machine running smoothly and efficiently. By adhering to a few simple guidelines, you can significantly extend the lifespan of your device and enhance its overall performance.

1. Regular Oil Changes: Frequent oil changes are crucial for maintaining engine health. Using high-quality oil and adhering to the recommended change intervals will help reduce wear and tear on engine components.

2. Clean Air Filters: A clean air filter is vital for optimal airflow and engine efficiency. Check and replace filters as needed to prevent debris from entering the engine, which can hinder performance.

3. Spark Plug Inspection: Inspecting and replacing spark plugs regularly can prevent starting issues and ensure smooth operation. Worn plugs can lead to misfires and decreased power.

4. Fuel Quality: Always use fresh, high-quality fuel to prevent clogs and deposits that can affect engine performance. Stale fuel can lead to starting problems and decreased efficiency.

5. Routine Cleaning: Keep the exterior of the machine clean to prevent rust and corrosion. Regularly remove dirt and debris from the housing to promote better airflow and cooling.

Implementing these maintenance tips will not only enhance the reliability of your equipment but also contribute to its long-term performance, ensuring that it operates at peak efficiency when you need it most.

How to Access Parts Diagrams

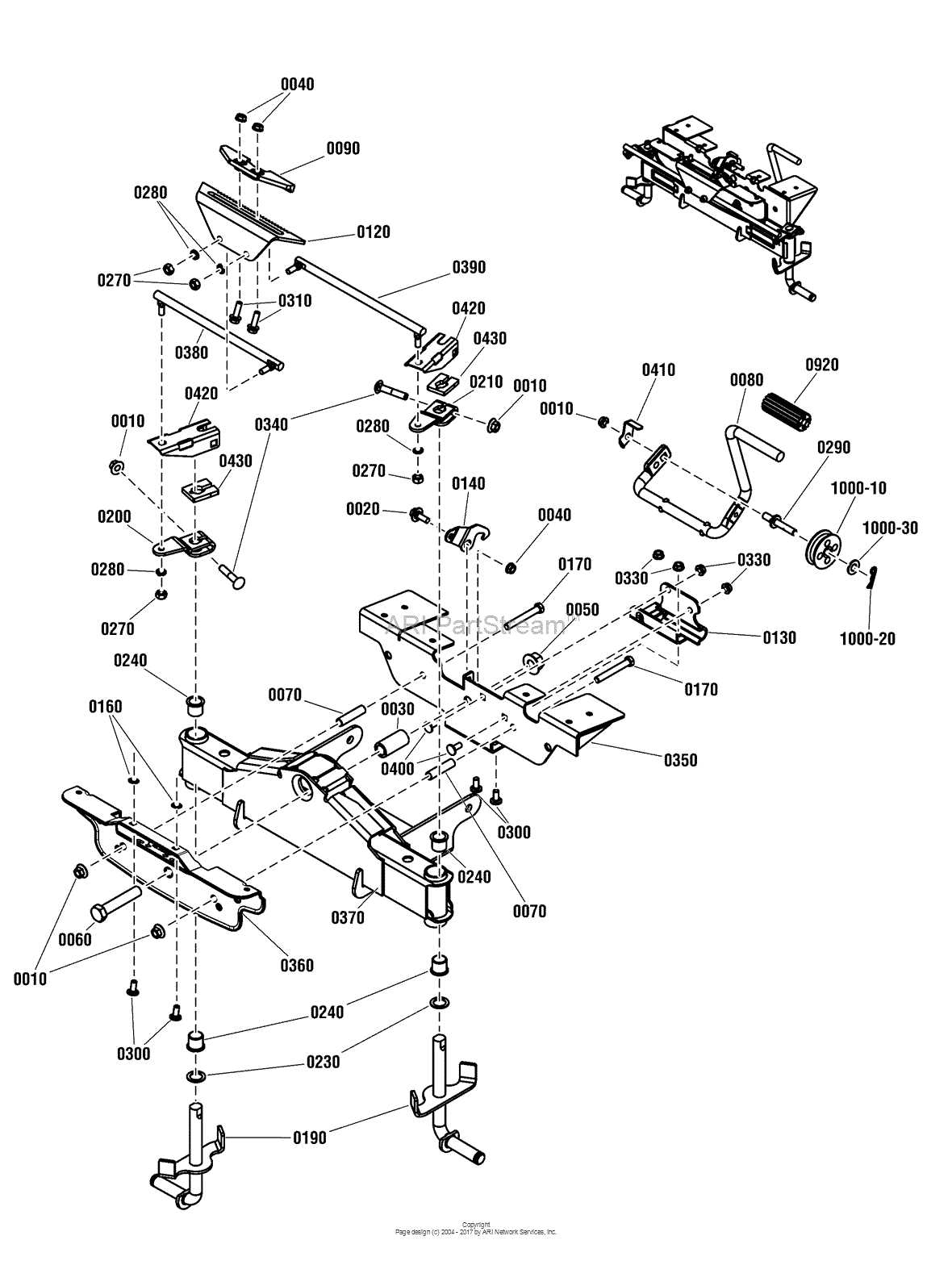

Accessing detailed schematics for your equipment can enhance your understanding and simplify maintenance tasks. These illustrations provide a visual reference for components, enabling efficient identification and replacement. Here’s how you can easily find these resources.

- Manufacturer’s Website: Visit the official site where you can often find a dedicated section for technical resources. Look for categories related to support or service manuals.

- Online Retailers: Many online stores that sell equipment may also host diagrams for various models. Search for your model number to locate specific schematics.

- User Forums: Community forums are excellent places to find shared resources. Users often upload diagrams and troubleshooting guides for reference.

- Instruction Manuals: Check the documentation that came with your equipment. Many manuals include simplified illustrations and breakdowns of parts.

Utilizing these resources can save time and ensure that you have the necessary information for repairs or replacements.

Identifying Replacement Parts Easily

When it comes to maintaining outdoor equipment, understanding how to find the correct components is essential for efficient repairs. With a systematic approach, identifying necessary items can become a straightforward task, ensuring your machinery runs smoothly and effectively.

Understanding Component Types

Each piece of machinery comprises various elements, each serving a distinct function. Familiarizing yourself with the different categories can greatly assist in pinpointing the specific items you need. For instance, components can range from filters and spark plugs to gaskets and belts.

Using Visual References

Visual aids can significantly enhance your ability to identify components. Diagrams and charts can provide a clear overview of each part’s location and its relationship with others. Below is a table summarizing common component types and their functions:

| Component Type | Function |

|---|---|

| Air Filter | Prevents dirt and debris from entering the engine. |

| Fuel Filter | Ensures clean fuel reaches the engine for optimal performance. |

| Oil Seal | Prevents leakage of lubricants and contaminants. |

| Spark Plug | Ignites the air-fuel mixture for combustion. |

Tools Needed for Repairs

Having the right tools is essential for effective maintenance and repairs of small engines. Proper equipment not only ensures efficiency but also enhances safety during the repair process.

Here is a list of essential tools that can assist in the repair and upkeep:

- Socket Set: A comprehensive socket set will allow you to tackle various nuts and bolts.

- Screwdriver Set: Both flathead and Phillips screwdrivers are necessary for disassembling components.

- Wrench Set: A range of wrenches will help you tighten or loosen fasteners effectively.

- Torque Wrench: This tool is crucial for ensuring that fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Useful for diagnosing electrical issues and checking voltage and continuity.

- Fuel Line Pliers: These specialized pliers make it easier to work with fuel lines without causing damage.

- Safety Gear: Always wear gloves and safety glasses to protect yourself during repairs.

With these tools at hand, you can confidently approach your repair tasks and maintain optimal performance.

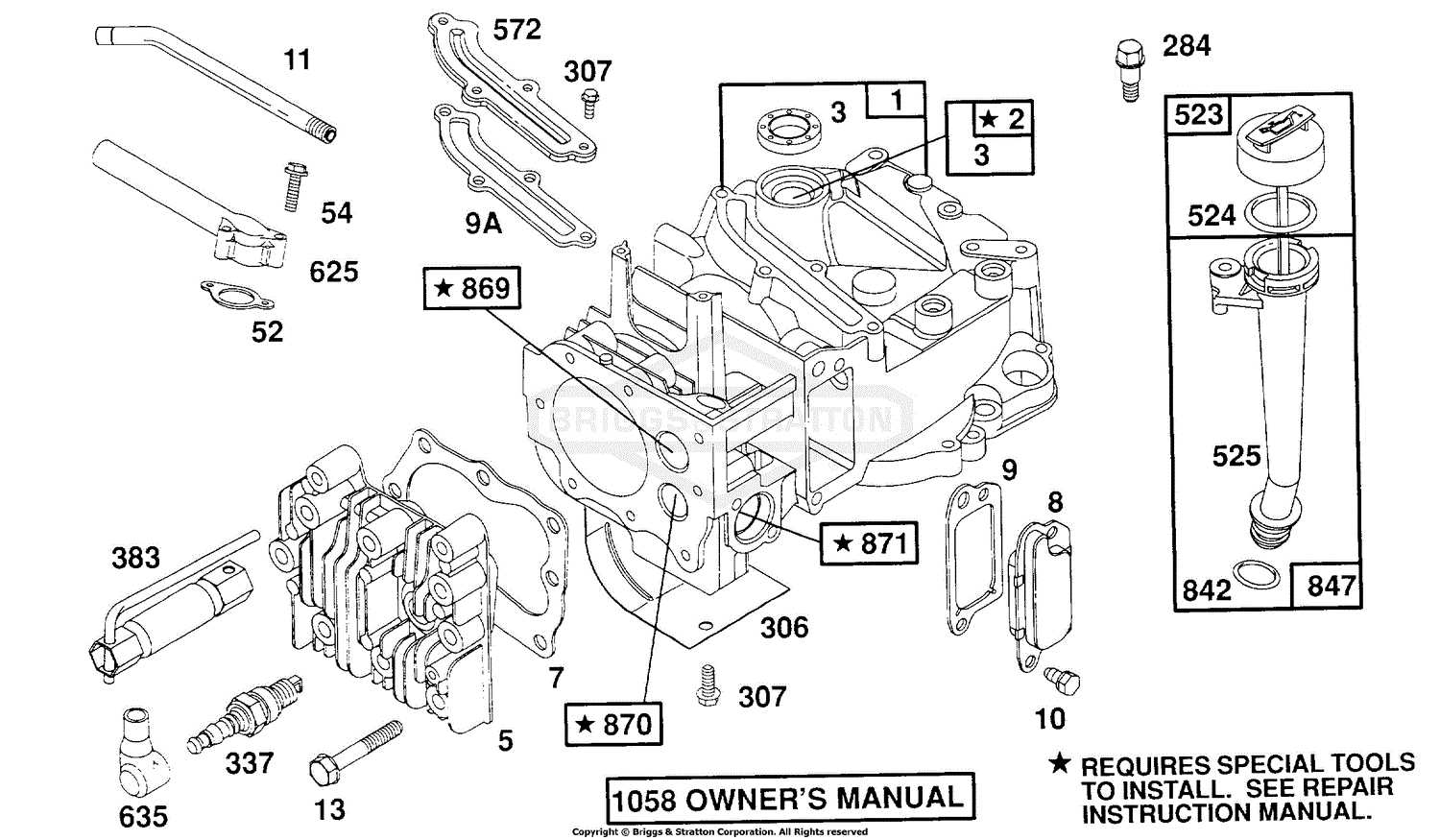

Steps for Engine Disassembly

Disassembling an engine is a crucial procedure for maintenance and repair. It involves carefully removing various components to access the internal parts. This process requires attention to detail and a systematic approach to ensure that everything is documented and organized for reassembly.

Preparation Before Disassembly

Prior to beginning the disassembly process, gather all necessary tools and materials. Ensure that the workspace is clean and free from clutter. Label all parts and fasteners to avoid confusion during reassembly. Following these preparatory steps can save time and prevent errors later on.

Disassembly Process

Begin the disassembly by removing the external components such as covers and filters. Gradually work your way to the core parts of the engine, taking care to keep track of the order in which components are removed. This methodical approach facilitates easier reassembly and helps identify any worn or damaged parts.

| Step | Description |

|---|---|

| 1 | Gather tools and materials. |

| 2 | Label parts and fasteners. |

| 3 | Remove external components. |

| 4 | Access internal parts systematically. |

| 5 | Document condition of each component. |

Reassembling the 625EX Engine

Reassembling an engine requires careful attention to detail and a systematic approach to ensure all components fit together seamlessly. This process is crucial for restoring the engine’s functionality and longevity. By following the steps outlined below, you can achieve a successful reassembly that meets operational standards.

Preparing for Reassembly

Before starting the reassembly, ensure that all components are clean and free from debris. Inspect each part for wear and damage, replacing any that do not meet quality standards. Organizing your tools and parts will streamline the process, allowing for a more efficient assembly.

Step-by-Step Assembly Process

Begin the assembly by placing the crankcase in a secure position. Carefully install the crankshaft, ensuring it aligns properly with the bearings. Next, attach the cylinder head, securing it with the appropriate fasteners. Pay special attention to the torque specifications to prevent future issues. Finally, reattach all external components, such as the fuel system and ignition, following the manufacturer’s guidelines for optimal performance.

In conclusion, meticulous reassembly will contribute to the overall efficiency and reliability of your engine, enabling it to perform at its best for years to come.

Safety Precautions During Maintenance

Ensuring safety while conducting maintenance on equipment is crucial for both personal well-being and the longevity of the machinery. By adhering to essential guidelines, users can prevent accidents and enhance their understanding of proper handling procedures.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the machine is powered off and disconnected from any energy sources before beginning maintenance.

- Work in a well-ventilated area to avoid inhaling fumes or dust particles.

- Keep the workspace organized and free from clutter to reduce the risk of tripping or falling.

Handling Tools and Equipment

- Use the correct tools for each task to avoid damaging components or causing injury.

- Inspect tools regularly for wear and tear, replacing any damaged items immediately.

- Store tools properly after use to prevent accidents and maintain organization.

- Be cautious of sharp edges and moving parts during the maintenance process.

Where to Find Genuine Parts

Locating authentic components for your engine can be a challenging task. It’s essential to ensure that the replacements you choose are of high quality to maintain optimal performance and longevity. Numerous sources provide access to original elements, which can enhance the functionality of your equipment.

Here are some reliable options for sourcing genuine components:

| Source | Description |

|---|---|

| Authorized Dealers | Visit local authorized retailers for certified products that meet the manufacturer’s standards. |

| Online Retailers | Many reputable e-commerce platforms offer a wide selection of original components, often with customer reviews to guide your choice. |

| Manufacturer’s Website | Check the official site for direct purchases and detailed information on available items. |

| Repair Shops | Local repair services often stock genuine items and can assist with installation and maintenance. |