When exploring the intricate workings of marine propulsion systems, it is essential to familiarize oneself with the various elements that contribute to their overall performance and reliability. A comprehensive overview of these components enables enthusiasts and professionals alike to enhance their understanding and maintenance of watercraft machinery.

In the realm of aquatic engines, every single component plays a vital role in ensuring smooth operation. Knowledge of the layout and function of these parts not only aids in efficient troubleshooting but also enhances the capability to conduct necessary repairs or upgrades. Each element interacts harmoniously with others, creating a seamless experience on the water.

Familiarity with the structure of marine engines can significantly improve one’s ability to address mechanical issues. By delving into the specifics of each segment, users can gain insights into their maintenance and functionality. This understanding ultimately leads to improved performance and longevity of the entire system.

As we examine the various sections and their interconnections, a clearer picture emerges of how these elements work together to power watercraft. This knowledge is crucial for anyone involved in marine activities, whether for recreational purposes or professional operations.

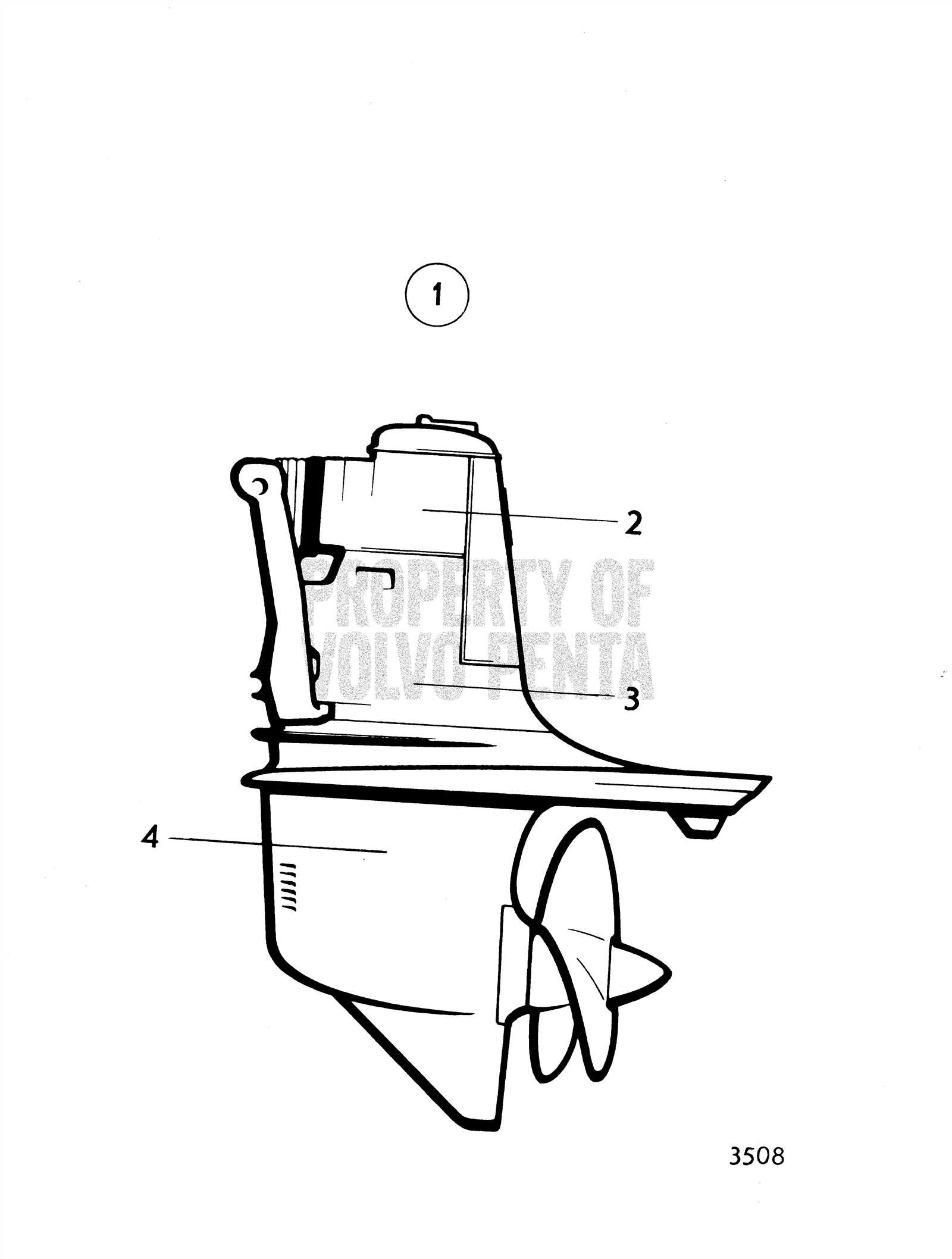

Understanding Volvo Penta 290 DP Components

This section provides an overview of the essential elements that make up a specific marine propulsion system. Each component plays a vital role in ensuring efficient operation, performance, and reliability in various boating conditions. Familiarity with these parts can enhance maintenance practices and contribute to optimal functionality.

| Component | Description |

|---|---|

| Drive Unit | The main assembly responsible for transferring power from the engine to the propeller, facilitating movement through water. |

| Propeller | This rotating blade mechanism converts rotational energy into thrust, enabling navigation and maneuverability. |

| Gimbal Housing | An enclosure that supports the drive unit, allowing it to pivot for steering while maintaining structural integrity. |

| Oil Seal | A crucial component that prevents fluid leaks, ensuring the lubrication system functions effectively. |

| Trim Tab | This adjustable flap helps stabilize the vessel’s attitude in the water, improving handling and efficiency. |

| Coupling | Connects the engine to the drive unit, allowing for smooth power transfer while accommodating minor misalignments. |

Overview of Volvo Penta 290 DP

This section provides an overview of a popular marine propulsion system known for its performance and efficiency. Designed for both recreational and professional use, this equipment integrates advanced technology to enhance the boating experience. Understanding its key components and functionality can help users maximize their operational capabilities.

Key Features

- Robust construction ensuring durability and longevity

- Streamlined design for improved hydrodynamics

- Enhanced maneuverability and handling

- Compatibility with various types of vessels

Applications

- Ideal for leisure boating and water sports

- Suitable for fishing boats and small commercial vessels

- Effective in various water conditions

Essential Parts for Optimal Performance

To ensure your system runs smoothly and efficiently, it’s crucial to focus on the key elements that contribute to its overall function. By maintaining these critical components, you can extend the longevity of your equipment and avoid unnecessary breakdowns. Understanding which areas require the most attention allows for better maintenance and improved performance.

Regular checks on mechanical elements, fluid levels, and seals play a significant role in keeping everything in peak condition. These checks prevent wear and tear that could affect efficiency. Prioritizing these essential components will help keep your equipment performing at its best for a longer time.

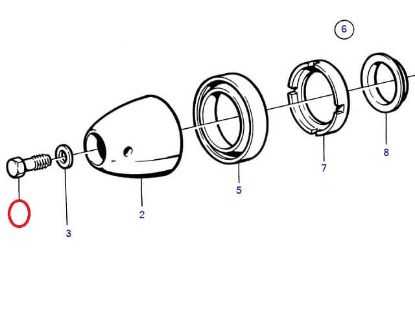

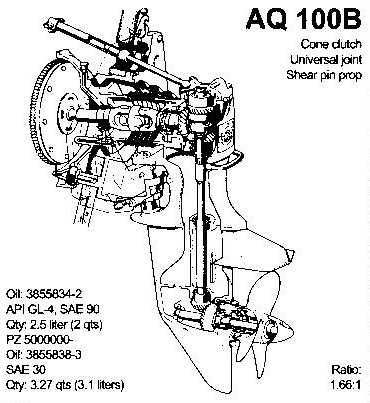

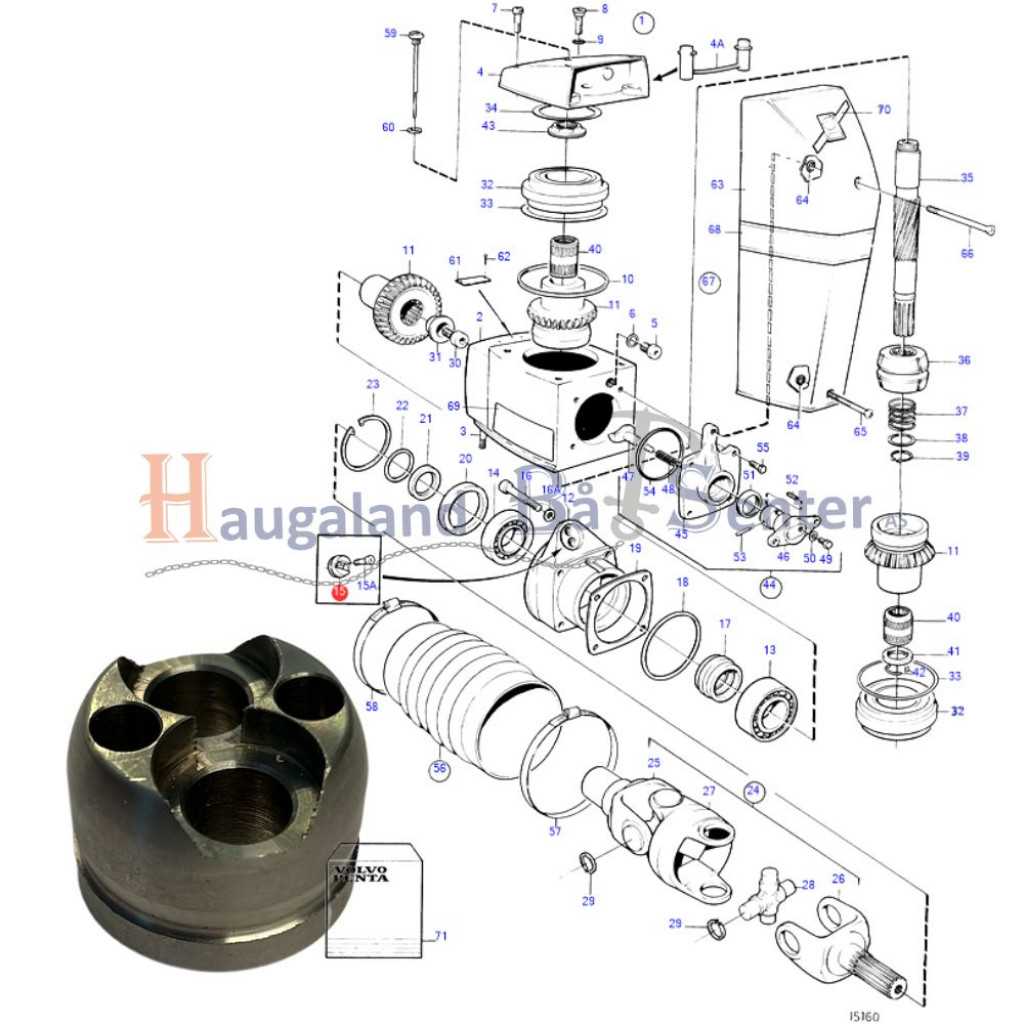

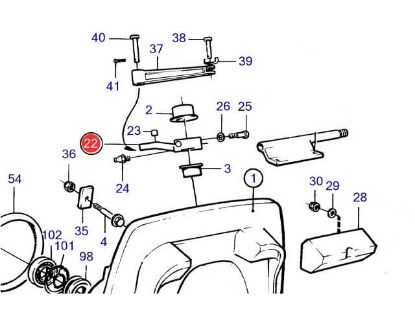

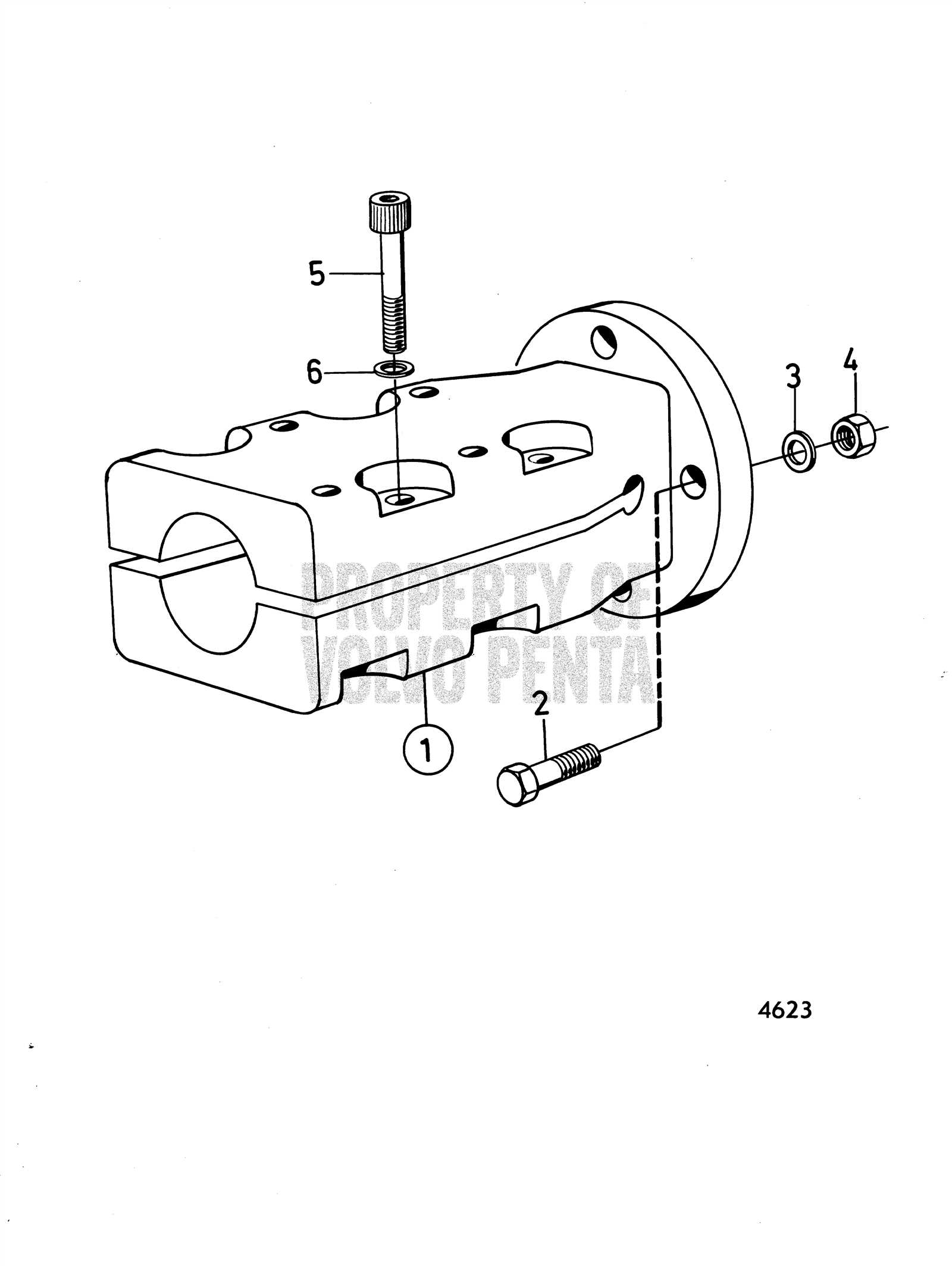

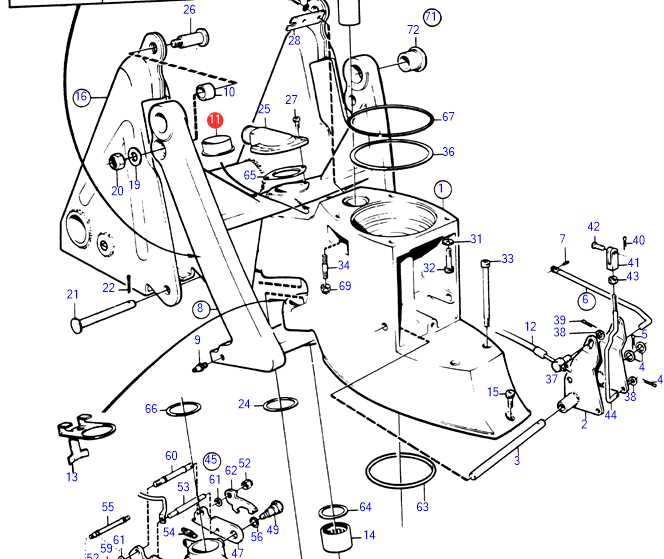

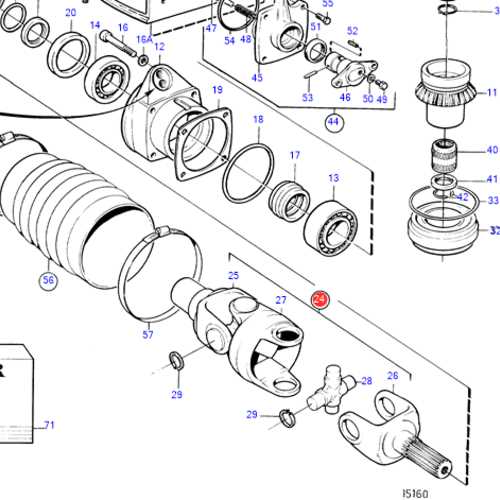

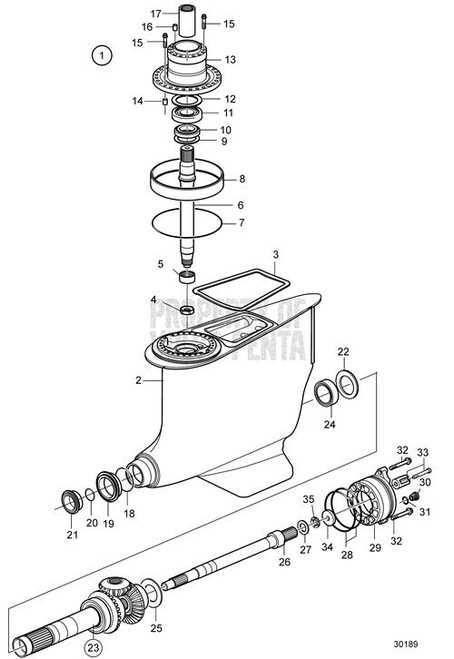

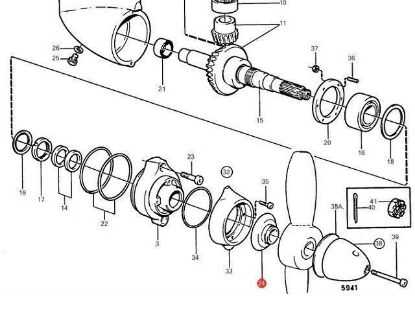

Visual Representation of Key Components

The layout of crucial elements provides a clear understanding of how different mechanical pieces work together within the system. A detailed view allows users to grasp the interconnectedness of the components, making it easier to identify individual parts and their functions. This visualization offers valuable insights into the operational flow, which can be especially helpful for maintenance and troubleshooting purposes.

Understanding the Structure involves recognizing the major elements that contribute to the functionality of the system. Each part plays a specific role, and having a clear representation aids in the overall comprehension of how the system operates efficiently.

Highlighted areas showcase key points of interest, focusing on the most critical aspects for smooth operation. These highlighted sections are designed to simplify complex mechanisms, making them more accessible for various technical tasks.

Common Issues with 290 DP Parts

Many owners of marine propulsion systems encounter recurring problems with various components that make up these units. Understanding the most frequent malfunctions can help identify solutions faster and ensure the smooth operation of the drive system. These issues are typically related to wear and tear, as well as environmental factors such as corrosion.

Corrosion and Rusting: One of the main challenges for boat engines is corrosion. Constant exposure to saltwater or harsh weather conditions often leads to rust, which can severely affect the lifespan of metallic elements.

Leaks and Seal Failures: Seal integrity is crucial to maintaining proper performance. Over time, seals may degrade, causing oil or fluid leaks that impact overall efficiency and can lead to costly repairs if not addressed promptly.

Gear and Bearing Wear: Due to frequent use and the high-pressure environment, gears and bearings are prone to wear over time. This can lead to increased noise, vibrations, and reduced performance if not regularly inspected and maintained.

Maintenance Tips for Longevity

Regular upkeep is crucial to ensuring the long-term reliability of your equipment. By following a consistent maintenance routine, you can help avoid unexpected issues and extend the operational life of your system. Proper care and attention to small details can prevent costly repairs in the future.

| Task | Frequency | Notes |

|---|---|---|

| Inspect and clean filters | Every 50 hours | Ensure optimal airflow for better performance. |

| Check fluid levels | Every 100 hours | Maintaining appropriate levels prevents overheating. |

| Examine hoses and belts | Every 150 hours | Replace any worn or cracked components immediately. |

| Lubricate moving parts | Every 200 hours | Regular lubrication minimizes friction and wear. |

Where to Find Replacement Parts

When it comes to sourcing components for your equipment, finding reliable options is crucial to ensure longevity and performance. Various suppliers provide solutions that match different models and needs, but identifying the right source can save time and effort.

Many platforms, both online and offline, offer a variety of choices. These range from authorized dealers to specialized shops that stock necessary components. Selecting the appropriate retailer often depends on availability, pricing, and warranty coverage.

| Supplier | Type of Components | Location |

|---|---|---|

| Marine Equipment Store | Mechanical, Electrical | Global Shipping |

| Authorized Service Centers | OEM Products | Local Branches |

| Online Marketplaces | Aftermarket Options | Worldwide |

Installation Guide for New Components

When setting up fresh mechanical elements, it’s essential to follow a clear process to ensure everything fits and functions as intended. This guide provides key steps to help integrate new parts smoothly, preventing potential issues during assembly and future operation.

Preparation Before Installation

Start by ensuring all necessary tools and equipment are on hand. Carefully inspect the new components to confirm they are in good condition, free from any defects or damage. Clean the area where the part will be installed, removing debris or old materials to provide a secure fit.

Step-by-Step Installation Process

Begin by aligning the new piece with the designated location. Make sure that it matches the existing structure and connections. Tighten fasteners evenly to avoid imbalance and ensure proper alignment. Once secured, double-check all connections, seals, and bolts for a tight, firm fit. Finally, test the system under low load to verify functionality before putting it into full operation.

Comparative Analysis with Similar Models

When evaluating marine propulsion systems, it is essential to compare the features and performance across different models. This helps to identify strengths and weaknesses, providing clarity on which system offers the best combination of reliability, efficiency, and power output.

Key Differences in Design

- Drive configurations vary significantly, affecting handling and maneuverability in different water conditions.

- Engine compatibility can differ, influencing both installation complexity and long-term maintenance requirements.

- The material composition of components plays a crucial role in durability, especially for saltwater environments.

Performance and Efficiency

- Fuel consumption rates often vary, impacting operating costs for both short and long voyages.

- Acceleration and top speed are influenced by propeller design and engine pairing, making it critical to consider the intended use.

- Noise and vibration levels can differ, affecting onboard comfort during extended periods at sea.

By comparing similar models, users can make informed decisions, ensuring they select the right system for their specific needs.

Understanding the Parts Diagram

The illustration provides a clear overview of the different components and their arrangement within the mechanical system. This visual representation is essential for identifying and assembling key elements of the machinery. By examining the diagram, one can better understand how each element interacts with others to ensure smooth functionality and efficiency.

Main Components Overview

- Engine assembly – the central unit powering the entire system.

- Transmission – responsible for transferring power from the engine to other moving parts.

- Propeller – the component that directly controls movement and navigation.

Tips for Efficient Usage

- Familiarize yourself with the layout to identify components quickly.

- Check for potential wear and tear by understanding the placement of each element.

- Ensure compatibility of replacement parts by comparing with the diagram.

Important Specifications to Note

Understanding the key specifications of your system ensures smooth operation and optimal performance. Whether you’re dealing with maintenance, upgrades, or troubleshooting, having a solid grasp of these details can make all the difference. This section highlights the critical elements to focus on, helping you maintain efficiency and longevity.

Key Features to Monitor

- Engine Capacity: Ensures the system operates within its designed limits for power and efficiency.

- Drive Type: Understanding the type of drive system is crucial for selecting compatible components and ensuring proper functionality.

- Cooling System: Regular checks of the cooling mechanism prevent overheating and prolong system lifespan.

Additional Considerations

- Lubrication Requirements: Follow recommended lubrication schedules to prevent wear and tear.

- Material Compatibility: Ensure all components are made of durable materials to resist corrosion and damage in harsh conditions.

Frequently Asked Questions

This section addresses the most common queries related to the maintenance and operation of marine propulsion systems. Whether you are looking for guidance on specific components or troubleshooting, the following questions will provide useful insights.

What should I do if the engine is overheating?

- Check the cooling system for blockages.

- Inspect the water pump for any signs of wear or failure.

- Ensure that the thermostat is functioning correctly.

How can I improve fuel efficiency?

- Regularly clean the fuel filters to maintain optimal performance.

- Ensure proper engine tuning and servicing.

- Use high-quality fuel that meets recommended standards.

For additional support, refer to the full user guide or consult with a professional technician.

Resource Links for Further Reading

This section provides a compilation of valuable resources for those seeking to expand their knowledge about marine propulsion systems and their components. Engaging with various materials can enhance understanding and offer insights into the complexities of these mechanical structures.

Online Articles and Guides

- Comprehensive Overview of Marine Drive Systems

- Understanding the Mechanisms of Aquatic Engines

- Maintenance Tips for Marine Gearboxes

Technical Manuals