The functionality of modern kitchen machines relies on a range of interconnected elements working together in harmony. Each piece has its role, ensuring that the entire process runs smoothly and efficiently. Knowing how these elements fit and operate can be extremely useful when it comes to maintenance and troubleshooting.

By gaining a clear understanding of the internal layout, you will be better equipped to identify potential issues or replace worn-out components. This knowledge not only helps prolong the life of the equipment but also allows for a more seamless repair process when necessary.

In the following guide, we will break down the various sections and highlight their significance within the overall system, ensuring you have a complete picture of how everything fits together.

Understanding the Maytag Dishwasher Components

In any modern cleaning appliance, each internal element plays a crucial role in ensuring efficient operation. These devices are equipped with a variety of interconnected parts, each contributing to the overall performance. By familiarizing yourself with the key components, you can better understand how the machine functions as a whole and troubleshoot potential issues more effectively.

Core Mechanical Systems

The heart of this type of machine lies in its mechanical systems, which drive water circulation and control the cleaning cycles. A combination of pumps and motors ensures water is distributed properly, while valves regulate the flow. Understanding these elements allows for a clearer view of how water pressure and temperature are maintained throughout each cleaning process.

Key Internal Elements

Besides the mechanical components, the internal structure includes various filters, dispensers, and racks that are essential for its functionality. Filters trap food particles and debris, keeping the internal environment clean. Dispensers release the appropriate amount of detergent at the right time, while the racks are designed to hold items securely, ensuring effective cleaning.

Knowing the role of each element within the system can help in identifying and resolving common issues, ultimately extending the lifespan of the device. A comprehensive understanding of these components is vital for both regular maintenance and any necessary repairs.

Key Internal Parts of a Maytag Dishwasher

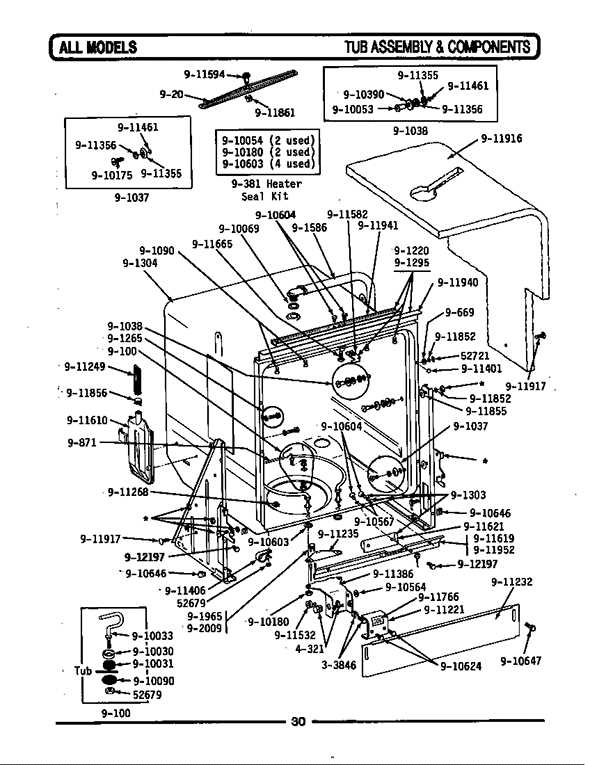

The internal components of this kitchen appliance are designed to efficiently handle the cleaning process by utilizing a variety of mechanical and electronic systems. Understanding the main elements of this system allows users to maintain and troubleshoot potential issues with greater ease.

One essential element is the pump, which circulates water throughout the washing cycle. Another important component is the heating element, responsible for raising the water temperature to ensure thorough cleaning and drying. The control module governs the entire washing process, managing the timing and operation of different functions. Spray arms, located at different levels, are designed to distribute water evenly over the items being cleaned.

Filters play a crucial role by trapping food particles and preventing them from clogging the system. Finally, the door seal ensures that water stays inside the unit during operation, maintaining a secure and efficient cleaning cycle.

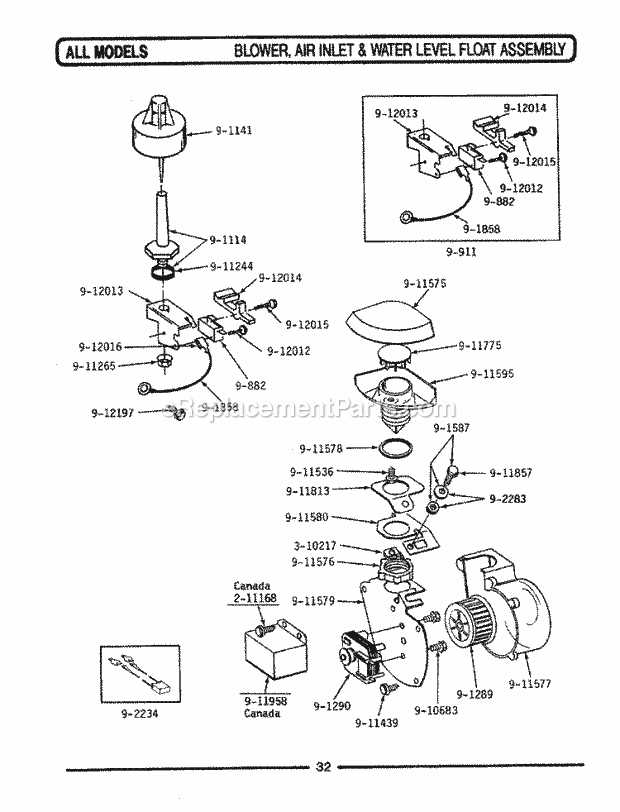

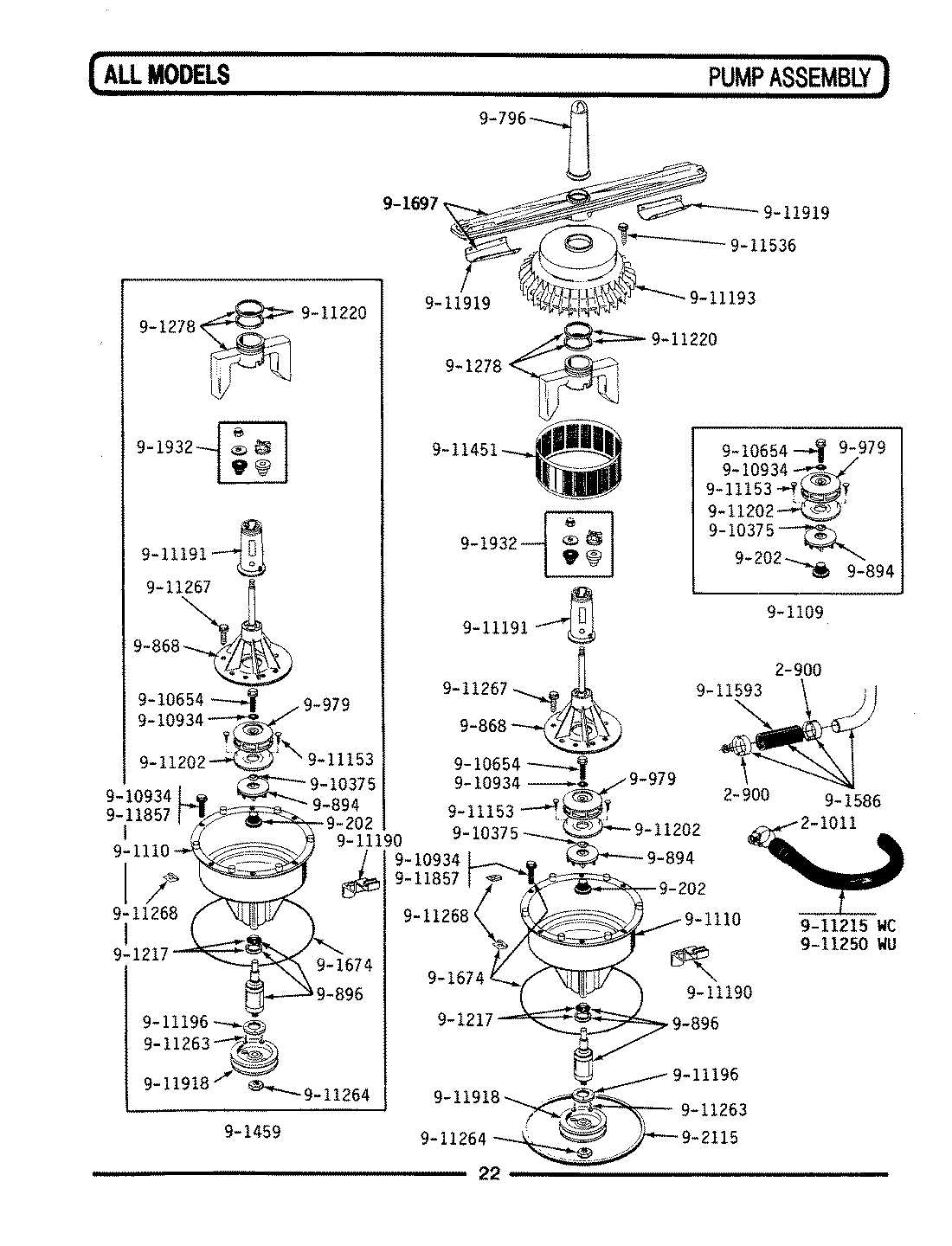

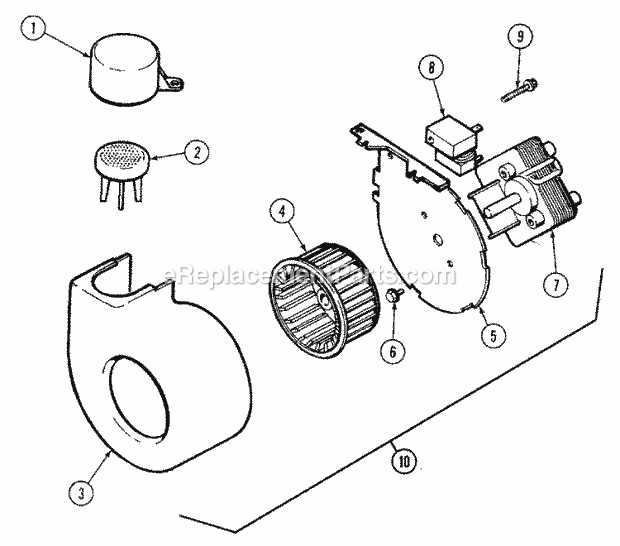

Exploring the Pump and Motor Assembly

The pump and motor assembly is a critical component in ensuring efficient water circulation and pressure. Understanding how these elements work together can help in identifying potential issues and maintaining overall performance. This section will provide a detailed look at the key elements involved in this system and offer insights into their operation.

Main Components of the Assembly

- Pump: Responsible for moving water through the system, ensuring consistent flow and pressure.

- Motor: Powers the pump, driving the water circulation through various stages of the cleaning process.

- Seals and Gaskets: Prevent water leakage and maintain pressure, crucial for optimal functioning.

How the Assembly Works

The motor activates the pump, creating water pressure that flows through the system. The pump forces the water through nozzles or jets, enabling effective water distribution. The seals ensure that this pressure is contained, preventing any loss of efficiency. Regular maintenance, such as checking for leaks or wear, can extend the lifespan of the system.

- Inspect the motor and pump for any signs of damage or wear

Control Panel Functions and Features

The control panel offers a range of functions that provide users with easy access to various operational settings. It allows for simple adjustments to suit different needs and preferences during operation. Understanding the functions and features on the control interface is key to optimizing performance and ensuring efficient usage.

Power and Start Buttons: These buttons allow users to turn the device on or off and initiate the desired cycle with a single touch.

Cycle Selection: The panel includes multiple cycle options, each designed to handle specific tasks. Users can choose between different modes depending on the intensity and duration required.

Delay Start Function: This feature allows users to set a delayed start time, enabling the machine to begin a cycle at a more convenient time.

Indicators and Alerts: LED indicators provide visual feedback about the current status of the process, including when additional actions, such as adding a cleaning agent, are necessary.

Child Lock: For added safety, a child lock function can be activated to prevent unintended usage or changes to settings.

Familiarity with the control panel’s functions enables more personalized and effective use, ensuring each operation is carried out efficiently.

How to Identify and Replace the Heating Element

When your appliance no longer effectively warms or dries, the root cause may lie in the heating element. Identifying this component and knowing how to replace it can help restore proper functionality to your device. This process involves a few steps that require careful attention to avoid potential damage to the unit.

First, locate the heating element, typically found at the base of the machine. It’s a thin, metallic rod designed to generate heat. Once you’ve identified it, check for signs of damage such as breaks, burns, or discoloration. If the element appears compromised, it will need to be replaced.

Before proceeding with the replacement, ensure the unit is disconnected from its power source. Remove any necessary panels to access the heating element. Carefully detach the wiring connected to the ends of the element, making sure to note their original positions for reinstallation.

Next, unscrew or unclip the element from its mounting points and remove it from the appliance. Install the new component by securing it in place and reconnecting the wiring. Finally, reassemble the appliance and restore power. Test the heating function to ensure the repair was successful.

Understanding the Water Inlet Valve

The water inlet valve plays a crucial role in regulating the flow of water into your cleaning appliance. This component ensures that the right amount of liquid enters the system at the appropriate times during the washing cycle. Without this essential part, the cleaning efficiency and overall performance could be compromised.

This valve is typically activated by an electronic control or timer, which signals when to allow water to enter. It acts as a gateway, opening and closing based on the appliance’s requirements. Understanding its function can help users troubleshoot common issues related to water flow and filling.

Function Description Regulation of Water Flow Controls the entry of water into the system, ensuring the correct levels are maintained. Activation Mechanism Operated by electronic signals from the control panel, determining when to fill. Common Issues Can include leaks, failure to open, or restricted flow, leading to inadequate washing. Maintenance Tips Regular checks and cleaning of the valve can help prevent clogs and ensure proper function. Importance of the Maytag Door Seal Gasket

The seal surrounding the entrance of a kitchen appliance plays a crucial role in ensuring efficient operation. This component not only prevents leaks but also maintains optimal temperature and pressure within the unit. A well-functioning gasket is essential for the longevity of the appliance and for achieving effective cleaning results.

Preventing Water Leakage

One of the primary functions of the door seal is to create a tight barrier that stops water from escaping during operation. Without a proper seal, leaks can occur, leading to water damage in the surrounding area and potential mold growth. Regular inspection of this component is vital to avoid costly repairs and maintain a clean environment.

Enhancing Energy Efficiency

In addition to preventing leaks, the gasket helps retain heat within the appliance, which is crucial for energy efficiency. A compromised seal can result in increased energy consumption as the appliance works harder to maintain its temperature. By ensuring the integrity of this component, users can not only save on energy bills but also contribute to a more sustainable household.

How the Dishwasher Drain Hose Works

The drain hose is a crucial component of any cleaning appliance, designed to effectively remove waste water from the interior after a cycle. Its function ensures that dirty water is expelled efficiently, preventing any potential backflow that could lead to contamination or inefficiency. Understanding its operation can help in troubleshooting common issues and maintaining optimal performance.

Functionality and Mechanism

This flexible conduit typically connects the cleaning machine to the household plumbing system. During operation, a pump forces the used water through the hose, directing it away from the unit. The design of the hose often includes features that prevent blockages and allow for easy installation.

Common Issues and Solutions

Over time, wear and tear can affect the performance of the drainage system. Some common issues include clogs, leaks, or kinks in the hose that can disrupt proper water flow. Regular inspection and maintenance are essential to ensure that these problems are identified early. Here are some solutions:

Issue Solution Clogs Clear the hose with warm water and a plumbing snake. Leaks Inspect connections and replace worn-out sections of the hose. Kinks Avoid sharp bends during installation and reposition the hose. Rack and Spray Arm Mechanisms Explained

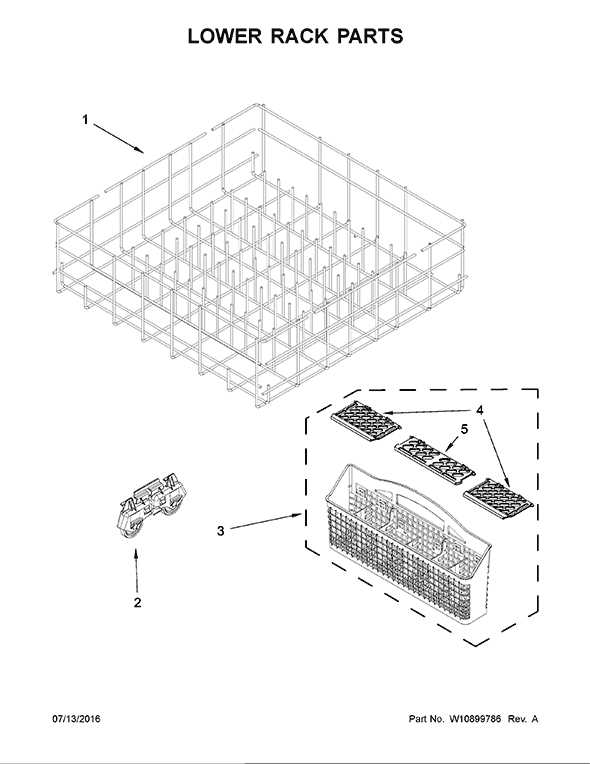

The effective cleaning of kitchenware relies heavily on the intricate design of the support and water distribution systems within modern cleaning appliances. Understanding how these components function can enhance maintenance practices and ensure optimal performance over time. This section delves into the mechanisms behind the support racks and spray arms, highlighting their roles and interdependencies in delivering spotless results.

Structure and Function of Support Racks

Support racks are crucial for holding items securely during the cleaning cycle. Their design allows for flexibility and organization, accommodating various types of kitchenware. Typically made from durable materials, these structures can withstand repeated use while providing easy access for loading and unloading.

Water Distribution via Spray Arms

Spray arms are engineered to distribute water evenly across the items placed in the support racks. They rotate and deliver pressurized water jets, ensuring comprehensive coverage and effective cleaning. The design of spray arms often includes multiple nozzles that optimize water flow, adapting to different load configurations.

Component Function Material Support Rack Holds items in place Plastic/Metal Spray Arm Distributes water Plastic/Metal Replacing the Dishwasher Detergent Dispenser

Maintaining optimal functionality in your cleaning appliance often involves replacing essential components, such as the detergent release unit. This section outlines the steps necessary to remove and install a new dispenser, ensuring effective cleaning performance.

Identifying the Need for Replacement

Symptoms indicating that the detergent dispensing mechanism may need attention include ineffective cleaning, detergent residue remaining after cycles, or failure to open during the wash. Recognizing these signs early can prevent more significant issues down the line.

Step-by-Step Replacement Process

To successfully replace the detergent release unit, follow these steps:

- Disconnect the Appliance: Before beginning any repair, ensure that the device is unplugged or that the circuit breaker is turned off.

- Access the Dispenser: Remove the inner door panel, which typically requires unscrewing several screws. Once removed, locate the detergent dispenser.

- Detach the Old Unit: Carefully disconnect the wires and unfasten the dispenser from its housing. Ensure you take note of the arrangement for reassembly.

- Install the New Unit: Position the new dispensing unit into place, reconnect the wiring, and secure it firmly.

- Reassemble the Door: Replace the inner panel and tighten all screws. Finally, restore power to the appliance.

Following these instructions will help restore your cleaning equipment to optimal working order, ensuring effective and efficient operation.