When dealing with home maintenance, it’s essential to have a clear understanding of the key elements that keep your household equipment running smoothly. In this guide, we’ll dive into the details of a widely used cleaning machine, exploring its essential sections, how they function, and the ways they contribute to its overall performance.

Whether you’re troubleshooting or simply curious about how everything fits together, this article will provide a comprehensive look at the various elements that make up the core of your laundry device. From the internal mechanisms to external features, knowing the specific roles of each component can save time and prevent future malfunctions.

By the end of this section, you’ll have a better grasp of the different sections that make up this household essential, making maintenance tasks and repairs more straightforward. Understanding the structure and function of each element can enhance your appliance’s longevity and efficiency.

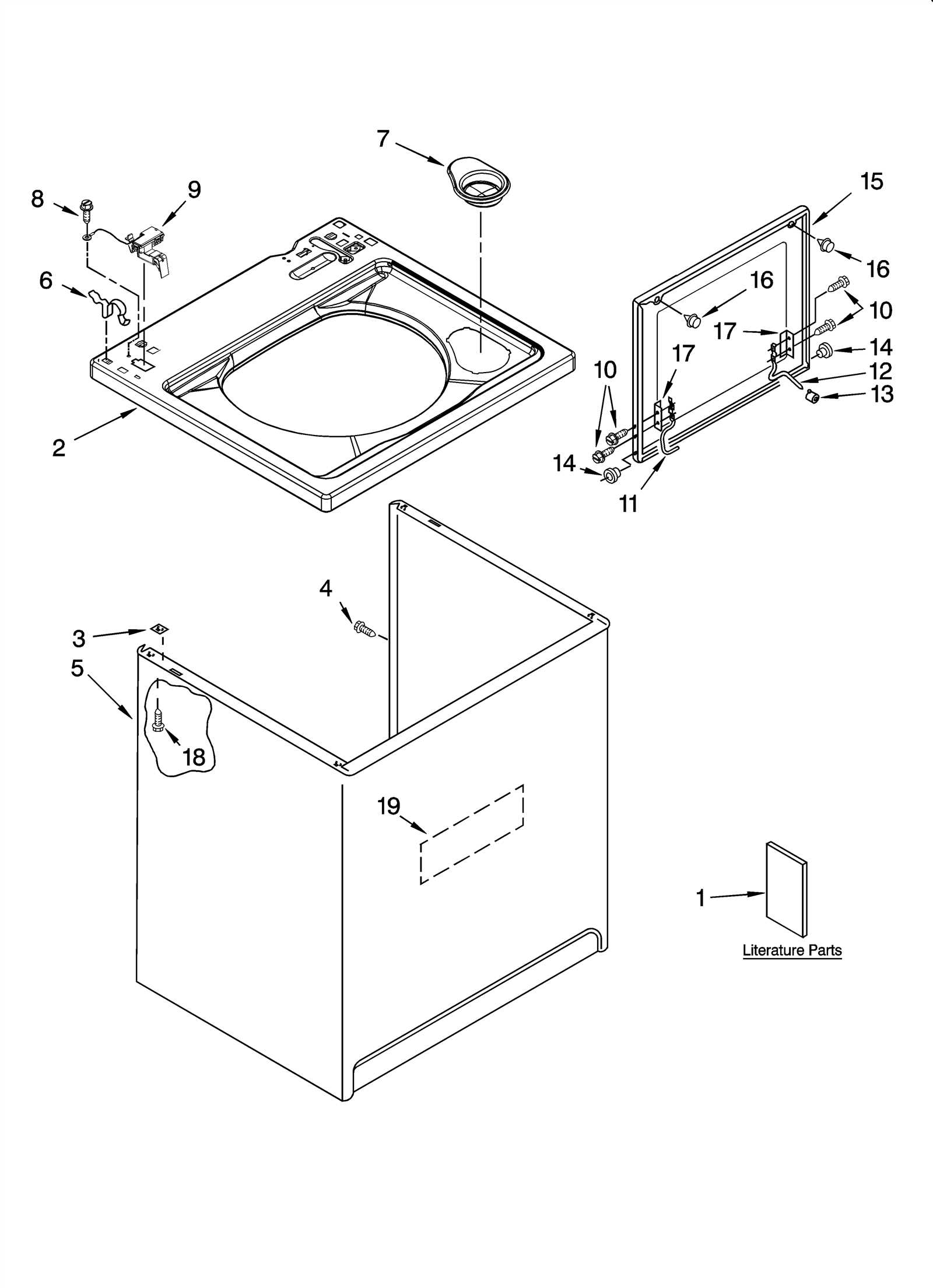

Understanding the Kenmore 600 Washer System

The appliance’s system functions as a cohesive unit, designed to handle various stages of laundry care. Each component plays a vital role, working together to ensure efficient and reliable operation. By exploring how these elements interact, one can gain a deeper understanding of how the system operates and troubleshoot potential issues effectively.

Main Functional Areas

The device operates through a combination of key mechanisms, each responsible for a different phase of the process. These areas include fluid management, mechanical motion, and control systems that govern the appliance’s performance. Proper synchronization between these elements ensures seamless functionality and optimal results.

Control and Adjustment

The system is equipped with controls that allow for easy adjustment of various settings, such as water levels, cycle durations, and spin speeds. Understanding how to modify these parameters based on fabric types and load

Key Components of the Kenmore 600 Model

In this section, we will explore the essential elements that contribute to the overall functionality and performance of this particular household appliance. Understanding these features will help ensure smooth operation and proper maintenance over time.

Motor Assembly: The engine is the core driving force that powers the entire system. It ensures the appliance operates efficiently, managing various cycles with precise control over speed and direction.

Control Panel: The control interface allows users to select and customize various settings. It is designed for intuitive operation, offering a range of options that cater to different fabric types and cleaning needs.

Drum and Agitator: These components are responsible for the physical movement during operation. The drum holds the items being cleaned, while the agitator

How to Identify Washer Parts

Understanding the structure and components of your laundry appliance is essential for effective maintenance and troubleshooting. Knowing the specific roles of each component can help you address issues efficiently, ensure smooth operation, and extend the lifespan of the machine. Below is a guide to recognizing the key elements of your device.

| Component | Description | Common Issues | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control Panel | The interface where you select cycles and settings, often containing various buttons and dials. | Buttons may become unresponsive or display errors. | ||||||||||||||||||||||||||

| Drum | The central rotating part where clothes are placed, responsible for spinning and agitation during cleaning. | Can become imbalanced or produce noise if overloaded. | ||||||||||||||||||||||||||

| Motor |

| Function | Benefit |

|---|---|

| Creates movement in the wash tub | Ensures clothes are agitated evenly for optimal cleaning |

| Facilitates water circulation | Helps distribute detergent evenly for effective stain removal |

| Prevents tangling | Reduces the risk of fabric damage and improves wash quality |

| Promotes fabric care | Allows for gentle handling of delicate items while still providing thorough cleaning |

Common Issues with Washer Bearings

Bearings play a crucial role in the functionality of laundry appliances, enabling smooth rotation of the drum during cycles. Over time, these components can experience wear and tear, leading to several common problems that may affect performance.

Noise: One of the most noticeable issues is the presence of unusual sounds, such as grinding or squeaking, which often indicates that the bearings are failing. This noise can disrupt the washing process and signal the need for immediate attention.

Vibration: Excessive vibrations during operation can also be a sign of bearing problems. When bearings are worn, they may not support the drum properly, causing it to shake uncontrollably. This can lead to further damage to the appliance and surrounding areas.

Leaks: In some cases, failing bearings may allow water to seep out of the appliance. This can result in puddles underneath the unit and create a risk of damage to the flooring and surrounding surfaces.

Drum Movement: If the drum does not rotate freely or feels stuck, it could be due to bearing failure. Proper movement is essential for effective cleaning, and any restriction can hinder the washing process.

Regular maintenance and prompt attention to these issues can extend the lifespan of the appliance and ensure efficient operation.

Wiring Diagram for Kenmore 600 Washers

This section provides an overview of the electrical connections and configurations essential for maintaining and troubleshooting the appliance. Understanding the layout of these connections is crucial for effective repairs and ensuring the unit operates efficiently.

The following table outlines the key components and their corresponding connections, facilitating a better understanding of the internal electrical structure.

| Component | Description | Connection Points |

|---|---|---|

| Power Supply | Provides electrical energy to the appliance. | Line In, Neutral |

| Control Board | Regulates all electronic functions. | Power In, Signal Out |

| Motor | Drives the drum for washing and spinning. | Power In, Ground |

| Water Inlet Valve | Controls the flow of water into the drum. | Power, Water Supply |

| Drain Pump | Removes water from the drum after a cycle. | Power, Drain Hose |

Maintaining the Lid Switch and Lock

Proper upkeep of the lid mechanism is essential for ensuring the smooth operation of your appliance. The lid switch and lock play a crucial role in activating the device during cycles, and any malfunction can disrupt performance. Regular attention to these components can help prevent issues and extend their lifespan.

Here are some key maintenance tips to consider:

- Regular Inspection: Frequently check the lid switch for any signs of wear or damage. Look for cracks, loose wiring, or misalignment.

- Cleaning: Keep the area around the switch free from debris and buildup. Use a damp cloth to clean the switch and surrounding areas, ensuring no foreign objects hinder its function.

- Testing Functionality: Periodically test the lid lock by closing the lid and starting a cycle. If the device does not engage, further inspection may be necessary.

- Lubrication: If the lock mechanism feels stiff or difficult to operate, apply a suitable lubricant to ensure smooth action.

- Replacement: If any components are found to be faulty, replace them promptly to avoid further complications. Use compatible parts to ensure proper fit and function.

By following these guidelines, you can maintain the efficiency and reliability of the lid switch and lock, promoting a seamless experience during use.

Troubleshooting Control Panel Problems

Issues with the control interface can lead to various operational challenges in home appliances. Recognizing the symptoms and understanding potential causes are essential steps in resolving these difficulties. This section provides insights into common problems, helping users identify and address issues effectively.

One of the most frequent concerns involves unresponsive buttons or displays. This can stem from faulty connections, debris accumulation, or internal electronic failures. Ensuring that the control panel is clean and free of obstructions is a good starting point. If cleaning does not resolve the issue, checking the wiring for any signs of damage or disconnection may be necessary.

Another common issue is erratic performance, where the appliance may behave unpredictably. This can often be traced back to software glitches or malfunctions within the control module. Resetting the appliance by unplugging it for a few minutes can sometimes restore normal functionality. If the problem persists, consulting the user manual for specific troubleshooting steps related to the control system may provide additional guidance.

Additionally, error codes displayed on the control panel can indicate specific problems. Each code corresponds to a particular issue, and referring to the user manual can help decode these signals. Addressing the underlying cause indicated by the error code is crucial for restoring the appliance to its intended operation.