In the world of automotive engineering, the intricate systems that facilitate smooth gear shifting play a crucial role in vehicle performance. This section delves into the essential elements that make up an automatic gearbox, offering insights into their functions and interconnections. By comprehending these components, one can appreciate how they contribute to the overall efficiency and reliability of the vehicle’s drivetrain.

The complexity of an automatic gearbox requires a well-coordinated assembly of various elements, each serving a specific purpose. From the crucial mechanisms that enable seamless transitions between gears to the support structures that ensure durability, understanding these components is vital for any automotive enthusiast or professional. Familiarity with these components can greatly enhance one’s ability to diagnose issues and perform maintenance.

Furthermore, this exploration provides a visual representation of the intricate relationships among these elements, allowing for a better grasp of their functionality. Whether for educational purposes or practical applications, mastering the layout and roles of each part equips individuals with the knowledge needed for effective troubleshooting and repairs.

This section aims to provide a comprehensive overview of a specific automotive system commonly found in various vehicles. Understanding the components of this mechanism is crucial for both maintenance and repair. The following headings will explore different aspects, ensuring a thorough grasp of its functionality and design.

1. Introduction to the Automotive System

Learn about the significance of this system in vehicle performance and efficiency.

2. Key Components Explained

- Component A: Description and function

- Component B: Description and function

- Component C: Description and function

3. Functionality Overview

Understand how the components work together to enhance vehicle operation.

4. Common Issues and Solutions

- Issue 1: Description and potential fixes

- Issue 2: Description and potential fixes

- Issue 3: Description and potential fixes

5. Maintenance Tips

Explore essential maintenance practices to prolong the lifespan of the system.

6. Upgrades and Modifications

- Upgrade 1: Description

- Upgrade 2: Description

7. Troubleshooting Guide

A guide to help diagnose and resolve common problems effectively.

8. Professional Assistance

- When to seek help from experts

- Benefits of professional servicing

9. Comparison with Other Systems

Analyze how this system stacks up against similar configurations in different vehicles.

10. Frequently Asked Questions

- Question 1: Answer

- Question 2: Answer

11. Resources for Further Learning

List of books, websites, and other materials for deeper understanding.

12. Conclusion

Summarize the key takeaways and importance of understanding the system’s components.

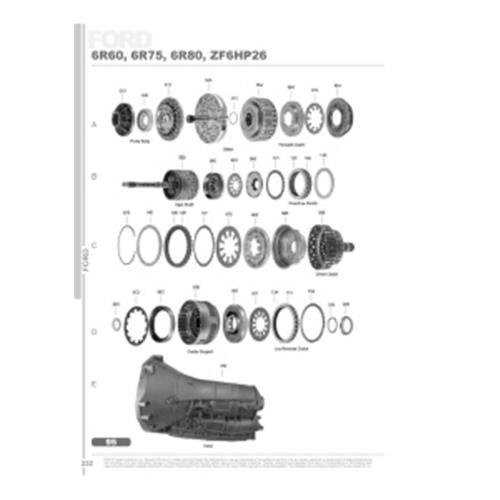

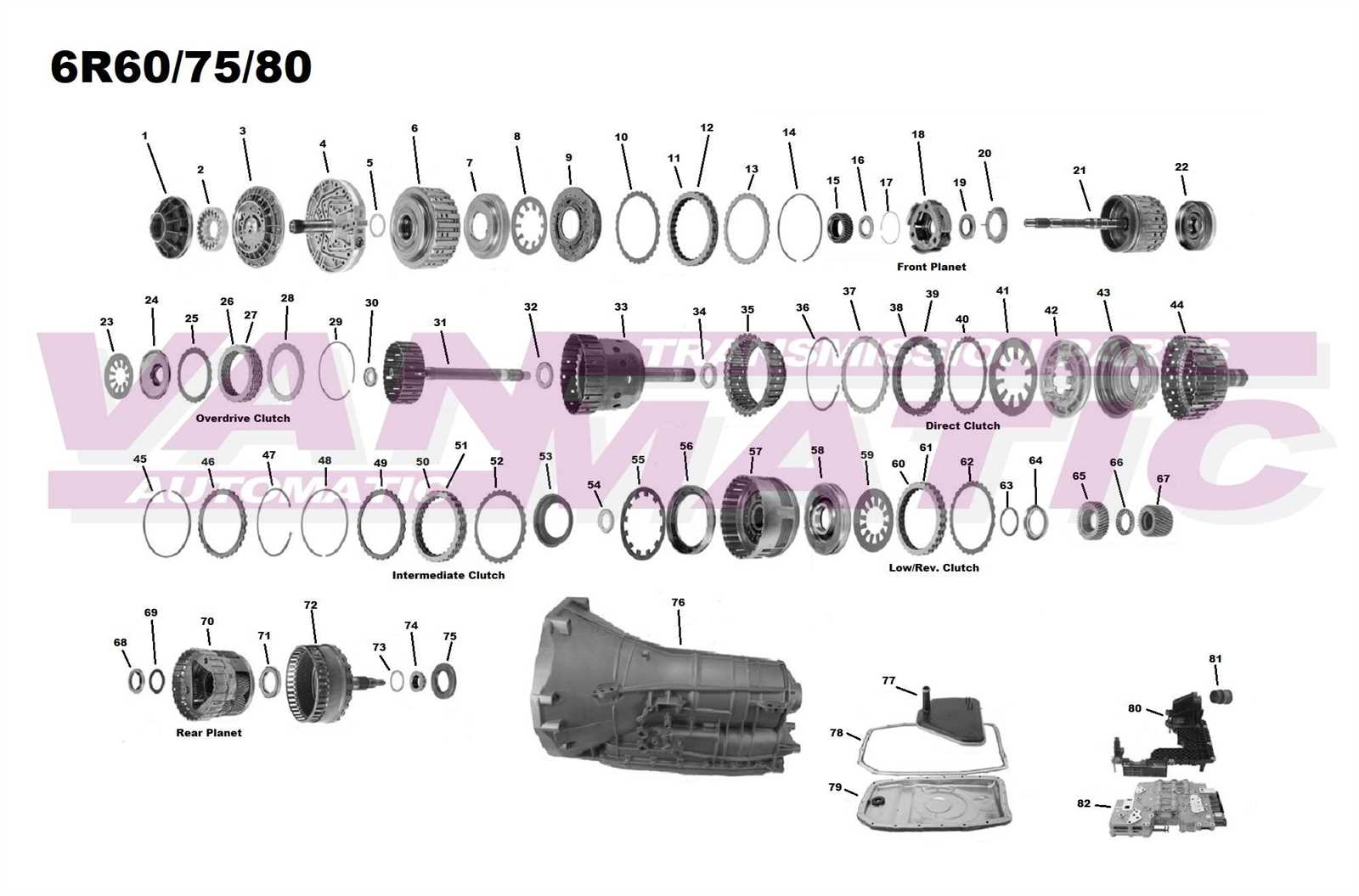

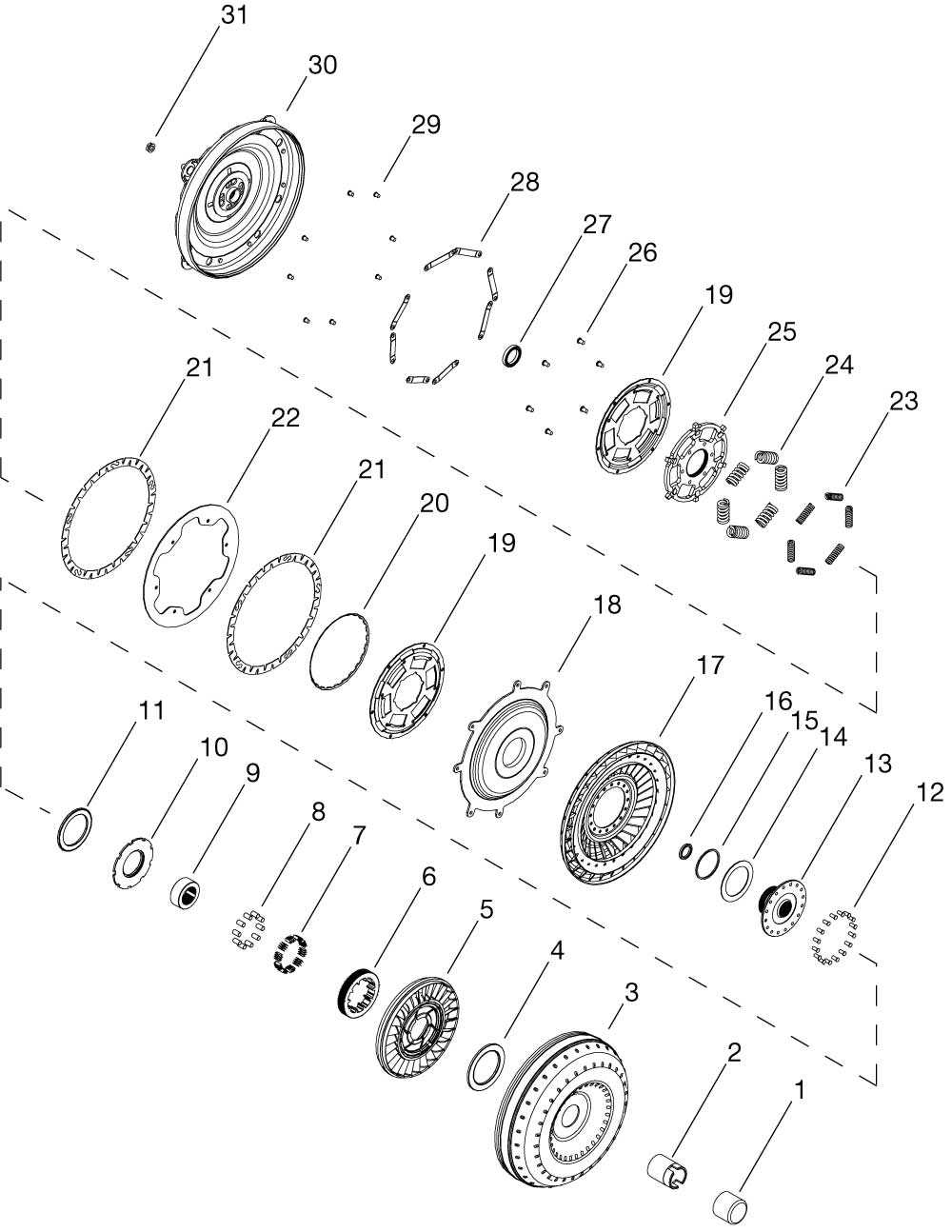

Key Components of the 6R80

This section provides an overview of essential elements found in a specific automatic gearbox used in various vehicles. Understanding these components is crucial for recognizing how they contribute to the overall functionality and performance of the system.

The assembly includes several vital elements, such as the gear sets, which allow for smooth shifting between different driving modes. Additionally, hydraulic systems play a significant role in managing fluid pressure to ensure efficient operation. Control modules are also critical, as they regulate shifting patterns based on driving conditions.

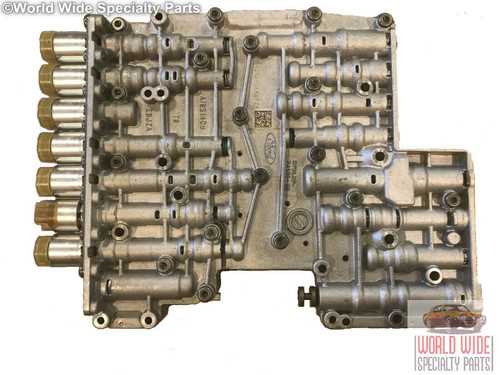

Moreover, the torque converter enhances power transfer from the engine to the drivetrain, optimizing performance during acceleration. Other important components include the valve body, which directs hydraulic fluid to the appropriate clutches and bands, and the pump, responsible for circulating fluid throughout the system.

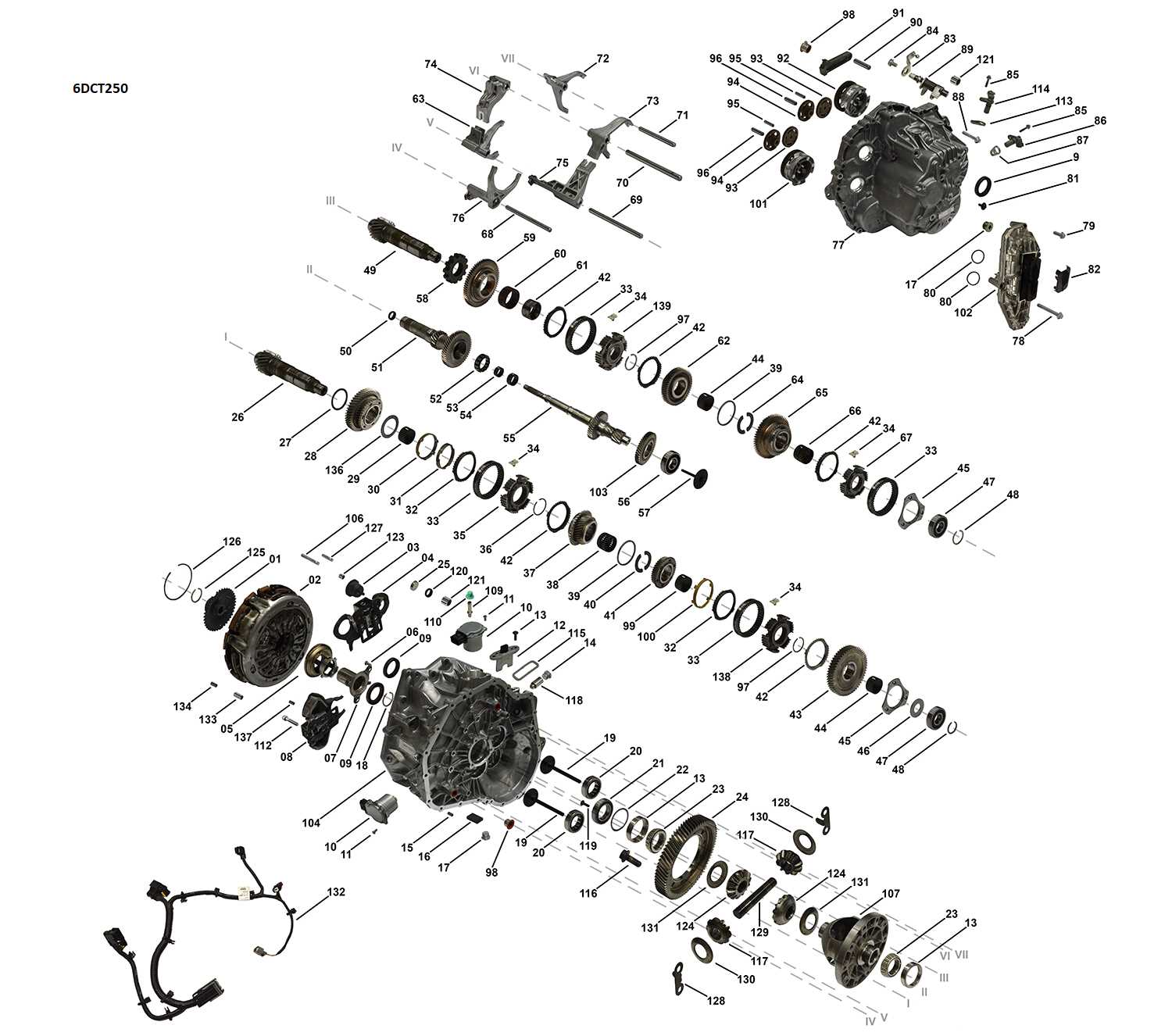

Functionality of Each Part

This section delves into the essential roles played by various components within the assembly. Each element contributes to the overall operation, ensuring efficiency and reliability in the system’s performance. Understanding how these elements work together is crucial for maintaining optimal functionality.

Key Components and Their Roles

Among the vital elements, one can find various gears and valves that regulate flow and pressure. These elements are designed to work in unison, facilitating smooth transitions and enhancing responsiveness. Additionally, the housing provides structural integrity, protecting the internal mechanisms from external factors.

Interconnections and Coordination

The interplay between the components is equally important. For instance, synchronizers aid in matching speeds, allowing for seamless engagement. This coordination is pivotal for achieving the desired performance, making it imperative to comprehend the significance of each component in the assembly.

Common Issues with 6R80 Parts

The complexity of modern gear systems can lead to a variety of challenges that users may encounter. Understanding the most frequent problems can aid in early detection and effective resolution, ensuring optimal performance and longevity.

Frequent Malfunctions

- Overheating: Excessive heat can lead to wear and tear, affecting overall functionality.

- Fluid Leaks: Loss of hydraulic fluid can cause significant operational issues and may require immediate attention.

- Shifting Difficulties: Problems with engaging or disengaging gears can indicate underlying issues that need investigation.

Maintenance Recommendations

- Regular Fluid Changes: Maintaining the correct fluid level and quality is essential for system health.

- Visual Inspections: Routine checks for leaks or signs of wear can help identify potential issues before they escalate.

- Prompt Repairs: Addressing minor problems quickly can prevent more extensive damage and costly repairs.

Replacing Transmission Components

Replacing the internal components of a vehicle’s gear-shifting system is a crucial task that ensures optimal performance and reliability. This process can enhance the efficiency of power transfer and prolong the lifespan of the system.

Before beginning the replacement, it is essential to gather the necessary tools and components. Below is a list of important steps to follow during this procedure:

- Prepare the vehicle by lifting it securely and ensuring a safe working environment.

- Drain the fluid from the system to avoid spills during disassembly.

- Remove any protective covers or shields that may obstruct access to the components.

- Carefully detach the old components, taking note of their arrangement for proper reinstallation.

- Inspect the removed parts for wear and damage to determine if further replacements are needed.

- Install the new components, ensuring they are positioned correctly and securely fastened.

- Refill the system with the appropriate fluid and check for leaks.

By following these guidelines, you can effectively replace components and maintain the efficiency of the gear-shifting system. Regular checks and timely replacements will help in avoiding more significant issues in the future.

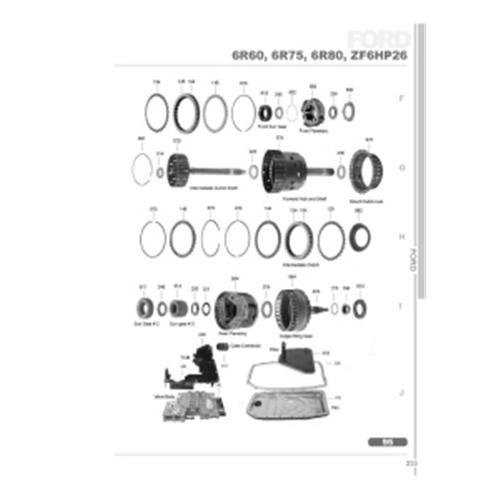

Identifying 6R80 Transmission Diagrams

Understanding the intricate layout of an automatic gearbox is essential for effective maintenance and repair. This section aims to provide insight into recognizing the essential schematics that depict the various components and their interconnections. By familiarizing oneself with these illustrations, one can better comprehend the functionality and potential issues within the assembly.

Common Features of Gearbox Illustrations

Typical schematics showcase various elements such as clutches, gears, and hydraulic systems. Each component is often labeled, allowing for easier identification. Additionally, these visuals may include arrows indicating fluid flow and operational pathways, providing a clearer understanding of how the mechanism functions.

How to Use the Illustrations for Troubleshooting

Utilizing these visual aids can significantly enhance troubleshooting efforts. By comparing the actual assembly to the representation, one can pinpoint discrepancies or areas requiring attention. Observing wear patterns or misalignments becomes simpler when one has a reliable reference to work from.

Maintenance Tips for 6R80 Transmission

Proper upkeep of your vehicle’s automatic gear system is essential for optimal performance and longevity. Regular maintenance can help prevent costly repairs and ensure smooth operation over time. Here are some crucial guidelines to follow for keeping this vital component in excellent condition.

Regular Fluid Checks

Monitoring the fluid level and condition is critical. Low or contaminated fluid can lead to significant issues, affecting the system’s overall functionality. Aim to check the fluid level at least once a month and replace it as necessary.

Heat Management

Excessive heat can be detrimental to the longevity of the gear mechanism. Ensure that your vehicle is equipped with an adequate cooling system to maintain optimal temperatures during operation. Installing an external cooler can further enhance heat dissipation, contributing to better performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Fluid Level Check | Monthly | Look for signs of contamination. |

| Fluid Replacement | Every 30,000 miles | Use recommended fluids. |

| Cooling System Inspection | Every 6 months | Ensure proper functioning. |

Understanding Fluid Types

Choosing the right type of fluid is essential for the optimal performance of any vehicle’s drivetrain system. Each fluid type serves specific functions, such as lubrication, cooling, and cleaning, ensuring that components operate smoothly and efficiently.

There are several common types of fluids, each with distinct characteristics:

- Mineral Oil: A traditional choice, often derived from refining crude oil. It offers good lubrication but may require more frequent changes.

- Synthetic Fluid: Engineered for high performance, synthetic options provide enhanced protection and longevity, making them ideal for extreme conditions.

- Multi-vehicle Fluid: Versatile fluids designed to be compatible with various systems, reducing the need for multiple products.

- High-mileage Fluid: Formulated for vehicles with over 75,000 miles, these fluids contain additives that help reduce wear and leaks.

When selecting a fluid, consider the manufacturer’s specifications and the driving conditions to ensure optimal performance and protection for the system.

Signs of Transmission Failure

Identifying the indicators of mechanical failure is crucial for maintaining vehicle performance. Various symptoms can suggest that a component responsible for power transfer is malfunctioning. Recognizing these signs early can prevent further damage and costly repairs.

Unusual Noises

One of the first signs of potential issues is the presence of strange sounds. These can include grinding, whining, or clunking noises that occur during operation. Such auditory warnings often indicate problems with internal components or fluid levels.

Difficulty Shifting Gears

Experiencing challenges while changing gears can be a significant red flag. Hesitation or unexpected slips during gear transitions may suggest underlying mechanical issues. This symptom often necessitates immediate inspection to determine the root cause and prevent further complications.

Tools Needed for 6R80 Repairs

When working on complex automotive assemblies, having the right tools is essential for efficient and effective repairs. This section outlines the necessary equipment to ensure a successful overhaul of the specific assembly in question. Proper tools not only streamline the process but also help prevent damage to components.

The following list includes key instruments and devices that will be beneficial during the repair procedure:

- Wrenches: A variety of sizes is required for loosening and tightening fasteners.

- Sockets and Ratchets: Essential for accessing hard-to-reach bolts and nuts.

- Screwdrivers: Both flathead and Phillips types are necessary for removing covers and panels.

- Pliers: Useful for gripping and manipulating small parts.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Gasket Scraper: Helps in removing old gasket material without damaging surfaces.

- Oil Catch Pan: Important for collecting fluid during disassembly to keep the workspace clean.

- Shop Vacuum: Useful for cleaning debris and maintaining a tidy work area.

Additionally, it is recommended to have safety gear, including gloves and goggles, to protect against potential hazards during repairs.

Upgrading 6R80 Transmission Parts

Enhancing the performance of your vehicle’s gear-shifting system can lead to improved efficiency and power. Upgrading components can significantly impact acceleration and overall driving experience. This section explores various enhancements that can be implemented to achieve better functionality.

Consider the following modifications to optimize your system:

- High-Performance Clutch Kits: Upgrading to a superior clutch kit can provide enhanced grip and responsiveness.

- Enhanced Valve Body: A performance-oriented valve body can improve fluid flow, leading to faster shifting times.

- Aftermarket Torque Converters: Installing a high-stall torque converter can improve power delivery and responsiveness during acceleration.

- Improved Gaskets and Seals: Upgrading to high-quality gaskets and seals can prevent leaks and ensure longevity.

- Cooling System Enhancements: A better cooling system can help maintain optimal operating temperatures, improving overall reliability.

By investing in these upgrades, you can enhance the performance and durability of your vehicle’s gear-shifting system, providing a more enjoyable driving experience.

Manufacturer Specifications and Standards

The guidelines established by manufacturers play a crucial role in ensuring the performance and reliability of automotive components. These specifications outline the essential criteria that parts must meet to function effectively within the overall system.

Understanding the requirements set forth by manufacturers allows for optimal integration and performance of individual elements. Adhering to these standards is vital for maintaining safety and efficiency during operation. Regular assessments and compliance checks help identify potential issues before they escalate, ensuring longevity and reliability.

Moreover, precise specifications aid in the development of replacement components, guaranteeing compatibility and functionality. This comprehensive approach enhances the overall driving experience and reduces the likelihood of failures.

Resources for Further Information

For those seeking additional knowledge and insights regarding automotive gear systems, various materials are available that provide detailed explanations and guidance. These resources can enhance understanding and assist in effective maintenance and repair tasks.

Books and Manuals

Literature on mechanical systems often contains comprehensive information on assembly, functionality, and troubleshooting. Consider consulting the following resources:

| Title | Author | Publication Year |

|---|---|---|

| Automotive Mechanics | John Doe | 2019 |

| Understanding Gear Systems | Jane Smith | 2021 |

| Advanced Repair Techniques | Emily Johnson | 2020 |

Online Forums and Communities

Engaging with online groups and forums can provide practical advice and shared experiences from fellow enthusiasts and professionals. These platforms often serve as valuable hubs for troubleshooting tips and recommendations.