Keeping your lawn care tools in excellent working condition is essential for ensuring long-lasting performance. Regular inspections, along with timely replacements of key elements, play a crucial role in maintaining their efficiency. This section provides valuable insights to help you understand the core components and their functionality, making it easier to identify potential issues before they become serious problems.

Understanding the structure and interaction of different mechanisms within your equipment allows for better maintenance and troubleshooting. This detailed overview will guide you through the essential elements that contribute to optimal performance, ensuring that your tools continue to function smoothly throughout their service life.

By referencing this guide, you will be able to familiarize yourself with the necessary steps for identifying worn-out or damaged elements, allowing for timely replacement. Regular care ensures the longevity of your machinery, helping you avoid unnecessary downtime during critical work periods.

Toro Recycler 22 Mower Components Overview

This section provides a detailed exploration of the essential mechanisms that power the popular lawn maintenance equipment. Understanding the core elements of the machine helps ensure smooth operation and proper maintenance, contributing to a longer lifespan of the tool. Below, we will examine the key mechanical and functional systems, highlighting how each part plays a role in efficient lawn care.

Engine and Drive Mechanism

The mower is powered by a reliable engine, which drives the cutting blades and ensures propulsion across the lawn. The self-propelling system integrates seamlessly with the engine, allowing the user to easily navigate various terrains. Regular inspection and maintenance of these components ensure optimal performance and fuel efficiency.

Cutting and Grass Management System

The cutting mechanism consists of high-quality blades designed to produce a precise, even cut. Alongside this, the grass handling system efficiently collects clippings or mulches them, depending on user preference. Ensuring the blades remain sharp and the grass management system unclogged enhances the machine’s cutting capability and overall efficiency.

Understanding the Toro 22 Blade Mechanism

The cutting mechanism of a 22-inch lawn tool is a critical component responsible for efficient grass trimming. This section delves into how the rotating system operates and the key factors that influence its performance during regular use. Proper understanding of the mechanism ensures optimal function and extends the lifespan of the device.

Key Components of the Cutting System

The blade setup consists of sharp, durable metal that spins at high speeds, allowing for precise and clean cutting. The design ensures a balance between sharpness and durability, making it effective in handling various types of grass. Regular maintenance of this component is essential for consistent performance.

Performance Considerations

Several factors, such as rotation speed, sharpness, and blade alignment, play a crucial role in ensuring smooth operation. Proper adjustments and routine inspections help maintain efficiency, ensuring that the lawn is evenly trimmed. Monitoring wear and tear on the cutting edges helps avoid uneven cuts and extends the system’s longevity.

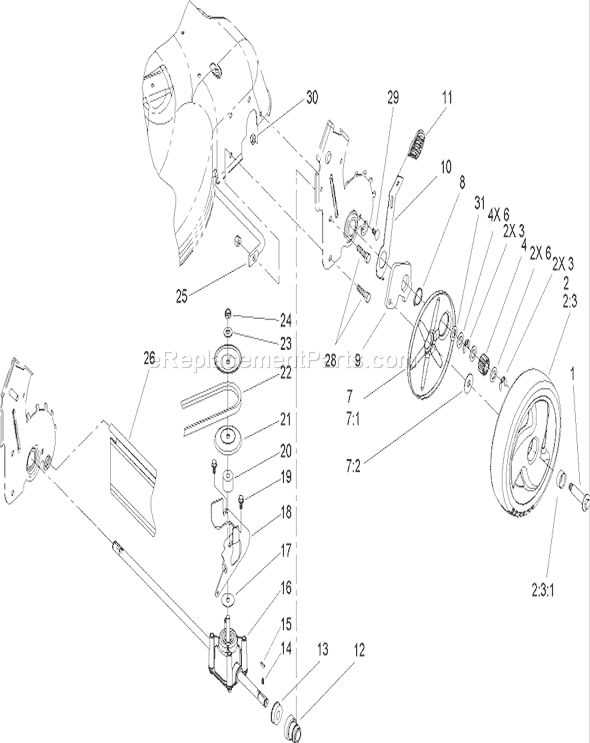

Wheel Assembly and Maintenance Tips

Ensuring proper functionality and long-lasting performance of the wheel system is essential for smooth and efficient operation. Regular checks and upkeep of the wheels help to prevent wear and tear, extending the lifespan of the equipment. This section will guide you through essential advice on maintaining and assembling the wheels, focusing on critical elements such as alignment, lubrication, and securing key components.

Steps for Proper Assembly

When assembling the wheels, it’s important to first ensure all components are in place and free from any damage. Align the wheel axles carefully to avoid unnecessary friction during movement. Secure the wheels using the appropriate fasteners, ensuring that each connection is tightened to prevent wobbling or imbalance during use. A thorough inspection at each step guarantees reliable operation and safety.

Maintenance Recommendations

For optimal wheel performance, routine maintenance is crucial. Regularly clean any debris that may accumulate around the wheels, as this can cause blockages or excessive strain. Lubricate the axles periodically to reduce friction and ensure smooth movement. Inspect the tires for signs of wear, and replace them if necessary to

Guide to the Engine Housing Layout

The engine housing is a critical component of any lawn maintenance equipment. This section provides an overview of the key elements and structure of the housing, highlighting how it protects essential internal components and supports the overall functionality of the machine. Proper understanding of the housing arrangement ensures effective maintenance and longer equipment lifespan.

Key Components of the Engine Housing

The housing is designed to safeguard the engine while providing access to critical systems. It generally includes sections for air intake, cooling, and exhaust systems. These sections are carefully positioned to ensure smooth airflow, minimizing the risk of overheating and ensuring optimal performance.

Housing Structure Overview

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Air Intake Section | Allows fresh air to enter, ensuring combustion efficiency. | ||||||||

| Exhaust Outlet | Safely expels exhaust gases away from critical parts. | ||||||||

| Feature | Description |

|---|---|

| Attachment Mechanism | The bag is secured to the rear of the mower using a simple locking system, ensuring it remains in place during operation. |

| Airflow Optimization | Airflow from the cutting chamber helps guide grass into the bag, maximizing the space used for collection. |

| Capacity | The bag has a spacious interior, allowing it to hold a large volume of clippings before needing to be emptied. |

| Easy Emptying | The design allows for quick and hassle-free emptying, minimizing downtime between mowing sessions. |

Inspecting the Drive Belt and Pulley

Regular examination of the drive mechanism is essential for ensuring optimal performance and longevity of your equipment. The drive belt and pulley system play a crucial role in transferring power from the engine to the cutting mechanism, making it vital to keep them in good condition.

Begin your inspection by checking the drive belt for signs of wear or damage. Look for fraying, cracking, or any signs of stretching that may affect its performance. A worn belt can slip or break, leading to a loss of power and efficiency.

Next, inspect the pulley for any visible damage or wear. Ensure that it rotates freely without any obstruction. Look for grooves or scoring on the surface that could hinder the belt’s grip. Proper alignment between the belt and pulley is crucial for smooth operation, so make sure they are correctly positioned.

After your inspection, consider replacing any components that show signs of significant wear. Regular maintenance will help prevent unexpected breakdowns and ensure that your equipment operates efficiently for years to come.

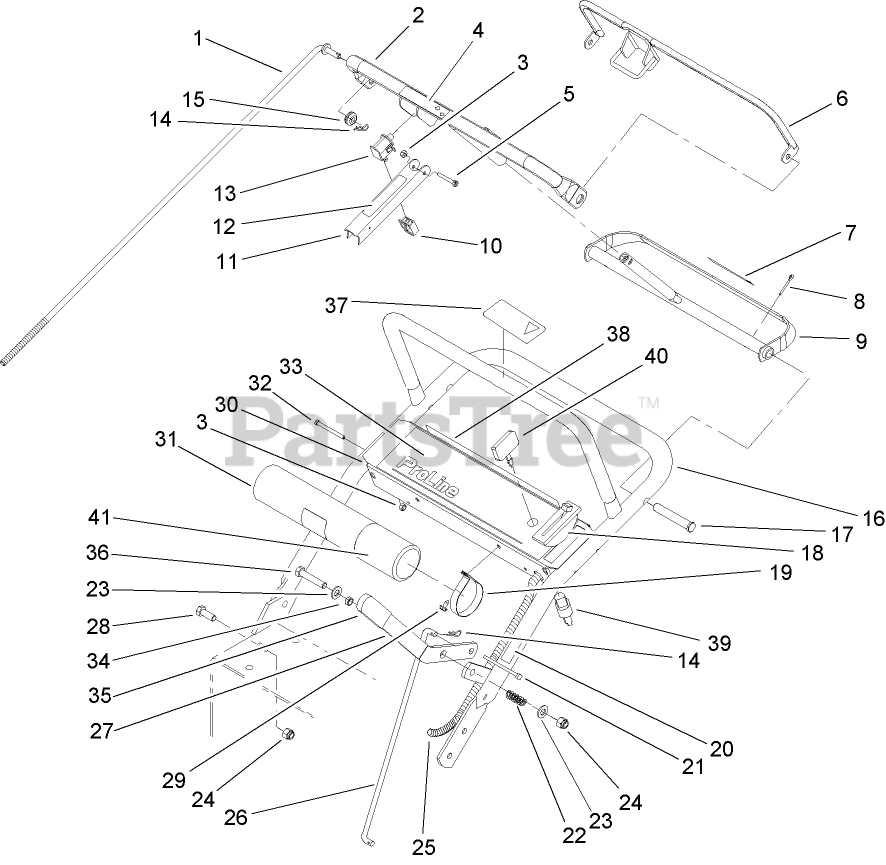

Handle and Control Levers: Functionality

The components responsible for steering and managing the operation of outdoor equipment play a crucial role in ensuring user comfort and efficiency. These elements not only enable precise movement but also allow for easy manipulation of various settings, enhancing the overall performance of the machinery.

Functionality is paramount when it comes to the levers and handles that dictate the operation of the device. They are designed to offer intuitive control, allowing users to adjust speed, direction, and other important functions with minimal effort. The ergonomic design of these components ensures that they can be operated easily, reducing fatigue during extended use.

Durability is another key aspect, as these elements must withstand frequent handling and the rigors of outdoor environments. Quality materials and robust construction contribute to their longevity, ensuring reliable performance throughout the lifespan of the equipment.

In summary, the handles and control levers are vital for enhancing usability and functionality, providing a seamless experience while operating outdoor machinery.

Deck Design and Material Analysis

The structure of a lawn mowing unit is crucial for optimal performance and durability. Understanding the intricacies of its design and the materials used can significantly influence the efficiency and longevity of the equipment. This section delves into the various aspects of the design and material selection for the mowing deck, highlighting their impact on functionality and user experience.

Design Considerations

- Shape and Size: The geometry of the deck affects the cutting path and grass flow. A well-designed shape can enhance airflow, ensuring an even cut and efficient grass discharge.

- Weight Distribution: Proper weight distribution contributes to stability during operation. A balanced design minimizes the risk of tipping and enhances maneuverability.

- Accessibility for Maintenance: Design features that facilitate easy access to the blade and engine components are essential for routine maintenance, ensuring optimal performance over time.

Material Selection

- Steel: Commonly used for its strength and durability, steel provides a robust structure that withstands wear and tear. However, it may be prone to rust if not properly coated.

- Aluminum: Lightweight and resistant to corrosion, aluminum offers a good balance between durability and ease of handling, making it an attractive option for many models.

- Composite Materials: Some manufacturers use composite materials to reduce weight and enhance resistance to corrosion. These materials can provide flexibility in design while maintaining structural integrity.

Throttle and Choke Cable Placement

Proper positioning of throttle and choke cables is crucial for optimal performance in lawn care equipment. These components play a significant role in controlling the engine’s speed and air intake, affecting how the machine operates under various conditions.

To ensure efficient functionality, cables should be routed securely, avoiding sharp bends and potential obstructions. The attachment points must allow for smooth movement without friction, enabling the user to easily adjust settings during operation. Regular inspection and maintenance of these cables will help prevent wear and ensure longevity, contributing to reliable performance.

When installing or replacing these cables, it’s essential to follow manufacturer guidelines for correct placement. This practice guarantees that the components work harmoniously, enhancing the overall efficiency of the machine. Additionally, any signs of damage or deterioration should be addressed promptly to maintain optimal operation.

Exploring the Rear Discharge Chute

The rear discharge chute is an essential component of lawn maintenance equipment, designed to optimize grass clippings’ distribution during mowing. This feature enhances efficiency by directing cuttings in a specific direction, ensuring an even spread across the lawn. Understanding its structure and functionality can significantly improve mowing performance and the overall appearance of the yard.

Functionality and Benefits

This chute serves a dual purpose: it allows for the efficient expulsion of grass cuttings while also minimizing the buildup of debris on the mower itself. By directing clippings to the back, it reduces the chances of clogging and ensures a smoother operation. Moreover, a well-designed rear discharge chute promotes better mulching, returning nutrients to the soil and supporting healthier grass growth.

Maintenance Considerations

Regular maintenance of the rear discharge chute is crucial for optimal performance. Ensuring that it remains clear of obstructions and free from damage can enhance its efficiency. Periodic inspections help in identifying wear and tear, allowing for timely repairs or replacements. This proactive approach not only extends the lifespan of the component but also maintains the quality of mowing results.

Troubleshooting the Front Axle System

The front axle system is a critical component of any mower, affecting its maneuverability and overall performance. Understanding the potential issues that may arise can help users efficiently diagnose and resolve problems, ensuring a smooth operation.

Common Issues

- Steering Difficulty: If the mower is hard to steer, it may indicate a problem with the axle alignment or damaged components.

- Noisy Operation: Unusual sounds while operating can signal worn bearings or loose fittings within the axle system.

- Uneven Tire Wear: Discrepancies in tire wear patterns can suggest misalignment or improper inflation.

Troubleshooting Steps

- Inspect the axle for visible damage or wear.

- Check tire pressure and ensure they are inflated to the recommended levels.

- Examine the steering mechanism for any loose or damaged parts.

- Test the alignment by comparing the front and rear wheel positions.

- Replace any damaged components as necessary and retest the mower’s performance.

Fuel System Diagram and Key Parts

The fuel mechanism is a crucial component of any motorized device, ensuring that the engine receives the necessary energy to operate efficiently. Understanding the essential elements of this system can help users maintain optimal performance and troubleshoot any issues that may arise. This section will explore the primary components involved in fuel delivery and management.

Fuel Tank: The reservoir that stores the fuel before it reaches the engine. A well-maintained tank is essential for preventing contamination and ensuring a steady supply of energy.

Fuel Filter: This element plays a vital role in cleaning the fuel by removing impurities and particles, which can harm the engine. Regular checks and replacements are necessary to maintain performance.

Fuel Lines: These conduits transport fuel from the tank to the engine. Ensuring these lines are free of cracks or leaks is critical for efficient fuel flow and preventing potential hazards.

Fuel Pump: Responsible for moving fuel from the tank to the engine, this component needs to function properly to maintain the correct pressure and flow rate.

Carburetor or Fuel Injector: Depending on the design, this part mixes the fuel with air to create a combustible mixture. Proper tuning and maintenance of this component are vital for engine efficiency and performance.

By familiarizing oneself with these key components, users can better understand how to care for their equipment and address any performance issues that may occur.

Understanding the Mulching Feature Assembly

The mulching component of a lawn mower plays a crucial role in enhancing the efficiency of grass cutting. This feature allows for the fine shredding of grass clippings, which can then be redistributed back onto the lawn. This process not only nourishes the soil but also promotes a healthier lawn ecosystem.

Key Elements of the Mulching System

- Blades: Sharp, specially designed blades are essential for effective mulching. They chop the grass into fine pieces, ensuring quick decomposition.

- Chamber: The mulching chamber collects clippings as they are cut, allowing for optimal airflow and further shredding.

- Deflector: A deflector directs the clippings into the chamber rather than allowing them to exit the mower, maximizing the mulching efficiency.

Benefits of Using the Mulching Feature

- Environmental Impact: By recycling grass clippings, you reduce waste and minimize the need for chemical fertilizers.

- Time Efficiency: Mulching eliminates the need for bagging or disposing of clippings, saving time during lawn maintenance.

- Soil Health: Decomposed clippings return valuable nutrients to the soil, promoting healthy grass growth and reducing the need for additional feeding.