When engaging different vehicles, it’s essential to grasp the fundamental components that facilitate secure and effective attachments. This section delves into the intricate mechanisms designed for these purposes, ensuring a reliable link between vehicles. Understanding these elements enhances safety and efficiency in various transport scenarios.

The focus here lies in the various elements that play a critical role in achieving a steadfast union. Each component contributes to the overall functionality, enabling seamless operations when transporting loads. A comprehensive view of these mechanisms allows users to appreciate the engineering behind reliable connections.

By exploring the arrangement and function of these essential features, one can better understand their significance in enhancing operational efficiency. Whether for personal use or industrial applications, mastering these connections ensures optimal performance and safety.

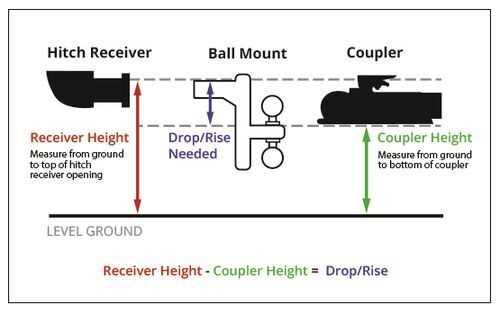

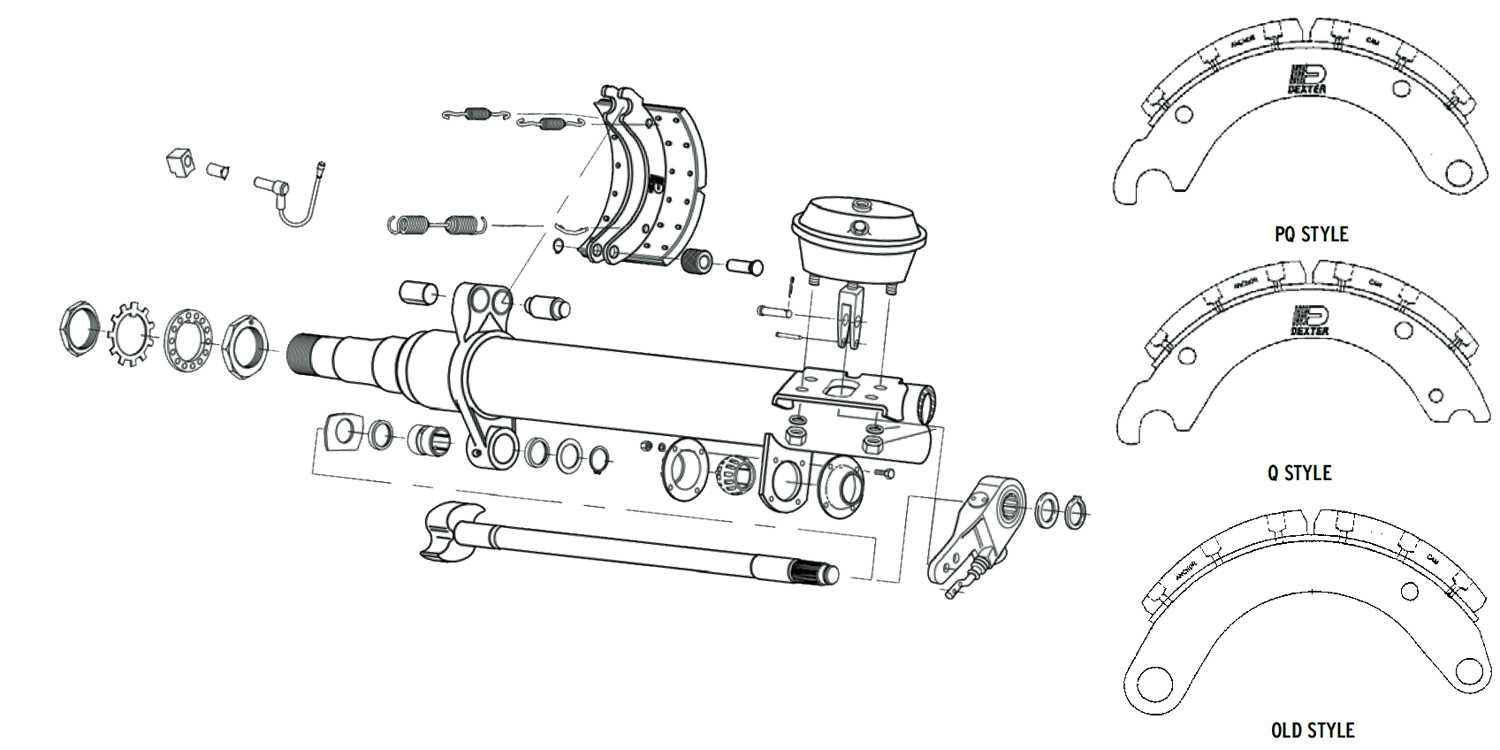

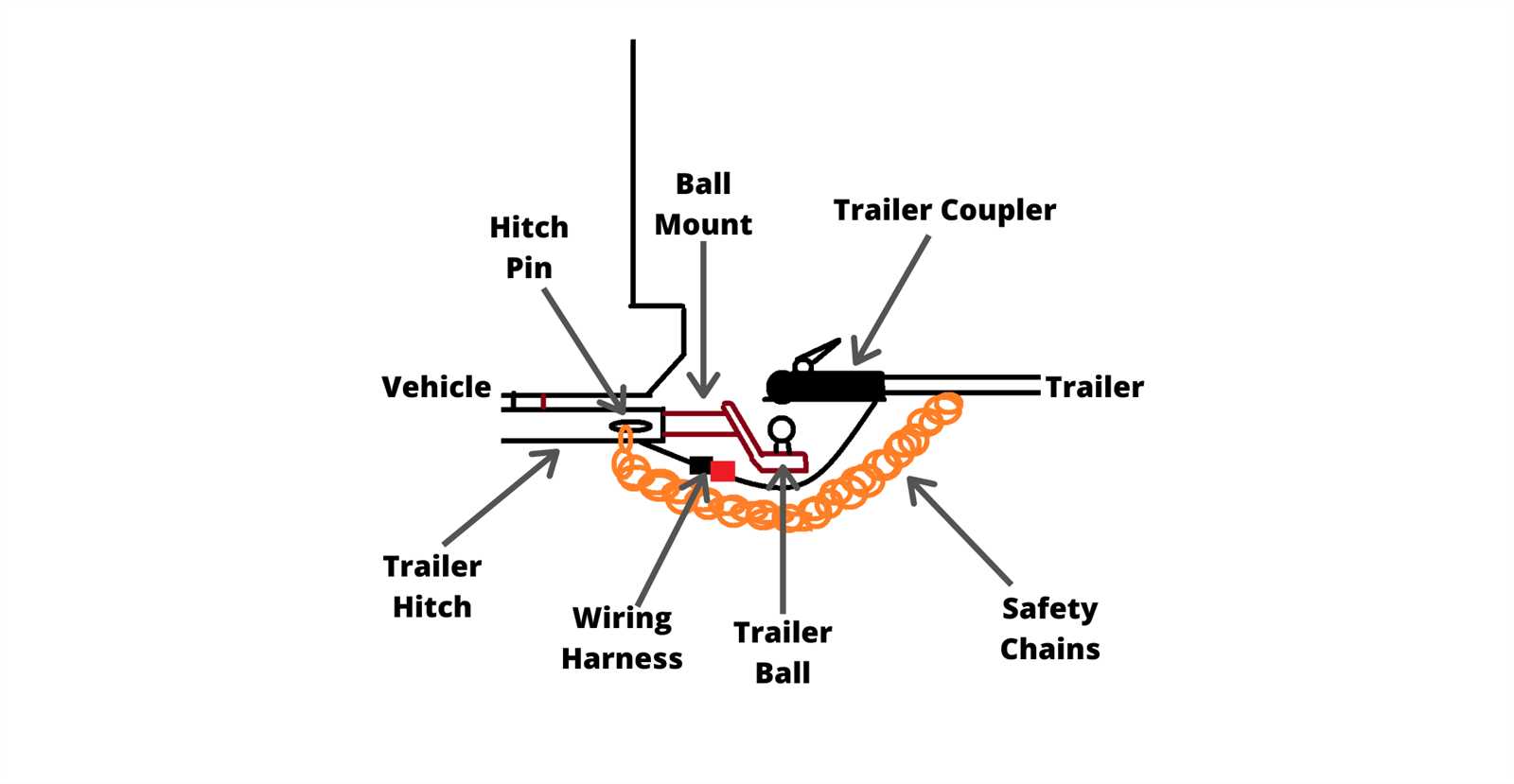

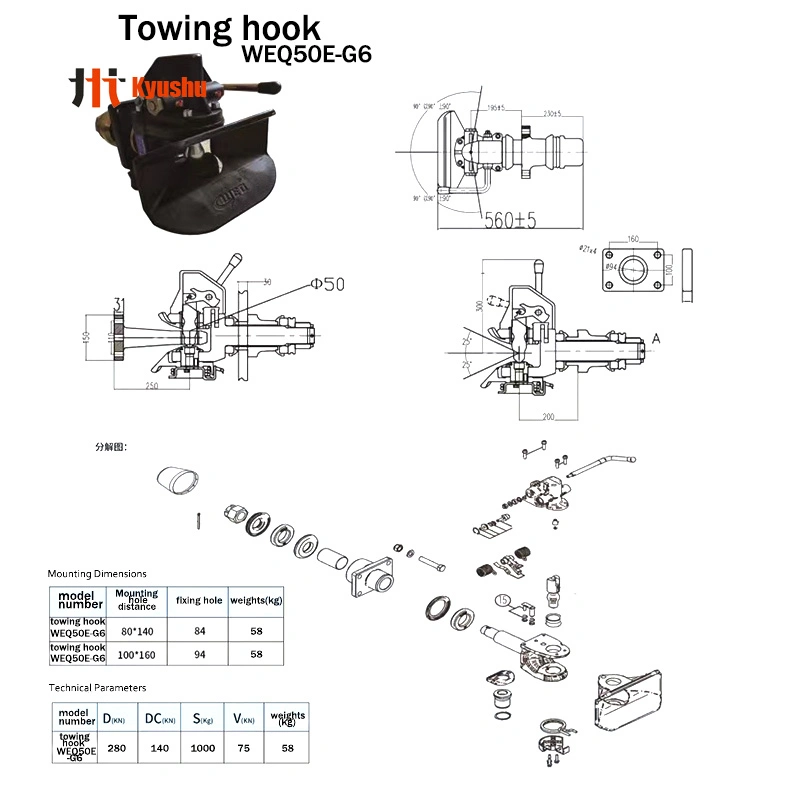

This section provides a comprehensive overview of essential components involved in hitching mechanisms. These elements play a crucial role in ensuring secure connections between towing and towed vehicles. Understanding their functions and interrelations is vital for maintaining safety and efficiency during transportation.

Key Elements of the Connection System

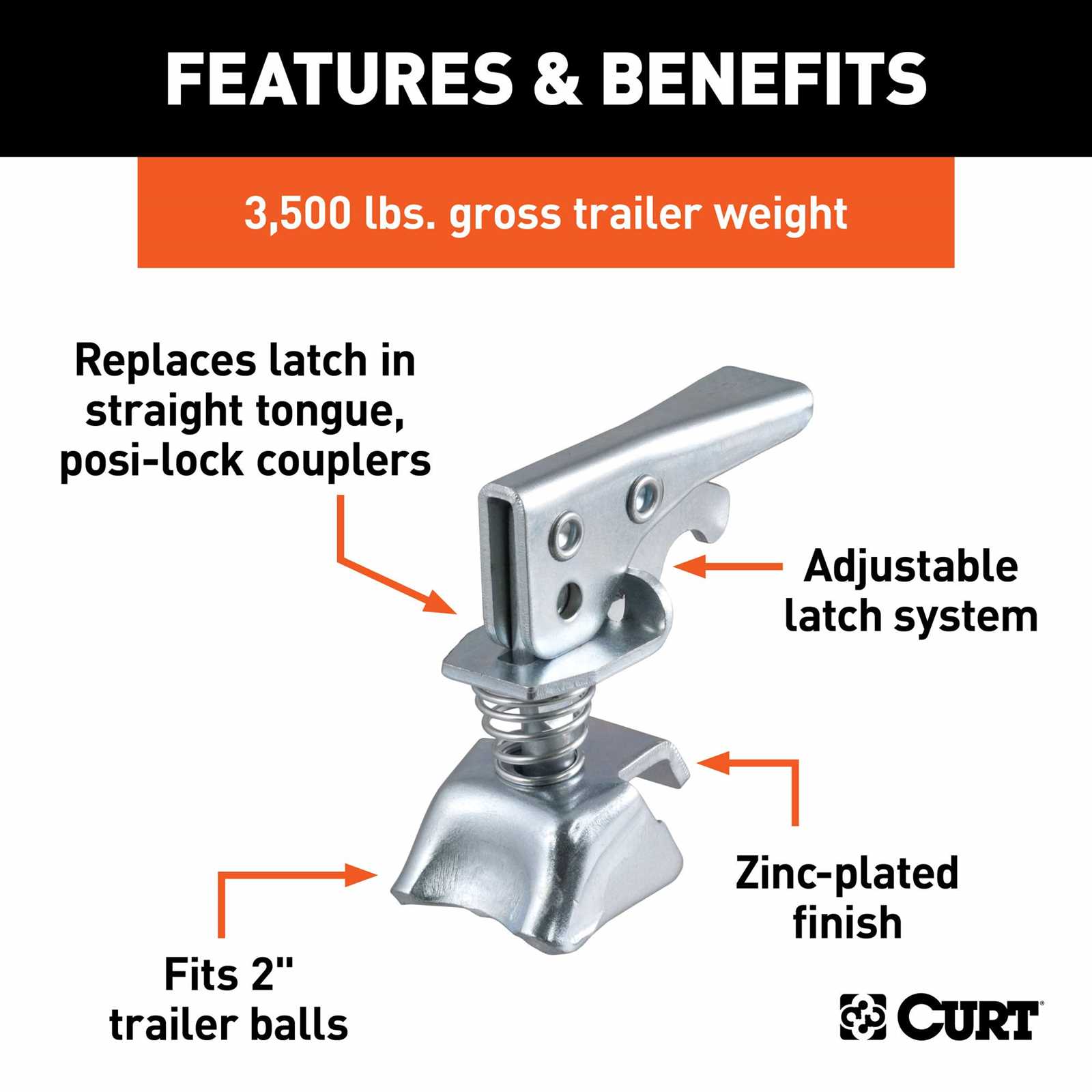

- Connector: Serves as the main interface for attaching two vehicles.

- Locking Mechanism: Ensures a tight and secure fit to prevent accidental disconnection.

- Frame: Provides structural integrity to support various loads during travel.

Functionality and Importance

Each element contributes to the overall reliability of the hitch system. A well-designed locking mechanism, for instance, enhances safety by reducing the risk of detachment while on the road. The frame’s durability is equally significant, as it bears the weight and stress of towing.

Maintenance and Care

- Regular inspections to identify wear and tear.

- Lubrication of moving parts to ensure smooth operation.

- Replacement of damaged components to maintain functionality.

By understanding these vital components and their functions, users can make informed decisions regarding maintenance and upgrades. This knowledge ultimately leads to safer and more efficient towing experiences.

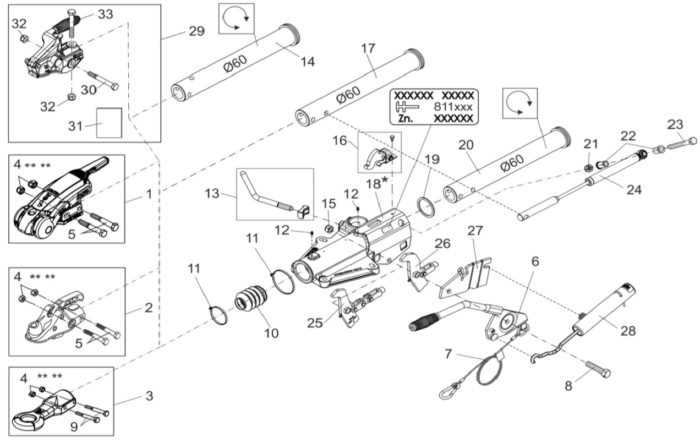

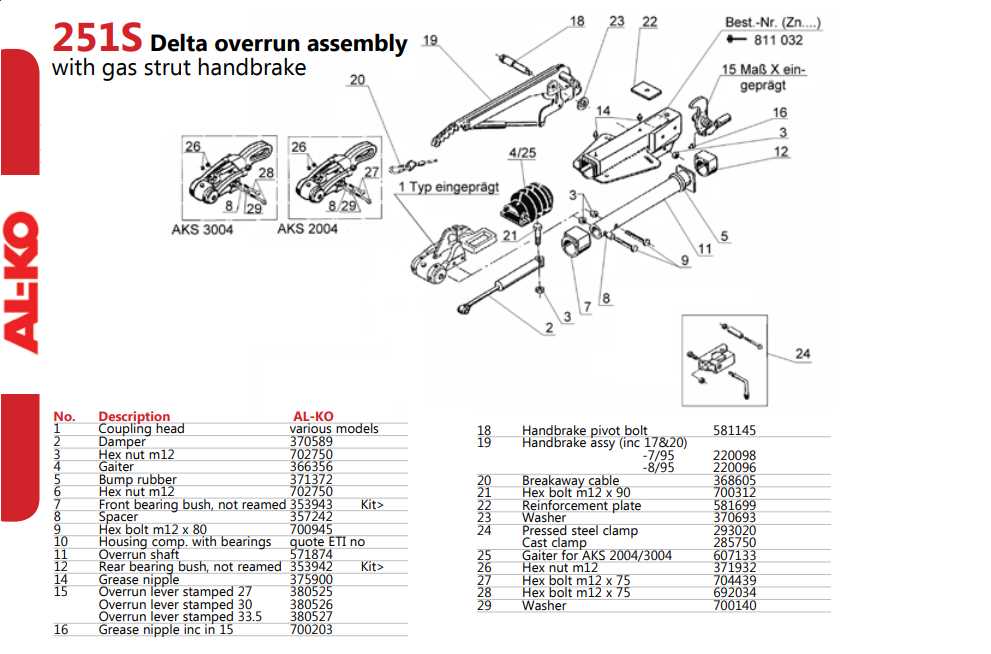

Key Functions of Coupler Parts

Ensuring smooth attachment and reliable movement between linked systems requires components that serve both secure fastening and operational flexibility. Each element in the setup plays a critical role in managing forces, enhancing stability, and enabling seamless interaction during transport or towing activities.

Locking Mechanisms and Their Purpose

- Maintain firm connection under dynamic loads.

- Prevent unintended detachment during motion.

- Provide easy release when needed for disconnection.

Support Structures and Stability Control

- Distribute weight evenly to reduce strain.

- Ensure alignment for smooth operation.

- Absorb shocks and minimize vibrations.

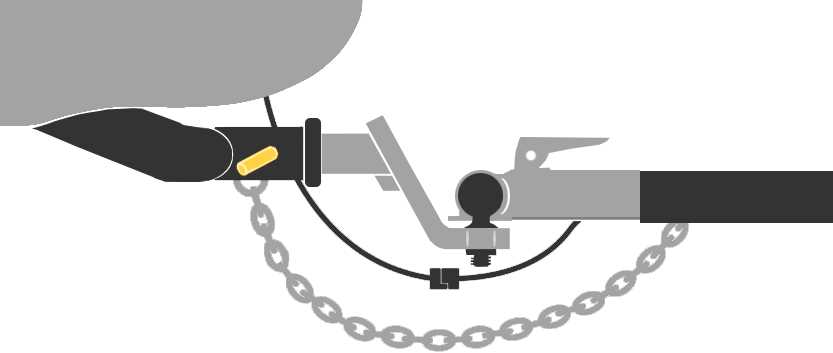

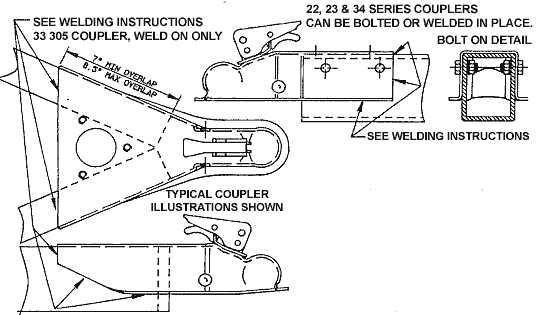

Types of Trailer Couplers Explained

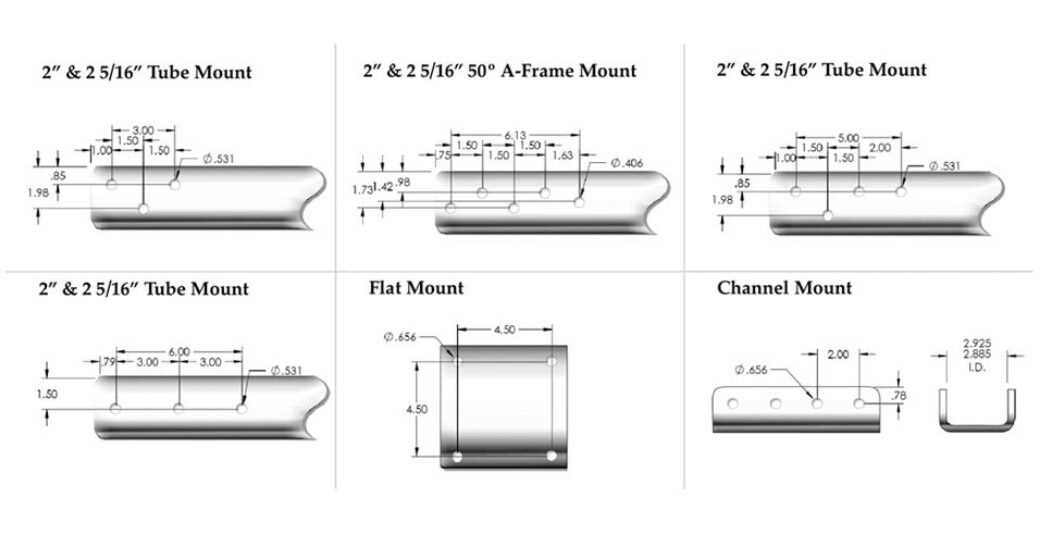

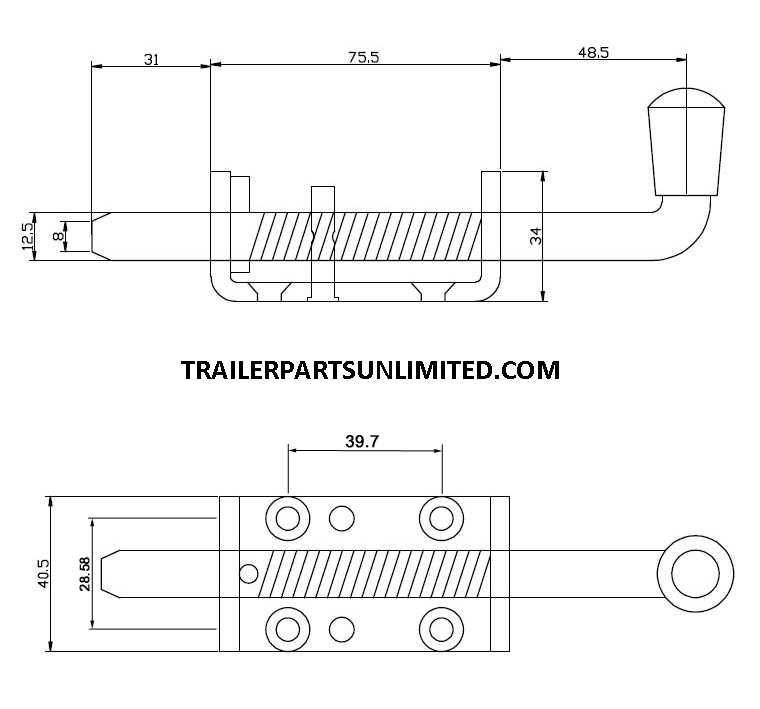

Understanding the variety of connection mechanisms used in towing ensures the right match between the towing vehicle and what’s being towed. Each design serves different weight capacities, hitch styles, and road conditions, making it essential to choose the right option for both safety and performance.

- A-frame connections: These are mounted at the front of a V-shaped chassis. They provide solid alignment and stability, especially for larger loads.

- Channel-style mechanisms: Often adjustable, these allow for vertical movement, making them ideal for varying road heights and different vehicles.

- Flat mounts: These fit directly onto level surfaces and are preferred for light-duty applications or smaller equipment attachments.

- Pintle setups: Known for their ruggedness, these designs use a hook and ring system, providing extra flexibility for off-road use and uneven surfaces.

- Bumper-mounted solutions: Common for vehicles with rear-mounted hitch points, these offer a straightforward way to connect lightweight items or small trailers.

Common Materials Used in Construction

Materials play a crucial role in ensuring durability and efficiency in the creation of modern structures. Choosing the right components directly influences strength, longevity, and safety, making it essential to understand the typical elements used across industries.

Metals for Strength and Flexibility

Steel and aluminum are widely employed due to their ability to withstand heavy loads and resist corrosion. These metals are essential for frames, hinges, and other structural elements that require both flexibility and toughness over time.

Polymers and Coatings

Various plastics and protective coatings, such as rubberized compounds, are used to enhance performance by preventing rust and wear. These materials provide a lightweight solution and can withstand exposure to harsh weather conditions.

| Material | Key Benefit | Common Use | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel | High strength | Structural support | |||||||||||||||||||||

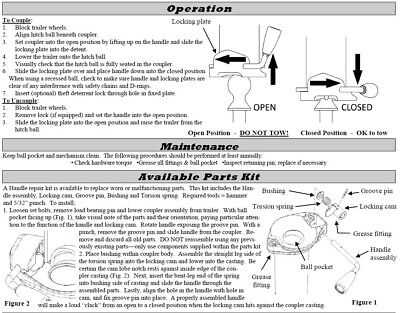

| Aluminum | Importance of Proper Maintenance

Regular upkeep ensures that mechanical connections and devices remain in optimal working condition over time. Components exposed to environmental factors and frequent use can wear out, leading to potential safety risks or reduced performance. A consistent care routine helps prevent unexpected issues, ensuring reliability during operation. Lubrication and cleaning are key steps to prolonging the lifespan of essential equipment. By minimizing friction and corrosion, these measures protect against early degradation. Inspections allow users to identify weak points early, reducing the chance of sudden malfunctions. Neglecting basic care routines can lead to costly repairs or even replacement of critical elements. Scheduling maintenance ensures everything continues to function as intended, offering peace of mind and preventing downtime. The result is smoother operations and better long-term performance. How to Identify Coupler IssuesRecognizing faults in connection mechanisms is essential to maintain safe and efficient performance. These systems experience wear over time, which may lead to alignment problems, instability, or unexpected disconnections. Identifying early signs of trouble ensures a smooth and secure experience during use. One common indication of a malfunction is difficulty locking or releasing the mechanism. This can suggest internal blockages, rust buildup, or misalignment. Regular inspection helps prevent these minor inconveniences from turning into larger safety concerns. Pay attention to unusual noises, such as grinding or squeaking. These sounds can point to missing lubrication or structural degradation. Additionally, inspect for loose components, as they can compromise stability and control, especially when handling heavy loads. If unexpected movement is noticed during operation, it might indicate that the fitting is not secure. In such cases, adjusting or replacing worn-out elements is necessary. Early intervention extends the life of the connection system and prevents costly repairs. Installation Process for Coupler PartsSetting up components for smooth attachment requires attention to detail and the right sequence of actions. Each element must fit properly to ensure secure connections and safe operation during use. Step-by-Step AssemblyBegin by aligning the key elements in their designated positions, ensuring the alignment matches the locking mechanism. Tighten bolts carefully, avoiding excessive pressure to prevent damage. Use a torque wrench where necessary to meet recommended settings. Verify that each moving part operates freely without obstruction. Checking for Stability

After assembly, inspect every connection point for proper fit and stability. Ensure all nuts, bolts, and screws are fastened securely but not over-tightened. Testing the mobility of the locking system helps confirm it engages and releases smoothly. Apply lubricant if needed to reduce friction and prolong the lifespan of the setup.

|