When dealing with mechanical systems, understanding the layout and function of each element is crucial for proper maintenance and repair. Every component in a machine works together, and a clear visual representation of these connections can greatly assist in troubleshooting and assembly tasks.

In this guide, we explore the intricate network of elements found in a widely used lawn maintenance device. By breaking down the structure, we provide insights into how the various sections interact, making it easier to identify, replace, or adjust necessary elements when needed.

Whether you’re maintaining or upgrading your equipment, having a detailed map of the system’s elements ensures that the process is smooth and efficient, reducing the chances of errors or overlooked details during assembly or repair.

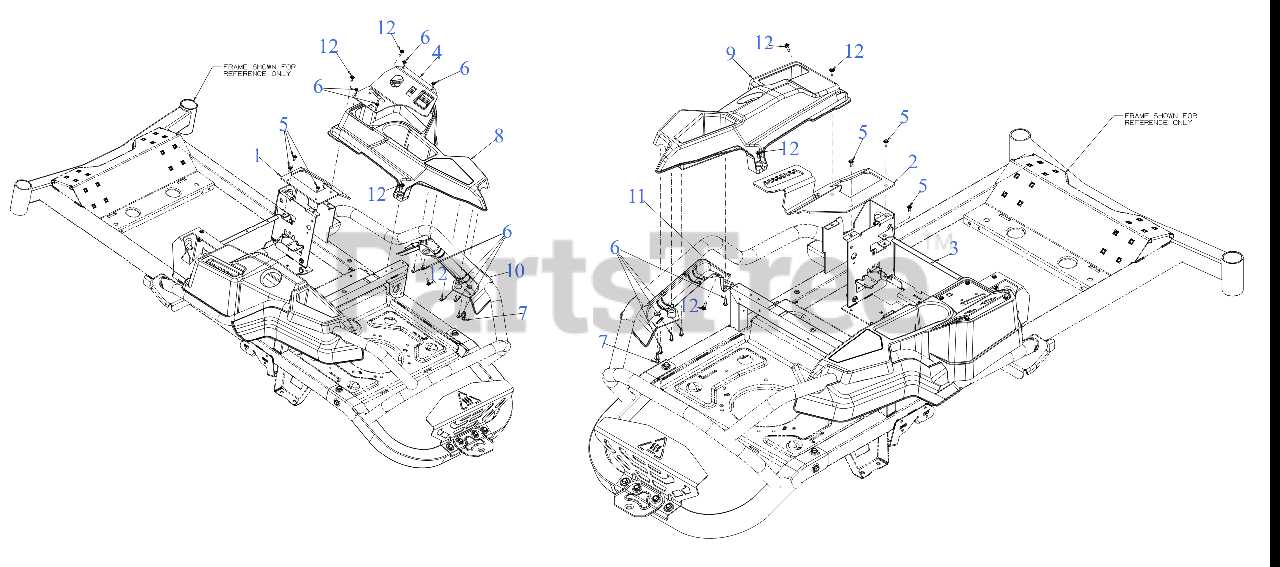

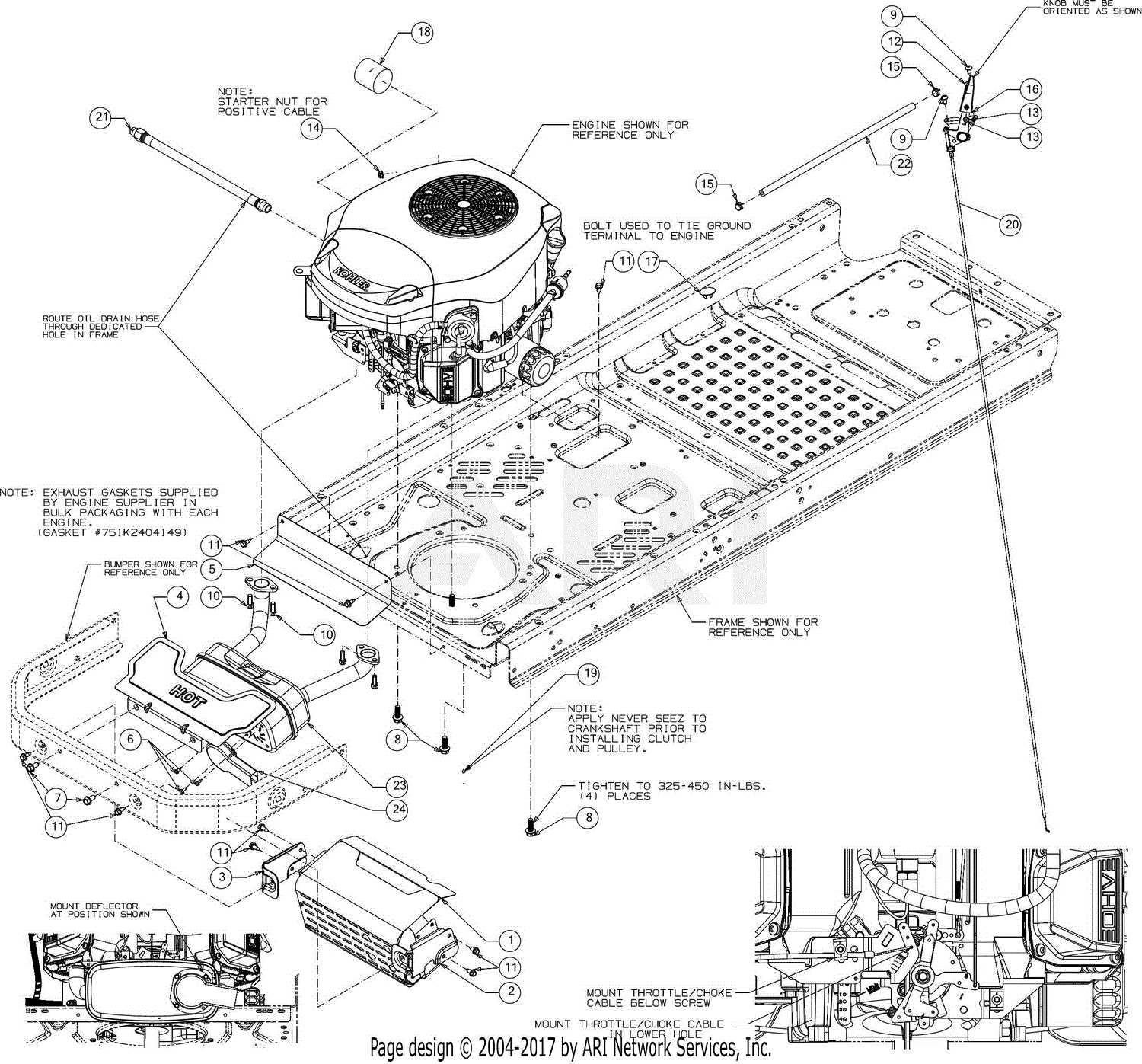

Troy Bilt Mustang 42 Parts Overview

Understanding the various elements that make up this efficient mower can help ensure optimal performance and ease of maintenance. These components are carefully designed to work in harmony, providing reliable functionality for various tasks in lawn care.

Key Mechanical Components

- Engine assembly – the powerhouse that drives the entire system.

- Blades – responsible for clean and even cuts on different grass types.

- Drive system – ensures smooth movement and control during operation.

Maintenance Essentials

- Air filter – protects the motor by preventing debris from entering.

- Belts – crucial for transferring power from the engine to the wheels and blades.

- Spind

Engine Components and Their Functions

The inner workings of a machine rely on various elements working together to ensure smooth operation. These components form a critical system that generates power, transfers energy, and ensures efficient functioning. Understanding these elements can help in maintaining the overall performance and longevity of the machine.

- Cylinder: The chamber where fuel combustion occurs, converting chemical energy into mechanical force.

- Piston: Moves within the cylinder, transferring the force generated from combustion to other parts of the system.

- Crankshaft: Converts the linear motion of the piston into rotational energy, powering other components.

- Valves: Regulate the intake of air and fuel as well as the release of exhaust gases from the combustion chamber.

- Spark Plug: Ignites the air-fuel mixture in the

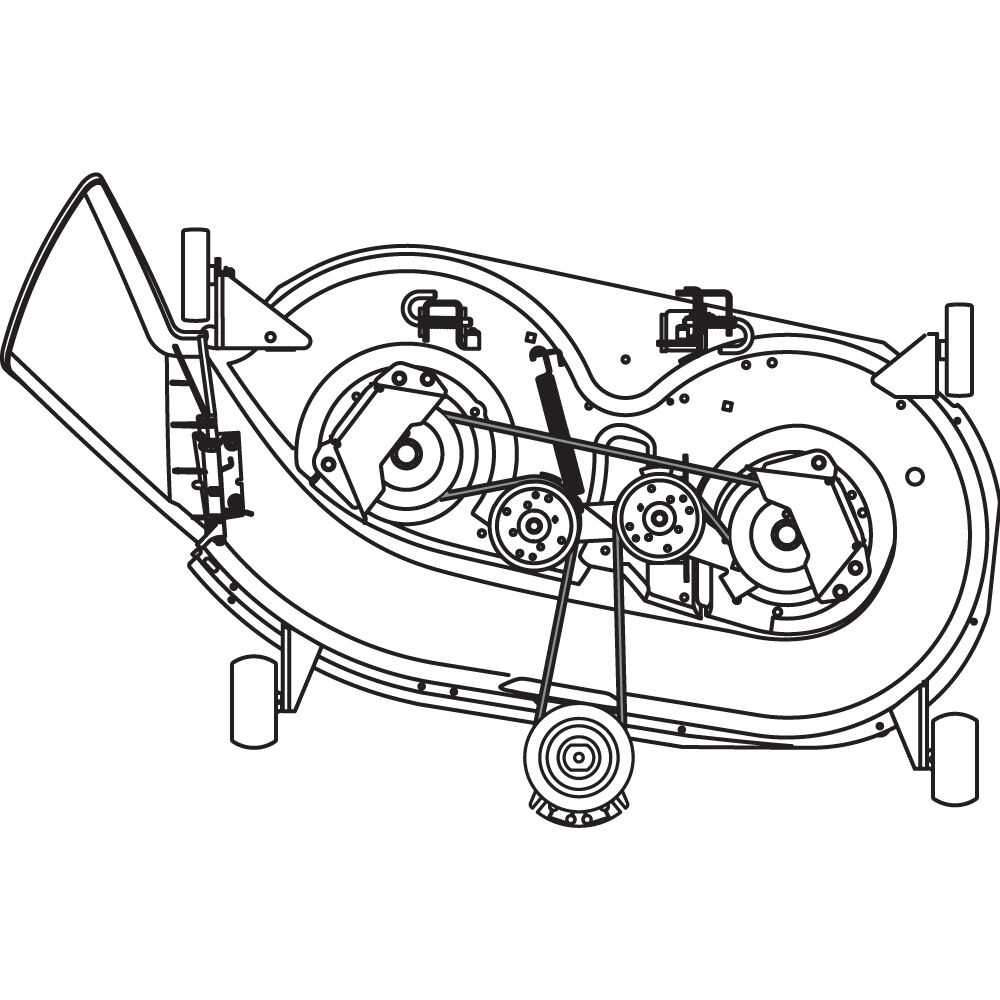

Understanding the Cutting Deck Mechanism

The cutting deck is a critical component that plays a vital role in ensuring efficient and even grass trimming. It operates through a precise arrangement of elements working together to deliver a clean cut, adjusting to different conditions and terrains. Its design is key to achieving a smooth and well-maintained lawn, contributing to the overall performance of the machine.

Blade Arrangement and Functionality

At the core of this system is the arrangement of blades, designed to spin rapidly, slicing through grass with precision. The blades are positioned strategically to cover the entire width of the deck, ensuring that no patches are missed. The sharpness and angle of the blades are essential for consistent results, minimizing the need for multiple passes over the same area.

Height Adjustment Mechanism

The cutting deck also includes a height adjustment feature, allowing the user to set the desired grass length. This feature is crucial for adapting to varying grass types and growing conditions. The adjustment mechanism is designed to

Drive System and Transmission Parts

The mechanism responsible for moving the equipment forward relies on a combination of interconnected components that ensure smooth and efficient operation. The seamless functioning of these elements is crucial to maintaining consistent movement, whether the machinery is in motion or idle.

Core Elements of the Propulsion Mechanism

The primary function of the propulsion system is to convert energy into mechanical motion, allowing the machine to traverse various surfaces. This is achieved through a series of gears, belts, and pulleys that work in harmony to provide controlled movement. Regular inspection of these elements helps to identify potential wear, ensuring long-term performance.

Transmission and Power Distribution

At the heart of the transmission is

Steering Assembly Breakdown

The steering system plays a vital role in ensuring smooth navigation and control, enabling precise direction changes. Understanding the detailed structure of the steering mechanism can help with maintenance and repair tasks, ensuring the equipment continues to operate effectively. This section provides an in-depth view of the key elements that form the steering setup.

Key Components of the Steering System

Within the assembly, several parts collaborate to provide accurate control. These elements include the linkage responsible for connecting the steering wheel to the front wheels, along with other supportive mechanisms that enhance stability and response.

Component Description Steering Shaft Transfers rotational motion from the wheel to the linkage. Linkage Electrical System Components

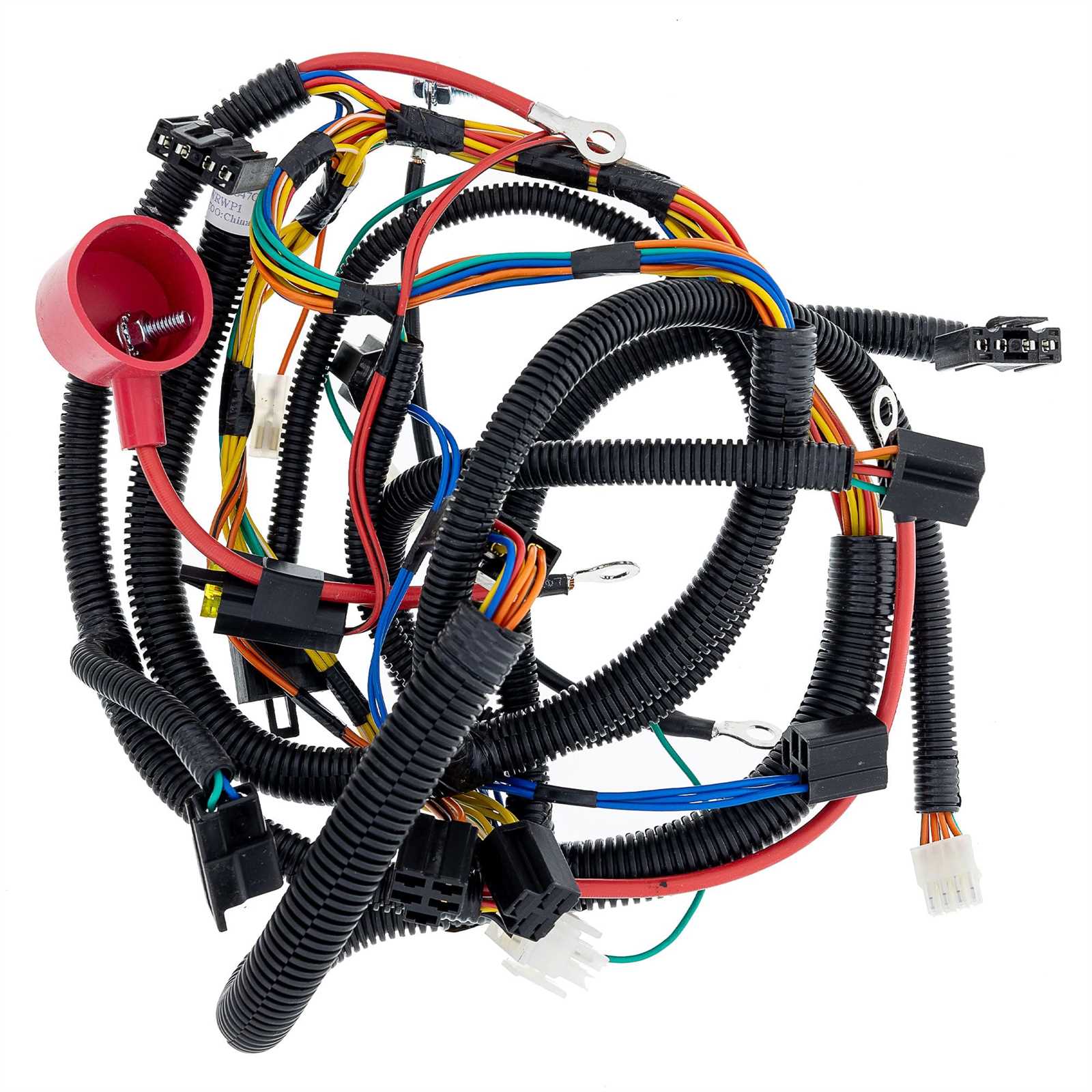

The electrical system plays a crucial role in ensuring the smooth functioning of machinery, delivering power to various essential elements. This network of connections distributes energy where it’s needed, making certain that all elements work in harmony. Understanding the core elements within this system helps to maintain efficiency and prevent potential issues.

Wiring and Connectors

A critical component in any electrical system is the network of wires and connectors. These elements serve as conduits, transmitting power between different sections. Ensuring these connections are secure and free of corrosion is essential for maintaining a reliable flow of electricity. Regular inspection and upkeep of these pathways can prevent electrical malfunctions.

Battery and Charging Mechanism

The battery acts as the primary source of energy, supplying

Identifying Fuel System Parts

The fuel system is essential for the efficient operation of any engine. Understanding the various components involved can greatly enhance troubleshooting and maintenance efforts. This section will provide insight into the critical elements that contribute to fuel delivery and management, ensuring optimal performance.

Key Components: The fuel system typically includes several vital components such as the fuel tank, pump, filters, and injectors. Each of these parts plays a specific role in ensuring that fuel is delivered to the engine effectively. Recognizing these elements is crucial for identifying potential issues.

Maintenance Tips: Regular inspection of the fuel system components can prevent performance problems. Look for signs of wear, leaks, or blockages that may affect the system’s efficiency. Keeping the fuel system clean and well-maintained will enhance the overall lifespan of the engine.

Maintenance Tips for Blade Components

Ensuring the optimal performance of cutting elements is crucial for achieving a clean and efficient mowing experience. Regular upkeep not only enhances functionality but also extends the lifespan of these essential components. By following some key practices, you can maintain the sharpness and integrity of your blades while preventing premature wear.

Regular Inspection and Cleaning

Consistent evaluation of the cutting edges is vital. After each use, inspect the blades for any signs of damage, such as nicks or dullness. Cleaning them thoroughly to remove grass clippings and debris will help prevent corrosion and maintain performance. A clean surface allows for smoother operation and reduces the strain on the machine.

Sharpening Techniques

Keeping the edges well-honed is essential for efficient cutting. Employing a sharpening tool or file specifically designed for lawn mower blades can enhance the cutting performance significantly. It is advisable to sharpen the blades at least once per season or more frequently if you mow regularly. Remember to balance the blades after sharpening to ensure even performance during operation.

How to Replace Tires and Wheels

Changing the rolling elements of your equipment is essential for maintaining optimal performance and ensuring safety during operation. This process involves removing the old components and installing new ones, which can enhance traction and stability. Whether you are preparing for a seasonal adjustment or addressing wear and tear, understanding the correct procedure is crucial.

Necessary Tools and Materials

Before starting, gather all required tools and materials to streamline the process. Ensure you have the following items ready:

- Socket set

- Wrench

- Jack

- Wheel chocks

- Replacement tires and wheels

Step-by-Step Replacement Process

Follow these steps to successfully replace the rolling elements:

- Secure the area and use wheel chocks to prevent movement.

- Raise the equipment with the jack to access the wheels.

- Remove the nuts from the old wheels using a wrench or socket set.

- Take off the old wheels and set them aside.

- Align the new wheels with the mounting surface and hand-tighten the nuts.

- Lower the equipment and then tighten the nuts securely in a crisscross pattern to ensure even pressure.

Step Description 1 Secure area and use wheel chocks. 2 Raise equipment with the jack. 3 Remove nuts from old wheels. 4 Take off old wheels. 5 Align and hand-tighten new wheels. 6 Tighten nuts in a crisscross pattern. Examining the Safety Mechanisms

Understanding the protective features incorporated into machinery is essential for ensuring user safety and enhancing operational efficiency. These mechanisms are designed to prevent accidents and minimize risks during operation. By examining these systems, one can appreciate the importance of safety protocols in machinery functionality.

Key Safety Features

The following are critical components that contribute to the overall safety of the equipment:

Feature Description Emergency Stop Switch A readily accessible button that halts all functions immediately, preventing potential hazards. Operator Presence Control This mechanism ensures that the equipment ceases operation if the operator leaves their designated position. Safety Guards Physical barriers that protect users from moving parts, reducing the risk of injury. Automatic Shutoff Systems that turn off the machine after a set period of inactivity to prevent overheating or accidents. Importance of Regular Maintenance

Regular inspection and maintenance of these safety features are crucial for their effectiveness. Ensuring that each mechanism functions correctly not only enhances the longevity of the equipment but also provides peace of mind for the operator.

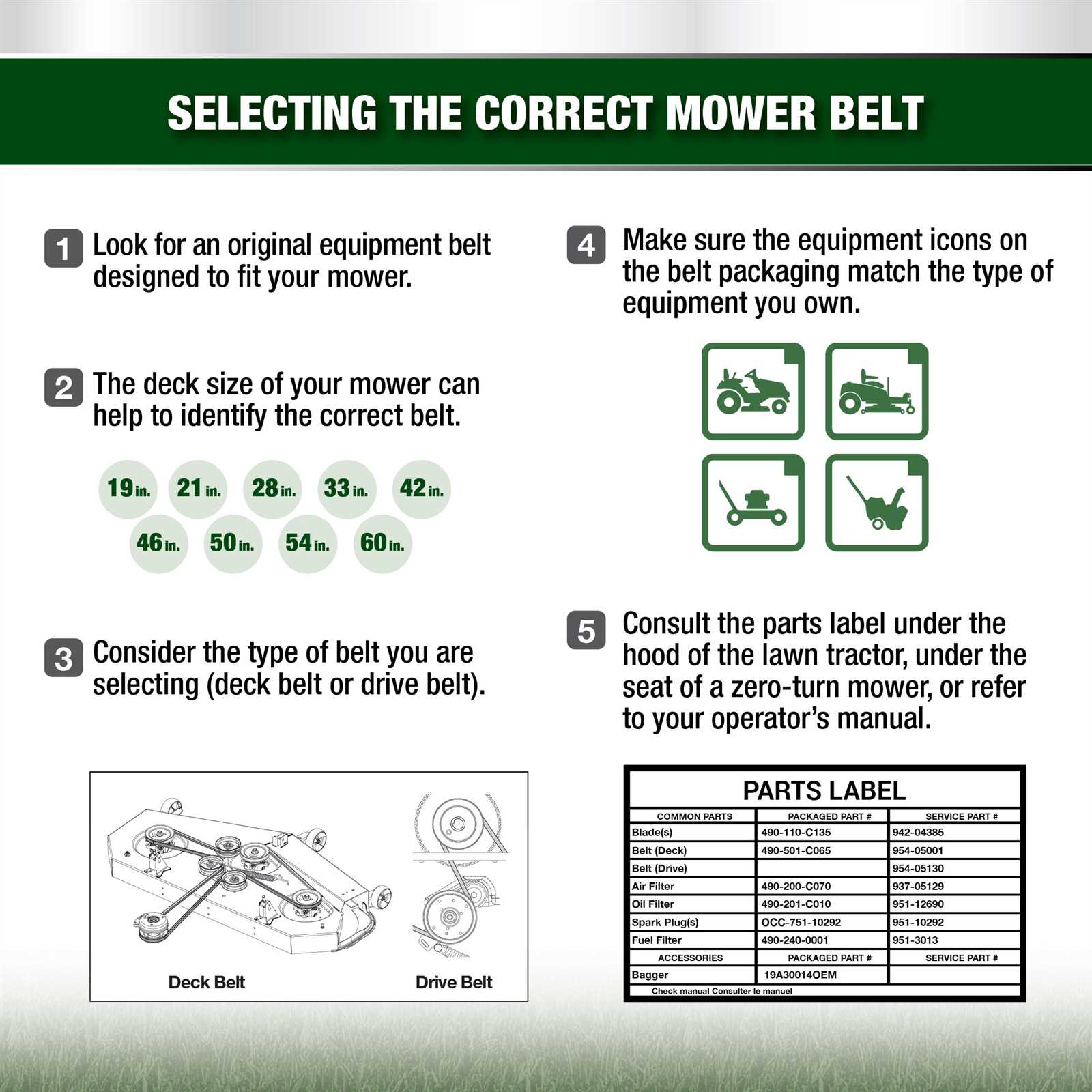

Tips for Locating Replacement Parts

Finding the right components for your outdoor machinery can seem daunting, but with the right approach, it can be streamlined and efficient. Whether you’re looking to maintain performance or replace worn-out elements, following a few key strategies will simplify the process and help ensure you get the correct items.

Here are some effective methods to assist you in your search:

- Consult the Manual: Always refer to the user guide that accompanies your equipment. It usually contains detailed information about compatible elements and their specifications.

- Online Resources: Utilize various websites dedicated to machinery support. Many offer searchable databases where you can find components by model number or description.

- Local Dealers: Visit nearby retailers or authorized service centers. They can provide invaluable assistance and may have the necessary components in stock.

- Forums and Community Groups: Engage with online forums or social media groups related to outdoor equipment. Fellow enthusiasts often share experiences and recommendations on where to source parts.

- Manufacturer Support: Contact the manufacturer’s customer service for direct guidance. They can offer insights on where to purchase genuine items or suitable alternatives.

By utilizing these tips, you can enhance your ability to find the necessary components efficiently and effectively, ensuring your machinery remains in optimal condition.