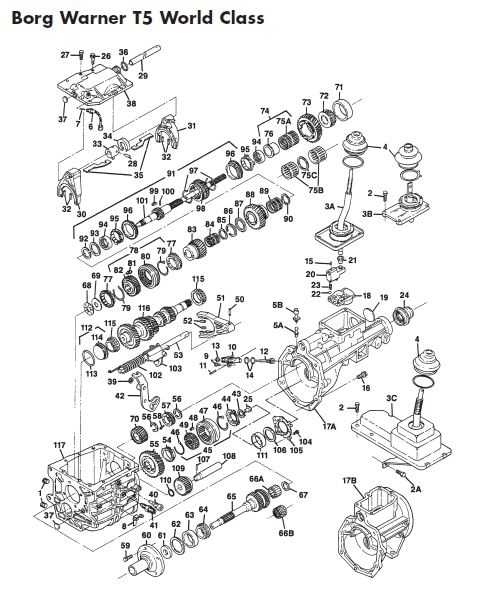

The intricate nature of vehicle gear mechanisms often necessitates a thorough exploration of their internal structure. Each element plays a vital role in ensuring optimal performance, contributing to the seamless operation of the entire system. By examining these essential components, one can gain insight into how power is effectively transferred and managed within automotive applications.

Delving into the specifics of these mechanisms reveals a wealth of information regarding their arrangement and functionality. Analyzing the layout of various components can clarify their interactions and the overall efficiency of the system. This exploration not only enhances comprehension but also assists in troubleshooting and maintenance practices, allowing for more informed decisions in repair and enhancement processes.

Understanding the arrangement and role of each element equips enthusiasts and professionals alike with the knowledge needed to optimize performance. By grasping the intricate connections and functions, one can appreciate the complexity behind what makes modern vehicles operate smoothly. This knowledge is invaluable for anyone involved in automotive maintenance or modifications.

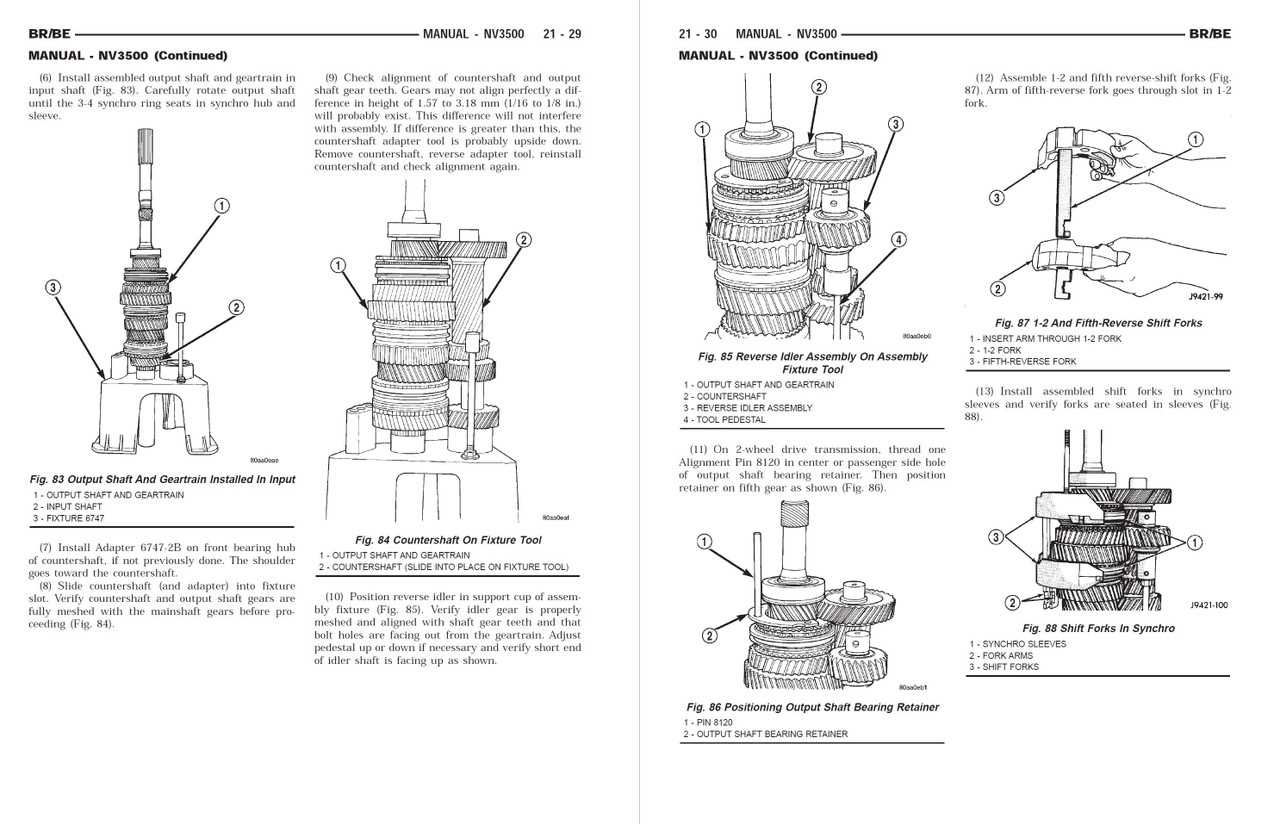

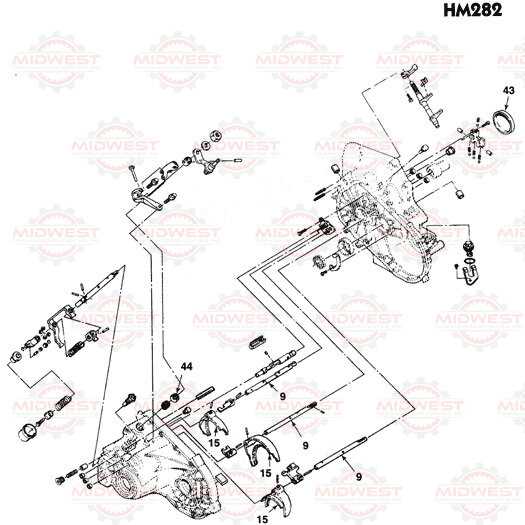

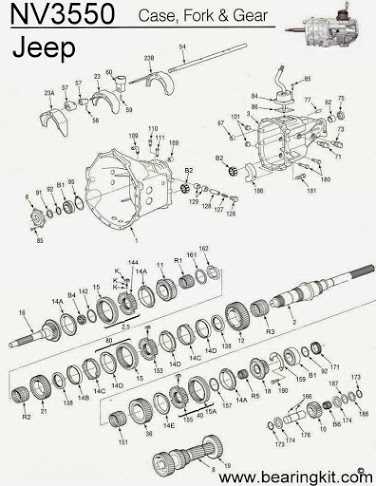

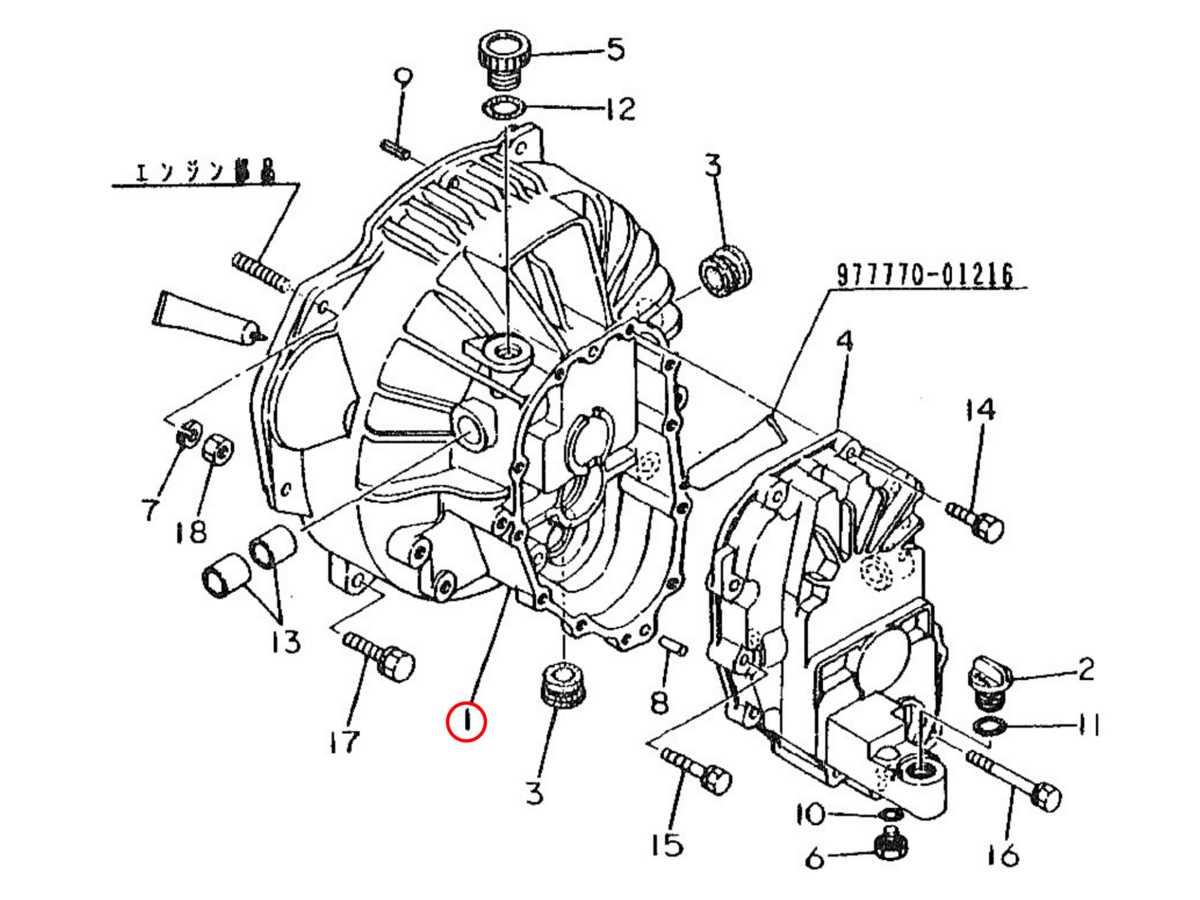

Key Components of the NV3500

The NV3500 system is composed of various essential elements that work in harmony to ensure optimal functionality and performance. Understanding these crucial components is vital for anyone interested in the mechanics and efficiency of this system.

Among the primary elements are the gear assemblies, which facilitate smooth operation by managing speed and torque. Additionally, the clutch mechanism plays a significant role in engaging and disengaging power transfer, providing the driver with control over the vehicle’s acceleration and deceleration.

Another important aspect is the input shaft, responsible for transferring power from the engine to the assembly. Coupled with the output shaft, these components ensure that power is effectively delivered to the wheels, enabling movement.

Furthermore, the shift forks and synchronizers are integral in allowing smooth transitions between gears, enhancing the overall driving experience. Each of these components contributes to the efficiency and reliability of the system, making them indispensable in its operation.

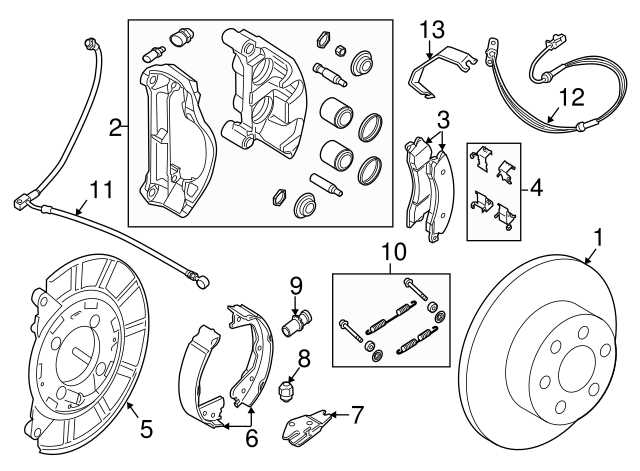

Understanding Transmission Functionality

Grasping the mechanics behind a vehicle’s power delivery system is essential for recognizing how various components work together to enable smooth operation. This system plays a crucial role in managing engine output and ensuring that power is efficiently transmitted to the wheels.

At its core, this mechanism involves several key elements that interact seamlessly. Here’s an overview of how these components function:

- Power Generation: The engine produces energy that needs to be effectively utilized.

- Gear Ratios: Different settings allow for adjustments in speed and torque, accommodating various driving conditions.

- Fluid Dynamics: Lubrication and hydraulic systems play a vital role in ensuring smooth transitions and reducing wear.

- Control Systems: Electronic and mechanical controls dictate how power is managed and directed.

Understanding these elements helps in troubleshooting issues, performing maintenance, and appreciating the complexity of automotive engineering. Each component contributes to the overall efficiency and effectiveness of the vehicle’s operation.

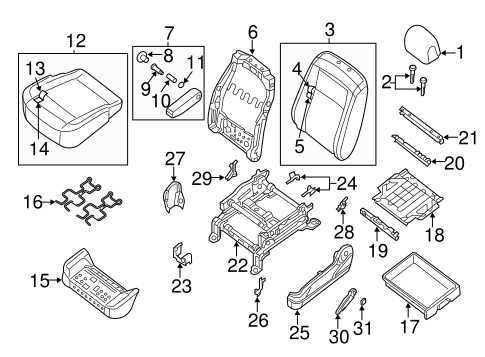

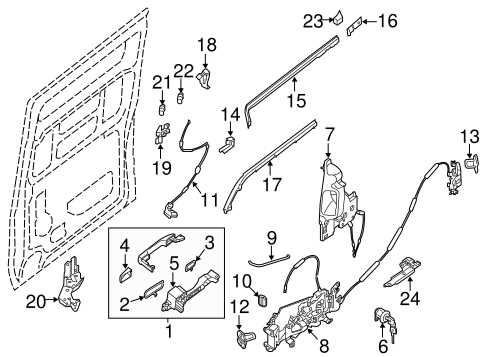

Parts Identification and Roles

This section provides an overview of various components and their functions within the mechanical system, emphasizing how each element contributes to the overall operation.

Understanding the significance of each element is crucial for maintenance and repair. Every piece plays a unique role, ensuring efficient performance and reliability.

Key components include the gears, which facilitate speed changes, and the hydraulic mechanisms that enable smooth transitions. Additionally, control units regulate functionality, providing essential feedback and adjustments during operation. Recognizing these elements allows for better troubleshooting and enhances the longevity of the entire assembly.

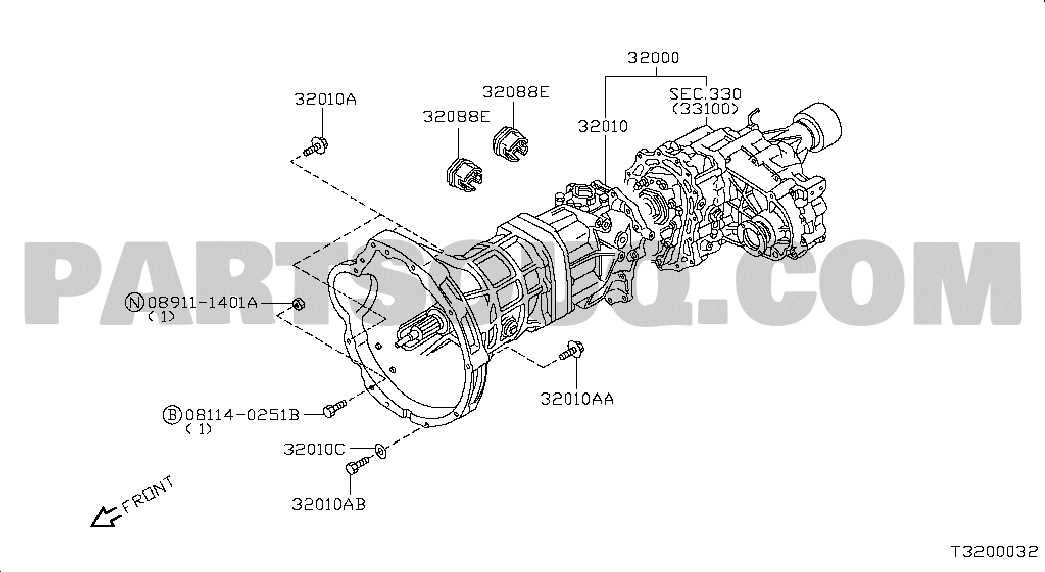

Transmission Assembly Process Explained

The assembly procedure for gear systems involves a series of meticulously coordinated steps that ensure optimal functionality and reliability. This process is crucial for the overall performance of vehicles, as it directly affects their efficiency and driving experience.

Initial Preparation and Component Selection

Before the actual assembly begins, it is vital to gather all necessary components and tools. This stage involves inspecting each item for defects and ensuring compatibility. Proper organization of parts facilitates a smoother assembly process, reducing the likelihood of errors.

Assembly and Alignment Techniques

During the assembly, precise alignment of the components is critical. Technicians employ various techniques to ensure that each piece fits together seamlessly. Torque specifications are adhered to meticulously, and lubrication is applied where necessary to prevent friction and wear. Attention to detail in this phase can significantly extend the lifespan of the system.

Common Issues with NV3500 Parts

The reliability of vehicle components is crucial for optimal performance. Various components within the system can encounter problems over time, leading to diminished functionality and potential repairs. Understanding the common issues associated with these elements can aid in identifying symptoms early and ensuring timely maintenance.

One frequent concern is leaks, which may occur due to wear or damage to seals and gaskets. These leaks can lead to a loss of essential fluids, impacting overall performance. Additionally, excessive wear on specific components may result from prolonged use, causing irregularities in operation and potentially leading to more significant failures.

Unusual noises are also a common indicator of underlying problems. Sounds such as grinding or whining can suggest misalignment or insufficient lubrication. Early detection of these auditory signals is vital for preventing further complications. Regular inspections and maintenance can help in addressing these issues promptly, preserving the efficiency and longevity of the system.

Maintenance Tips for Transmission Longevity

Ensuring the durability and efficiency of your vehicle’s gear system requires regular care and attention. Proper upkeep not only enhances performance but also extends the lifespan of crucial components. Here are some key practices to help maintain optimal functionality.

| Tip | Description |

|---|---|

| Regular Fluid Checks | Monitor the quality and level of fluid regularly to prevent overheating and wear. |

| Scheduled Changes | Change the fluid and filter according to the manufacturer’s recommendations to keep the system clean. |

| Routine Inspections | Conduct visual checks for leaks, corrosion, or damage to identify issues early on. |

| Avoid Overloading | Do not exceed the weight limits set for your vehicle, as excessive strain can lead to premature failure. |

| Use Quality Components | When replacements are necessary, opt for high-quality parts to ensure compatibility and performance. |

How to Replace NV3500 Components

Replacing the components of a vehicle’s gearbox can enhance performance and extend the lifespan of the system. This process requires careful attention to detail and a methodical approach to ensure everything is reassembled correctly.

Before starting the replacement, gather the necessary tools and components. Ensure that you have a suitable workspace and adequate lighting. Familiarize yourself with the layout and function of the various elements to streamline the replacement process.

Step 1: Begin by disconnecting the battery to prevent any electrical hazards. Then, drain the fluid from the assembly, taking care to dispose of it properly.

Step 2: Remove any surrounding components that may obstruct access to the parts needing replacement. Keep track of the bolts and fasteners, as they will be needed for reassembly.

Step 3: Carefully detach the worn components, ensuring you do not damage any adjacent parts. Use a torque wrench to avoid over-tightening during the installation of new elements.

Step 4: Once the new components are in place, reassemble the removed parts in the reverse order of disassembly. Check all connections and ensure everything is secure.

Step 5: Finally, refill the system with the appropriate fluid and reconnect the battery. Start the vehicle and conduct a test drive to ensure proper operation.

By following these steps, you can successfully replace the components of the gearbox, improving your vehicle’s overall functionality.

Importance of Quality Replacement Parts

When it comes to maintaining the performance and longevity of machinery, the significance of using high-quality components cannot be overstated. Selecting superior substitutes ensures that systems operate smoothly and efficiently, reducing the likelihood of future issues.

Reliability is a crucial factor when considering alternative components. High-grade options are manufactured to meet strict standards, guaranteeing that they will function effectively under various conditions. This reliability translates into improved performance and fewer unexpected failures.

Moreover, investing in quality replacements can lead to significant cost savings in the long run. Although premium components may come with a higher initial price tag, their durability often means less frequent replacements, ultimately resulting in lower overall expenses.

Lastly, using top-notch substitutes contributes to the overall safety of the equipment. Inferior options can compromise not only the machinery itself but also the safety of its operators. Therefore, choosing high-quality replacements is essential for both performance and safety.

Tools Required for Transmission Work

Working on vehicle gear systems requires a variety of specialized instruments to ensure proper assembly and disassembly. Having the right tools not only facilitates the repair process but also contributes to the longevity and performance of the mechanisms involved.

Below is a list of essential instruments that are commonly needed:

- Socket Set: A complete socket set with various sizes is crucial for removing and securing bolts.

- Torque Wrench: This tool is necessary for applying precise torque to fasteners, preventing over-tightening.

- Gear Puller: A gear puller aids in removing gears without damaging the surrounding components.

- Fluid Pump: Useful for transferring oils and lubricants into the system.

- Seal Installer: Ensures that seals are fitted properly to avoid leaks.

Additional tools that may enhance the workflow include:

- Magnetic Tray: To keep small parts organized and prevent loss during repairs.

- Inspection Mirror: Helpful for viewing hard-to-reach areas.

- Flashlight: Provides necessary illumination when working in dimly lit spaces.

- Cleaning Supplies: Ensuring that all components are clean before reassembly is vital for optimal performance.

Equipping yourself with these tools will significantly improve the efficiency and effectiveness of any repairs performed on vehicle gear systems.

FAQs about NV3500 Transmission Repairs

This section addresses common inquiries regarding the repair process for specific vehicle systems. Understanding the essential aspects of maintenance and potential issues can greatly assist vehicle owners in making informed decisions.

What are the most common issues faced during repairs?

Frequent complications during servicing include fluid leaks, overheating, and unusual noises. Identifying these symptoms early can help prevent more extensive damage and costly repairs.

How can I ensure quality repairs?

Choosing a reputable mechanic is crucial for successful repairs. Look for certified professionals with experience in handling similar systems. Additionally, requesting customer reviews and warranties on parts can provide further assurance of quality service.

Maintaining open communication with your repair technician will help clarify any concerns and ensure that you understand the necessary steps throughout the repair process.