Understanding the inner workings of a modern vehicle’s intricate mechanisms can greatly enhance both performance and longevity. In this guide, we’ll explore one of the key systems responsible for ensuring smooth and efficient operation on the road. This component is not only vital for managing energy distribution but also for maintaining optimal control during varying driving conditions.

By delving into the specific elements and their arrangement within this system, we aim to provide clarity on how each individual piece contributes to the overall functionality. This comprehensive breakdown will highlight the essential segments, focusing on their interactions and the importance of proper alignment and maintenance.

Whether you’re a professional mechanic or an enthusiast looking to expand your knowledge, this detailed exploration offers insights into the major components and how they work together harmoniously. We’

The design of this advanced mechanism relies on a number of critical elements working together seamlessly to ensure smooth operation and efficient power transfer. Each element within the system serves a distinct role, contributing to the overall functionality and performance.

Main Internal Elements

- Control Module: This unit is responsible for managing the entire system’s shifting behavior, regulating the flow of energy and ensuring that the movement is precise and coordinated.

- Clutch Packs: These are essential for engaging and disengaging various gear sets, allowing for smooth transitions between different speeds.

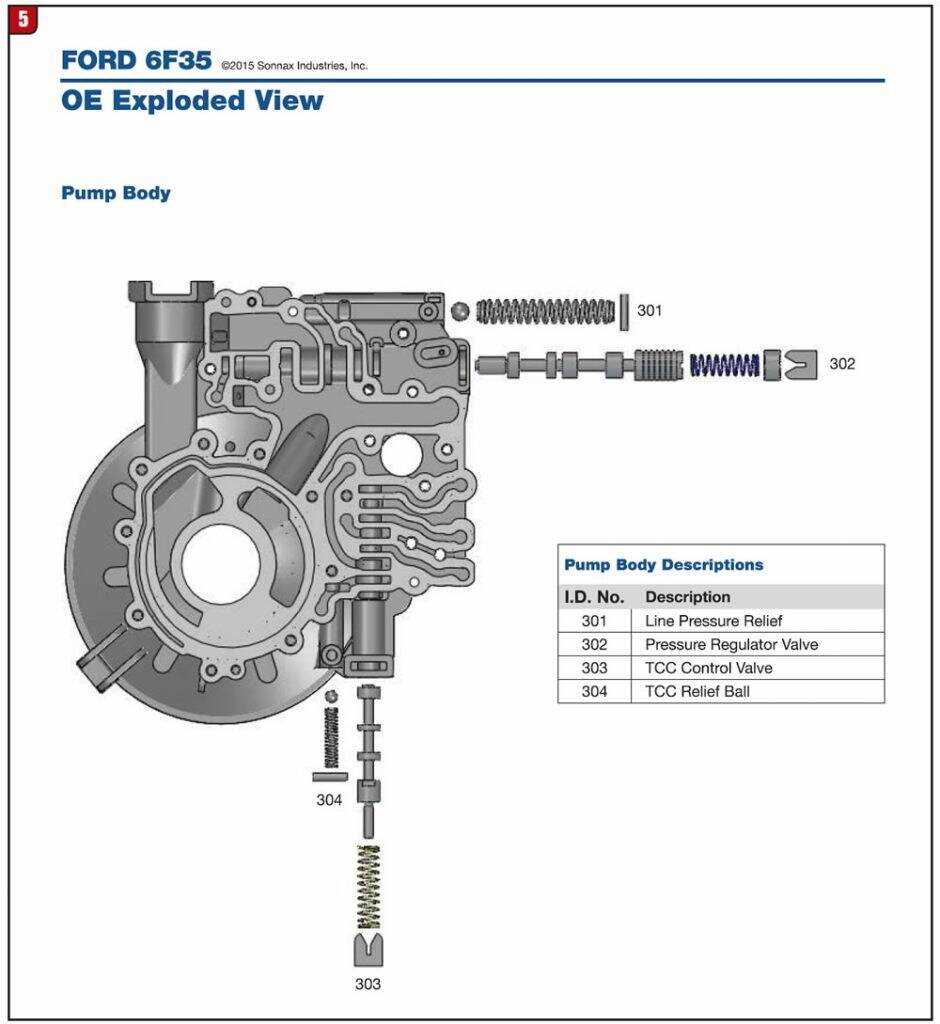

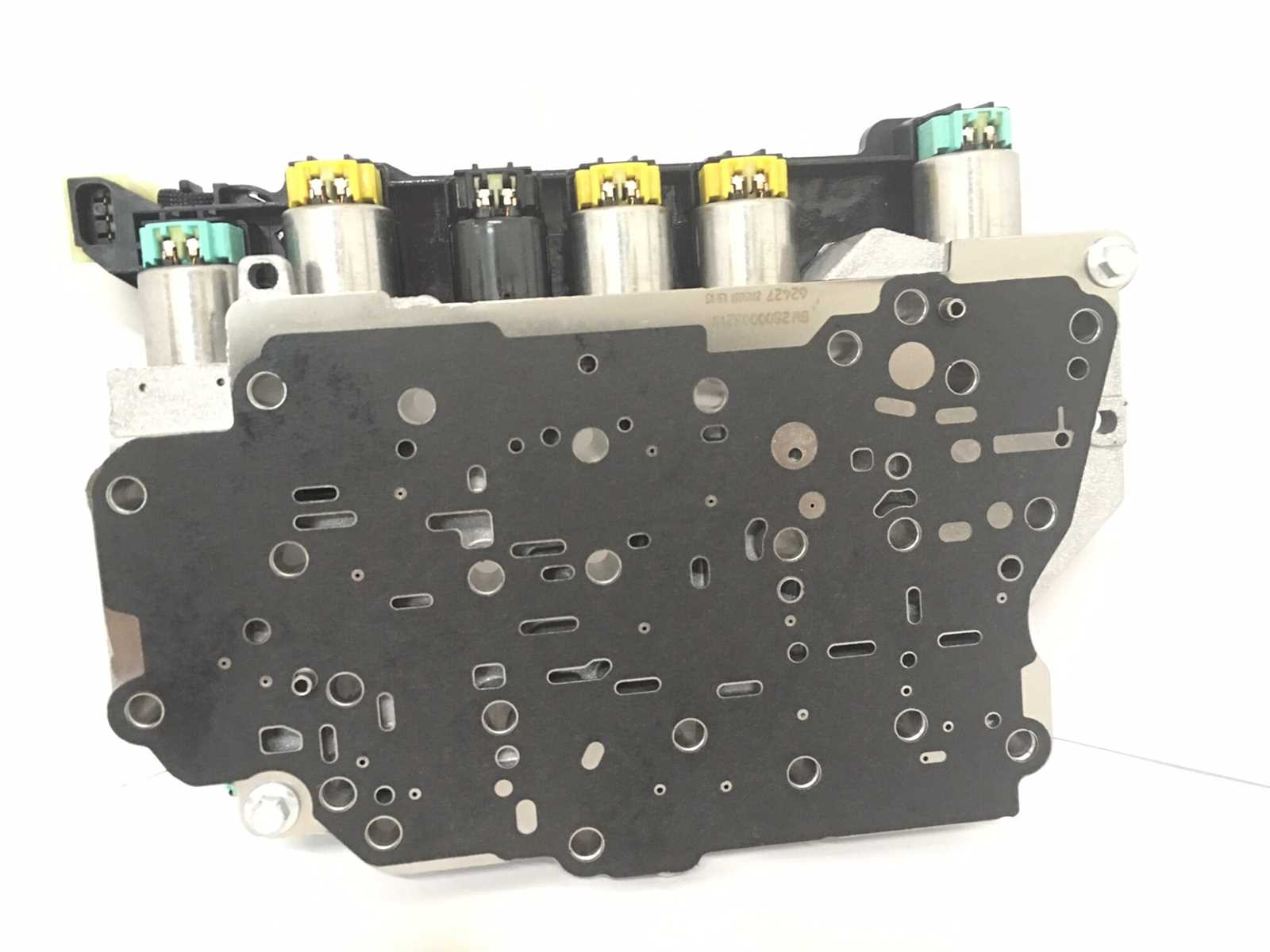

- Valve Body: The distribution hub of the system, controlling the hydraulic circuits that enable fluid movement to activate various components.

Supportive Components

- Torque Converter: This part helps in transferring rotational force from the engine to the system, ensuring a smooth and efficient engagement with the wheels.

- Common Issues with 6F35 Parts

The system in question, which governs the interaction between mechanical and fluid dynamics, often presents challenges over time due to wear and specific component failures. Various elements within the mechanism can degrade, leading to operational inefficiencies or total malfunction. Understanding common faults and their symptoms can help in early diagnosis and preventive maintenance.

Component Typical Issue Signs of Failure Valve Mechanism Obstruction or wear Hard or erratic shifting Fluid Control System Leakage or contamination Overheating, slipping Seals and Gaskets Degradation or improper fitting Fluid leaks, pressure loss Solenoid Unit Electrical failure Incon Assembly Process of 6F35 Transmission

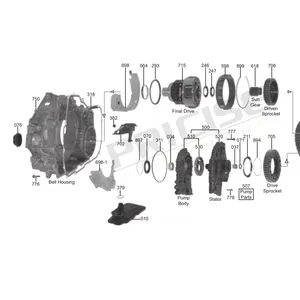

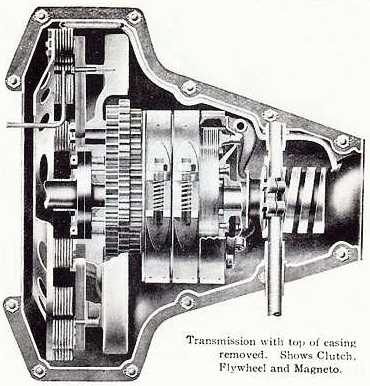

The assembly procedure for this mechanical system involves a series of carefully organized steps to ensure proper functionality. Precision is key in aligning the various components, where each element plays a crucial role in maintaining seamless performance. The process requires an understanding of how each piece fits together and interacts with the surrounding elements, ensuring a smooth operation once fully assembled.

Core Structure Alignment

During the assembly phase, the main structure is aligned with supporting elements to form the foundational framework. This stage involves attaching and securing critical sections, followed by the installation of rotational and stabilizing elements that ensure balance. Attention to detail at this stage prevents misalignment issues that could affect overall performance.

Component Integration Table

Step Description Initial Setup Preparation of core components for assembly, ensuring all pieces are inspected and ready for integration. Mount Maintenance Tips for 6F35 Components

Regular care and attention to key elements of this system ensure long-lasting performance and prevent unexpected malfunctions. Proper upkeep not only extends the life of individual elements but also enhances overall efficiency. By following basic guidelines, you can maintain optimal functionality and minimize the risk of issues arising from wear and tear.

Fluid Checks and Replacement

Ensuring that the lubrication remains clean and at the appropriate level is crucial. Contaminated or low fluid levels can lead to overheating and increased friction, which may cause significant damage over time. Periodically inspect and replace the fluid according to the manufacturer’s recommendations for best results.

Inspecting Seals and Gaskets

Seals and gaskets play an essential role in keeping the internal mechanisms protected from external

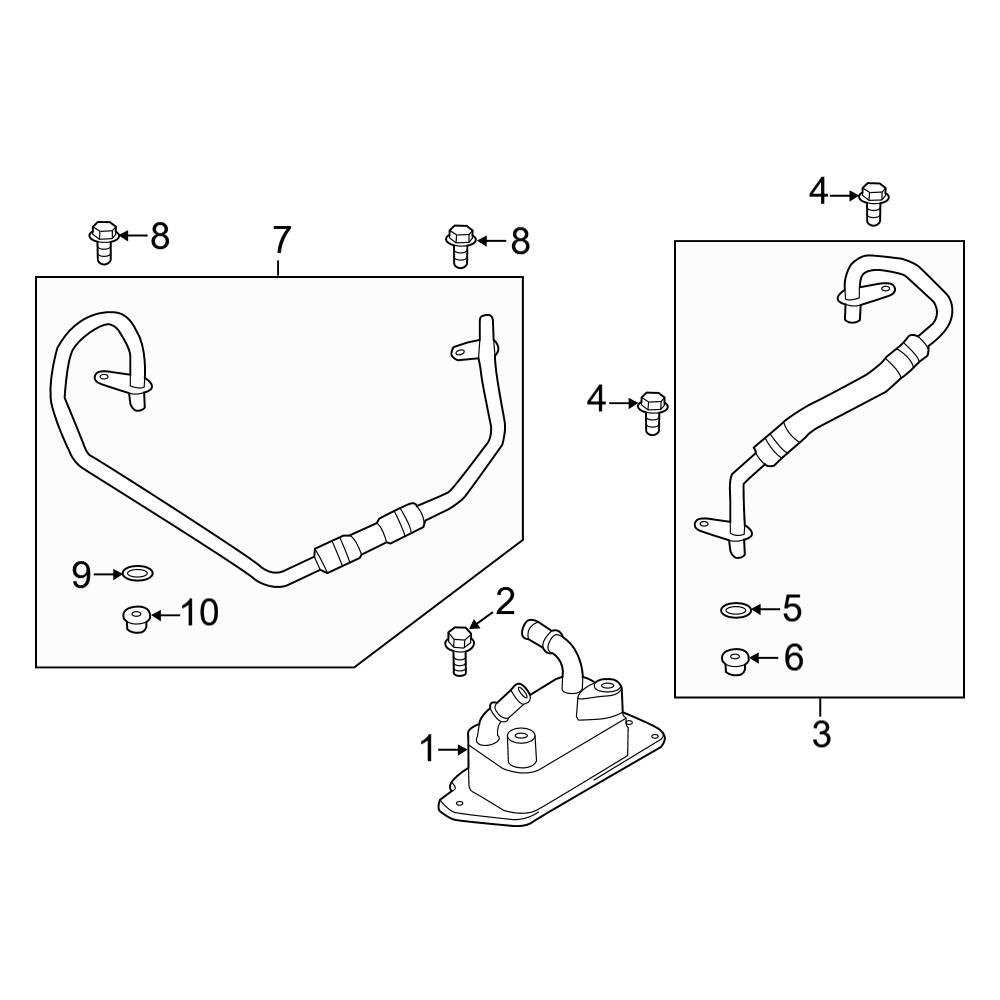

Replacement Parts for 6F35 Transmission

When maintaining a vehicle’s gear shifting mechanism, several key components often require attention to ensure optimal performance. These elements wear down over time, impacting the smooth functioning of the system. By focusing on individual elements and their role in the system, it becomes easier to identify what needs replacing during routine service.

Component Function Clutch Packs Responsible for engaging and disengaging gears during operation. Solenoid Valves Regulate fluid flow to enable gear shifting. Seals and Gaskets Prevent fluid leaks, maintaining pressure within the system. Performance Enhancements for 6F35

When optimizing mechanical components for better efficiency and durability, several upgrades can significantly improve reliability and overall operation. These adjustments focus on fine-tuning specific aspects, ensuring smoother engagement, reduced wear, and enhanced precision. By addressing common performance issues, these upgrades can lead to a more responsive and consistent operation under varying conditions.

Improved Gear Engagement

One of the key areas for enhancement involves refining how mechanical gears interact. By upgrading internal components to more robust materials, wear is minimized, leading to smoother transitions. Additionally, recalibrating the synchronization process ensures faster response times and reduced friction.

Enhanced Fluid Dynamics

Another critical upgrade focuses on fluid circulation. Optimizing the flow within the system not only maintains temperature control but also reduces internal strain. Modern fluid additives can further improve efficiency by minimizing resistance and enhancing lubrication properties, providing better longevity.

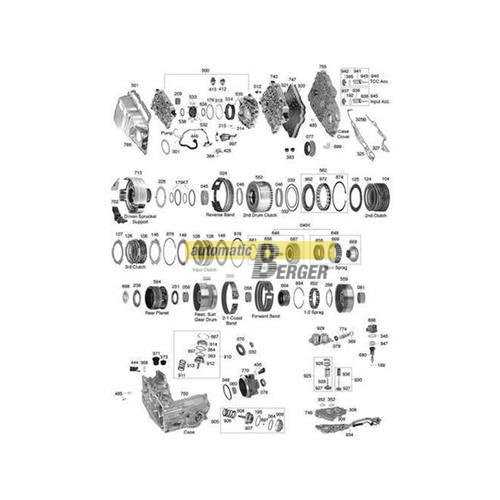

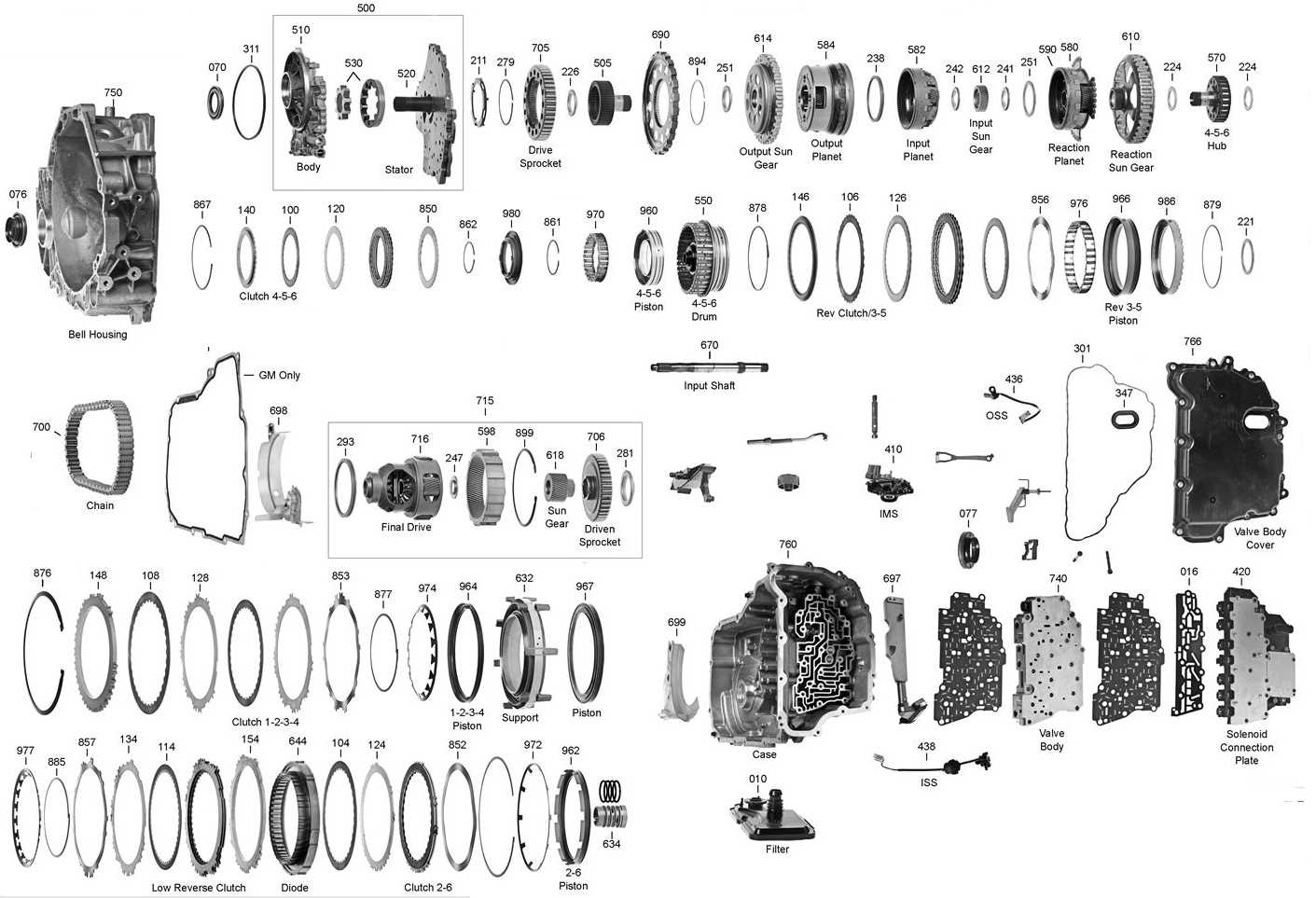

Visual Guide to 6F35 Parts Layout

Understanding the internal structure of this system is crucial for anyone involved in maintenance or repair. This layout provides an overview of the key components, showing how each section is organized and interacts with the others. Knowing the exact arrangement helps in identifying where each element is situated, ensuring a smoother process when performing inspections or replacements.

Main Components Overview: The design is made up of several critical elements that contribute to its efficient operation. These include a range of interconnected mechanisms, each serving a unique function. From the external housing to the intricate internal sections, every piece plays a role in maintaining optimal performance.

Key Connections and Functions: Each section of the layout is strategically positioned to support seamless interaction between moving parts. Whether it’s controlling the flow of energy or ensuring proper alignment, the layout emphasizes durability and smooth functionality. Understanding these connections ensures a deeper grasp of how the entire assembly operates as a unified system.

Tools Needed for 6F35 Repair

Repairing complex mechanical systems requires a precise set of instruments designed to handle various tasks efficiently. From dismantling components to performing detailed inspections, having the right tools is crucial for a successful repair process. Below is a breakdown of the essential equipment you will need to handle this type of work effectively.

Tool Description Socket Set Used for loosening and tightening bolts of different sizes, ensuring proper disassembly and assembly of parts. Torque Wrench Necessary for applying the correct amount of torque to fasteners, preventing overtightening or undertightening. Seal Puller Helps in removing seals without damaging surrounding surfaces, making it easier to replace worn components. Snap Ring Pliers Testing Procedures for 6F35 Efficiency Evaluating the performance and functionality of automotive gear systems requires a systematic approach to testing. This ensures optimal operation and longevity of the components involved. By employing specific methodologies, one can accurately assess how well the system performs under various conditions.

Initially, it is crucial to establish baseline performance metrics. This involves running the assembly under controlled conditions to gather data on its efficiency. Measurements such as fluid pressure, temperature variations, and response times should be meticulously recorded. Analyzing these parameters provides insight into the operational state and highlights any anomalies that may indicate potential issues.

Next, conducting load tests is essential. This process involves subjecting the system to varying levels of stress to observe its behavior. Observing how the assembly handles different torque levels can reveal weaknesses or inefficiencies. Additionally, utilizing diagnostic tools can facilitate real-time monitoring, allowing for immediate feedback on performance during testing phases.

Finally, thorough documentation of all findings is vital. Comparing test results against manufacturer specifications helps in identifying discrepancies and potential areas for improvement. Regular testing and analysis not only enhance performance but also contribute to proactive maintenance strategies, ultimately extending the lifespan of the entire assembly.

Frequently Asked Questions about 6F35

This section addresses common inquiries related to a specific automotive mechanism known for its efficient performance and design. Below, you will find answers to some of the most frequently posed questions about this component.

- What is the primary function of this assembly?

This assembly is designed to facilitate smooth gear transitions, ensuring optimal power delivery and enhancing driving experience.

- What are the signs of malfunction?

Common indicators of issues may include unusual noises, slipping gears, or warning lights on the dashboard.

- How can I maintain this assembly?

Regular maintenance practices include checking fluid levels, performing fluid changes, and inspecting components for wear and tear.

- What should I do if I experience problems?

If you encounter issues, it is advisable to consult a certified technician who can conduct a thorough examination and recommend necessary repairs.

- Are there aftermarket options available?

Yes, there are various aftermarket alternatives that can enhance performance or replace worn components, but it is essential to ensure compatibility.

- What is the primary function of this assembly?