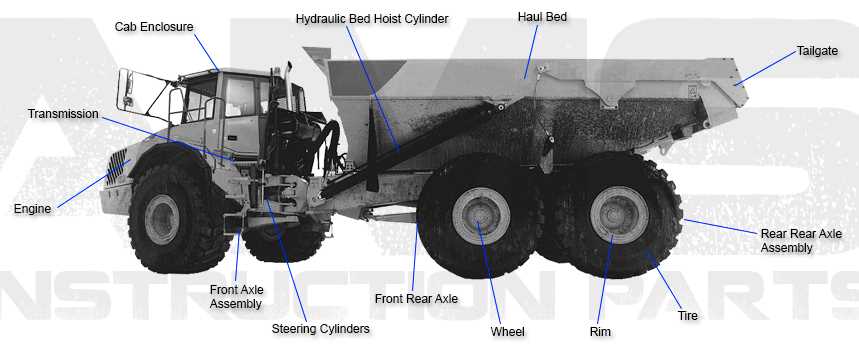

The intricate assembly of heavy-duty trucks encompasses numerous elements, each contributing to the overall functionality and performance of the vehicle. This section aims to provide clarity on the various components that make up these robust machines, offering insights into their arrangement and interrelationships.

Familiarity with these essential elements is crucial for maintenance and repair. Recognizing how different sections connect can greatly enhance troubleshooting efforts and facilitate efficient service. A comprehensive understanding empowers owners and technicians alike to optimize performance and longevity.

By exploring the layout of these critical features, readers can gain valuable knowledge that assists in effective decision-making and planning for repairs or upgrades. Knowledge of the structure ultimately contributes to the successful operation of heavy-duty trucks in various demanding environments.

Understanding the Volvo VNL Design

This section delves into the intricate architecture and engineering elements that define this heavy-duty truck model. The thoughtful arrangement of components enhances performance, reliability, and driver comfort, making it a preferred choice in the transportation industry.

Central to the vehicle’s construction is a robust frame that supports the entire structure, contributing to its durability under various conditions. A well-designed cabin ensures a pleasant driving experience, offering ergonomic controls and ample space for operators.

| Feature | Description |

|---|---|

| Chassis | Engineered for strength, ensuring stability and longevity. |

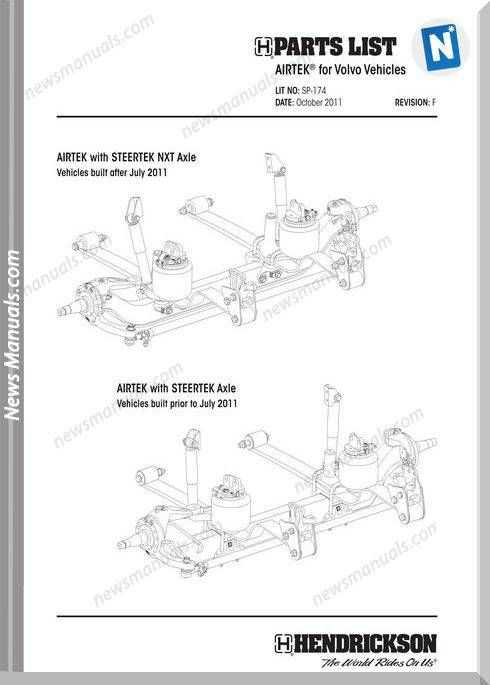

| Suspension | Advanced system that provides a smooth ride, reducing fatigue. |

| Cab Interior | Spacious layout with intuitive controls, enhancing usability. |

| Engine Placement | Strategically located for optimal weight distribution and efficiency. |

The interplay of these design elements not only maximizes operational efficiency but also prioritizes safety, ensuring that operators can handle the vehicle with confidence on long journeys.

Essential Components of the VNL

This section explores the fundamental elements that contribute to the functionality and performance of the heavy-duty vehicle. Each component plays a vital role in ensuring efficiency, safety, and durability during operation.

Key Systems

- Powertrain: Responsible for delivering power and torque.

- Suspension: Enhances stability and comfort while driving.

- Braking System: Ensures reliable stopping capability under various conditions.

Interior Features

- Dashboard: Central control panel providing critical information to the driver.

- Seating: Designed for comfort and support during long hauls.

- Storage Solutions: Optimized space for tools and personal items.

Understanding these essential components allows for better maintenance and optimization of the vehicle’s performance.

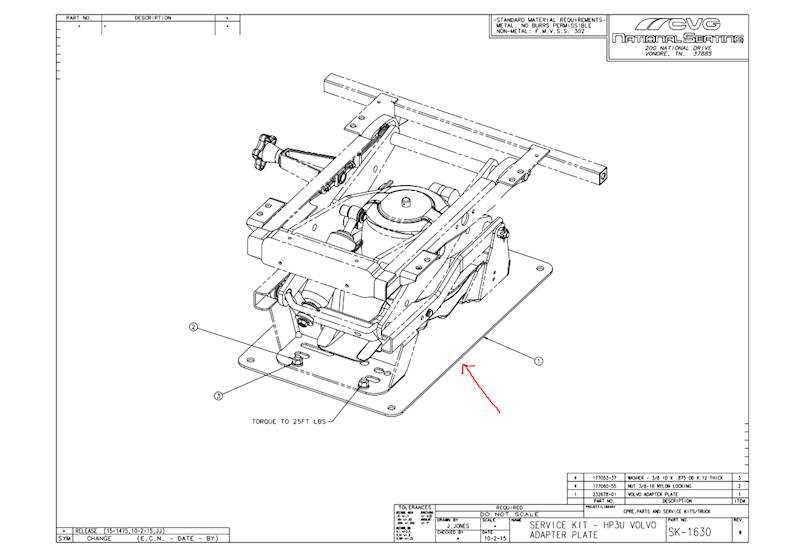

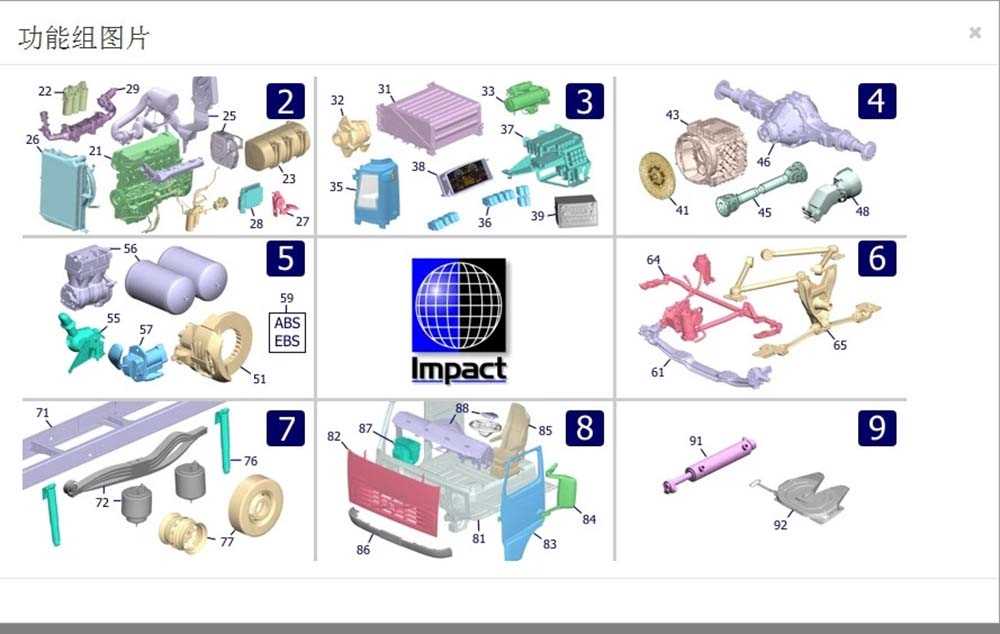

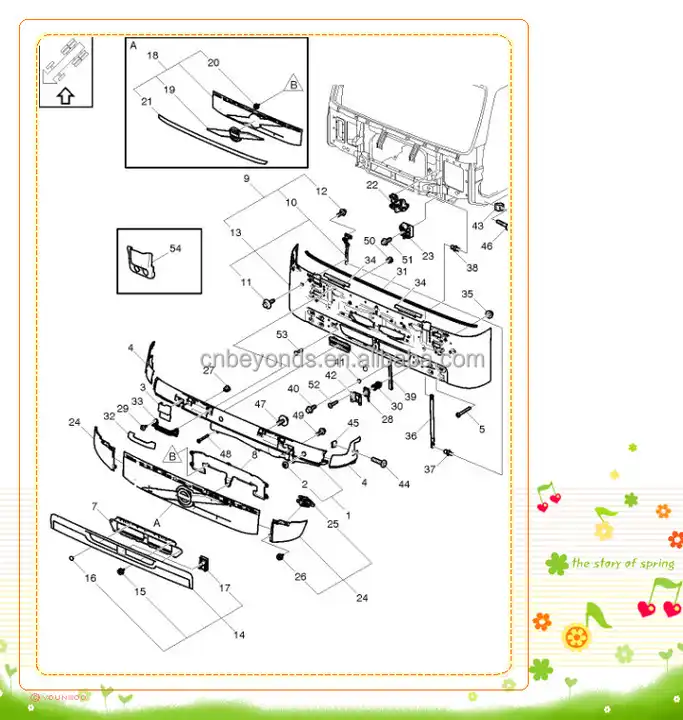

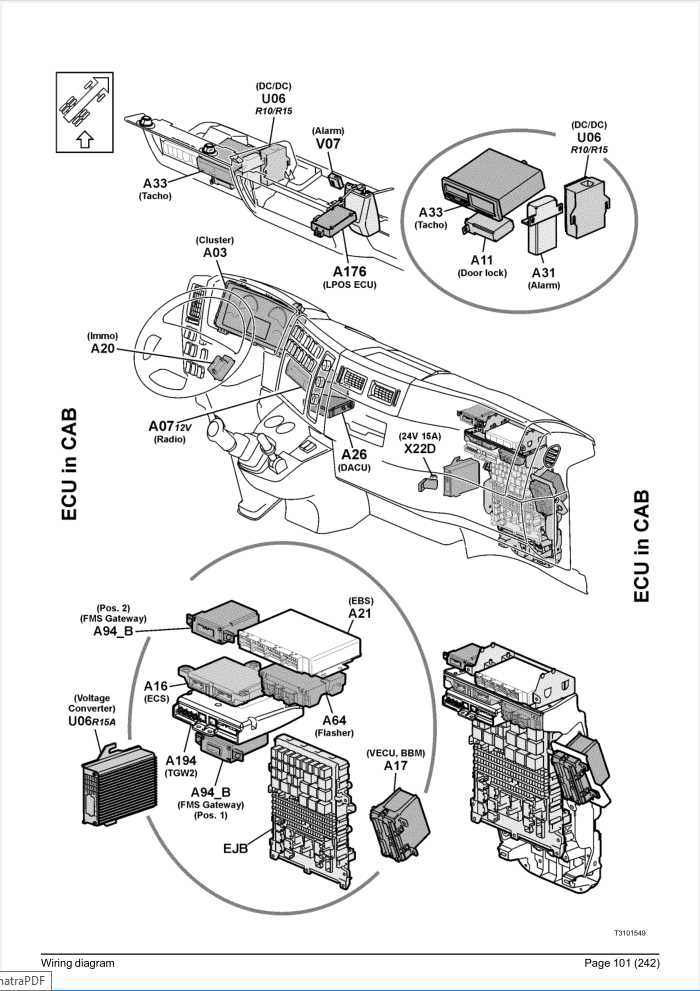

Identifying Key Parts in Diagrams

Understanding essential components within technical illustrations is crucial for effective maintenance and repair. By recognizing these elements, users can navigate through the information more efficiently, ensuring they locate the necessary items for their tasks.

Common Component Categories

Illustrations often categorize components into various sections. Familiarity with these categories allows for quicker identification and assessment of the items needed for specific repairs or evaluations.

| Component Type | Description |

|---|---|

| Engine | The central unit that powers the vehicle, critical for performance. |

| Transmission | Responsible for transferring power from the engine to the wheels. |

| Suspension | System that supports the vehicle and absorbs shocks from the road. |

| Electrical System | Includes wiring and components that manage power distribution. |

Utilizing Visual Aids for Clarity

Visual representations enhance understanding by providing clear depictions of each element. Utilizing these aids not only streamlines the repair process but also reduces the likelihood of errors during maintenance.

Maintenance Tips for Volvo Trucks

Regular upkeep is essential for ensuring optimal performance and longevity of heavy-duty vehicles. Implementing a consistent maintenance schedule can help prevent unexpected breakdowns and enhance overall efficiency.

1. Check Fluid Levels: Ensure that all essential fluids, such as oil, coolant, and brake fluid, are at appropriate levels. Regular checks help maintain the engine’s health and prevent overheating.

2. Inspect Tires: Frequent examination of tire pressure and tread depth is vital. Properly inflated tires improve fuel efficiency and ensure safe handling on the road.

3. Brake System Maintenance: Pay attention to brake components. Regular inspections can prevent issues that may lead to compromised safety.

4. Battery Care: Monitor battery health by checking for corrosion and ensuring connections are secure. A well-maintained battery ensures reliable starts and prevents electrical problems.

5. Follow Service Intervals: Adhere to manufacturer-recommended service intervals for oil changes, filter replacements, and other essential services. Keeping up with these guidelines is key to vehicle reliability.

By prioritizing these maintenance practices, operators can ensure their vehicles remain in peak condition, ultimately leading to better performance and reduced costs over time.

Common Issues and Solutions

This section addresses prevalent challenges encountered in heavy-duty vehicles and offers practical remedies to enhance performance and reliability.

- Electrical Failures:

Issues with the electrical system can lead to various malfunctions.

- Check and replace faulty fuses.

- Inspect wiring for damage or corrosion.

- Ensure battery connections are clean and tight.

- Engine Overheating:

Overheating can result from several factors affecting engine efficiency.

- Verify coolant levels and top up as necessary.

- Examine the radiator for blockages or leaks.

- Test the thermostat and replace if faulty.

- Transmission Issues:

Transmission problems can disrupt vehicle operation and lead to costly repairs.

- Check fluid levels and refill if low.

- Inspect for leaks around seals and gaskets.

- Consider flushing the transmission fluid if it’s dirty.

Parts Replacement Procedures Explained

This section provides a comprehensive overview of the essential steps involved in the process of replacing components in heavy-duty vehicles. Understanding these procedures ensures that maintenance is performed efficiently, prolonging the life of the vehicle and maintaining optimal performance.

Step-by-Step Approach

The first step involves identifying the specific component that requires replacement. Once identified, the necessary tools and replacement items should be gathered. It is crucial to follow the manufacturer’s guidelines for disassembly, ensuring that any surrounding elements are not damaged in the process.

Final Checks and Testing

After the new component is installed, it’s important to conduct thorough checks to confirm proper installation. This includes inspecting connections and ensuring everything is secure. Finally, performing a test run will help verify that the replacement functions correctly and that the vehicle operates smoothly.

How to Use the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This guide aims to clarify how to navigate and utilize these illustrations to ensure proper identification and replacement of essential elements.

Identifying Components

Begin by familiarizing yourself with the layout of the illustration. Each section typically corresponds to a specific area, allowing you to locate parts efficiently. Pay attention to the labeling, as this will guide you in recognizing individual items and their respective numbers.

Planning Your Repairs

Once you have identified the necessary elements, make a checklist of items needed for your maintenance task. This approach streamlines the repair process and ensures that you have all required components on hand, minimizing delays and enhancing productivity.

Benefits of Accurate Diagrams

Precise representations play a crucial role in understanding complex systems. They serve as essential tools for technicians and engineers, facilitating effective communication and streamlined processes. High-quality visuals enhance comprehension, enabling users to quickly identify components and their relationships.

Here are some key advantages of utilizing accurate visuals:

| Benefit | Description |

|---|---|

| Improved Efficiency | Clear representations reduce time spent on troubleshooting and repairs, leading to faster project completion. |

| Enhanced Safety | Accurate visuals help prevent errors, minimizing risks associated with incorrect assembly or maintenance. |

| Effective Training | Well-crafted visuals serve as valuable educational resources, aiding in the training of new personnel. |

| Cost Savings | By preventing mistakes and misunderstandings, accurate representations can lead to significant cost reductions. |

Aftermarket Parts for Volvo VNL

Exploring alternative components for heavy-duty trucks can enhance performance and prolong vehicle life. These replacements often provide cost-effective solutions without compromising quality, ensuring that your vehicle operates efficiently on the road.

Many owners choose to upgrade or replace specific elements to improve durability and functionality. Below is a table highlighting some popular aftermarket options and their benefits.

| Component | Description | Benefits |

|---|---|---|

| Brake Systems | High-performance braking components for enhanced safety. | Improved stopping power and reduced wear. |

| Suspension Kits | Upgraded suspension for better handling and comfort. | Increased stability and ride quality. |

| Lighting Solutions | LED lights for better visibility and energy efficiency. | Longer lifespan and brighter illumination. |

| Engine Filters | High-efficiency filters to enhance engine performance. | Improved air quality and fuel efficiency. |

Understanding OEM vs. Aftermarket Parts

When it comes to vehicle maintenance and repair, the choice between original equipment manufacturer (OEM) components and those produced by third-party suppliers can significantly impact performance and longevity. Each option presents unique advantages and considerations, making it essential for owners to understand the distinctions and implications of their choices.

OEM components are designed and manufactured by the same company that produced the vehicle. This ensures a perfect fit and compliance with original specifications. However, these parts often come at a premium price.

On the other hand, aftermarket components are produced by external manufacturers and may offer more affordable alternatives. While some aftermarket options can match or exceed the quality of OEM products, others may not meet the same rigorous standards, leading to potential performance issues. It is crucial to conduct thorough research and select reputable suppliers when considering aftermarket options.

Ultimately, the decision between OEM and aftermarket components depends on individual priorities, budget constraints, and desired performance levels. Understanding these differences empowers vehicle owners to make informed choices that align with their specific needs.

Resources for Further Information

For those seeking to deepen their understanding of vehicle components and their configurations, a variety of resources are available. These materials can assist in identifying specific elements and their functions, ensuring optimal maintenance and repair practices.

Online Platforms

- Manufacturer Websites: Official sites often provide detailed specifications and guides.

- Automotive Forums: Communities dedicated to vehicle enthusiasts share valuable insights and experiences.

- Technical Blogs: Many experts write articles covering specific issues and solutions related to various models.

Publications and Manuals

- Repair Manuals: Comprehensive guides that detail assembly and disassembly processes.

- Service Bulletins: Important updates issued by manufacturers regarding product enhancements or recalls.

- Technical Reference Books: In-depth literature covering engineering principles and vehicle mechanics.