In the realm of farming equipment, the functionality and efficiency of machinery play a crucial role in ensuring optimal performance. A thorough grasp of the various elements that comprise such machinery is essential for effective maintenance and repair. By familiarizing oneself with the intricate network of components, operators can enhance the longevity and productivity of their equipment.

Exploring the intricate layout of these essential elements not only aids in troubleshooting but also empowers users to make informed decisions when it comes to upgrades or replacements. Each segment serves a unique purpose, contributing to the overall effectiveness of the machinery. Delving into the arrangement of these parts reveals valuable insights into their interrelationships and functions.

Gaining knowledge about the assembly and connections of the essential elements equips operators with the tools needed to optimize their equipment. Understanding the mechanics at play allows for a more hands-on approach to upkeep, leading to greater efficiency in agricultural operations.

The model in question is a remarkable piece of machinery known for its reliability and efficiency in various agricultural tasks. Understanding its components and layout is essential for maintenance and operation, ensuring that users can maximize its capabilities.

This section will provide a comprehensive look into the various segments of the machine, highlighting their functions and importance in overall performance. Familiarity with these elements aids in effective troubleshooting and repair.

- Engine: The powerhouse of the equipment, responsible for providing the necessary energy for operation.

- Transmission: This system enables the transfer of power from the engine to the wheels, allowing for different speeds and torque.

- Hydraulics: Essential for lifting and operating various attachments, the hydraulic system enhances versatility in operations.

- Chassis: The frame that supports all components, contributing to the stability and durability of the machinery.

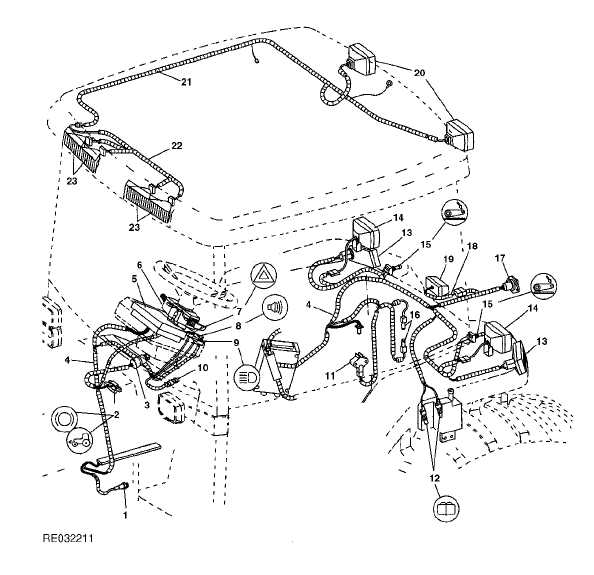

- Electrical System: This includes all wiring and components that power the electronic systems, crucial for starting and operational controls.

Each of these areas plays a vital role in ensuring the machine operates smoothly, and understanding them is key for anyone involved in its upkeep. Whether performing routine maintenance or troubleshooting issues, a clear grasp of these components fosters better handling and longevity of the equipment.

Key Features of the Ford 7700

The model in question stands out due to its robust design and reliable performance in various agricultural tasks. With a focus on efficiency and user-friendliness, this machine has become a preferred choice for many in the farming community.

Power and Performance

Equipped with a powerful engine, this machine offers exceptional torque and horsepower, ensuring optimal performance even in demanding conditions. The drivetrain is designed to provide smooth operation and excellent maneuverability, making it suitable for both heavy-duty work and precision tasks.

Comfort and Usability

Operator comfort is prioritized with a spacious and ergonomic cabin, which includes adjustable seating and intuitive controls. The layout facilitates easy access to all functions, allowing users to operate the equipment with minimal effort. Additionally, the visibility from the operator’s position enhances safety and control during operation.

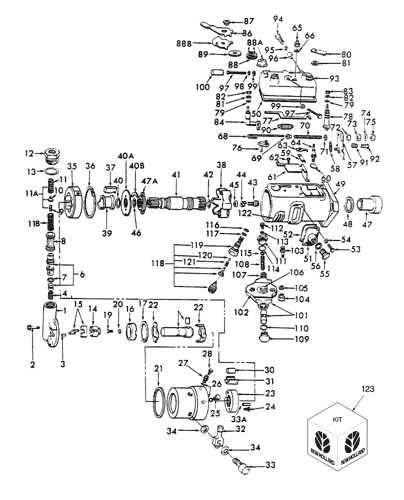

Importance of Accurate Parts Diagrams

Having precise illustrations of components is crucial in ensuring efficient maintenance and repair processes. These visual representations provide essential guidance for identifying specific elements within a machine, allowing for effective troubleshooting and replacement. When technicians have access to detailed schematics, they can swiftly locate issues, reducing downtime and enhancing overall productivity.

Clarity and Precision play a significant role in the successful execution of repairs. Clear graphics facilitate a better understanding of how individual components interact within the larger system. This understanding is vital for achieving optimal functionality and longevity of the equipment. When every detail is accurately depicted, it minimizes the risk of errors during assembly or disassembly, ensuring that everything fits together as intended.

Moreover, comprehensive documentation serves as an invaluable resource for both experienced mechanics and novices alike. It empowers individuals to tackle repairs with confidence, fostering a more informed approach to maintenance. In summary, reliable visual resources are not merely helpful; they are essential for effective upkeep and operational success.

Main Components of Ford 7700

This section explores the essential elements of a specific agricultural machine, focusing on the various key components that contribute to its functionality and efficiency. Understanding these fundamental parts is crucial for anyone interested in maintaining or operating this particular equipment.

Engine System

The engine system serves as the powerhouse, delivering the necessary energy for operation. Key features include:

- Combustion chamber for fuel ignition

- Cooling system to maintain optimal temperature

- Fuel injection mechanism for efficient performance

Transmission Mechanism

This system facilitates the transfer of power from the engine to the wheels, ensuring smooth movement. Important elements comprise:

- Gearbox to regulate speed and torque

- Clutch for engaging and disengaging power

- Drive shafts for delivering motion

Understanding the Engine Assembly

The engine assembly is a crucial component of any heavy-duty machinery, responsible for converting fuel into mechanical energy. It comprises various interconnected elements that work in unison to ensure optimal performance and efficiency. This section delves into the key components of the engine assembly, highlighting their functions and significance in the overall operation of the machine.

At the heart of the engine lies the block, housing cylinders where combustion takes place. Above this is the cylinder head, which plays a vital role in sealing the combustion chamber and housing important components such as valves and spark plugs. Together, these parts create a robust structure that withstands the immense pressures generated during operation.

| Component | Function |

|---|---|

| Engine Block | Forms the main structure of the engine and contains cylinders for combustion. |

| Cylinder Head | Seals the top of the cylinders and houses valves and spark plugs. |

| Piston | Moves up and down within the cylinder to convert energy from combustion into mechanical work. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion to drive the machine. |

| Camshaft | Controls the opening and closing of the valves, coordinating with the piston movement. |

Each of these components plays a pivotal role in ensuring that the engine operates smoothly and efficiently. Understanding their individual functions allows for better maintenance and troubleshooting, ultimately leading to improved performance and longevity of the machinery.

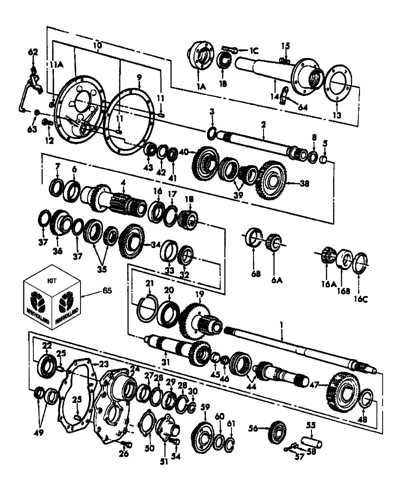

Transmission System Breakdown

The transmission system is a critical component of agricultural machinery, playing a vital role in power transfer from the engine to the wheels. Understanding its intricacies is essential for maintenance and repairs, ensuring optimal performance in the field.

This system comprises several key elements that work in unison to facilitate smooth operation. Below are the primary components:

- Gearbox: Responsible for changing the speed and torque, allowing the machine to adapt to various terrains.

- Clutch: Engages and disengages the engine’s power, providing control over the machine’s movement.

- Drive Shaft: Transmits power from the engine to the gearbox, playing a crucial role in overall functionality.

- Linkage Mechanism: Connects various components, ensuring synchronized operation and effective power transfer.

- Hydraulic System: Often integrated into the transmission, it enhances the operation of various functions, such as shifting gears.

Regular inspection and maintenance of these components can prevent costly breakdowns and ensure that the machinery operates efficiently throughout its service life.

Hydraulic Components Explained

Hydraulic systems play a crucial role in the operation of various machinery, facilitating the transfer of force through fluid movement. These systems are designed to enhance efficiency and effectiveness, allowing equipment to perform tasks with greater ease. Understanding the individual components that comprise these systems is essential for proper maintenance and functionality.

Key Components of Hydraulic Systems

The primary elements of hydraulic mechanisms include pumps, cylinders, and valves. Pumps are responsible for generating the pressure required to move the fluid throughout the system, ensuring that all components receive the necessary hydraulic force. Cylinders, on the other hand, convert hydraulic energy into mechanical power, enabling movement and operation of attached implements.

The Role of Valves

Valves serve as the control centers within hydraulic systems, directing the flow of fluid to various components as needed. They play a vital role in managing pressure and ensuring that the system operates smoothly. Additionally, filtering mechanisms are essential to prevent contaminants from causing damage to sensitive components, thereby extending the lifespan of the system.

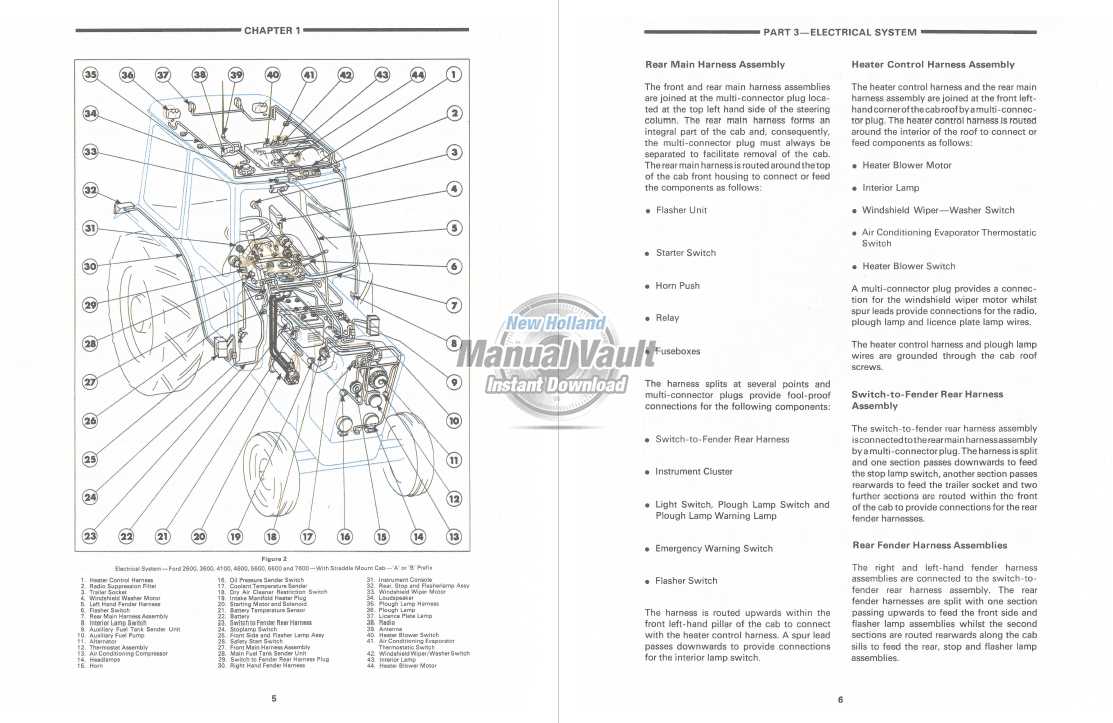

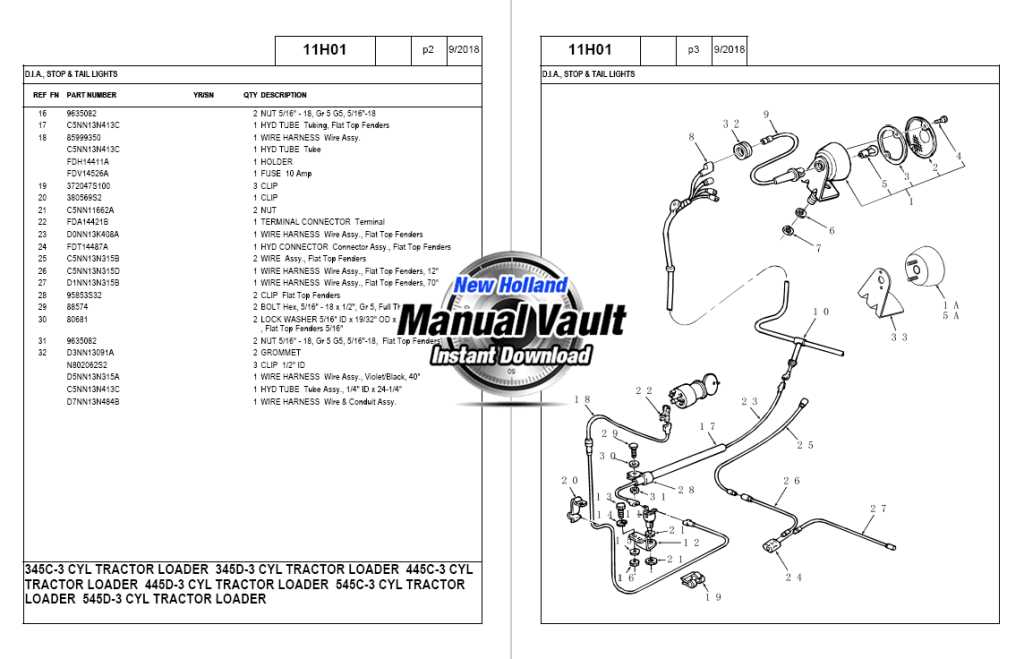

Electrical System Overview

The electrical framework of agricultural machinery plays a crucial role in ensuring optimal functionality and reliability. This system encompasses various components that work together to provide power and control for the machine’s operations. Understanding the structure and function of these elements is essential for effective maintenance and troubleshooting.

Key Components

- Batteries: Provide the necessary energy to start the engine and power electrical accessories.

- Alternator: Converts mechanical energy into electrical energy, recharging the battery while the engine is running.

- Starter Motor: Engages the engine to initiate combustion, allowing the machinery to start.

- Wiring Harness: Connects all electrical components, ensuring proper communication and power distribution.

- Fuses and Relays: Protect the electrical system from overloads and manage power flow to different circuits.

Functionality and Maintenance

Regular inspection and maintenance of the electrical system are vital for uninterrupted operation. Key practices include:

- Checking battery connections and ensuring they are clean and secure.

- Testing the alternator output to confirm it is functioning correctly.

- Examining wiring for any signs of wear, damage, or corrosion.

- Revising fuse conditions to prevent circuit malfunctions.

- Ensuring the starter motor engages smoothly without any unusual sounds.

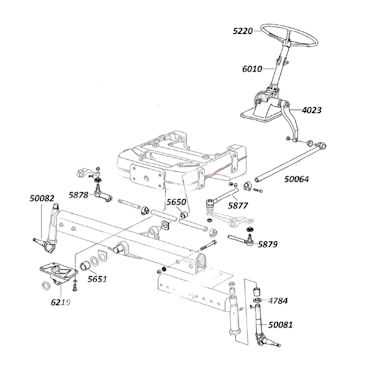

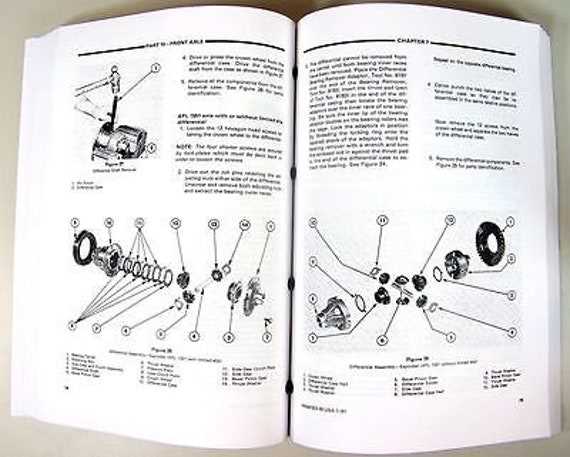

Front and Rear Axles Details

The functionality of agricultural machinery heavily relies on the efficiency of its wheel systems. The components that facilitate movement and support the vehicle’s weight play a critical role in performance. Understanding the intricacies of these assemblies can significantly enhance maintenance efforts and operational longevity.

Front axle configurations are engineered to provide stability and steering precision. These assemblies typically incorporate features that allow for adjustments to accommodate various terrain types, ensuring optimal traction and control. Regular inspections of joints, bearings, and seals are essential for preventing wear and tear that could lead to performance issues.

In contrast, the rear axle is designed primarily for load-bearing and power transfer. This assembly is crucial for delivering torque from the engine to the wheels, enabling efficient movement. Elements such as differential gears and drive shafts are key components, and maintaining them in good condition is vital for smooth operation. Proper lubrication and periodic checks can prevent costly repairs and extend the lifespan of the entire system.

By familiarizing oneself with these axle systems, operators can better manage their machinery and ensure reliable performance throughout their usage. A proactive approach to maintenance not only enhances efficiency but also contributes to the overall productivity of agricultural operations.

Cab and Controls Layout

The interior of the agricultural machine is designed to provide operators with a comfortable and efficient working environment. The layout plays a crucial role in enhancing usability, allowing for seamless interaction with various functions while minimizing operator fatigue.

Key elements of the interior arrangement include:

- Seating Area: The seat is ergonomically designed to support long hours of operation, often featuring adjustable options for optimal comfort.

- Control Panel: Centrally located, this panel provides easy access to essential controls, including gauges and switches for monitoring and operation.

- Steering Mechanism: A well-positioned steering wheel allows for precise handling, ensuring that the machine responds accurately to the operator’s inputs.

- Foot Pedals: Strategically placed pedals facilitate easy access to braking and acceleration functions, enhancing overall maneuverability.

In addition, the layout may include various storage compartments and cup holders, allowing for the safe keeping of tools and personal items. The design not only maximizes efficiency but also prioritizes safety, ensuring that all controls are within easy reach.

Maintenance Tips for Ford 7700

Proper upkeep is essential for ensuring the longevity and efficiency of any heavy machinery. Regular attention to various components can help prevent costly repairs and enhance performance. Following a systematic approach to maintenance will keep your equipment in optimal working condition.

Regular Inspections: Conduct frequent checks on critical elements such as the engine, hydraulic system, and electrical components. Look for signs of wear, leaks, or corrosion. Early detection of potential issues can save time and resources in the long run.

Fluid Changes: Keeping fluids at the correct levels is vital. Regularly replace engine oil, coolant, and hydraulic fluid according to the manufacturer’s recommendations. Clean fluids not only ensure smoother operation but also reduce the risk of overheating and damage.

Air Filter Maintenance: A clean air filter is crucial for optimal engine performance. Inspect and replace the air filter as needed to prevent dust and debris from entering the engine, which can lead to reduced efficiency and increased wear.

Battery Care: Ensure that the battery terminals are clean and connections are secure. Check the battery’s charge regularly, especially before heavy usage. A well-maintained battery prevents unexpected breakdowns and provides reliable starting power.

Tire Checks: Regularly inspect tires for proper inflation and tread wear. Maintaining the correct tire pressure improves fuel efficiency and enhances handling, contributing to safer operation.

By following these maintenance tips, operators can significantly extend the lifespan of their machinery and improve overall efficiency. Consistent care will lead to smoother operation and greater reliability, ensuring that the equipment remains ready for any task.

Where to Find Replacement Parts

Finding suitable components for your machinery can be a challenging task. Fortunately, there are numerous resources available to help you locate the exact items needed to restore your equipment to optimal condition. By exploring a variety of avenues, you can ensure that you acquire high-quality replacements.

Online Retailers

- Many websites specialize in heavy equipment components, offering a wide selection of items for different models.

- Check for customer reviews and ratings to gauge the reliability of the sellers.

- Utilize search filters to narrow down options based on specifications and compatibility.

Local Dealerships

- Authorized dealers often have a stock of genuine replacements tailored for specific machinery.

- Visiting a local dealership allows for personalized assistance and expert advice.

- Some dealers may offer warranties on the components, providing additional peace of mind.

By leveraging both online and local resources, you can effectively find the necessary components to keep your machinery running smoothly.

Common Issues and Solutions

In the realm of agricultural machinery, operators often encounter various challenges that can affect performance and efficiency. Understanding these common complications and their remedies is essential for maintaining optimal functionality. Addressing these issues promptly not only enhances the lifespan of the equipment but also ensures seamless operation during critical tasks.

Frequent Mechanical Failures

One prevalent problem involves mechanical failures, which can arise due to wear and tear over time. Regular inspections are crucial to identify any signs of damage or fatigue. Lubrication plays a key role in preventing these issues; ensure that all moving parts are adequately greased to minimize friction and reduce the risk of breakdowns. If a component shows signs of excessive wear, replacing it promptly can prevent more significant damage.

Electrical System Malfunctions

Another common issue pertains to electrical malfunctions, often manifested as starting difficulties or erratic behavior of controls. Checking the battery connections and ensuring that all wiring is intact can resolve many electrical problems. Additionally, inspecting fuses and relays for continuity will help identify faulty components. If issues persist, consulting an expert for a thorough diagnostic can save time and prevent further complications.