The intricate world of automatic gear systems is essential for the smooth operation of vehicles. Within this complex machinery lies a network of elements that work in harmony to ensure optimal performance. By exploring the various components involved, one can gain a deeper appreciation for the engineering that allows for seamless gear transitions.

Each component plays a crucial role in the functionality and efficiency of the entire system. From hydraulic mechanisms to electronic controls, understanding how these elements interact provides insight into the design and operation of modern automobiles. This exploration highlights not only the technical aspects but also the importance of regular maintenance and the impact of wear over time.

In this section, we will delve into the specific elements that constitute these systems. By examining their arrangement and function, readers will enhance their knowledge of how vehicles achieve power transfer and acceleration. This understanding can prove invaluable for both enthusiasts and professionals alike, fostering a greater respect for automotive technology.

Understanding the Ford C6 Transmission

This section delves into the essential components and mechanics of a well-regarded automatic shifting system that has made a significant impact in the automotive world. By grasping its workings, enthusiasts and mechanics alike can appreciate its robust design and performance.

The main features of this system include:

- High torque capacity

- Durability and reliability under various driving conditions

- Ease of maintenance and repairs

Key elements that contribute to its functionality encompass:

- Hydraulic System: This controls gear changes, ensuring smooth operation and responsiveness.

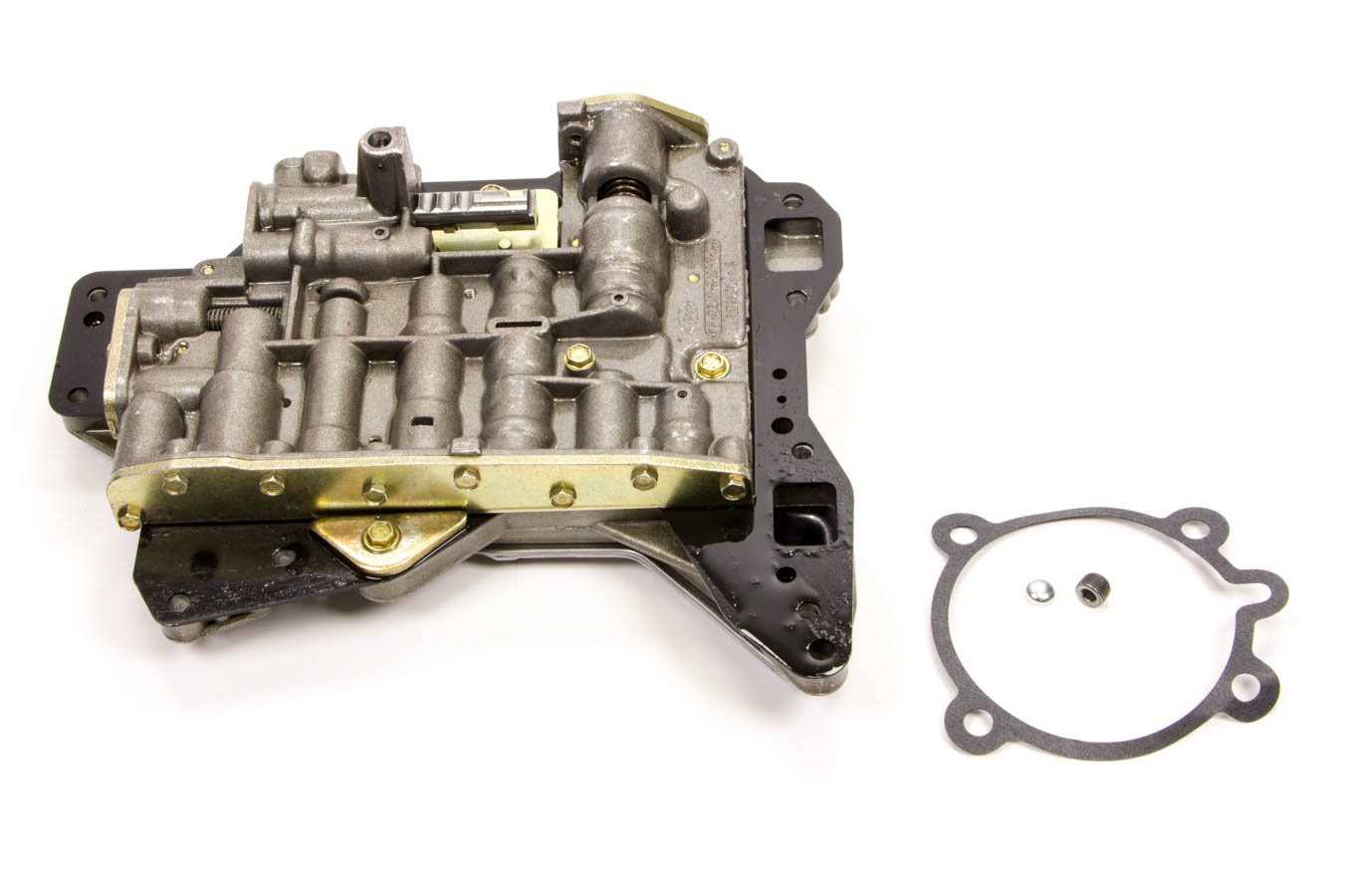

- Valve Body: Acts as the brain, directing fluid flow to engage and disengage gears.

- Clutch Packs: Provide the necessary friction for gear engagement, allowing for seamless shifting.

- Torque Converter: Transfers power from the engine, enhancing efficiency and performance.

Understanding these components can empower users to optimize performance, troubleshoot issues, and make informed decisions regarding upgrades or replacements.

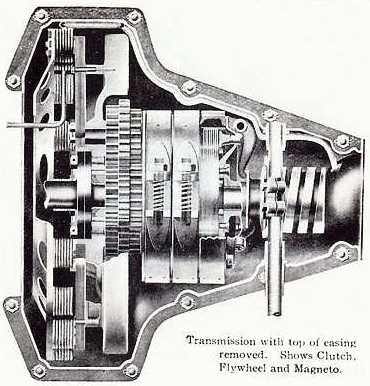

History of the C6 Transmission

The evolution of a particular automatic gearbox has been marked by significant milestones and innovations. Initially designed to meet the demands of a growing automotive market, this system has become synonymous with durability and performance. Its introduction in the mid-1960s represented a shift towards more advanced engineering solutions, reflecting the needs of both manufacturers and consumers.

Over the years, enhancements were made to improve efficiency and reliability. The innovative design featured a robust structure capable of handling increased torque, making it a favorite among various vehicles. As the automotive industry evolved, so did the technology behind this particular gearbox, incorporating new materials and refined manufacturing processes to ensure longevity and optimal function.

In the following decades, it garnered a reputation for being a workhorse in many heavy-duty applications. Enthusiasts and mechanics alike appreciated its straightforward design, which facilitated repairs and modifications. This combination of simplicity and strength solidified its place in automotive history, making it a preferred choice for both performance upgrades and restoration projects.

Today, the legacy of this automatic system continues, with aftermarket support and a dedicated community that celebrates its historical significance. The blend of engineering excellence and practical application has ensured that it remains relevant in various automotive circles, proving its enduring appeal across generations.

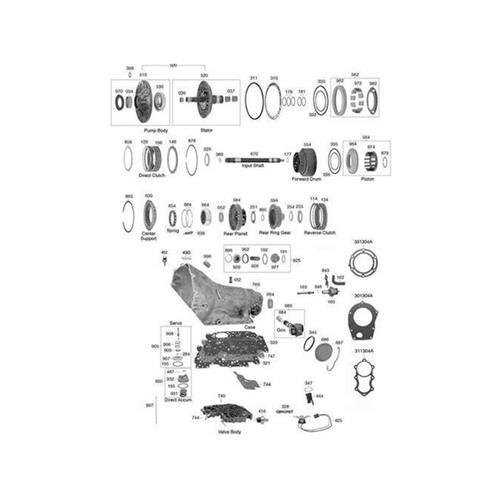

Key Components of the C6 System

The C6 system comprises several vital elements that work together to ensure efficient operation and performance. Understanding these components is essential for anyone looking to maintain or repair this specific mechanism.

Main Elements

- Hydraulic System

- Torque Converter

- Gear Sets

- Control Valve Body

- Oil Pump

Supporting Components

- Filter Assembly

- Seal Kits

- Governor Mechanism

- Linkage and Cables

- Electronic Controls

Each component plays a significant role in the overall functionality and reliability of the system, making familiarity with them crucial for effective service and repairs.

Transmission Operation Principles Explained

The fundamental principles behind the functioning of a vehicle’s gear-shifting system are crucial for understanding how power is efficiently transferred from the engine to the wheels. This process involves a series of mechanical interactions that allow for smooth acceleration and deceleration, ensuring optimal performance under varying driving conditions.

At the core of this system is the concept of torque multiplication, which enables the engine to provide sufficient power while maintaining efficiency. The interaction between different components, such as clutches and bands, facilitates the selection of the appropriate gear ratio based on speed and load demands. This dynamic adjustment is vital for enhancing the vehicle’s responsiveness and fuel economy.

Additionally, hydraulic systems play a significant role in automating the gear selection process. By utilizing fluid pressure, these systems engage and disengage various elements, allowing for seamless transitions between gears. The precision of this hydraulic mechanism contributes to overall driving comfort and performance, highlighting the sophistication of modern engineering in vehicular systems.

Common Issues with C6 Transmissions

The C6 design, known for its durability, can still experience several challenges that may affect its performance. Understanding these common problems can help owners and mechanics diagnose issues early and maintain the unit effectively. From fluid leaks to shifting difficulties, awareness of these concerns is crucial for anyone working with this model.

Fluid Leaks

One prevalent issue with the C6 design is fluid leakage. This can stem from worn seals or gaskets, which may degrade over time due to heat and pressure. Regular inspections can help identify leaks early, preventing further damage and ensuring optimal function.

Shifting Problems

Another common concern involves shifting irregularities. Owners may notice delayed engagement or harsh shifting between gears. These symptoms can result from low fluid levels, worn components, or maladjusted linkages. Addressing these issues promptly is essential to avoid more severe complications down the line.

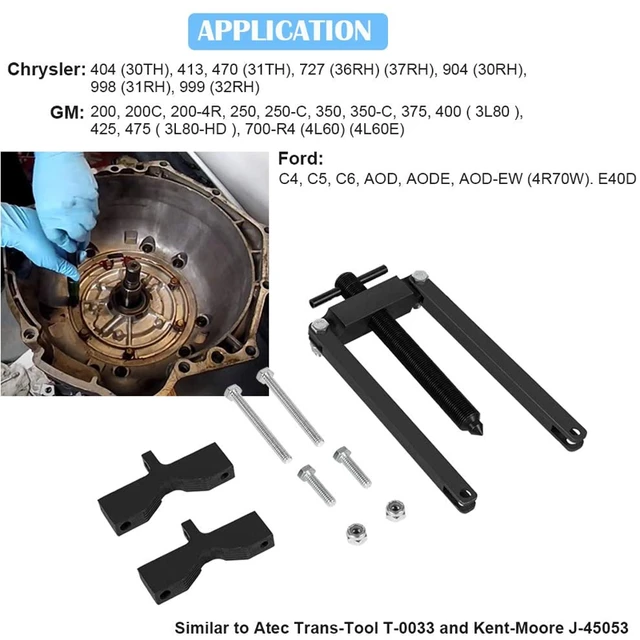

Repairing the C6: Essential Tools

When tackling the repair of an automatic gear system, having the right equipment is crucial for achieving successful results. The proper tools not only facilitate the process but also ensure safety and precision during each step of the procedure. This section will outline the essential instruments required for effectively servicing this specific model.

Basic Tools Needed

A well-equipped workshop is the foundation for any repair project. Below is a list of basic tools that are indispensable for working on the system:

| Tool | Description |

|---|---|

| Socket Set | Essential for loosening and tightening bolts and fasteners. |

| Wrenches | Variety of sizes needed for different nuts and bolts. |

| Screwdrivers | Both flathead and Phillips are necessary for various screws. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Pliers | Helpful for gripping and bending components. |

Specialized Tools

In addition to basic tools, specific instruments are designed to tackle unique challenges. These specialized tools can greatly enhance efficiency and accuracy:

| Tool | Description |

|---|---|

| Fluid Pump | Used for transferring fluids without spills. |

| Seal Installer | Facilitates the correct placement of seals and gaskets. |

| Input Shaft Tool | Helps with the installation and removal of the input shaft. |

| Magnetic Pick-Up Tool | Useful for retrieving dropped parts in tight spaces. |

| Diagnostic Scanner | Assists in identifying any issues or errors in the system. |

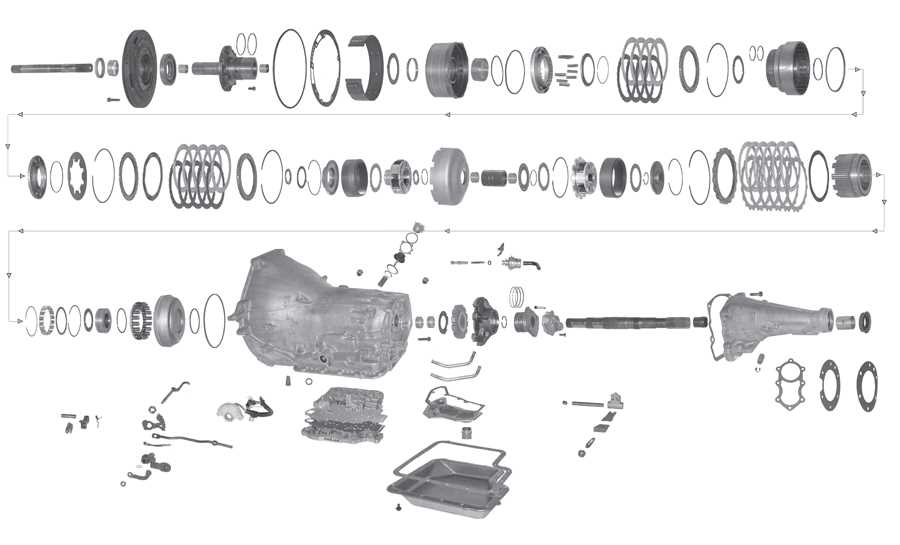

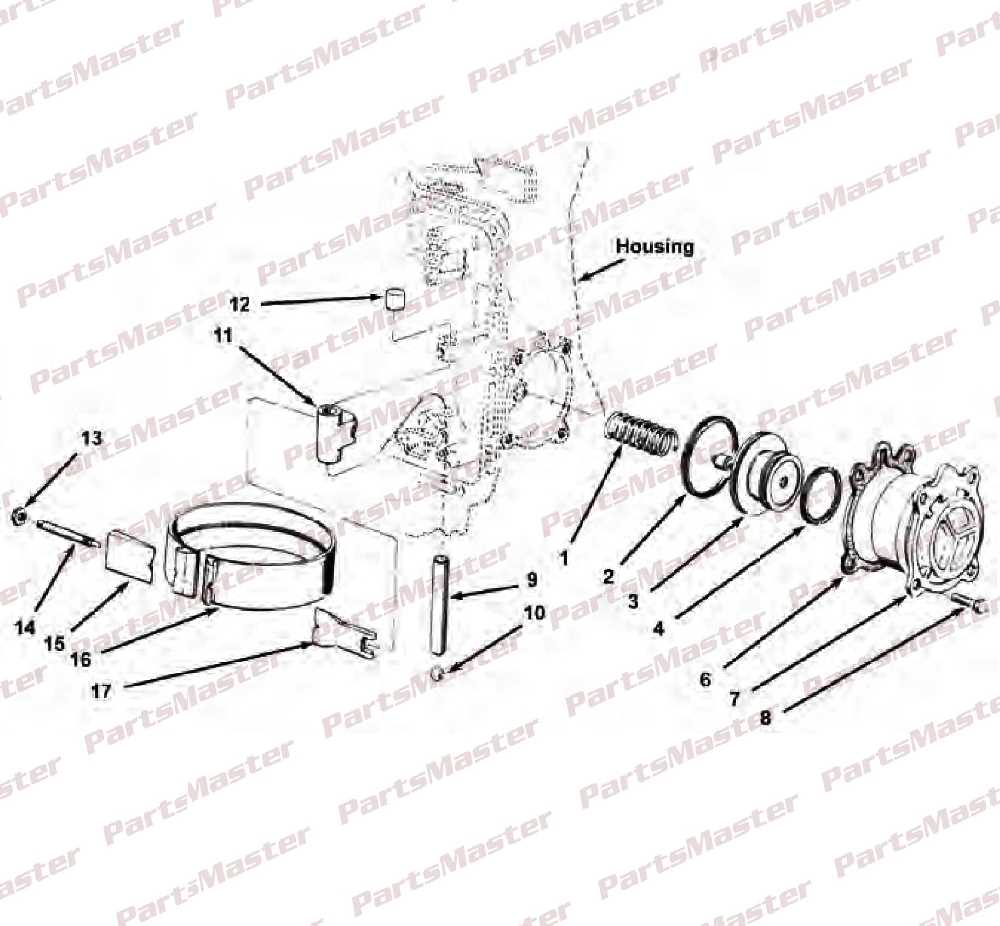

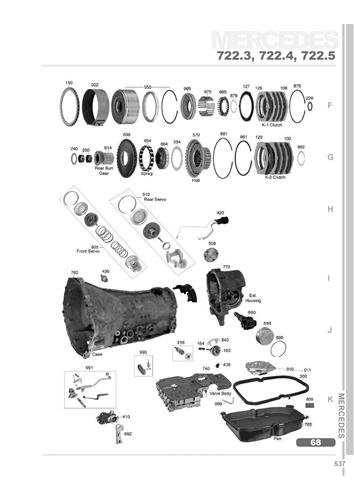

Parts Diagram: An Overview

This section provides a comprehensive look at the components involved in a specific mechanical assembly, emphasizing the intricate relationships and functionalities among them. Understanding these elements is crucial for maintenance, troubleshooting, and enhancing performance. Each part plays a vital role, contributing to the overall efficiency and reliability of the system.

Key Components

Among the numerous elements, certain ones stand out due to their significance in operation. These include various mechanical and hydraulic parts, each designed to perform specific tasks. A thorough grasp of their functions can lead to better diagnostic skills and effective repair strategies.

Component Interactions

The interplay between different elements is essential for optimal functionality. By recognizing how these components influence one another, users can make informed decisions regarding upgrades or modifications to improve performance.

| Component Name | Function |

|---|---|

| Gear Assembly | Facilitates power transfer through mechanical engagement. |

| Pump | Maintains fluid pressure necessary for operation. |

| Control Valve | Regulates flow and directs the movement of fluid. |

| Filter | Removes contaminants from the fluid to ensure system integrity. |

Identifying Components in the Diagram

Understanding the various elements illustrated in the schematic is essential for effective analysis and maintenance. Each component plays a significant role in the overall function, and recognizing them can enhance troubleshooting and repair efforts.

To assist in identifying the elements, consider the following key categories:

- Control Elements: These are responsible for regulating the flow and operation within the system.

- Mechanical Components: Essential for the physical movement and engagement of parts.

- Seals and Gaskets: Critical for preventing leaks and ensuring a tight assembly.

- Fasteners: These hold various parts together and maintain structural integrity.

When examining the schematic, take note of the labels and symbols associated with each item. This will aid in accurate identification and comprehension of their respective functions.

- Start by familiarizing yourself with the layout.

- Identify the control elements and their interactions.

- Assess the mechanical components and their arrangement.

- Look for any seals or gaskets that may indicate points of potential failure.

- Review fasteners to ensure they are adequately placed and secured.

By systematically analyzing these categories, one can gain a deeper understanding of the schematic, facilitating more effective repairs and optimizations.

How to Use the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This visual tool provides a clear overview of the elements involved, allowing users to identify each piece and its function within the system. By utilizing this resource, one can streamline the process of diagnosing issues and sourcing the necessary components.

Identifying Components

Start by familiarizing yourself with the layout. Each section is typically labeled, providing insight into the arrangement of elements. Take note of the various symbols and numbers, as these often correlate with specific items in inventory lists. This knowledge enables a more efficient approach to locating and selecting the right pieces when needed.

Planning Repairs

Once you have identified the required components, use the schematic to plan your repair process. Referencing the visual guide can help ensure that you understand how each element interacts within the assembly. This preparation minimizes mistakes and enhances the overall effectiveness of your work, leading to successful outcomes.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s drivetrain system requires regular attention and care. Proper maintenance not only enhances performance but also extends the lifespan of crucial components. By adopting a few simple practices, you can significantly reduce the likelihood of premature wear and costly repairs.

Regular Fluid Checks

Fluid levels and conditions play a vital role in the efficient operation of your drivetrain. Periodic inspections should be performed to ensure that fluids are clean and at the correct levels. Replace any contaminated fluids promptly to prevent unnecessary strain on internal mechanisms.

Temperature Monitoring

Overheating can lead to severe damage. Utilize gauges to monitor operational temperatures closely. If you notice elevated readings, it may be an indication of underlying issues. Implementing cooling solutions or addressing airflow problems can help maintain optimal temperatures, thus enhancing the system’s longevity.

Upgrading Parts for Performance Boost

Enhancing the efficiency and power of your vehicle can be an exciting journey. By carefully selecting superior components, enthusiasts can achieve a noticeable improvement in performance and responsiveness. This process not only optimizes functionality but also contributes to a more enjoyable driving experience.

Choosing High-Quality Components

Investing in high-grade materials is crucial for anyone looking to elevate their machine’s capabilities. Upgrading elements such as clutches, pumps, and valve bodies can lead to better torque management and improved durability. These modifications often result in quicker shifts and increased overall efficiency.

Tuning for Enhanced Performance

Beyond mere replacements, tuning the system can unlock significant potential. Adjusting electronic controls and calibrating the setup ensures that all upgraded components work harmoniously. This fine-tuning process maximizes the benefits of new installations, leading to an exhilarating driving experience and a notable performance boost.

Differences Between C4 and C6 Transmissions

When comparing two notable automatic systems commonly used in classic vehicles, several key distinctions emerge that influence performance, design, and application. These variations can affect everything from torque handling capabilities to installation nuances, making it essential for enthusiasts to understand their unique characteristics.

One of the primary differences lies in their construction and complexity. The first option is generally considered lighter and more compact, making it suitable for smaller engines and providing a quicker response in lower power scenarios. In contrast, the second option features a more robust design, which allows it to manage higher torque loads, making it a popular choice for heavy-duty applications.

Additionally, the shift patterns differ significantly. The first system typically offers a simpler gear arrangement, which can lead to smoother transitions at lower speeds. On the other hand, the second variant often boasts a more sophisticated setup, allowing for better performance at higher speeds, contributing to a more engaging driving experience.

Compatibility is another crucial aspect. While the first system can be easier to integrate into a broader range of vehicles, the latter often requires specific adaptations for seamless installation. Understanding these differences is vital for anyone looking to optimize their vehicle’s performance or restore a classic model.

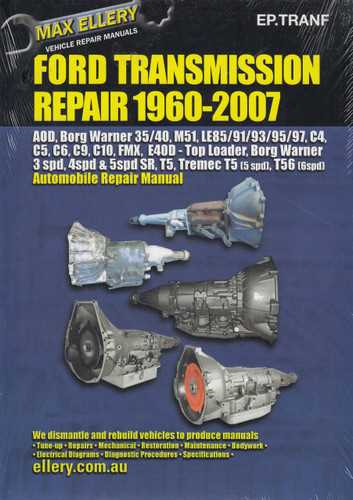

Resources for C6 Transmission Enthusiasts

For those passionate about automotive mechanics, particularly the iconic system designed for power and reliability, having access to quality information and resources is essential. Whether you’re a seasoned expert or just beginning your journey, a wealth of materials exists to enhance your knowledge and skills.

Here are some valuable resources to consider:

- Online Forums:

- Join communities where enthusiasts share tips, troubleshooting advice, and personal experiences.

- Participate in discussions to learn from seasoned professionals and fellow hobbyists.

- Service Manuals:

- Look for detailed guides that provide insights into maintenance and repair techniques.

- Consider both printed versions and downloadable PDFs for easy access.

- YouTube Channels:

- Explore video tutorials that visually demonstrate disassembly, repairs, and upgrades.

- Follow channels dedicated to performance enhancements and restorations.

- Specialty Shops:

- Visit local or online retailers that offer specialized components and tools.

- Seek advice from experts who can guide you on the best products for your needs.

- Books and Publications:

- Read literature focused on automotive engineering and specific systems.

- Check out magazines that feature articles on restoration and performance tuning.

Utilizing these resources can significantly enhance your understanding and enjoyment of automotive craftsmanship. Whether working on a project or simply deepening your knowledge, these tools will support your journey.