When maintaining a marine engine, it is essential to have a clear understanding of its various components and their functions. This knowledge not only aids in effective servicing but also enhances the overall performance of the vessel. Familiarity with the engine’s structure allows for timely identification of potential issues and facilitates easier repairs.

Each element plays a crucial role in the operation of the engine, contributing to its efficiency and reliability. From the primary mechanisms that drive performance to the auxiliary systems that ensure smooth operation, every component is interconnected. Gaining insight into these parts can significantly improve troubleshooting and maintenance efforts, ultimately leading to a more dependable maritime experience.

The functionality of a marine engine relies on various key components that work together seamlessly. Understanding these elements is crucial for optimal performance and maintenance.

| Component | Description |

|---|---|

| Crankshaft | Transforms linear motion into rotational energy, powering the vessel. |

| Piston | Moves within the cylinder, creating the necessary pressure for combustion. |

| Cylinder Head | Houses valves and spark plugs, facilitating the intake and exhaust processes. |

| Fuel Injector | Delivers fuel into the combustion chamber, ensuring efficient burning. |

| Cooling System | Regulates temperature, preventing overheating during operation. |

Common Maintenance Tools Required

Proper upkeep of marine engines necessitates a selection of essential tools to ensure efficient and safe operation. These instruments aid in routine inspections, repairs, and general maintenance tasks, contributing to the longevity of the engine.

Wrenches are crucial for tightening or loosening various components, while screwdrivers allow for adjustments in smaller fittings. An oil filter wrench is particularly useful for changing lubricants, ensuring optimal performance. Additionally, having a multimeter helps in diagnosing electrical issues, allowing for timely repairs.

Other valuable tools include pliers for gripping and cutting tasks, along with a set of sockets for ease of access to tight spaces. Maintaining a well-equipped toolbox not only streamlines maintenance procedures but also enhances safety during operation.

Key Features of D1-30 Design

The design of this marine engine emphasizes efficiency and reliability, making it suitable for various watercraft applications. It integrates advanced technology to enhance performance while minimizing environmental impact.

One of the standout characteristics is its compact structure, allowing for easy installation in limited spaces. The engine’s lightweight materials contribute to improved maneuverability and fuel efficiency.

| Feature | Description |

|---|---|

| Compact Size | Designed to fit in tight engine compartments, ensuring versatile applications. |

| Lightweight Construction | Utilizes materials that reduce overall weight, enhancing speed and fuel economy. |

| Efficient Fuel Usage | Optimized combustion process for lower fuel consumption and emissions. |

| Robust Performance | Engine delivers consistent power output across varying loads and conditions. |

Identifying Engine Parts by Function

Understanding the components of a marine engine is essential for maintenance and optimal performance. Each element plays a specific role, contributing to the overall functionality and efficiency of the system. Recognizing these parts by their purpose can greatly aid in troubleshooting and repairs.

Key Components and Their Roles

- Fuel System: Responsible for delivering fuel to the engine for combustion.

- Cooling System: Ensures the engine operates at a safe temperature, preventing overheating.

- Lubrication System: Reduces friction between moving parts, enhancing longevity and performance.

- Exhaust System: Directs harmful gases away from the engine, maintaining a safe environment.

- Ignition System: Initiates the combustion process, critical for engine startup and operation.

Maintenance Tips for Each Component

- Regularly check and replace fuel filters to ensure clean fuel flow.

- Inspect the cooling system for leaks and ensure proper coolant levels.

- Change oil and filters as per the manufacturer’s recommendations to maintain lubrication.

- Examine exhaust components for blockages or damage to ensure efficient gas expulsion.

- Test ignition components periodically to guarantee reliable starts.

Installation Guidelines for Components

When assembling various elements of your marine engine, following precise procedures is essential for optimal performance and longevity. Proper installation not only ensures that each component functions as intended but also contributes to the overall efficiency of the system.

Preparation Steps

Before beginning the installation, ensure that all necessary tools and replacement elements are at hand. Review the specifications to familiarize yourself with the required orientations and connections. It is crucial to work in a clean environment to avoid contamination that may affect functionality.

Installation Process

Start by securing each component in its designated position. Apply appropriate torque settings as indicated in the specifications to avoid damage. Ensure that all seals and gaskets are in good condition to prevent leaks. Regularly inspect the connections during the process to confirm proper alignment and fit.

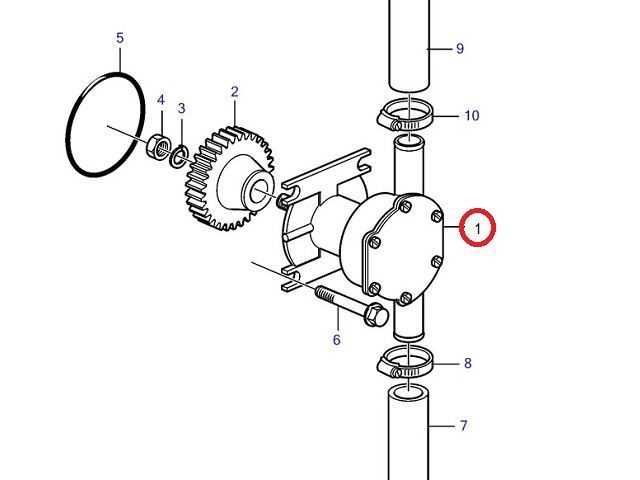

Diagram Analysis: Visual Representation

This section delves into the significance of visual layouts in understanding mechanical assemblies. By examining graphical illustrations, one can gain insights into the relationships and functions of various components, facilitating better comprehension of their interconnections.

Importance of Visual Layouts

Visual representations play a crucial role in simplifying complex systems. They allow for quick identification of parts and their respective roles within the overall framework, enhancing both learning and practical application.

Key Elements of Effective Illustrations

To create impactful visual aids, several factors must be considered, including clarity, detail, and accurate labeling. Each element contributes to a more effective understanding of the subject matter.

| Element | Description |

|---|---|

| Clarity | Ensures that each component is easily identifiable. |

| Detail | Provides necessary information for a comprehensive understanding. |

| Labeling | Identifies parts, aiding in recognition and learning. |

Ordering Replacement Parts Effectively

Ensuring optimal performance of your machinery often requires the timely acquisition of components. Effectively navigating the ordering process can save both time and resources, enabling seamless operation.

Identify the Right Component

Before placing an order, it is essential to accurately determine the specific item needed. Reviewing the equipment’s manual or consulting with a specialist can provide clarity on the exact specifications required.

Choose Reliable Suppliers

Selecting trustworthy vendors is crucial for obtaining high-quality components. Researching customer reviews and comparing prices from various suppliers can lead to better purchasing decisions. Establishing a good relationship with a supplier can also facilitate future transactions.

Troubleshooting Common Issues

This section provides guidance on identifying and resolving frequent problems encountered in marine engines. By understanding these challenges, users can maintain optimal performance and ensure longevity.

Identifying Symptoms

Recognizing signs of malfunction is crucial for effective repairs. Common symptoms may include unusual noises, reduced power, or irregular operation. By documenting these issues, users can better diagnose the root causes.

Basic Troubleshooting Steps

Before delving into complex repairs, follow these fundamental steps:

| Step | Action |

|---|---|

| 1 | Inspect the fuel supply for blockages or leaks. |

| 2 | Check electrical connections for corrosion or loose wires. |

| 3 | Examine the cooling system for obstructions or leaks. |

| 4 | Test battery voltage and ensure it is charged. |

| 5 | Review maintenance records to ensure timely service. |

Understanding Wiring and Electrical Layout

The organization of wiring and electrical components is crucial for ensuring optimal functionality and safety in marine engines. A clear layout not only facilitates troubleshooting but also enhances overall performance by minimizing electrical interference and ensuring reliable connections.

Key Components of the Electrical System

- Batteries: Provide the necessary power for starting the engine and operating electrical accessories.

- Wiring Harness: A collection of wires that connect various components, ensuring proper communication between them.

- Fuses: Protect the electrical circuits by preventing overloads and short circuits.

- Relays: Act as switches that control high-power circuits with low-power signals.

Importance of Proper Wiring Layout

- Ensures safety by reducing the risk of electrical fires.

- Enhances reliability of electrical systems, preventing unexpected failures.

- Facilitates maintenance and repairs by providing a clear understanding of connections.

- Improves efficiency by minimizing voltage drop across connections.

Benefits of Regular Component Inspection

Routine evaluation of machinery elements plays a crucial role in maintaining optimal performance and extending the lifespan of equipment. By consistently checking individual components, users can identify potential issues before they escalate into more significant problems.

Early Detection of Issues: One of the primary advantages of regular inspections is the ability to detect minor faults early. This proactive approach allows for timely repairs, reducing the risk of unexpected breakdowns and costly downtime.

Enhanced Safety: Regular assessments contribute to a safer operational environment. By ensuring that all components function correctly, the likelihood of accidents and malfunctions decreases significantly.

Improved Efficiency: Well-maintained equipment operates more efficiently, which can lead to lower fuel consumption and reduced operational costs. Regular inspections help keep machinery running smoothly and effectively.

Cost Savings: Investing time in routine checks can save money in the long run. Addressing small issues promptly prevents them from developing into more extensive repairs, which can be significantly more expensive.

Increased Reliability: Consistent inspections build confidence in the reliability of equipment. Operators can trust that their machinery will perform as expected, leading to better planning and productivity.

Resources for Parts and Support

When it comes to maintaining and repairing marine engines, having reliable resources is essential. Various avenues exist to help boat owners find necessary components and assistance, ensuring optimal performance and longevity of their vessels.

Online Retailers

Numerous online platforms specialize in marine engine components. These websites often provide detailed catalogs, allowing users to search for specific items based on their requirements. Many also offer customer reviews and ratings, which can be helpful in selecting quality products.

Manufacturer Support

Most manufacturers provide dedicated customer service channels. These can include help hotlines, email support, and extensive online FAQs. Engaging directly with the manufacturer often yields valuable insights and guidance regarding suitable components and troubleshooting methods.

| Resource Type | Examples |

|---|---|

| Online Retailers | Marine Engine Parts Shop, Nautical Supply Store |

| Manufacturer Support | Customer Service Hotline, Official Website FAQs |

| Community Forums | Boat Owners Forum, Marine Engine Discussion Groups |

Upgrading and Modifying the Engine

Enhancing and adapting your marine power unit can significantly improve performance and efficiency. This section explores various strategies for optimizing your engine’s capabilities while ensuring reliability and longevity.

- Performance Enhancements:

- Consider upgrading the fuel injection system for improved combustion efficiency.

- Install a high-performance exhaust system to increase airflow and reduce back pressure.

- Weight Reduction:

- Replace heavy components with lighter alternatives to improve power-to-weight ratio.

- Utilize composite materials for non-structural parts to decrease overall mass.

- Cooling Improvements:

- Upgrade the cooling system to prevent overheating during extended operation.

- Install an additional oil cooler to maintain optimal engine temperatures.

- Control Systems:

- Implement advanced electronic controls for better engine management.

- Consider integrating a monitoring system to track performance metrics in real-time.

By carefully selecting upgrades and modifications, you can enhance the overall efficiency and performance of your marine engine, ensuring it meets your specific needs and requirements.