When it comes to maintaining outdoor spaces, efficient tools are crucial for completing the task. Understanding how different elements of cleaning machines work together can help ensure they function smoothly and effectively. Knowing which elements require regular attention is key to keeping your equipment in top shape, providing reliable performance over time.

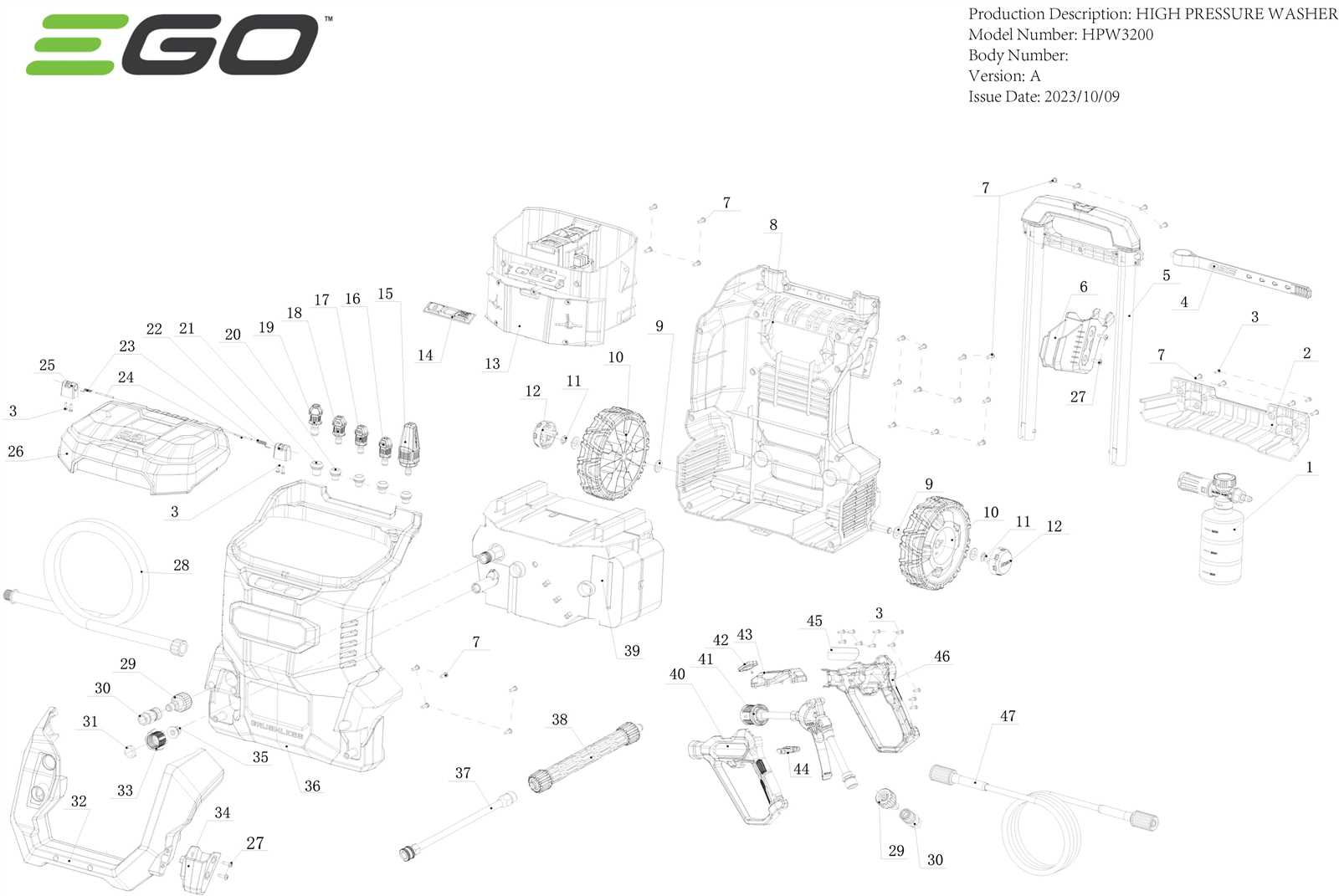

In this section, we will examine the essential elements that make up high-pressure cleaning devices. Whether you’re troubleshooting or simply performing routine maintenance, a clear understanding of the system’s core elements will assist in identifying what needs to be serviced or replaced.

From key mechanical features to vital connections, having a deeper knowledge of how everything integrates can greatly extend the lifespan of your equipment. Here, we’ll break down the primary features that contribute to efficient operation, offering insights into their functionality and maintenance needs.

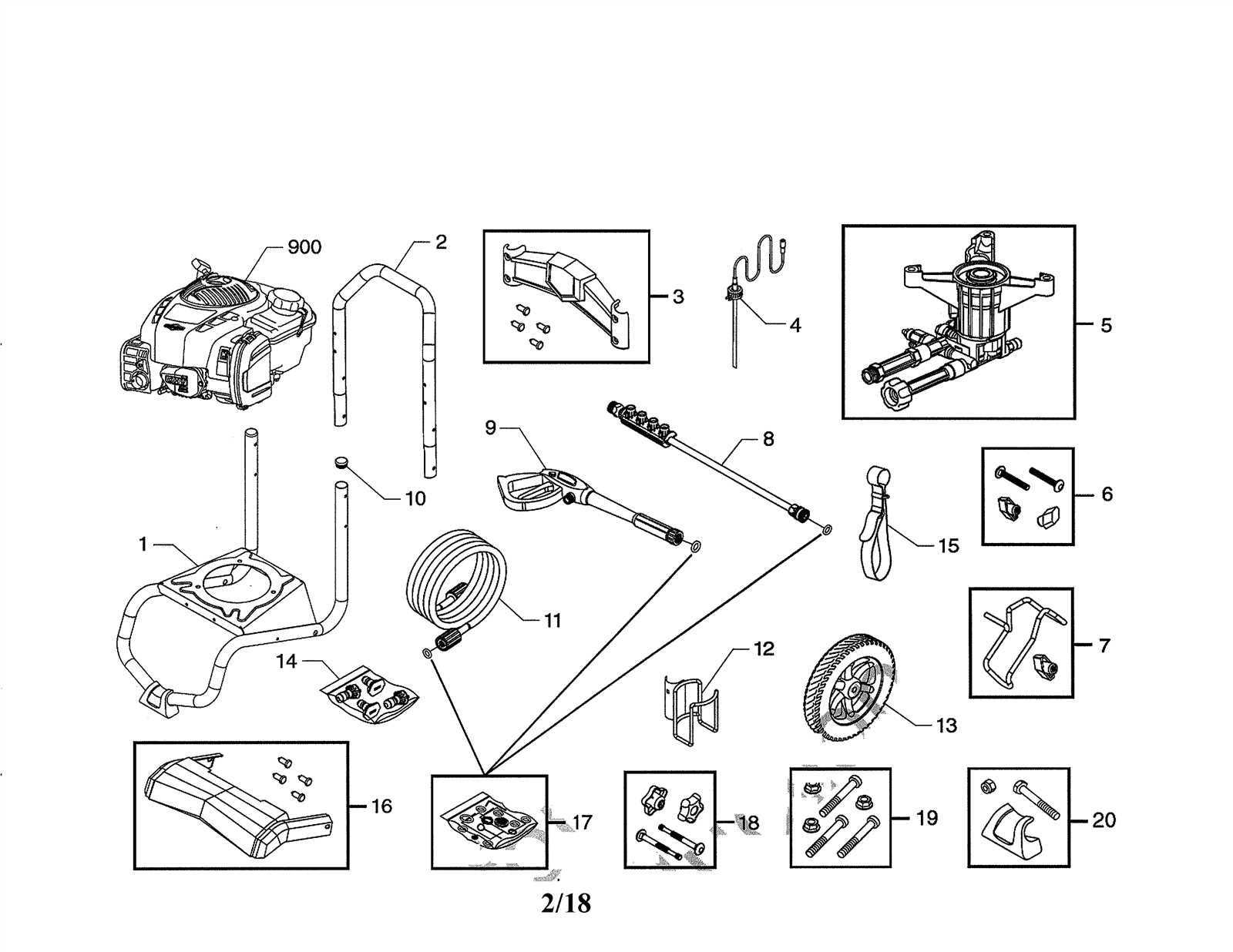

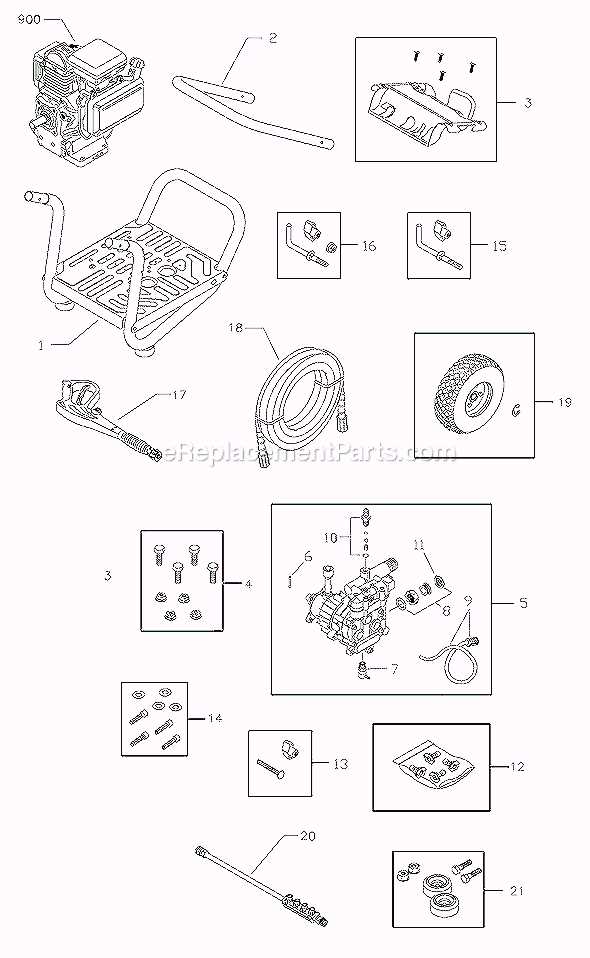

Overview of Honda Power Washer Components

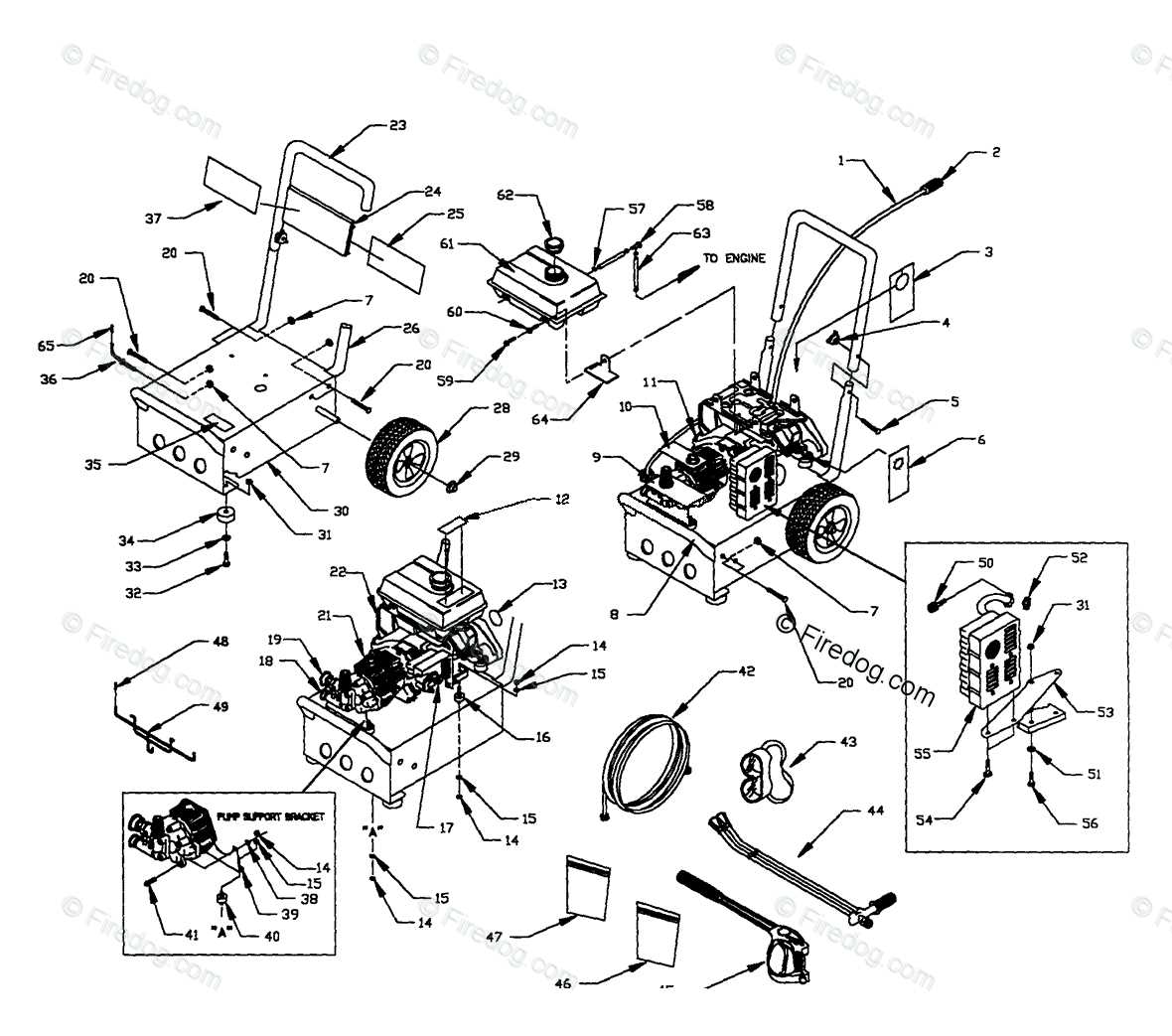

The components within these machines work together to deliver efficient cleaning performance. Each element plays a crucial role in ensuring the equipment operates smoothly and effectively. By understanding the key elements, you can better maintain and troubleshoot the system when needed.

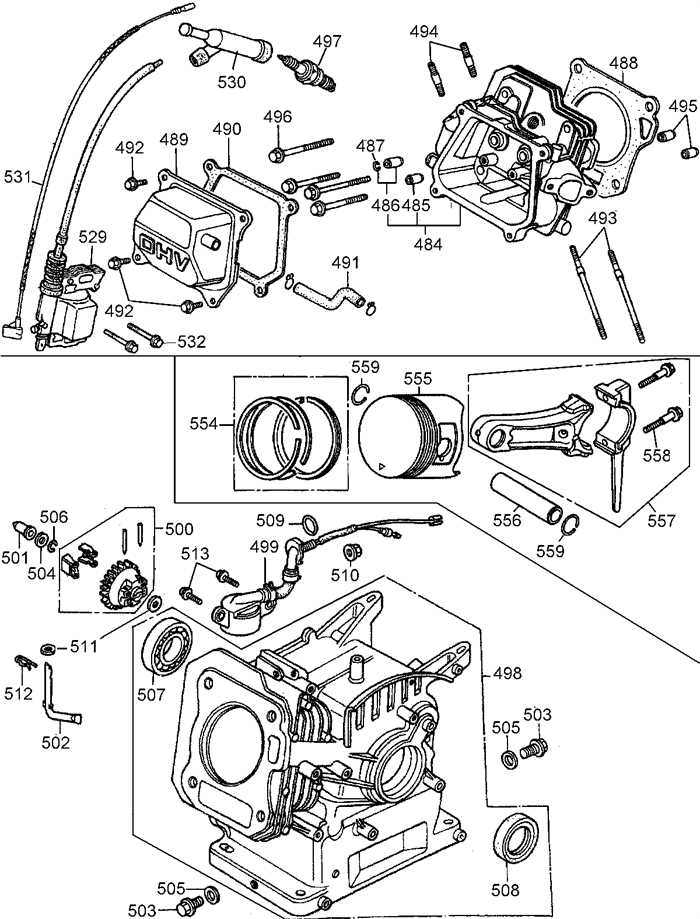

Core Mechanical Elements

The primary sections of the equipment include various mechanical elements that drive functionality. These mechanisms enable water flow and pressure regulation, ensuring a steady output for different cleaning tasks. The engine and pump are central to this process, with other supporting components aiding in precise control and stability.

Auxiliary Features and Connectors

Alongside the core elements, there are additional features designed for user convenience and safety. Hoses, nozzles, and connectors offer versatility, while safety mechanisms protect against potential malfunctions. These supplementary parts enhance the overall usability and adaptability of the machine.

| Component | Function | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine |

| Component | Description | Function |

|---|---|---|

| Base | Heavy-duty platform that supports the entire unit. | Stability and weight distribution. |

| Handles | Ergonomic grips for maneuverability. | Ease of use and control during operation. |

| Mounting Brackets | Connects various components securely. | Ensures alignment and prevents movement. |

Maintenance and Inspection

Regular checks of the frame and supporting elements are vital for ensuring safe operation. Signs of wear or damage should be addressed promptly to prevent any operational failures. Keeping the structure clean and free of debris will also contribute to its longevity and effectiveness.

Wheels and Mobility Elements

When it comes to portable cleaning equipment, the design and functionality of mobility components play a crucial role in ensuring ease of use and transportation. These features are specifically engineered to enhance maneuverability, allowing users to efficiently navigate various terrains while performing their tasks.

The wheels of such equipment are typically designed with durability and traction in mind, enabling seamless movement across different surfaces. A sturdy wheelbase provides stability, minimizing the risk of tipping during operation. Additionally, some models may include swivel casters for enhanced agility, making it easier to change directions without lifting the unit.

Furthermore, the overall layout of the mobility elements can impact the user experience significantly. Adjustable handles, for instance, allow users to customize the height for comfort, while foldable designs enable compact storage and transport. Each aspect is meticulously crafted to ensure that users can effortlessly move their equipment from one location to another, enhancing overall efficiency.

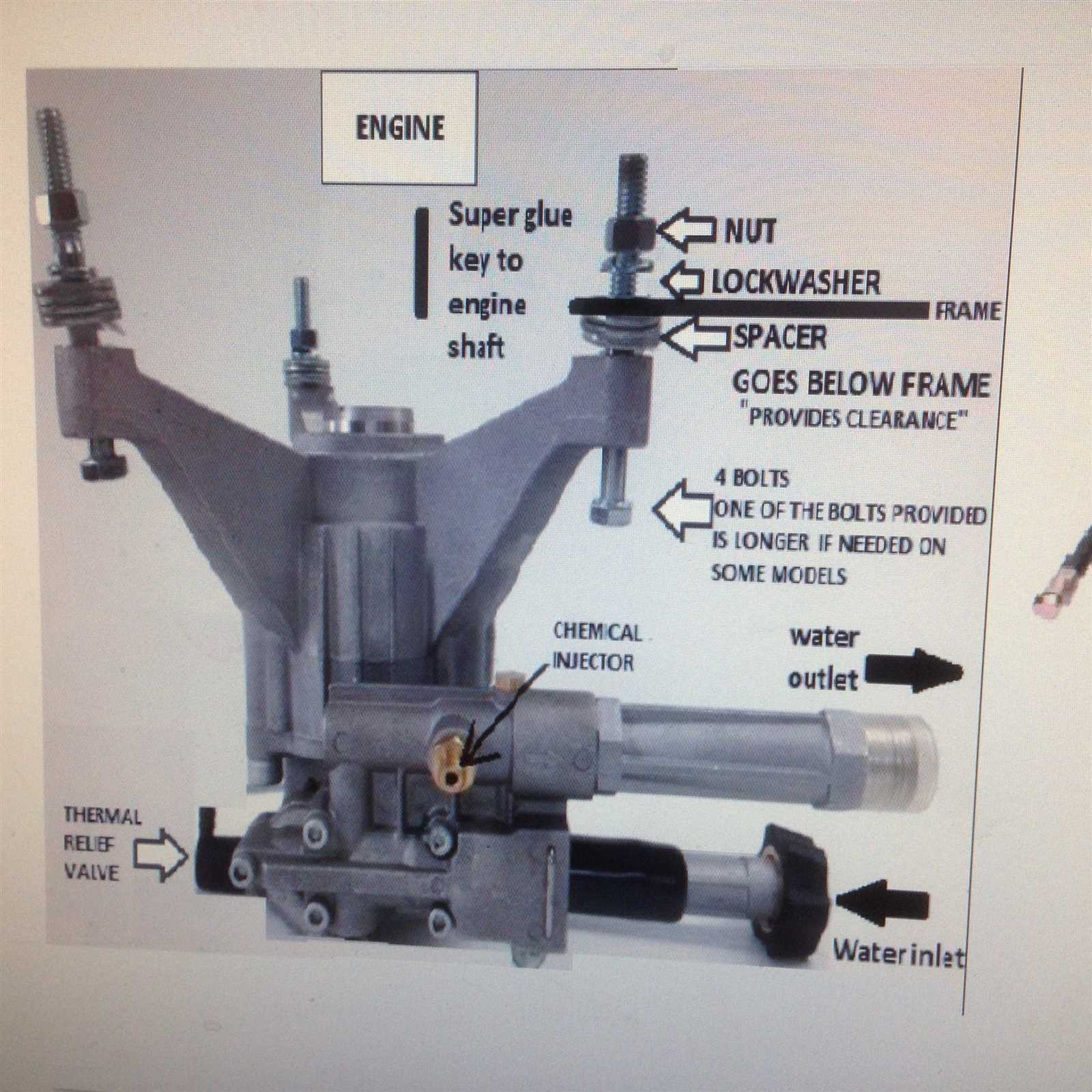

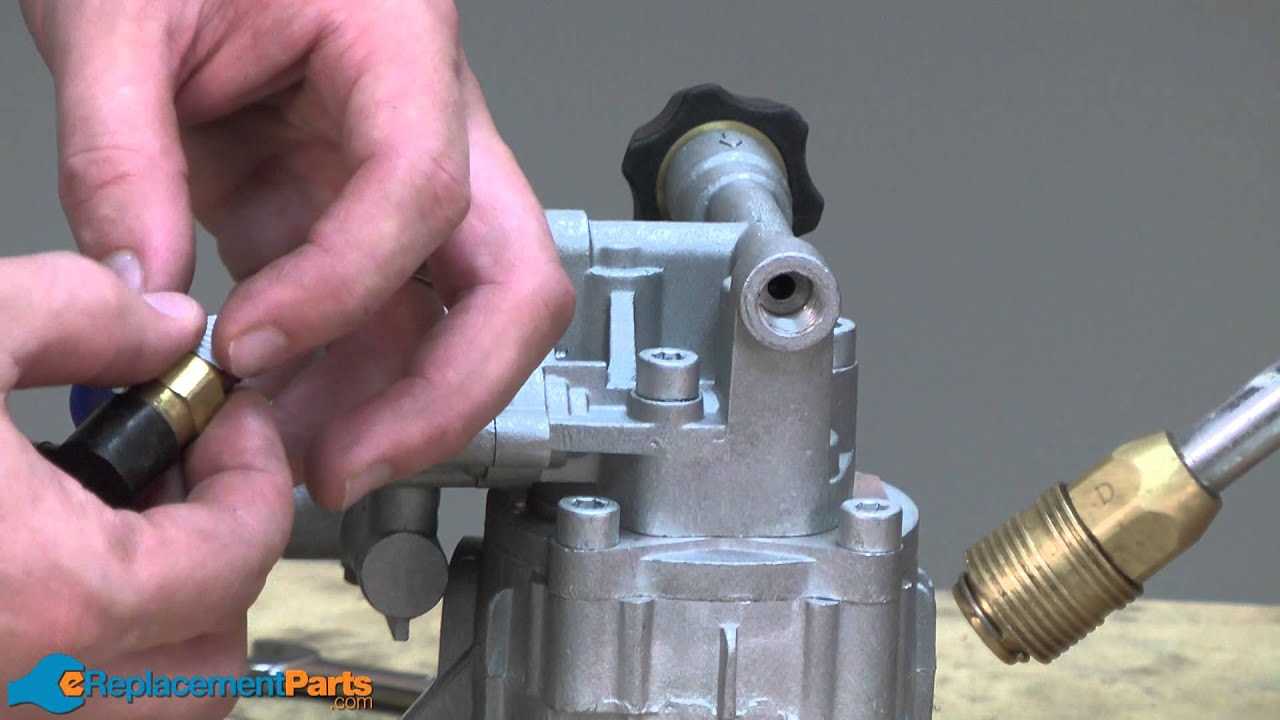

Detergent System and Soap Injection Parts

The detergent system is a crucial component designed to enhance the cleaning process by allowing the application of cleaning agents during operation. This system effectively aids in removing tough stains and grime, ensuring surfaces are thoroughly cleaned and sanitized.

Within this system, several elements work in harmony to facilitate the injection of soap or detergent. Understanding these components is essential for effective maintenance and operation:

- Soap Injector: This device introduces cleaning solution into the water stream, allowing for efficient distribution and application.

- Detergent Tank: A reservoir that holds the cleaning agent, ensuring a consistent supply for the soap injection process.

- Hoses: Flexible tubes that connect the injector to the spray gun, facilitating the flow of the solution as needed.

- Valves: Control mechanisms that regulate the flow of detergent, enabling the user to adjust the concentration as required.

- Filters: Essential for preventing clogs in the system by trapping debris before it reaches the injector.

Regular inspection and maintenance of these components are vital for optimal performance, ensuring that the cleaning solution is effectively mixed and applied for superior results.

Key Maintenance Parts for Longevity

Regular upkeep of essential components is crucial for ensuring the extended lifespan and optimal performance of your cleaning equipment. By focusing on a few critical elements, you can significantly enhance its reliability and efficiency, minimizing the risk of unexpected breakdowns and costly repairs.

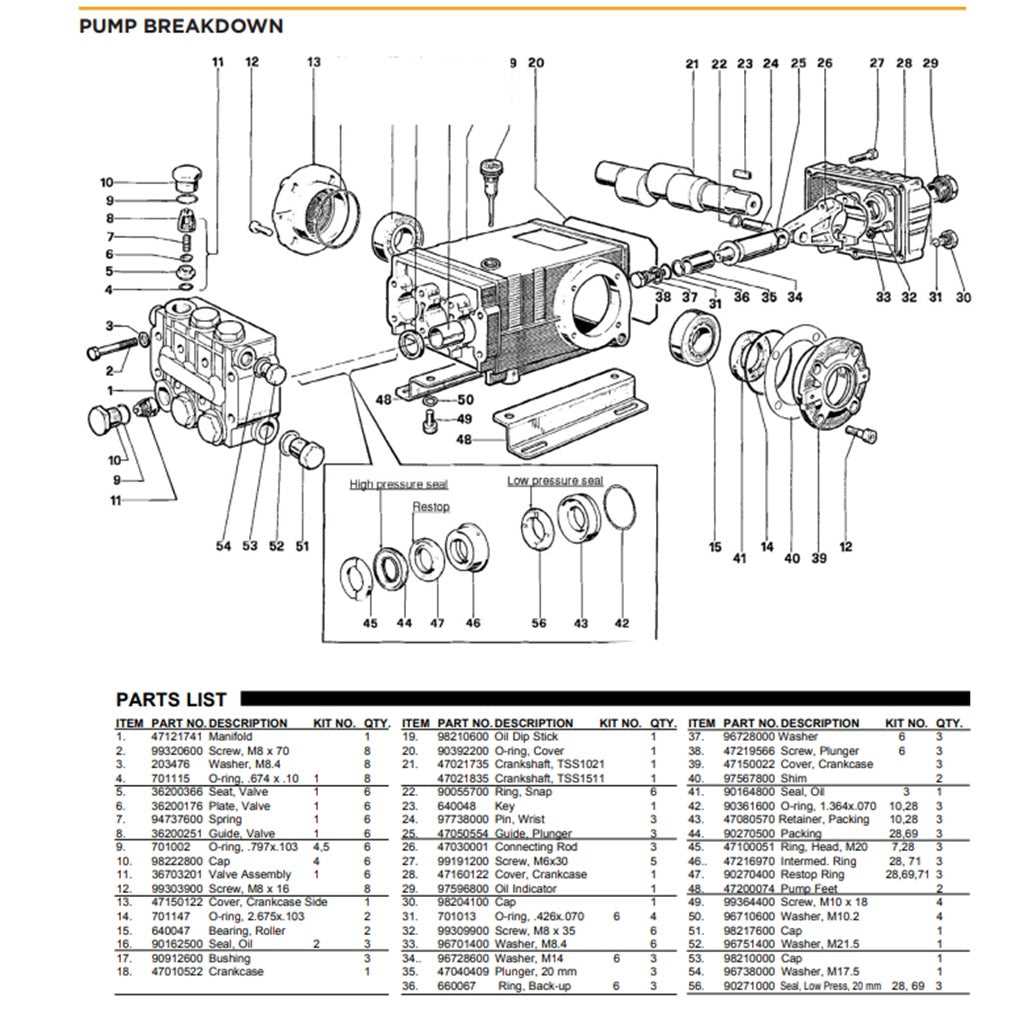

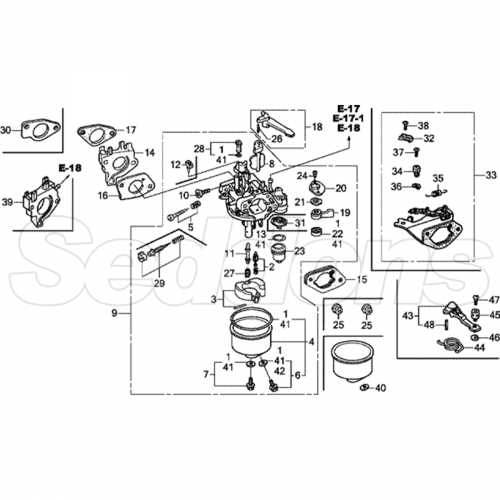

Filters and Screens

One of the most vital aspects of maintenance involves the cleaning and replacement of filters and screens. These components prevent debris from entering the system, which can lead to clogs and inefficiencies. Regular checks and replacements will help maintain a steady flow and protect the inner workings from damage.

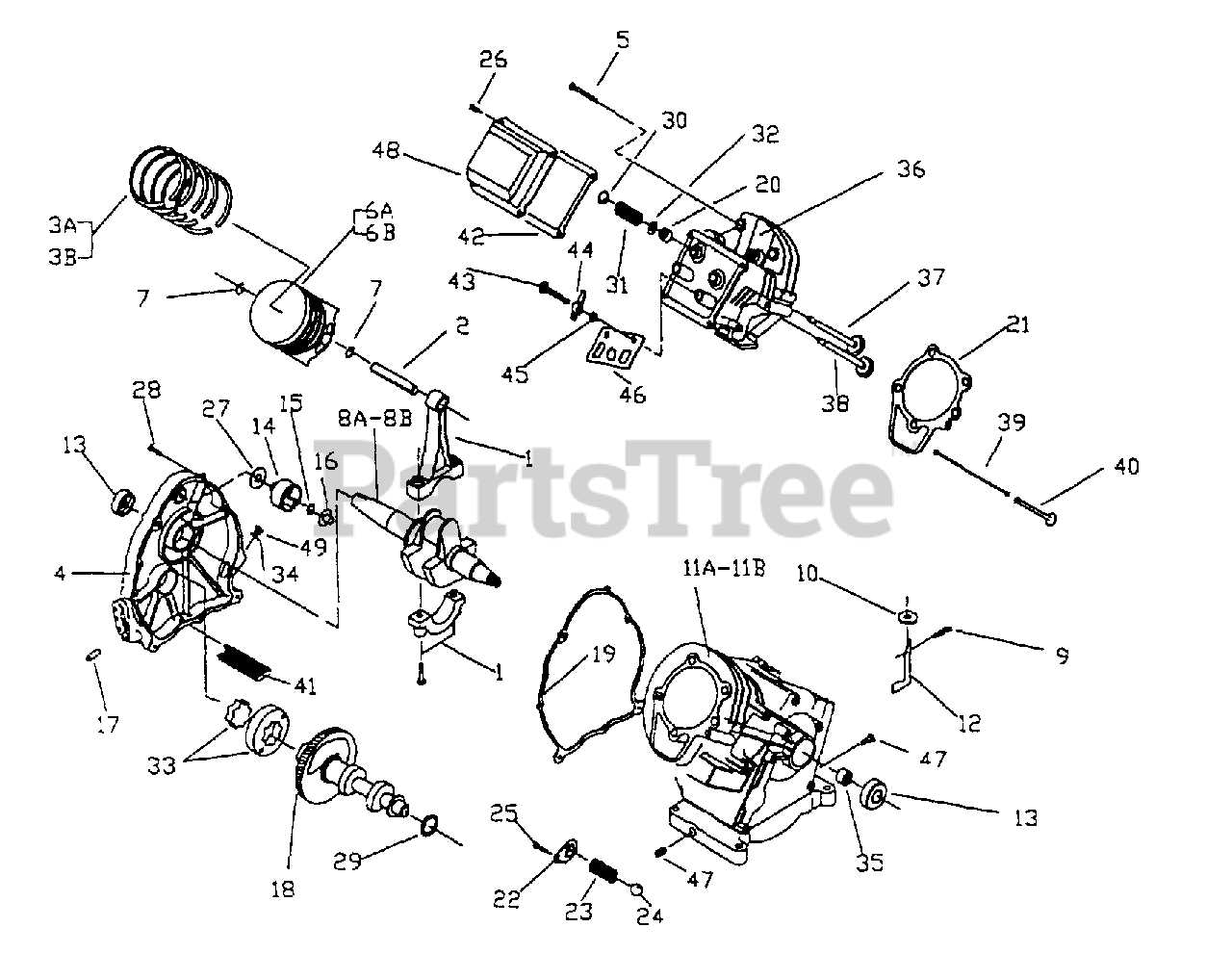

Seals and Gaskets

Seals and gaskets play an essential role in maintaining pressure and preventing leaks. Over time, these parts can wear out due to exposure to various elements. Inspecting and replacing them as needed will ensure that your equipment operates at peak efficiency, saving both water and energy in the long run.

Replacing Seals and Gaskets

Maintaining the integrity of your equipment requires attention to seals and gaskets. These components play a crucial role in preventing leaks and ensuring optimal performance. Over time, wear and tear can lead to diminished effectiveness, necessitating their replacement to restore functionality.

Here are key steps to follow when replacing these essential components:

- Identify the components that need replacing by inspecting for signs of damage such as cracks or deterioration.

- Gather necessary tools and replacement materials to facilitate a smooth process.

- Carefully remove the old seals or gaskets, ensuring not to damage surrounding areas.

- Clean the surfaces thoroughly to ensure a proper fit for the new components.

- Install the new seals or gaskets, ensuring they are seated correctly.

- Reassemble any parts that were removed and test the equipment to confirm that it functions without leaks.

Regular maintenance of these components will enhance the durability and efficiency of your equipment, ensuring it operates at peak performance.

Electrical Components and Wiring Layout

The electrical system of any machine plays a crucial role in its overall functionality. Understanding the arrangement and interconnections of these elements is essential for troubleshooting, maintenance, and ensuring optimal performance. This section provides an overview of the key electrical components and their wiring layout, offering insights into their roles and relationships within the system.

| Component | Description | Function |

|---|---|---|

| Motor | Converts electrical energy into mechanical energy. | Powers the main operational features of the device. |

| Switch | Controls the flow of electricity in the system. | Enables or disables the device. |

| Wiring Harness | Collection of wires bundled together. | Facilitates organized electrical connections between components. |

| Fuse | Safety device that prevents overcurrent. | Protects the electrical components from damage. |

| Relay | Electromechanical switch. | Controls high-current circuits using low-current signals. |

By familiarizing oneself with these elements, users can more effectively manage the electrical aspects of the machine. Understanding the layout and connections allows for efficient troubleshooting and enhances the longevity of the equipment.

Upgrading Accessories for Improved Performance

Enhancing the efficiency of your cleaning equipment can significantly elevate its overall functionality. By investing in high-quality attachments and upgrades, you can tailor your device to better suit various tasks, ensuring optimal results and a more satisfying user experience. Whether you aim to increase pressure, expand versatility, or improve convenience, selecting the right enhancements can make a substantial difference.

Choosing the Right Attachments

Selecting appropriate accessories can greatly influence the effectiveness of your equipment. Consider options such as specialized nozzles that adjust the spray pattern, allowing for targeted cleaning or broader coverage. Additionally, utilizing surface cleaners can help tackle larger areas swiftly, reducing cleaning time without compromising results.

Maintenance and Upgrades

Regular maintenance and timely upgrades are essential to prolong the life of your equipment. Components such as hoses and connectors can wear out over time, affecting performance. Upgrading to reinforced materials can enhance durability, while investing in high-efficiency filters can improve water flow and reduce downtime. Keeping your equipment well-maintained ensures that you maximize its potential and achieve the best results consistently.