Understanding how various mechanisms work together in a cohesive system is crucial for maintaining and optimizing performance. The layout of the key elements provides a clear roadmap to ensure smooth operation and efficient troubleshooting. By familiarizing yourself with the structure and connections, you can achieve a better grasp of how everything functions in harmony.

Efficient organization of these critical elements ensures that maintenance and repairs are done swiftly and accurately. Recognizing the exact placement of each item allows for faster identification, saving time during replacements or upgrades. This visual breakdown simplifies the process, ensuring that even intricate systems can be navigated with ease.

Whether you’re looking to optimize performance or simply maintain the current setup, having a clear understanding of the structure is essential. This guide provides a well-organized breakdown, helping you approach both routine tasks and unexpected challenges with confidence.

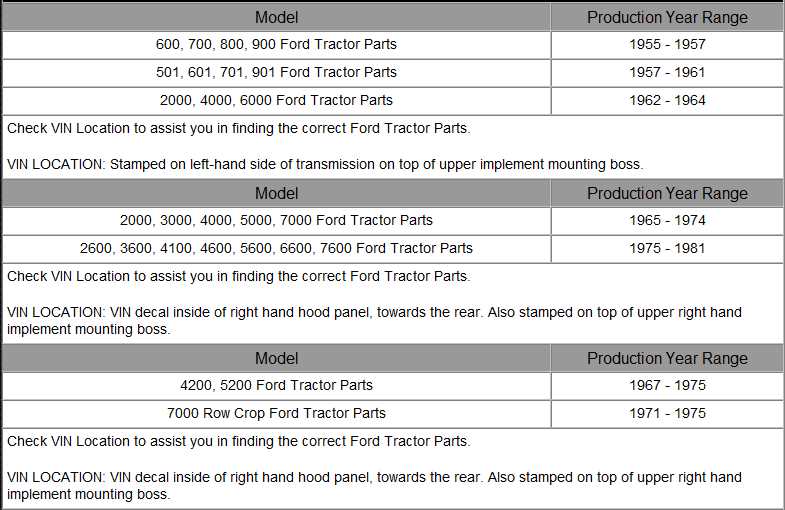

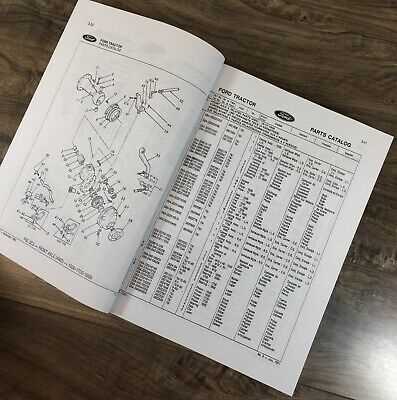

Ford 1700 Tractor Components Overview

Understanding the various mechanical elements of this agricultural machine is essential for maintaining its performance and ensuring its longevity. Each piece plays a critical role in the overall function, and knowing the main sections can aid in efficient maintenance.

| Component | Description |

|---|---|

| Engine | The powerhouse of the machine, providing the necessary energy for all operations. Regular checks of the oil and cooling system help maintain its efficiency. |

| Transmission | This section is responsible for transferring the engine’s power to the wheels. It ensures proper movement and speed control across various terrains. |

| Hydraulic System | Controls the machine’s lifting and lowering mechanisms. It is crucial for handling heavy loads and attachments effectively. |

| Steering and Braking | These components are vital for the operator’s control over the machine, ensuring safe navigation and precise stopping when necessary. |

Engine Assembly and Key Parts

The heart of any machinery relies on a well-organized power system, where multiple elements work together to ensure smooth operation. This section outlines the essential components involved in the assembly, providing a clear overview of how each piece fits into the bigger picture. Proper alignment and maintenance of these elements are critical to ensure long-lasting performance and reliability.

Core Components

- Crankshaft – The central element responsible for converting energy into motion, driving other mechanisms.

- Pistons – Operate within the cylinder to transfer the force generated by combustion.

- Cylinder Block – Houses the core moving parts, providing a solid foundation for the overall structure.

- Valves – Regulate the intake and exhaust of gases, ensuring efficient combustion cycles.

Supporting Elements

- Cooling System – Prevents overheating by circulating coolant around critical areas.

- Lubrication Mechanism – Reduces friction and ensures the longevity of moving parts.

- Timing Belt – Synchronizes the movements of the crankshaft and camshaft for precise operation.

Transmission System Breakdown

The transmission system plays a crucial role in ensuring smooth operation by transferring power from the engine to the wheels. Understanding its layout helps in identifying how different components work together to achieve efficient movement and control. This section provides an overview of the main parts involved in this essential system.

Main Components

- Clutch Assembly: Engages and disengages the power flow, allowing for gear shifts without stopping the engine.

- Gearbox: A collection of gears responsible for adjusting speed and torque, offering various driving modes.

- Driveshaft: Transmits rotational power from the gearbox to the differential, which distributes it to the wheels.

System Operation

- Power Transfer: The clutch connects or disconnects the engine’s output to the transmission.

- Gear Shifting: The gears in the gearbox adjust to provide the appropriate speed and torque for different conditions.

- Final Drive: The driveshaft delivers the rotational power to the wheels, ensuring smooth propulsion.

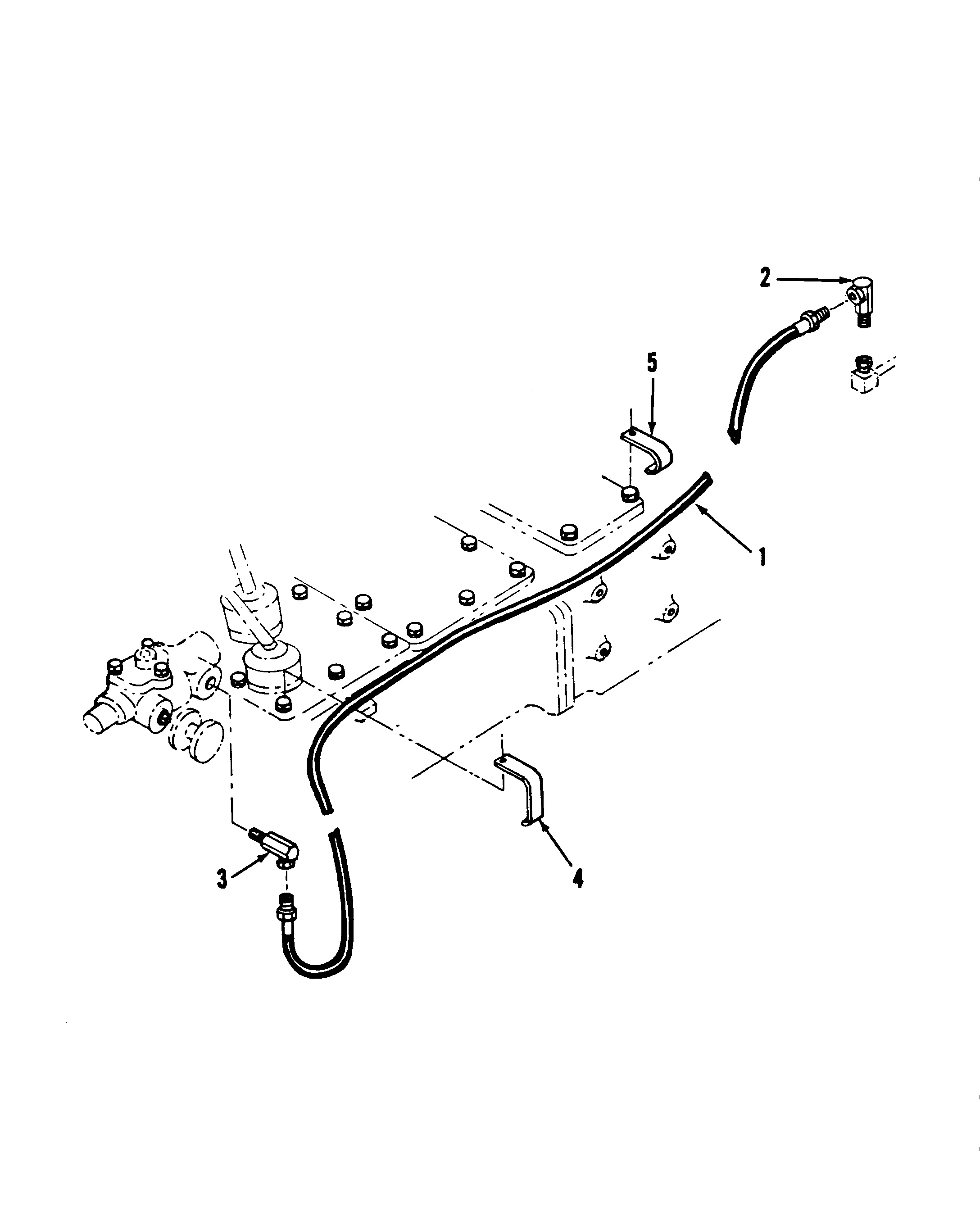

Hydraulic System Components

The hydraulic system plays a vital role in ensuring smooth and efficient operations, utilizing fluid pressure to generate force and control various functions. Its design integrates multiple elements that work together to deliver precise and responsive performance.

- Pump: This unit drives the fluid throughout the system, converting mechanical power into hydraulic energy.

- Reservoir: The storage container that holds the fluid, maintaining a steady supply for continuous operation.

- Valves: Control devices that regulate pressure and flow, ensuring the proper direction and amount of fluid movement.

- Cylinders: These components use fluid pressure to create linear motion, powering various mechanisms.

- Hoses and Lines: Serve as the pathways for hydraulic fluid, connecting different parts of the system and ensuring fluid transfer.

Each of these elements contributes to the system’s overall function, working in tandem to maintain reliable performance under diverse conditions.

Axle and Differential Details

The axle and differential are critical components that ensure smooth movement and power distribution across the machine’s wheels. These mechanisms work together to provide stability, traction, and proper handling on various surfaces. A well-functioning system in this area enhances performance during tasks that require precise maneuverability.

- Axle Housing: The housing serves as a protective shell, encasing the axle and differential. It maintains the correct alignment and prevents debris from interfering with internal parts.

- Gear Assembly: The differential gears balance the speed between the wheels, ensuring smooth turns without losing control. They are designed to adjust for uneven surfaces and load conditions.

- Drive Shafts: These shafts transfer power from the engine to the axle, allowing the wheels to move efficiently. Their durability is essential for continuous heavy-duty operation.

- Wheel Bearings: Bearings reduce friction and wear, providing smoother rotations and improving the lifespan of the axle system. They play a key role in reducing resistance and supporting load distribution.

Regular maintenance of these components is essential to avoid performance issues. A well-maintained axle and differential system will result in better efficiency and longer operational life.

Steering Mechanism and Parts

The steering system is essential for ensuring precise control and maneuverability of heavy machinery. This assembly allows the operator to guide the vehicle effectively, promoting safety and efficiency in various working environments. Understanding its components is crucial for maintenance and troubleshooting.

This mechanism typically comprises several key elements, including the steering wheel, column, gears, and linkages. Each component plays a significant role in translating the operator’s input into directional movement. Regular inspection of these parts is vital to prevent wear and ensure optimal performance.

Additionally, lubricating moving components and checking for any signs of damage can help maintain functionality. Knowledge of the steering assembly aids in recognizing potential issues early, ultimately extending the lifespan of the entire system.

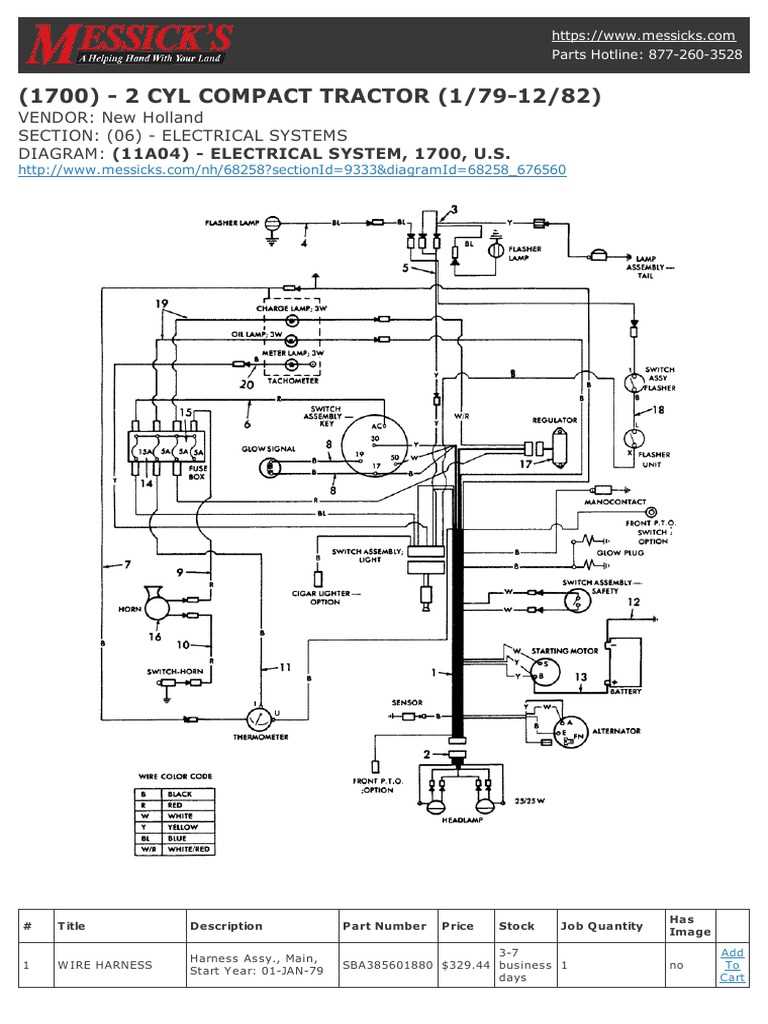

Electrical System Diagram

This section provides a comprehensive overview of the electrical layout and components essential for the functionality of the machine. Understanding this configuration is crucial for effective maintenance and troubleshooting, ensuring optimal performance and longevity.

Key elements of the electrical network include:

- Battery: Supplies the necessary power for starting the engine and operating various electrical systems.

- Starter Motor: Engages to initiate engine operation when the ignition is activated.

- Alternator: Responsible for recharging the battery while the engine is running and providing power to electrical accessories.

- Wiring Harness: Connects all electrical components, facilitating communication and power distribution.

- Fuses: Protect the electrical circuits from overload, ensuring safe operation of the system.

- Switches: Allow the operator to control different functionalities, such as lights and ignition.

Regular inspection of these components is vital for preventing electrical failures and ensuring reliable operation. Proper understanding of the electrical configuration aids in diagnosing issues effectively.

Cooling System Components

The effectiveness of a vehicle’s engine relies significantly on its cooling mechanism, which plays a crucial role in maintaining optimal operating temperatures. This system prevents overheating by dissipating excess heat generated during operation, ensuring the engine runs efficiently. Understanding the various elements that make up this system is essential for proper maintenance and functionality.

Key Elements of the Cooling System

Several critical components contribute to the overall effectiveness of the cooling system. The radiator serves as the primary unit for heat exchange, allowing coolant to release heat into the atmosphere. Additionally, the water pump circulates coolant throughout the engine, promoting effective heat transfer. The thermostat regulates coolant flow, ensuring the engine reaches its ideal temperature before allowing excess coolant to return to the radiator.

Maintaining Cooling Efficiency

Regular inspection and maintenance of cooling system components are vital for preventing overheating and ensuring longevity. Checking the condition of hoses and clamps helps prevent leaks, while monitoring coolant levels ensures that the system operates effectively. Flushing the cooling system periodically also removes contaminants and buildup, allowing for better heat transfer and overall performance.

Fuel System Layout

The layout of the fuel system is crucial for the efficient operation of any machinery. It ensures that fuel is delivered properly to the engine, optimizing performance and longevity. Understanding the various components and their arrangement can help in troubleshooting and maintenance, leading to enhanced functionality and reliability.

Key Components

This section outlines the primary elements involved in the fuel system, each playing a significant role in the overall performance.

| Component | Description |

|---|---|

| Fuel Tank | Stores the fuel until it is needed by the engine. |

| Fuel Pump | Transfers fuel from the tank to the engine, maintaining optimal pressure. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. |

| Injectors | Atomizes fuel and injects it into the combustion chamber for optimal burning. |

System Flow

The fuel flow begins at the tank, where the liquid is drawn by the pump. It then passes through the filter to ensure cleanliness before reaching the injectors. This organized flow is essential for maintaining performance and preventing engine issues.

Brake Assembly Overview

The brake assembly is a crucial component responsible for controlling the speed and stopping of a vehicle. It ensures safe operation by providing reliable braking performance. Understanding its structure and functionality is essential for maintaining optimal performance and safety.

Key Components

- Brake Pedal: The interface for the operator, allowing for brake engagement.

- Master Cylinder: Converts the pedal pressure into hydraulic force, activating the braking system.

- Brake Lines: Transmit hydraulic fluid from the master cylinder to the braking mechanism.

- Brake Calipers: Clamps the brake pads against the rotor to create friction and slow down the vehicle.

- Brake Pads: Friction material that presses against the rotor to facilitate stopping.

- Rotors: Metal discs that work in conjunction with the brake pads to create the necessary friction.

Maintenance Tips

- Regularly check the brake fluid level and replace it if necessary.

- Inspect brake pads and rotors for wear and replace them when they become thin.

- Examine brake lines for leaks or damage to ensure proper fluid transfer.

- Ensure the master cylinder is functioning correctly to maintain hydraulic pressure.

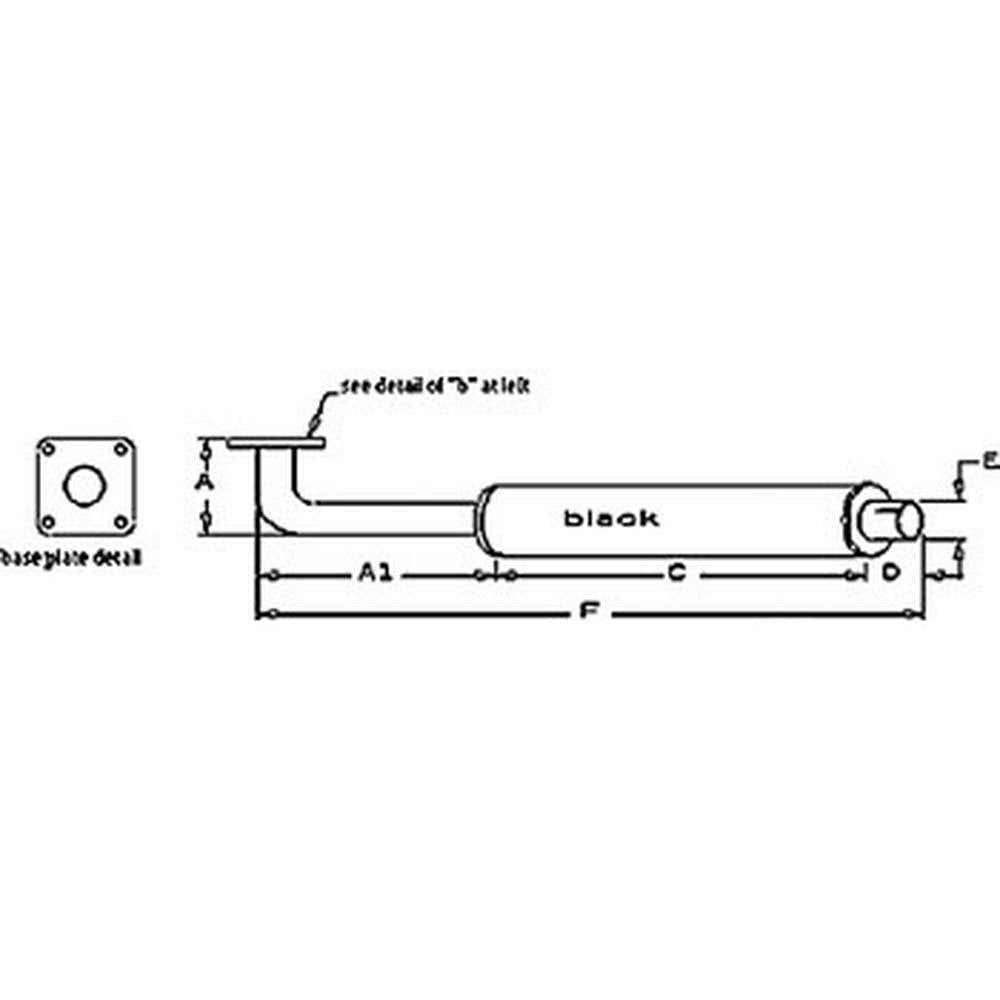

Exhaust System Components

The exhaust system plays a crucial role in ensuring the efficient operation of an engine by directing harmful gases away from the combustion chamber. Understanding the various elements involved in this system is essential for maintaining optimal performance and longevity. This section will explore the key components that make up the exhaust system, highlighting their functions and importance.

Key Elements of the Exhaust Assembly

At the heart of the exhaust system is the manifold, which collects exhaust gases from the engine and channels them into the pipe. This component is typically made from durable materials to withstand high temperatures. Following the manifold, the gases flow through a series of pipes that connect to the muffler.

Muffler and Emission Control Devices

The muffler is designed to reduce noise produced by the engine while also controlling exhaust flow. In modern systems, emission control devices are integrated to minimize harmful pollutants. Catalytic converters are vital for converting toxic substances into less harmful emissions, contributing to environmental protection.

Overall, each component of the exhaust system plays a significant role in ensuring efficient engine performance and compliance with environmental regulations.

Clutch and Linkage Details

This section provides essential information regarding the mechanisms involved in engaging and disengaging power transmission systems. Understanding these components is crucial for maintaining optimal functionality and performance.

The clutch assembly is a vital element, enabling the smooth transition between engaged and disengaged states. It comprises various parts, including the pressure plate, friction disc, and release bearing. Each component plays a significant role in ensuring that power is effectively transferred when needed.

Linkage mechanisms connect the pedal to the clutch, allowing for easy control by the operator. These linkages must be regularly inspected for wear and tear to ensure proper alignment and response. Proper adjustment is essential for achieving the desired engagement and disengagement feel, contributing to overall operational efficiency.

Regular maintenance and timely replacement of worn components are key to preventing potential issues that could hinder performance. Keeping these systems in good condition enhances reliability and ensures smooth operation in various conditions.

Tire and Wheel Assembly Breakdown

The assembly responsible for supporting the overall structure and providing mobility is crucial for any machinery. Understanding its components is essential for maintenance and performance optimization. This section explores the various elements that make up this assembly, ensuring that users are equipped with the knowledge necessary for effective upkeep.

Components Overview

At the core of this assembly are the rims and tires, which work in tandem to facilitate smooth movement across different terrains. The rims are typically constructed from durable materials, designed to withstand significant stress, while the tires are engineered for optimal traction and stability. Additional elements, such as inner tubes or bead seats, contribute to the overall integrity and functionality of the assembly.

Maintenance Considerations

Regular inspection and maintenance of the wheel assembly are vital to ensure safety and efficiency. Users should check for signs of wear, such as tread erosion or rim damage, and address any issues promptly. Proper inflation levels should also be monitored to enhance performance and prolong the lifespan of both tires and rims.