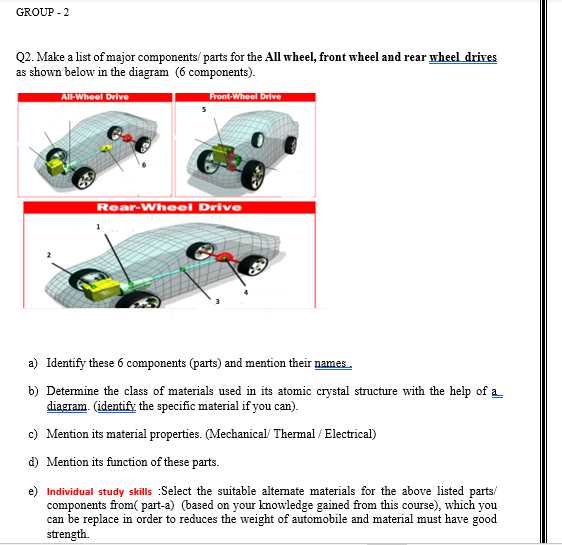

In the world of automotive engineering, comprehending the intricate mechanisms that enable a vehicle to operate efficiently is crucial. This section delves into the various elements that work together to ensure optimal performance. By examining the layout and relationship of these components, one can gain insights into the engineering behind modern automobiles.

Each element within the propulsion system plays a significant role in transferring power and enhancing maneuverability. The configuration and functionality of these components are essential for achieving a smooth driving experience. This exploration aims to shed light on how each part interacts, contributing to the overall effectiveness of the vehicle.

Furthermore, understanding these components can aid in troubleshooting and maintenance, ensuring that the vehicle remains in peak condition. Familiarity with the arrangement of these elements empowers owners and mechanics alike to address issues proactively and improve the longevity of the vehicle.

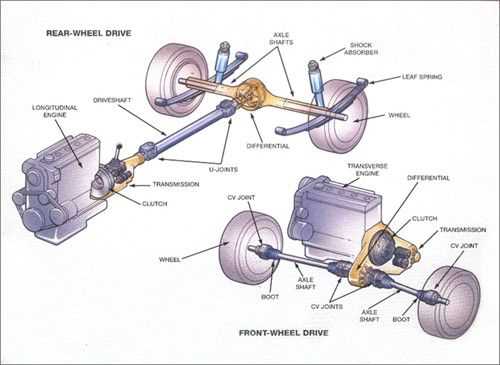

This section aims to explore the essential components and mechanisms that contribute to the functionality of certain automotive systems. By understanding the arrangement and interaction of these elements, one can gain insights into the performance and maintenance of vehicles equipped with this configuration.

| Component | Description |

|---|---|

| Transmission | Transmits power from the engine to the wheels, enabling movement and gear changes. |

| Axles | Support the weight of the vehicle while allowing wheels to rotate, providing stability and traction. |

| Suspension System | Absorbs shocks and maintains vehicle stability, ensuring a smooth ride over various terrains. |

| Steering Mechanism | Facilitates the control of direction, allowing the driver to navigate safely and effectively. |

| Brake System | Slows down or stops the vehicle, enhancing safety during operation. |

Components of Front Wheel Drive

This section delves into the essential elements that contribute to the efficient functioning of the vehicle’s propulsion system. These components work in harmony to ensure optimal traction and performance on various surfaces.

The assembly typically includes an array of interconnected elements, such as the transmission, which transmits power from the engine. Additionally, the axles play a critical role in transferring motion to the wheels. A pivotal feature is the differential, which allows for variations in wheel speed during turns, enhancing maneuverability.

Furthermore, the suspension system is integral to maintaining stability and comfort, as it connects the vehicle’s frame to the wheels. Each part is meticulously designed to withstand forces while ensuring smooth operation. Understanding these components is crucial for effective maintenance and repair.

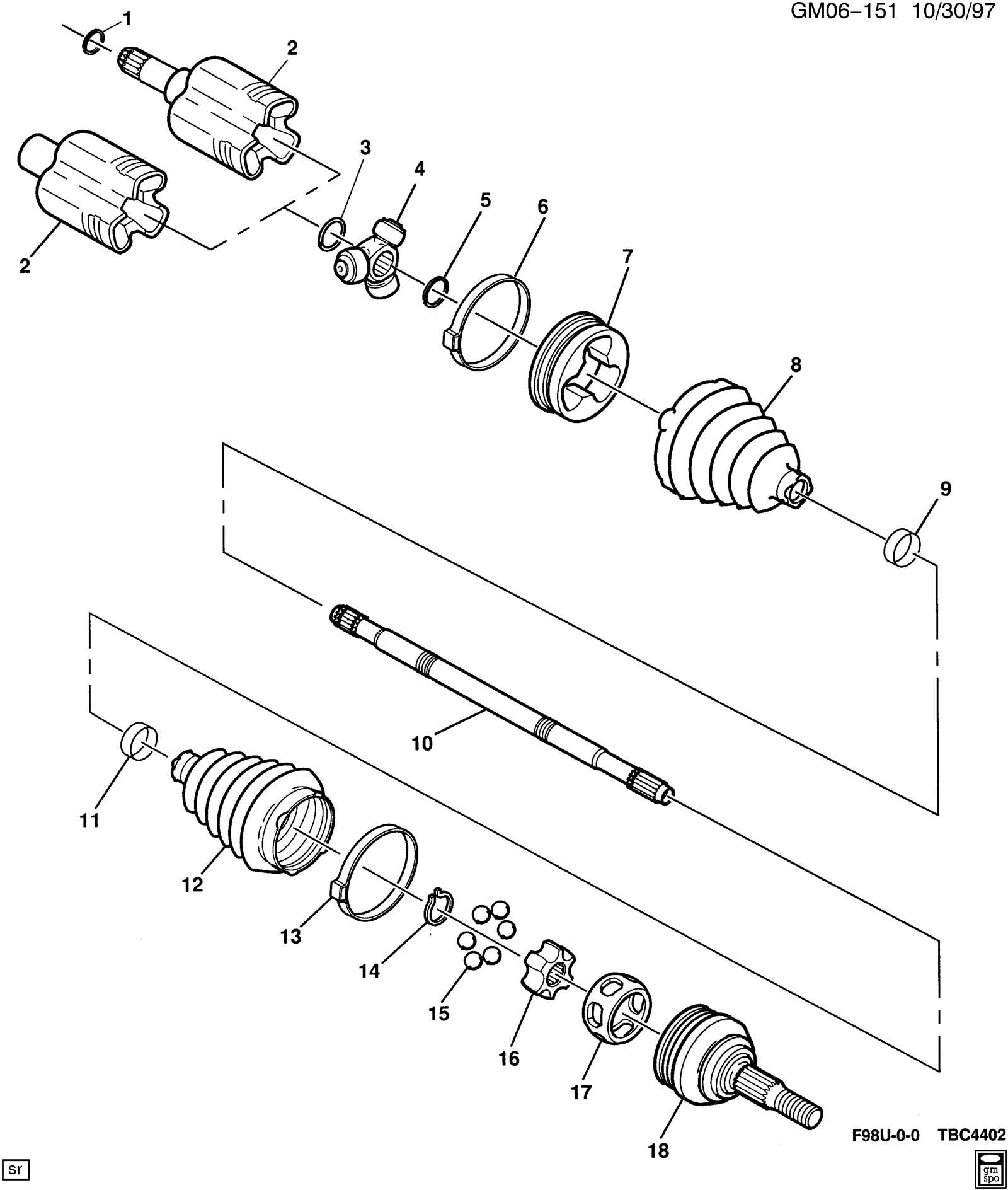

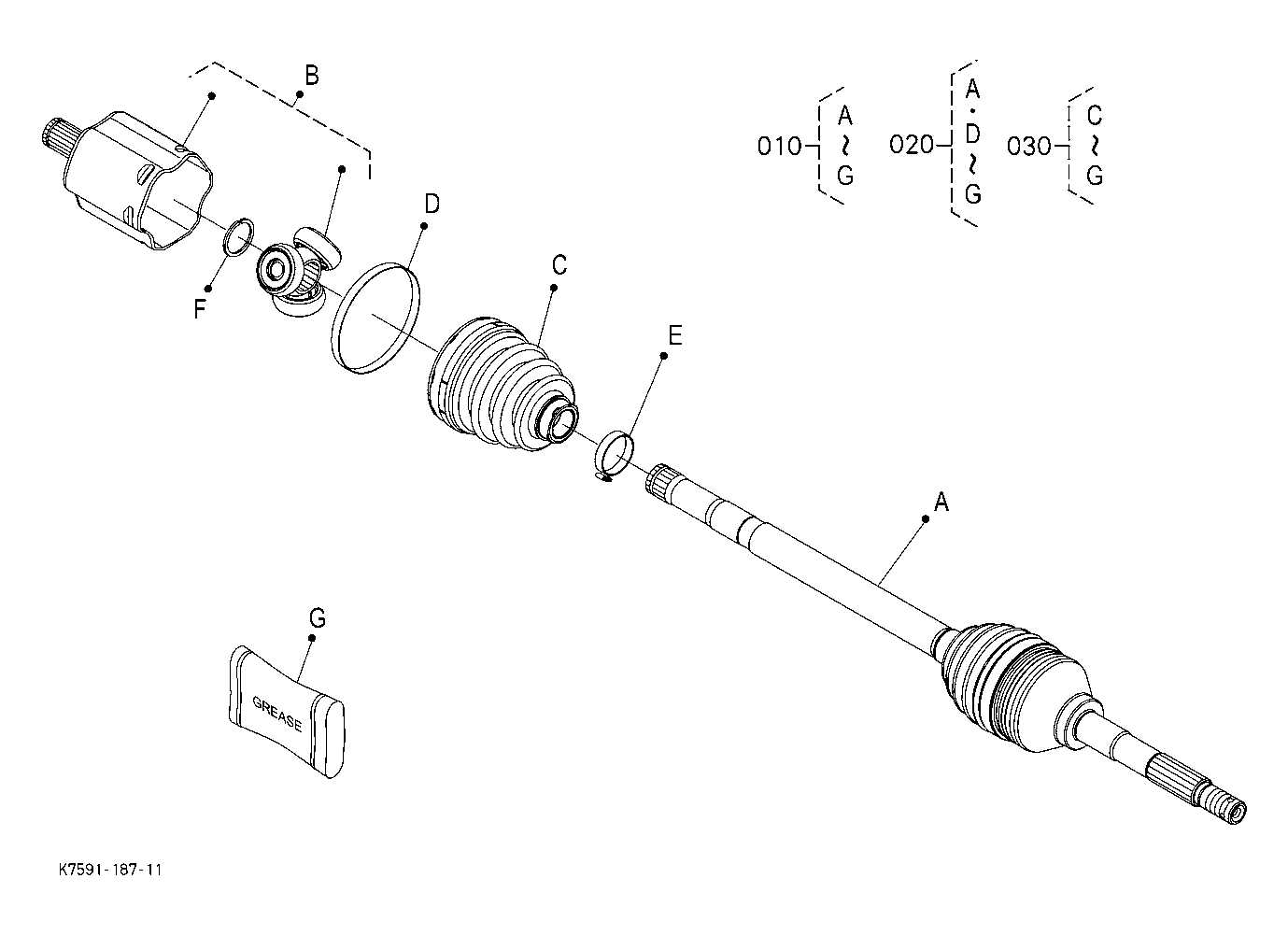

Functionality of Drive Axles

The essential components responsible for transferring power from the engine to the wheels play a crucial role in vehicle operation. These elements enable motion by connecting the power source to the wheels, allowing for efficient handling and maneuverability.

Key functions include:

- Power Transmission: They facilitate the transfer of torque generated by the engine.

- Stability Control: These components help maintain stability by distributing power evenly between the wheels.

- Suspension Support: They provide support for the vehicle’s suspension system, ensuring a smooth ride.

- Directional Movement: They allow for the appropriate steering response, aiding in navigation and handling.

In summary, these critical elements ensure that vehicles operate efficiently, providing both performance and safety on the road.

Importance of CV Joints

Constant velocity joints play a crucial role in the smooth operation of vehicles. They are essential components that facilitate the transfer of power from the transmission to the wheels, allowing for seamless movement and agility while navigating various terrains.

These joints offer several benefits that significantly enhance vehicle performance:

- Efficient Power Transfer: CV joints ensure that power is delivered effectively, minimizing energy loss and optimizing vehicle acceleration.

- Smoother Ride: They allow for smooth angular changes, reducing vibrations and ensuring a comfortable driving experience.

- Improved Handling: With their ability to accommodate steering movements, CV joints contribute to better maneuverability and control.

- Durability: Designed to withstand various driving conditions, these components are built for longevity, reducing the need for frequent replacements.

In conclusion, the significance of constant velocity joints cannot be overstated. Their function is vital for maintaining optimal vehicle performance and ensuring a safe and enjoyable driving experience.

Role of Transmissions in FWD

Transmissions play a crucial role in the operation and efficiency of vehicles designed with a specific orientation for power delivery. They facilitate the transfer of energy from the engine to the wheels, allowing for smooth acceleration and deceleration. This section explores the importance of these components and how they contribute to the overall performance of such vehicles.

Functions of Transmissions

- Power Transfer: The main function of transmissions is to transmit power from the engine to the driving mechanism, enabling movement.

- Gear Ratios: They provide various gear ratios that optimize engine performance under different conditions.

- Speed Control: Transmissions allow drivers to control the speed of the vehicle effectively.

Types of Transmissions

- Automatic: These systems shift gears automatically based on speed and load, providing convenience for the driver.

- Manual: Drivers have full control over gear changes, allowing for a more engaged driving experience.

- Continuously Variable: This type provides a seamless transition between gears, enhancing fuel efficiency and performance.

Analyzing the Differential Mechanism

The differential mechanism plays a crucial role in enabling smooth transitions of motion within a vehicle’s system. This component is designed to allow the driven elements to rotate at varying speeds, which is essential during turns and while navigating uneven surfaces. Understanding its function can significantly enhance one’s knowledge of automotive engineering.

At its core, the mechanism consists of several key elements that work in harmony to distribute power efficiently. These include the gears and housing, which facilitate the transfer of energy from the engine to the wheels. The primary function is to compensate for the difference in distance traveled by the inner and outer components during a curve, thereby preventing tire wear and ensuring stability.

Moreover, the design of the differential is often optimized for performance and durability. Advanced engineering techniques have led to the development of various configurations, each tailored to specific vehicle requirements. This adaptability is essential for enhancing handling characteristics and overall driving experience.

In summary, a thorough analysis of the differential mechanism reveals its importance in vehicle dynamics. A well-functioning system contributes to safety, comfort, and efficiency, making it a vital area of focus for both enthusiasts and professionals in the automotive field.

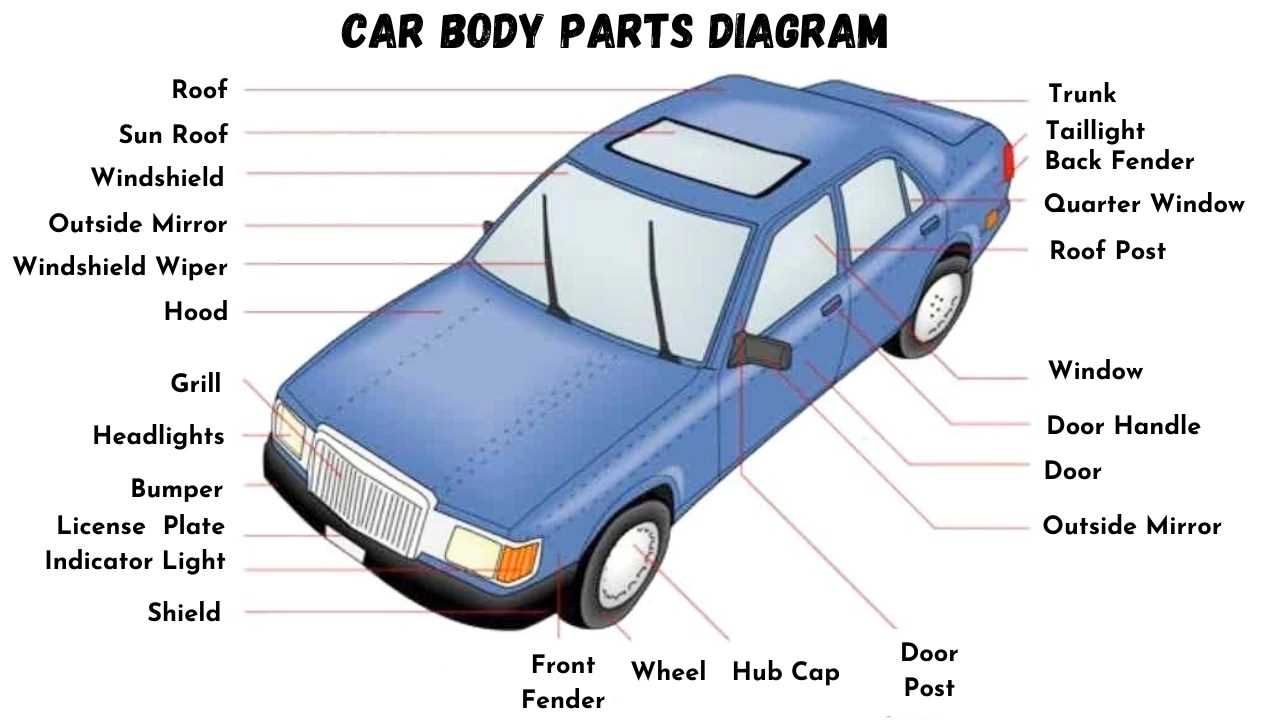

Steering Linkage and Its Purpose

The steering linkage is a crucial component of a vehicle’s maneuverability system. It connects various parts that facilitate the driver’s ability to control the direction of the automobile. This assembly translates the rotational movement of the steering wheel into linear motion, allowing for precise adjustments while navigating different terrains.

Functionality of the Steering Linkage

At its core, the steering linkage consists of several interconnected elements that work in unison. These include rods, joints, and connectors that allow for smooth transitions and responsive handling. When the driver turns the steering wheel, the linkage translates this motion to the wheels, ensuring that the vehicle follows the intended path.

Importance of Maintenance

Proper maintenance of the steering linkage is essential for safety and performance. Regular inspections can help identify any wear or damage, preventing potential issues that could affect vehicle control. Ensuring that all components are functioning correctly enhances not only the driving experience but also overall road safety.

Braking System in Front Wheel Drive

The braking mechanism plays a crucial role in ensuring the safety and control of a vehicle. This system is designed to slow down or halt the motion of the automobile, providing the driver with confidence during various driving conditions. Understanding its components and functionality can enhance the overall driving experience.

Components of the Braking Mechanism

The primary elements of the braking system include disc brakes and drum brakes, each serving distinct purposes. Disc brakes, typically found on the front, utilize friction from pads pressed against a rotating disc to create stopping power. On the other hand, drum brakes often reside at the rear, where brake shoes expand against the inner surface of a drum to achieve the same effect.

Functionality and Maintenance

Maintaining the braking system is vital for optimal performance. Regular checks of fluid levels, pad thickness, and overall integrity can prevent potential failures. A well-functioning braking mechanism ensures effective stopping power and enhances vehicle safety, especially in emergency situations.

Suspension Components and Their Functions

The suspension system is a crucial element of any vehicle, designed to enhance ride quality and handling. It comprises various components that work together to absorb shocks and maintain stability during movement. Understanding these elements and their roles is essential for appreciating how vehicles manage different terrains and driving conditions.

Main Components of the Suspension System

- Shock Absorbers: These devices dampen the impact of bumps and irregularities on the road, ensuring a smoother ride.

- Struts: Acting as a structural component, struts support the vehicle’s weight while also providing shock absorption.

- Springs: Springs bear the vehicle’s weight and help maintain the appropriate ride height while allowing for flexibility during travel.

- Control Arms: These link the chassis to the wheels, facilitating movement while maintaining alignment and stability.

- Anti-roll Bars: Also known as stabilizer bars, they reduce body roll during turns, enhancing cornering performance.

Functions of Suspension Components

- Improving Ride Comfort: The primary function is to provide a comfortable experience by absorbing shocks from road irregularities.

- Enhancing Vehicle Stability: By keeping tires in contact with the road, the suspension system promotes better traction and handling.

- Supporting Vehicle Weight: All components collectively manage the vehicle’s weight, ensuring proper distribution across the chassis.

- Allowing Wheel Movement: The system enables independent movement of the wheels, enhancing performance over uneven surfaces.

- Minimizing Wear: A well-functioning suspension helps reduce wear and tear on tires and other vehicle components, extending their lifespan.

Transmission Fluid and Maintenance Tips

Proper care and management of the fluid system are essential for ensuring the smooth operation of your vehicle. Regular attention to this component can enhance performance and extend the lifespan of the transmission. Below are key maintenance tips to consider.

- Check Fluid Level: Regularly inspect the fluid level using the dipstick, ensuring it is within the recommended range.

- Inspect Fluid Condition: Observe the fluid’s color and consistency. Healthy fluid is typically red and transparent; if it appears dark or has a burnt smell, it may need changing.

- Change Fluid Regularly: Adhere to the manufacturer’s guidelines for fluid replacement intervals to avoid buildup of contaminants.

- Use Quality Fluid: Always use high-quality transmission fluid that meets your vehicle’s specifications to ensure optimal performance.

- Monitor for Leaks: Regularly check for any signs of leakage under your vehicle, which can indicate issues within the system.

Implementing these maintenance practices will help keep your vehicle running smoothly and efficiently, preventing potential issues down the road.

Common Issues with FWD Parts

Many vehicles equipped with a specific type of drivetrain encounter various challenges over time. These complications can arise from normal wear and tear, improper maintenance, or external factors that affect overall performance. Understanding these issues is essential for effective troubleshooting and repair.

Here are some prevalent problems associated with this drivetrain system:

- Unusual Noises: Grinding or clicking sounds can indicate failing components, such as joints or bearings.

- Vibration: Excessive shaking during acceleration often points to misalignment or damaged shafts.

- Fluid Leaks: Leaks from seals or gaskets may lead to low lubrication levels, causing further damage.

- Steering Difficulties: Problems with steering responsiveness can signal issues with the associated mechanisms.

- Wear on Tires: Uneven tire wear can be a sign of misalignment or other suspension-related problems.

Addressing these issues promptly can help maintain optimal functionality and extend the lifespan of the vehicle’s drivetrain.

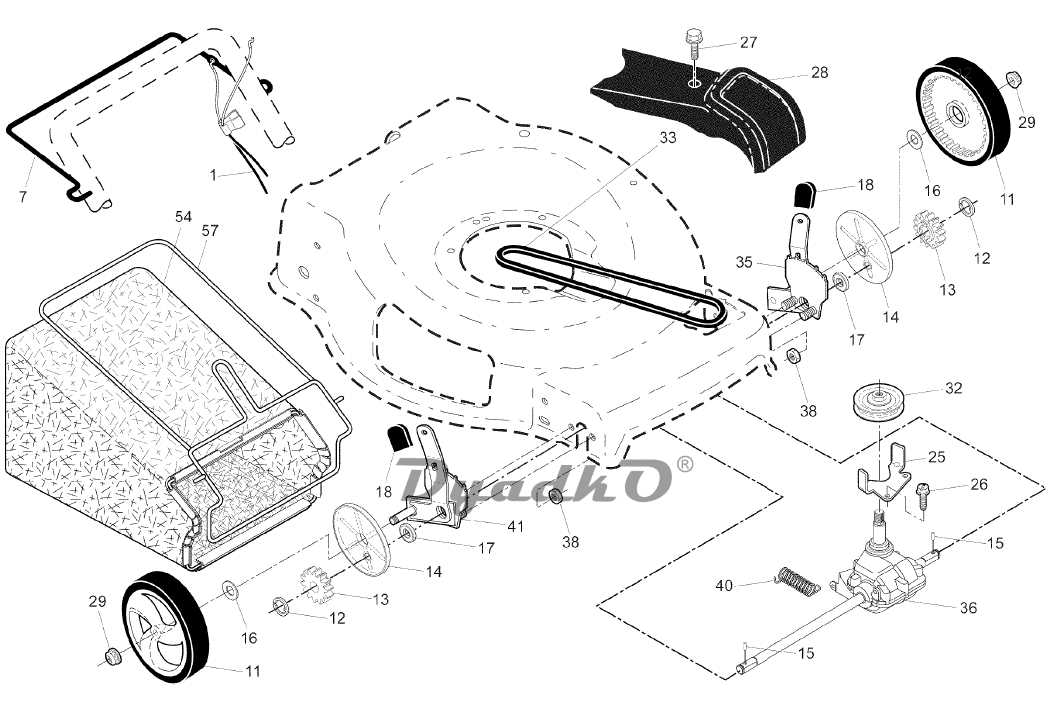

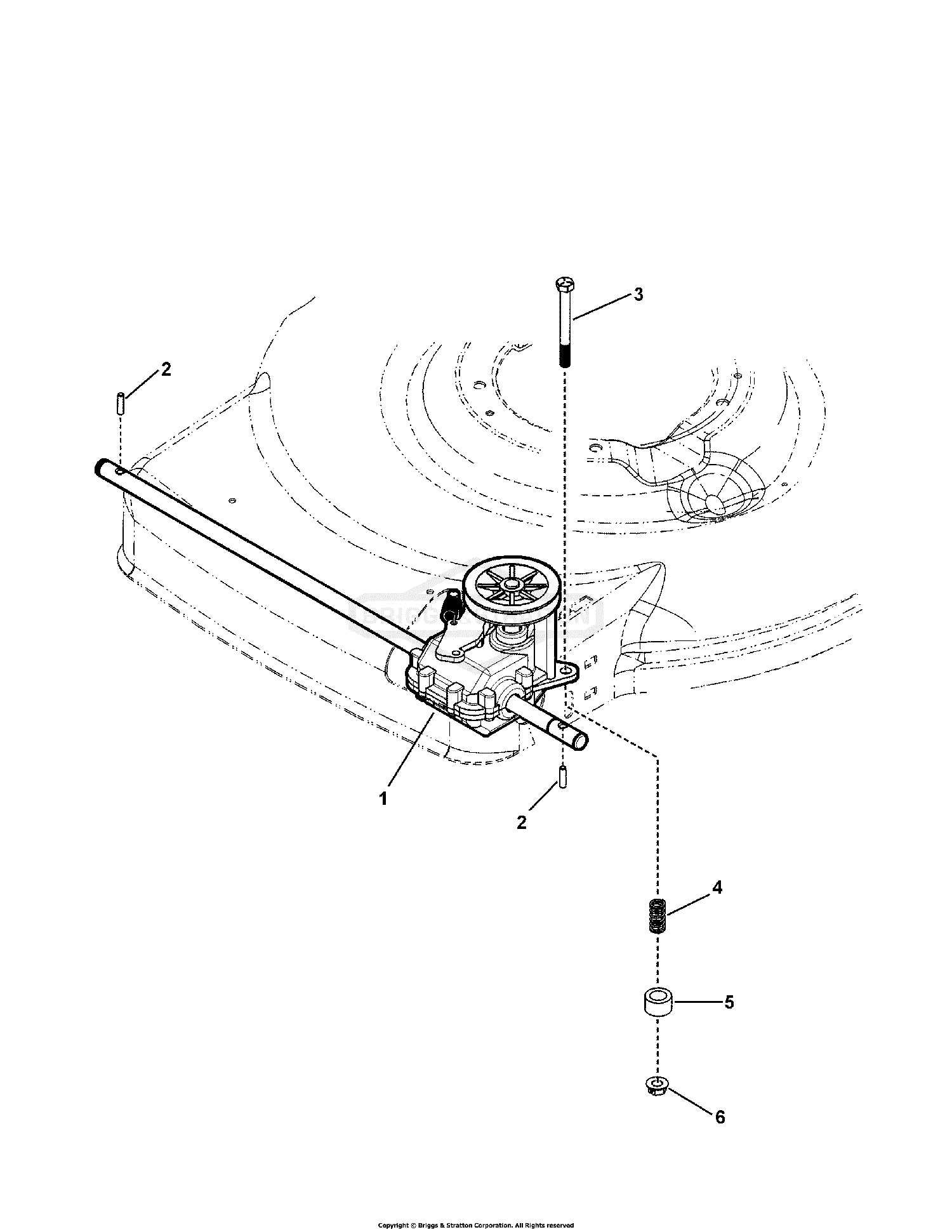

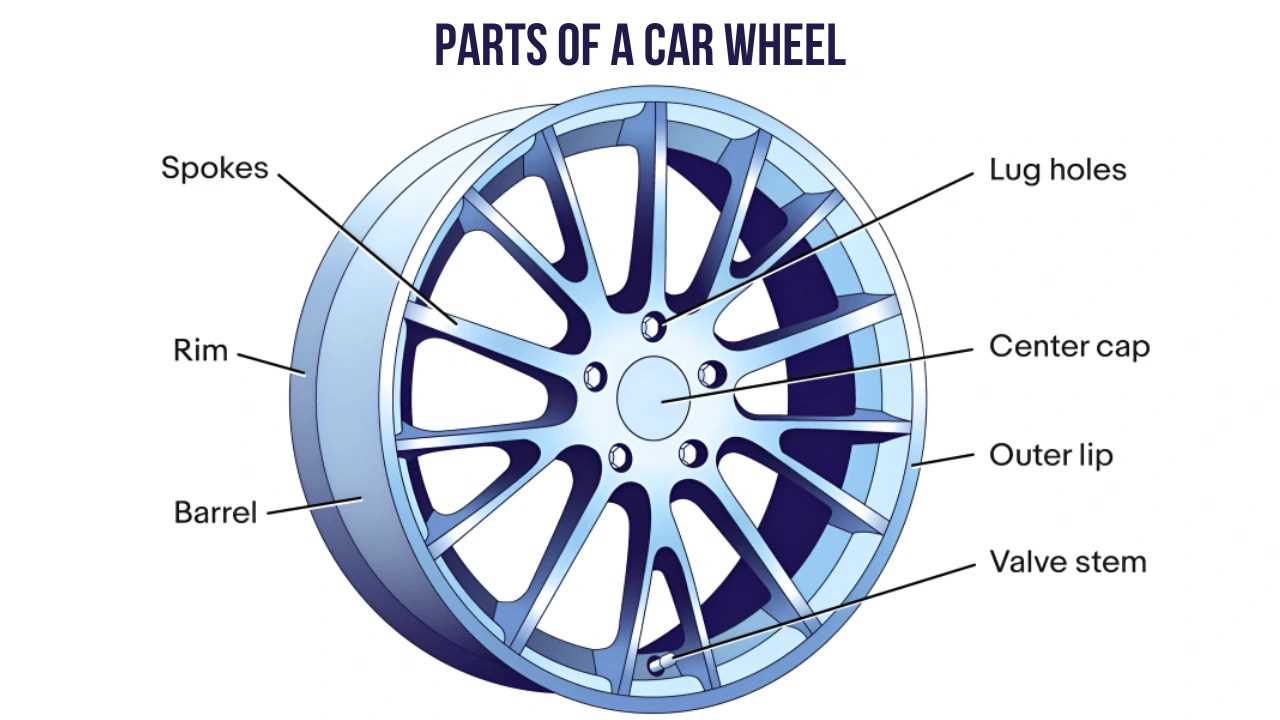

Visual Aids: Parts Diagram Overview

This section explores visual representations that enhance understanding of mechanical components and their relationships. These graphical tools provide clarity and facilitate comprehension, allowing users to better grasp the configuration and functionality of various elements within the system.

Utilizing illustrations can significantly aid in identifying individual components and their specific roles. By offering a clear depiction, these visuals make it easier for individuals to navigate complex assemblies and enhance overall knowledge of the machinery.

Incorporating such aids into study materials fosters a more intuitive learning experience, promoting effective troubleshooting and maintenance practices. Users can rely on these resources to quickly reference and locate specific components, thereby streamlining repair processes and improving efficiency.