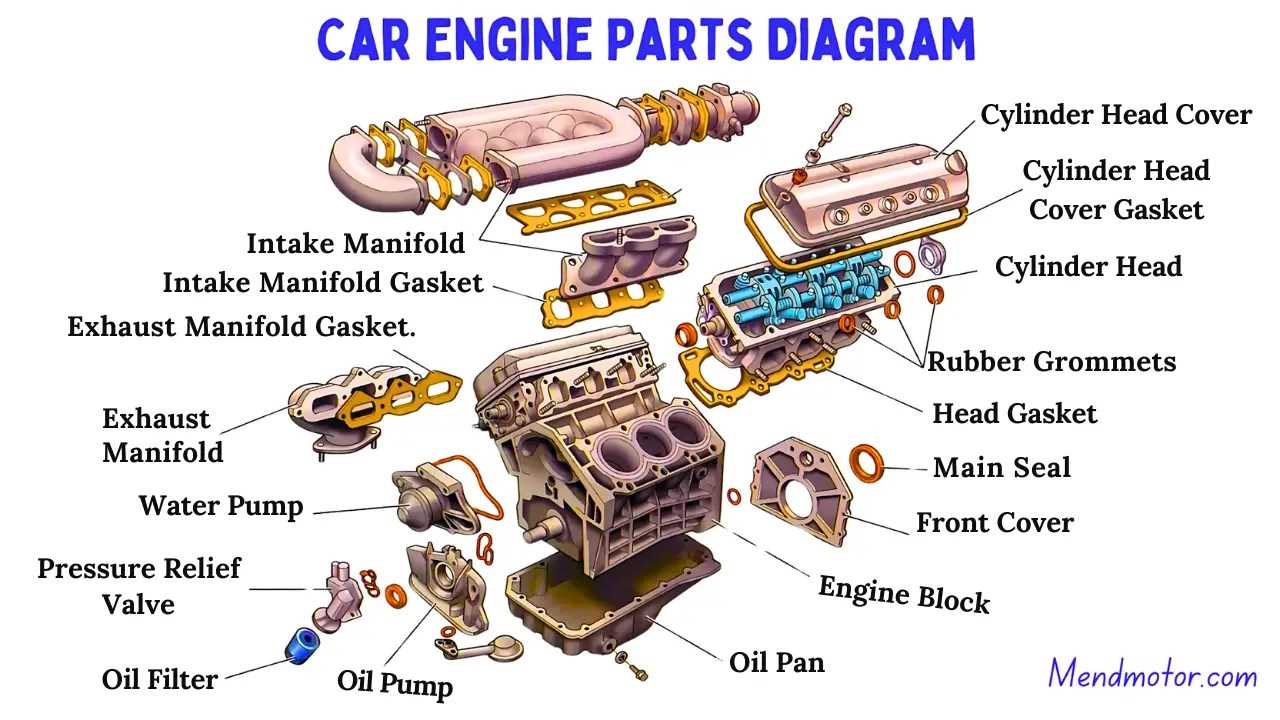

Modern machinery is built from various interconnected elements, each playing a vital role in ensuring smooth operation. These elements work together to transfer energy and motion, creating efficient functionality. By exploring the design and arrangement of these mechanisms, we can gain deeper insight into how they contribute to overall performance.

Every mechanism consists of multiple devices that must be aligned perfectly to achieve desired outcomes. Their interaction is essential in converting energy from one form to another, which is crucial for movement and operation in various systems. Recognizing the importance of each element helps maintain durability and ensures optimal performance.

Efficient assembly of these components enhances the effectiveness of the entire structure. By studying how each part fits and functions, we can better understand the intricate balance required for smooth and reliable operation.

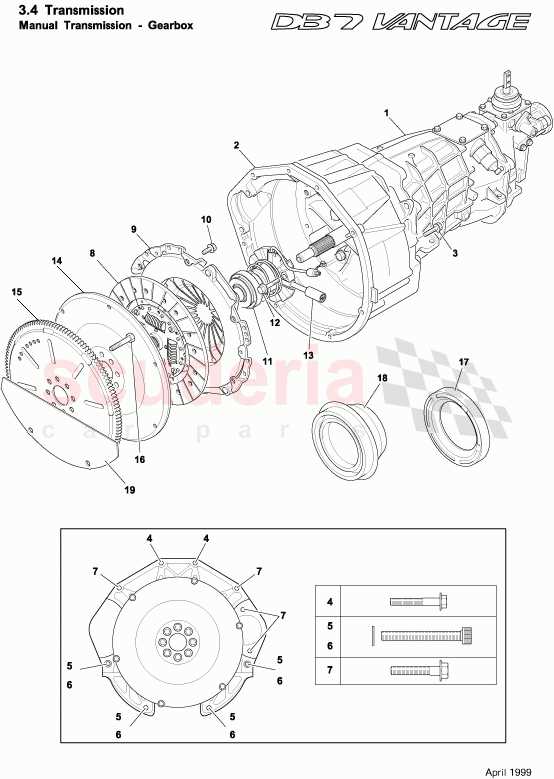

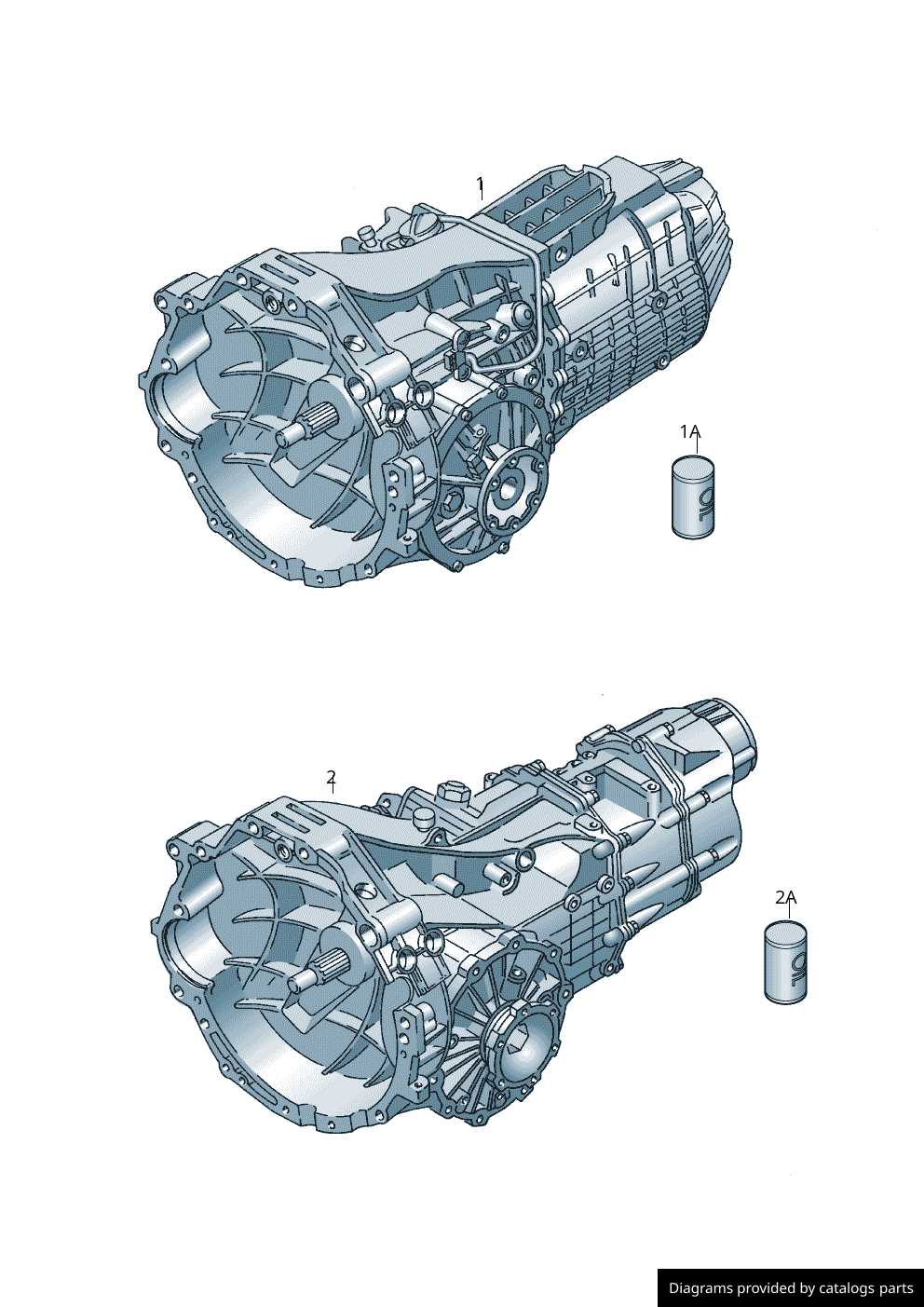

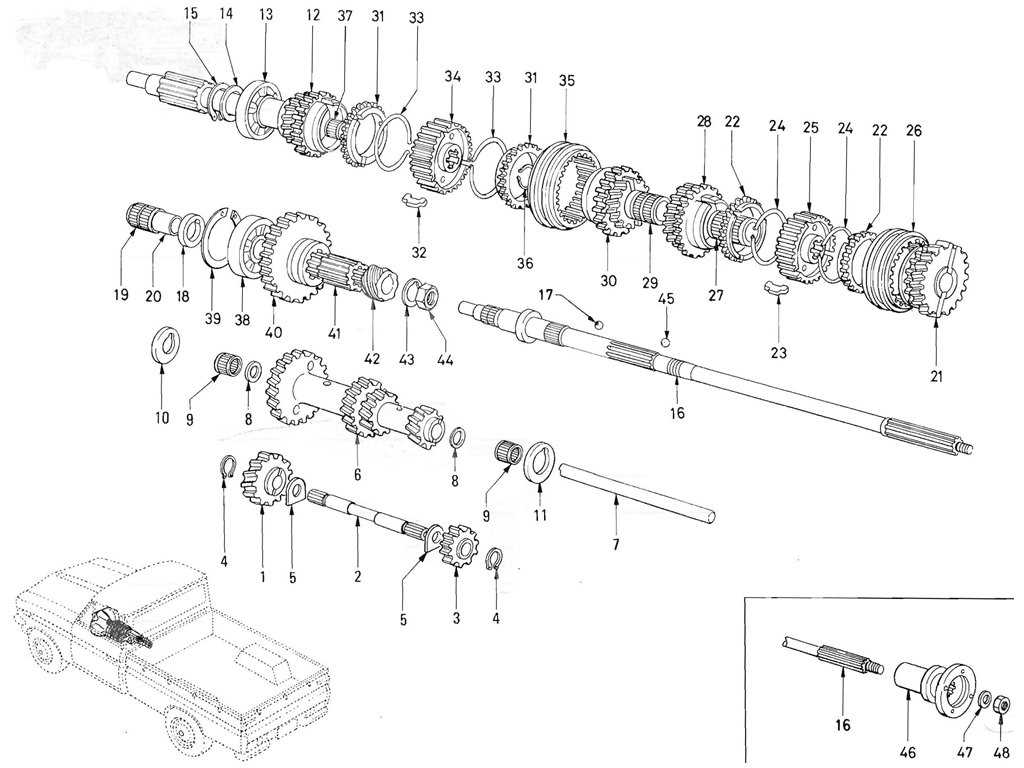

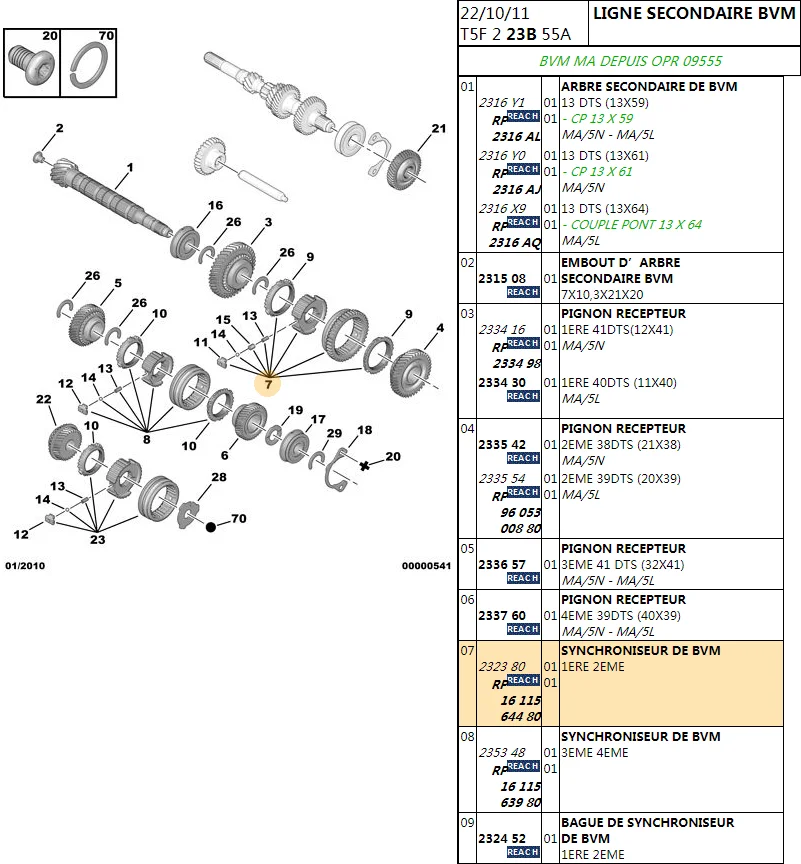

Car Transmission Parts Diagram

Understanding the complex system that allows vehicles to move efficiently involves analyzing various interconnected mechanisms. These components work in harmony to transfer energy from one area to another, ensuring smooth operation and effective power distribution. Each element has a specific function, contributing to the overall functionality of the driving process.

Key elements within this system are designed to handle different types of stress and movement, from controlling speed to regulating direction. Together, they form a sophisticated network, requiring precision and coordination for seamless performance. These intricate mechanisms ensure that energy is transmitted effectively, enabling the vehicle to respond to the driver’s commands with accuracy.

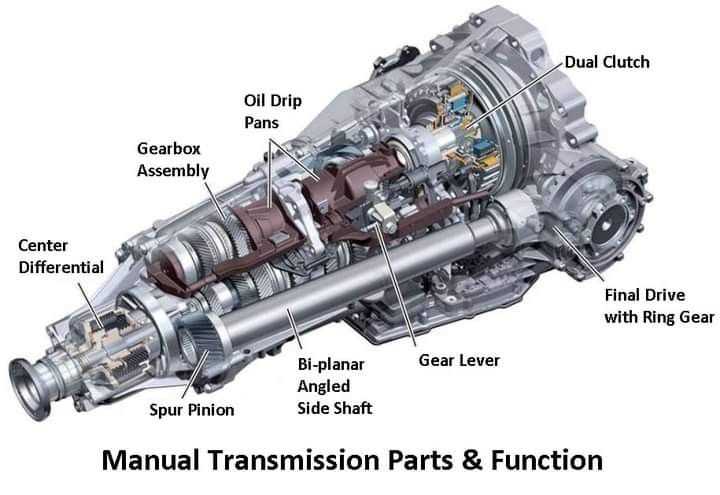

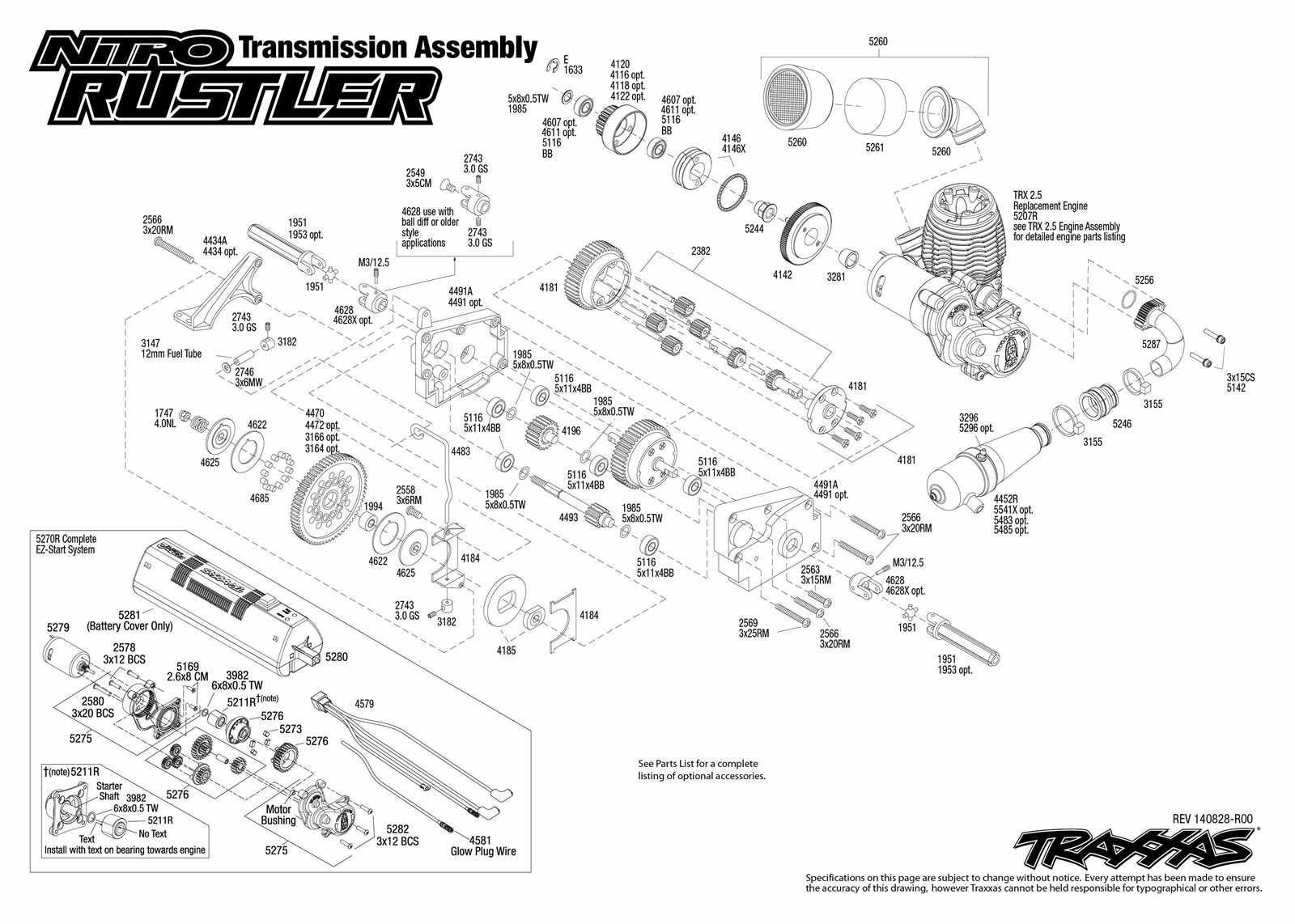

Overview of Transmission Components

In many mechanical systems, various elements work together to ensure smooth operation and power transfer. These components function in harmony, allowing for efficient movement and control. Each part plays a role in managing the energy distribution and ensuring seamless transitions between different stages of operation.

Key components include elements responsible for adjusting speed, managing torque, and facilitating smooth shifts between different states of motion. Some parts handle the flow of power, while others focus on supporting structure and motion control.

Understanding how these interconnected elements function together is crucial for maintaining performance and longevity. Proper maintenance ensures that all parts remain in good working condition, contributing to the overall efficiency and reliability of the system.

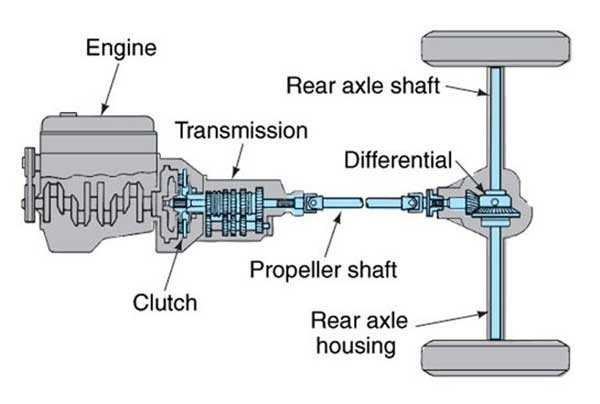

Key Functions of Transmission Parts

In any mechanical system, the components responsible for transferring power are crucial for smooth operation. These elements work together to adjust speed and distribute force, ensuring the system runs efficiently under varying conditions. Understanding the purpose of these elements provides insight into how energy is managed and directed during operation.

Power Distribution and Control

The primary role of these components is to distribute energy to different parts of the system. They regulate the flow of power, allowing for smooth transitions between different states of operation, whether it’s increasing speed or reducing force for more controlled movement.

Maintaining Efficiency and Durability

Another important function is ensuring that the system operates efficiently while minimizing wear and tear. These elements are designed to withstand significant stress and maintain performance over time, which helps extend the overall lifespan of the machine.

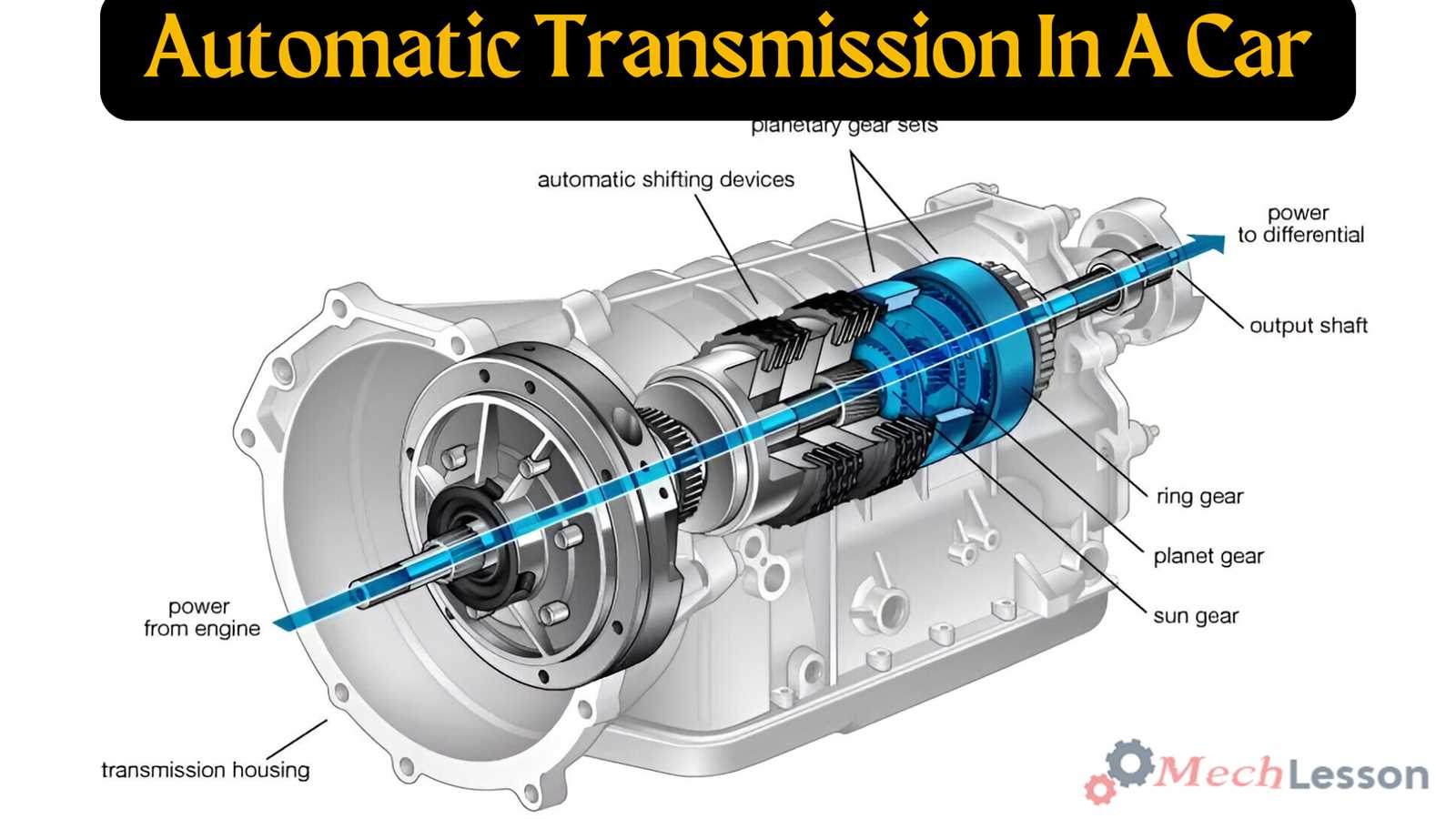

Types of Transmission Systems

There are several methods available to control power distribution and gear shifts in modern vehicles. These systems differ in how they operate, the level of automation they offer, and the driving experience they provide. Understanding the distinctions between them can help in choosing the right option based on driving preferences and performance needs.

| System Type | Key Features | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Manual | Requires the driver to manually engage gears, offering full control over power output. | |||||||||||||||||||||||||

| Automatic | Operates independently, adjusting gears based on speed and road conditions without driver input. | |||||||||||||||||||||||||

| Semi-Automatic | Combines manual control with automated features, allowing for gear shifts without a clutch pedal. | |||||||||||||||||||||||||

Continuously Variable

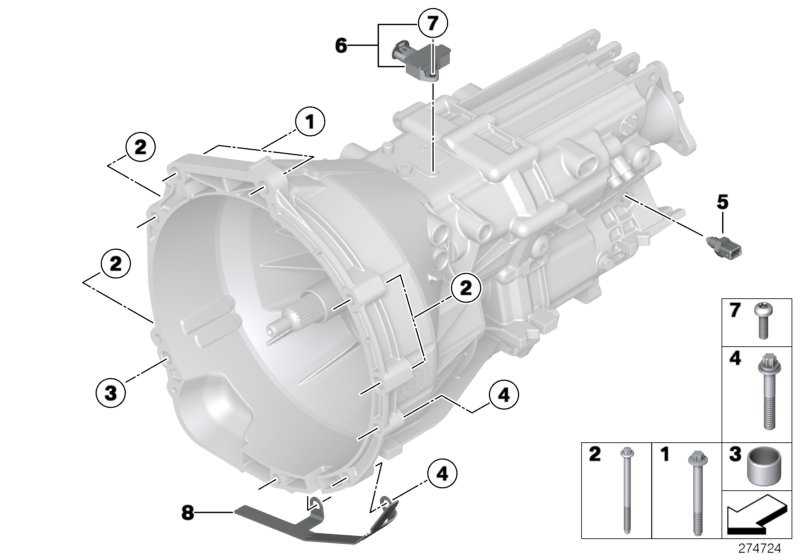

How Transmission Parts Work Together

Each component within the mechanism is designed to perform a specific role, ensuring the efficient transfer of energy. These elements, when synchronized, allow for seamless operation and optimal performance. Understanding how these different pieces interact can help one appreciate the intricate balance necessary for smooth functioning.

|