The intricate workings of engine fuel systems play a crucial role in ensuring optimal performance and efficiency. A comprehensive overview of these elements allows enthusiasts and technicians alike to grasp the importance of each piece in the assembly. With a clear understanding, one can enhance maintenance practices and troubleshooting techniques.

Visual representations of these elements can provide invaluable insight into their arrangement and function. By exploring the layout and interconnections, users can better appreciate how these components interact to deliver the necessary fuel mixture for combustion. Such knowledge is not only beneficial for repairs but also enhances the overall experience of engine care.

In this guide, we aim to delve into the key features and functions of these vital components. The ultimate goal is to equip readers with the understanding needed to navigate maintenance challenges confidently, ensuring that their engines run smoothly and efficiently.

Understanding Briggs and Stratton Carburetors

Comprehending the functionality of engine fuel management systems is essential for effective maintenance and performance. These mechanisms play a pivotal role in ensuring optimal air-fuel mixture for combustion, which directly affects efficiency and power output.

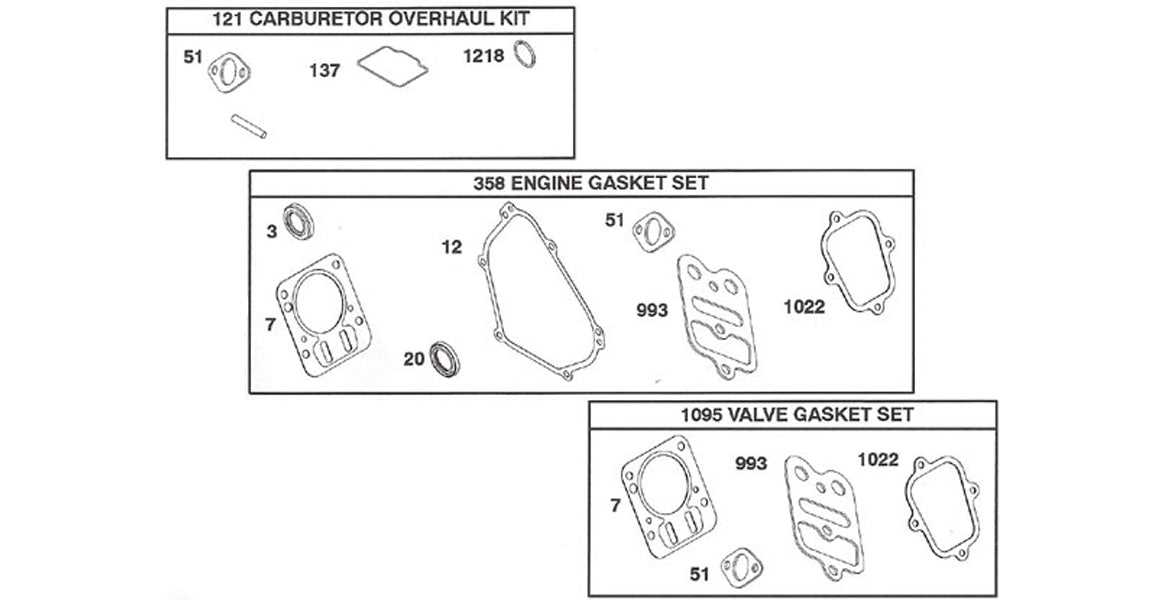

Key Components

- Fuel Bowl: Stores the fuel for delivery.

- Throttle Plate: Controls air intake and engine speed.

- Venturi: Facilitates air-fuel mixing.

- Diaphragm: Regulates fuel flow based on engine demand.

Common Issues

- Clogged passages affecting fuel flow.

- Worn gaskets leading to air leaks.

- Improper adjustments causing performance issues.

By understanding these aspects, users can enhance their knowledge and tackle maintenance challenges effectively.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate relationships within machinery. They serve as essential tools for both beginners and experienced technicians, enabling them to identify specific elements and their functions. This clarity enhances repair efficiency and overall maintenance practices.

Enhanced Understanding

Detailed visuals allow users to grasp the layout and assembly of intricate mechanisms. With a clear view, one can more easily troubleshoot issues and perform necessary replacements or repairs.

Streamlined Repairs

Accessing accurate visual references minimizes the time spent searching for information. This leads to quicker resolution of problems, ensuring equipment runs smoothly and effectively, thus optimizing performance.

Common Carburetor Issues Explained

Understanding the frequent complications that arise in fuel delivery systems is essential for effective maintenance and troubleshooting. These challenges can lead to performance problems, affecting the efficiency and reliability of small engines. Recognizing symptoms and their causes can significantly aid in restoring optimal function.

Symptoms and Causes

Various indicators signal underlying issues within the fuel system. Common signs include irregular engine performance, difficulty starting, or unexpected shutdowns. These problems often stem from factors such as contamination, incorrect adjustments, or wear over time.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Clogged fuel passage | Inspect and clean the fuel routes |

| Poor acceleration | Incorrect air-fuel mixture | Adjust mixture settings |

| Excessive smoke | Flooding | Check float and needle valve |

Prevention Tips

To minimize the likelihood of these issues, regular maintenance is crucial. Ensuring clean fuel, periodic inspections, and timely replacements of worn components can help sustain functionality. Taking proactive measures will lead to smoother operation and longer service life.

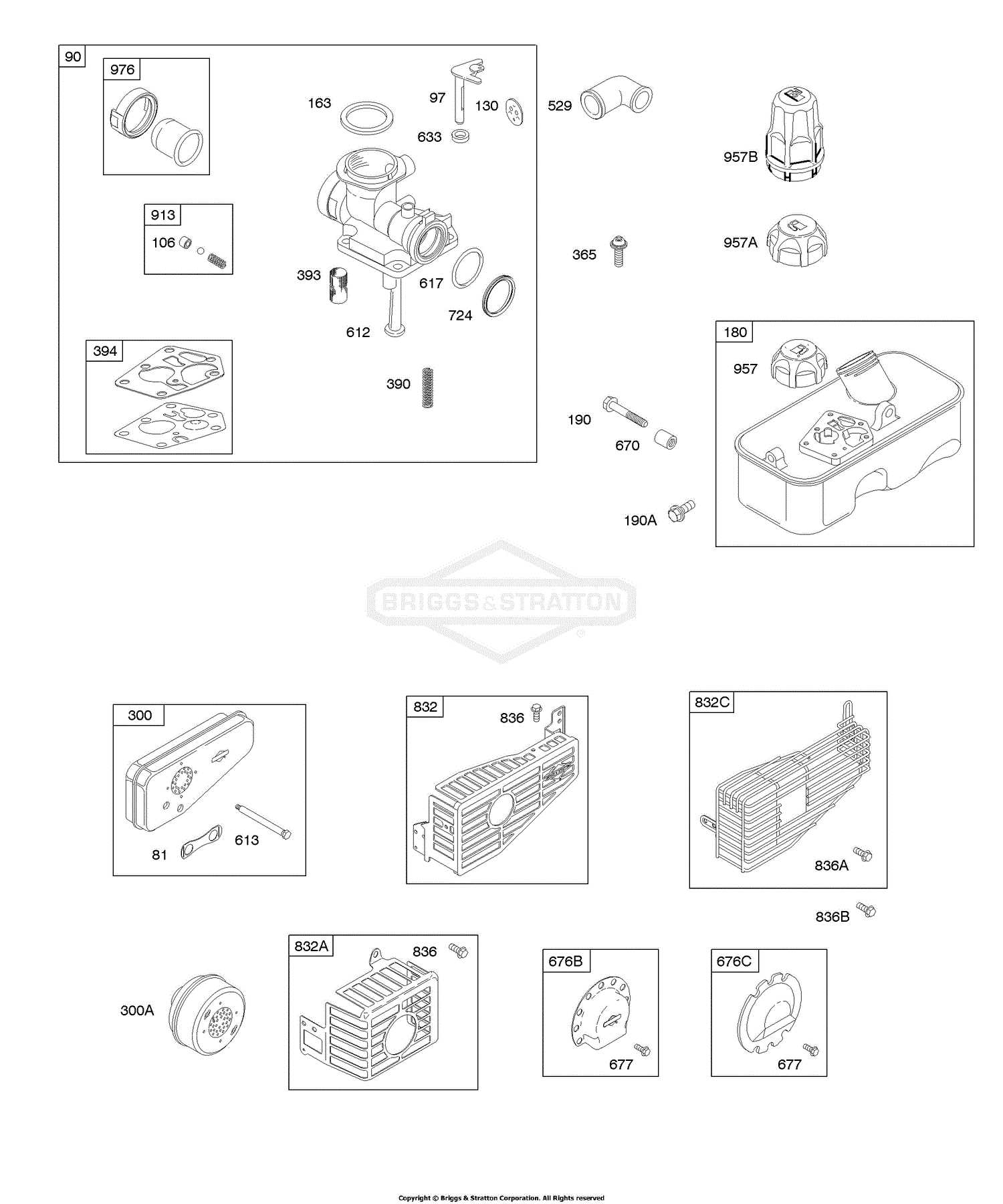

Components of a Carburetor

The intricate assembly responsible for mixing air and fuel in an engine comprises several essential elements. Each component plays a crucial role in ensuring optimal performance and efficiency during operation.

Among the key elements are the float chamber, which regulates fuel levels, and the throttle body, responsible for controlling airflow. The venturi creates a pressure drop to facilitate fuel atomization, while the needle valve manages fuel flow. Additionally, the choke assists in cold starts by enriching the mixture.

Understanding these components allows for better maintenance and tuning, ultimately enhancing engine performance and longevity.

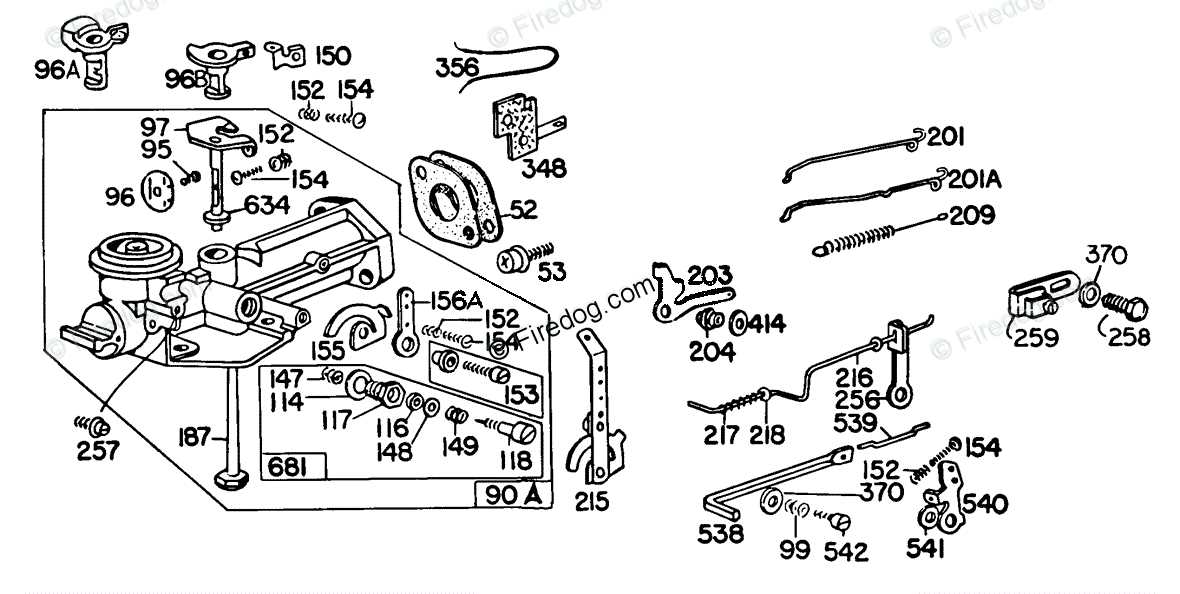

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair. This guide aims to simplify the process of interpreting these illustrations, enabling users to identify and locate each element efficiently.

Key Elements to Focus On

Start by familiarizing yourself with the labels and numbers associated with each component. Typically, these identifiers correlate with a corresponding list that provides detailed descriptions and specifications. Pay attention to the layout, which usually follows a logical order, making it easier to trace connections and functions.

Common Symbols and Notations

Various symbols may be used to represent specific functionalities. Recognizing these icons will enhance your ability to grasp how each piece interacts within the system. Additionally, notes or annotations often accompany these visuals, offering further insights into assembly and maintenance practices.

Tools Needed for Maintenance

Proper upkeep of your engine’s fuel delivery system requires a selection of essential instruments. Having the right tools at your disposal not only simplifies the process but also enhances efficiency and ensures thoroughness in every task.

Essential Instruments

- Socket Set: Necessary for removing and tightening various fasteners.

- Screwdriver Set: Both flathead and Phillips types are useful for adjusting components.

- Wrench Set: Adjustable wrenches help in securing fittings and connections.

- Fuel Line Pliers: Ideal for working with hoses without causing damage.

- Cleaning Brushes: Effective for removing debris and deposits from internal surfaces.

Additional Tools

- Torque Wrench: Ensures that all components are tightened to the correct specifications.

- Feeler Gauges: Useful for checking gaps and ensuring proper assembly.

- Safety Goggles: Protects your eyes from any debris during maintenance.

- Work Gloves: Provides grip and protects hands from sharp edges.

By gathering these necessary tools, you can confidently approach maintenance tasks, ensuring optimal performance and longevity of your equipment.

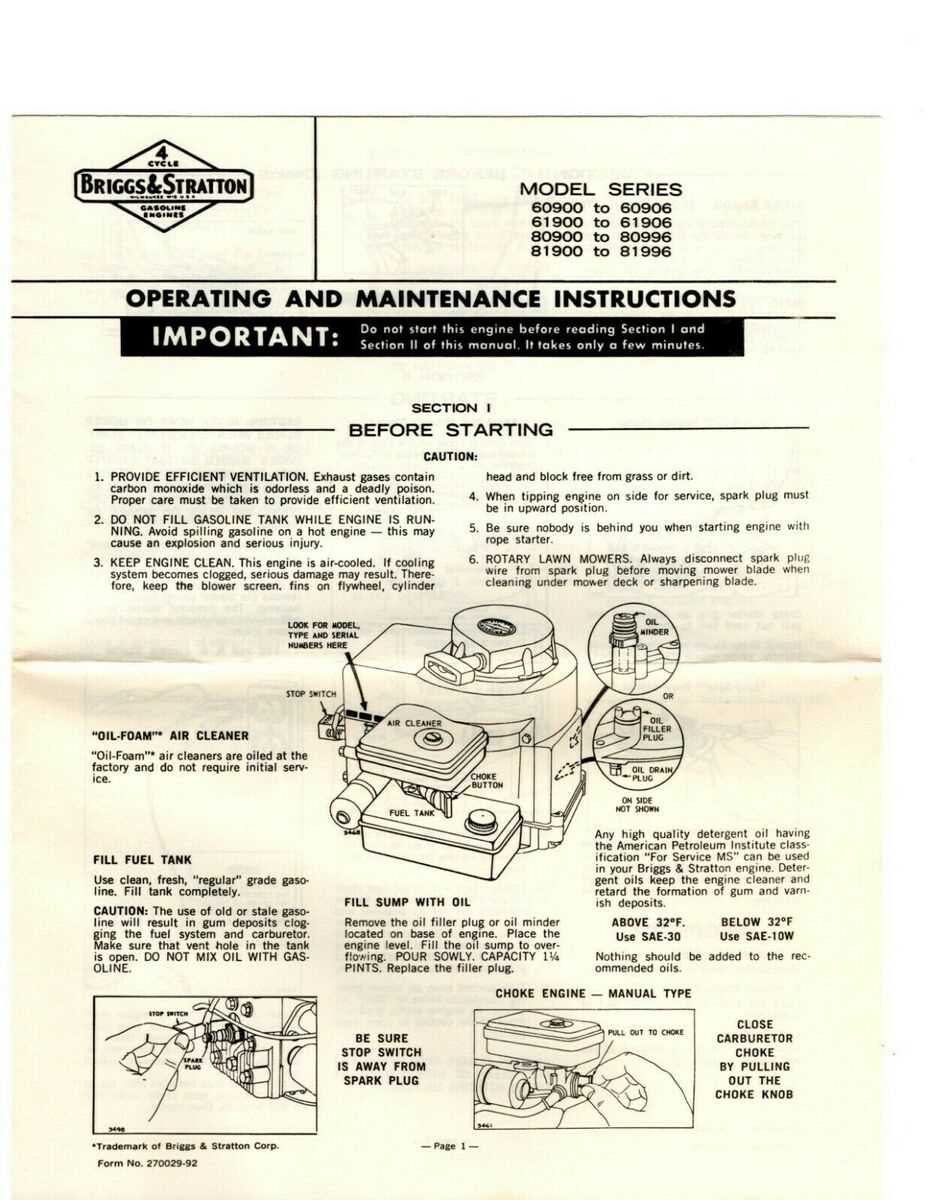

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring the functionality of a specific engine component. By following a series of organized steps, you can identify issues, perform maintenance, and enhance overall performance. Each phase of the process is crucial for ensuring long-lasting efficiency.

1. Gather Your Tools

Before starting, assemble the necessary tools including screwdrivers, wrenches, and cleaning supplies. Having everything at hand will streamline the procedure.

2. Safety First

Ensure that the engine is cool and disconnected from any power source. Use gloves and safety goggles to protect yourself during the repair.

3. Remove the Component

Carefully detach the assembly from the engine. Take note of the arrangement of each part, as this will aid in reassembly.

4. Inspect for Damage

Examine all elements for wear and tear. Look for cracks, corrosion, or blockages that could hinder functionality. Replace any damaged pieces as necessary.

5. Clean Thoroughly

Use a suitable solvent to eliminate dirt and buildup. Ensure all passageways are clear to promote proper airflow and fuel delivery.

6. Reassemble with Care

Reattach the components in the reverse order of removal. Pay attention to the original configuration to avoid complications later.

7. Test the Engine

Once everything is securely in place, reconnect the power and start the engine. Monitor its performance to ensure it operates smoothly.

8. Regular Maintenance

Establish a routine check to maintain optimal performance. Regular cleaning and inspection can prevent future issues and prolong the life of your engine.

Identifying Your Carburetor Model

Recognizing the specific type of fuel mixing component is essential for maintenance and repairs. Each variant comes with distinct features that aid in identification. Understanding these characteristics will ensure you obtain the right replacement parts and achieve optimal performance.

First, check the model number, usually found on the body or near the air intake. This identifier is crucial in pinpointing the exact type.

Next, examine the shape and size. Variations in design can provide clues about the specific model.

Finally, consult the manufacturer’s documentation or online resources to correlate your findings. This approach guarantees that you can effectively delve into troubleshooting or sourcing the ultimate components needed for repair.

Preventive Maintenance Tips

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. By following specific practices, you can minimize issues and enhance efficiency, leading to a smoother operation over time.

Routine Checks

Conduct frequent inspections to identify potential problems early. Look for any signs of wear or damage, and address them promptly to avoid further complications.

Cleaning and Lubrication

Keep all components clean and well-lubricated. Use appropriate cleaners and oils to maintain functionality, as this reduces friction and prevents buildup that could hinder performance. Regular maintenance not only extends lifespan but also enhances overall efficiency.

Where to Find Replacement Parts

Locating suitable components for your engine’s fuel delivery system can be a straightforward process with the right resources. Various channels are available, ensuring you can obtain the necessary items to restore optimal performance.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers offer genuine replacements, ensuring compatibility and reliability. |

| Online Marketplaces | Platforms like eBay and Amazon provide a wide range of options, often at competitive prices. |

| Local Hardware Stores | Neighborhood shops may carry essential items, allowing for immediate purchases. |

| Manufacturer’s Website | Visiting the official site often reveals a selection of components and helpful resources. |

FAQs About Carburetor Maintenance

Maintaining the vital component responsible for fuel mixing is essential for optimal engine performance. Here, we address common queries related to upkeep, ensuring longevity and efficiency of this crucial assembly.

How often should I clean my fuel mixing system?

It’s recommended to clean this assembly at least once a year or more frequently if you notice performance issues. Regular cleaning prevents build-up that can lead to inefficiency.

What signs indicate that my system needs maintenance?

Look for symptoms like poor acceleration, engine stalling, or difficulty starting. These could suggest that your fuel mixing mechanism requires attention.

Can I perform maintenance myself?

Yes, many maintenance tasks can be done at home with basic tools. However, if you’re unsure, consulting a professional may be wise to avoid potential damage.

What tools do I need for basic upkeep?

Typically, you’ll need screwdrivers, a cleaning brush, and some cleaning solution. Ensure you have the right tools before starting any maintenance work.

Is it necessary to replace components regularly?

While not all elements require frequent replacement, certain parts like gaskets and filters may need to be changed periodically to maintain optimal performance.

How can I prevent future issues?

Using high-quality fuel, storing your equipment properly, and conducting regular checks can help prevent many common issues associated with the fuel mixing assembly.