In the realm of marine technology, comprehending the essential elements that contribute to engine functionality is crucial for effective maintenance and performance. This section delves into the various components that play a pivotal role in the operation of a small watercraft engine, enabling users to enhance their boating experience.

By familiarizing oneself with the intricate relationships between these elements, enthusiasts and operators can troubleshoot issues more efficiently and ensure that their vessels remain in optimal condition. Clear visual representations aid in grasping the structure and function of each component, making it easier to navigate the complexities of marine engines.

Whether for routine upkeep or during more extensive repairs, a solid understanding of these crucial components empowers users to make informed decisions, ultimately leading to a safer and more enjoyable time on the water. This knowledge is essential for anyone looking to maximize the longevity and efficiency of their marine machinery.

Understanding the Engine Components

The functionality of a marine propulsion system relies heavily on its various engine elements. Each component plays a crucial role in ensuring optimal performance and reliability. Grasping the significance and interrelation of these parts is essential for maintaining the overall efficiency of the mechanism.

Key Elements of the Mechanism

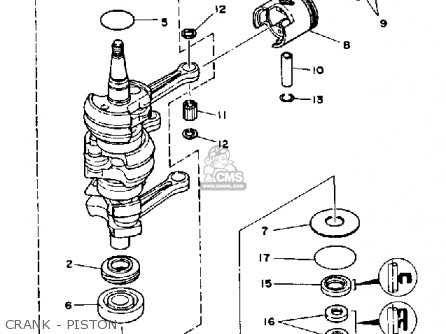

Several key components are integral to the operation of the propulsion unit. These include the combustion chamber, which facilitates fuel ignition, and the crankshaft, which converts the linear motion of the pistons into rotational energy. Additionally, the cooling system is vital for preventing overheating, while the fuel delivery system ensures a consistent supply of energy sources for combustion.

Importance of Regular Maintenance

To sustain optimal functionality, regular inspections and maintenance of these engine components are necessary. Preventive care helps identify potential issues before they escalate, ensuring longevity and peak performance. Understanding each part’s role allows for more effective troubleshooting and timely repairs, ultimately enhancing the reliability of the marine propulsion system.

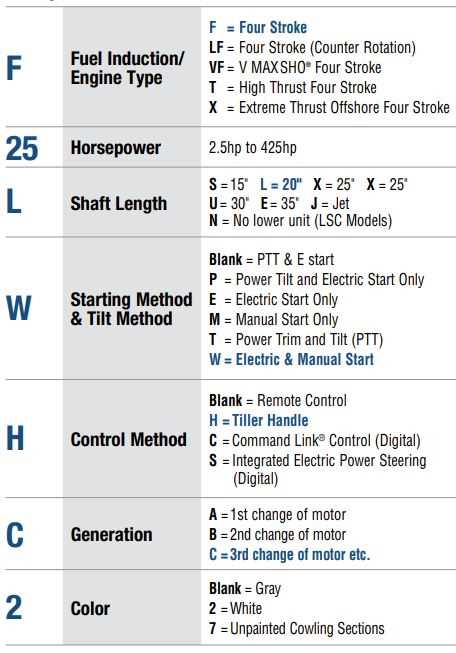

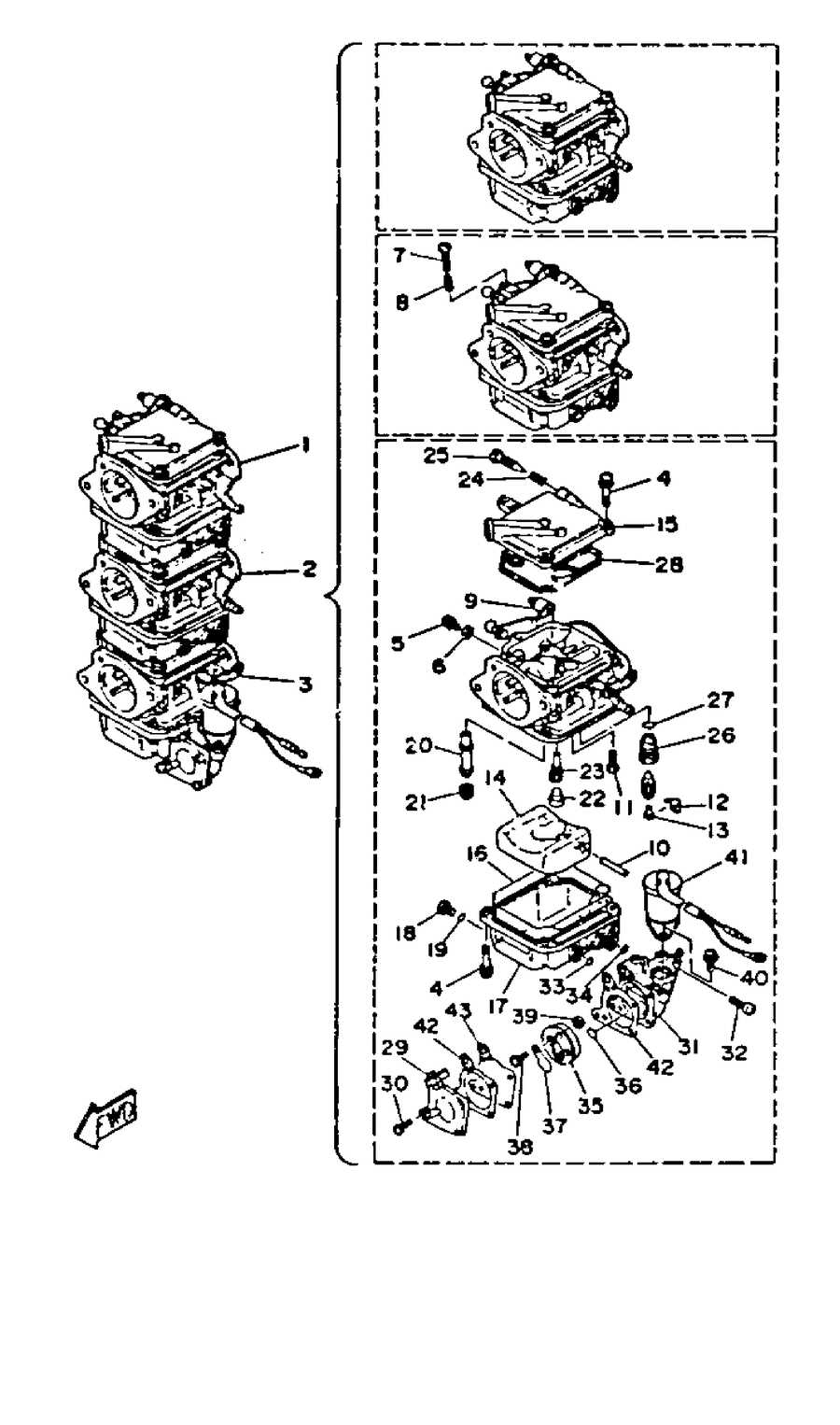

Key Features of the Outboard Motor

Understanding the fundamental characteristics of marine propulsion systems is essential for boat enthusiasts and operators. These features significantly enhance performance, reliability, and user experience on the water.

Performance and Efficiency: Modern propulsion systems are designed to deliver exceptional power while maintaining fuel efficiency. This balance allows for longer journeys without frequent refueling, making them ideal for various aquatic activities.

Durability and Build Quality: High-quality materials and construction techniques contribute to the longevity of these engines. They are engineered to withstand harsh marine environments, ensuring consistent performance even under challenging conditions.

Easy Maintenance: A well-designed propulsion system offers straightforward maintenance procedures. Accessible components allow for quick inspections and repairs, reducing downtime and enhancing reliability.

Advanced Technology: Integration of modern technology, such as electronic fuel injection and smart controls, improves overall efficiency and responsiveness. These innovations enhance user control and contribute to smoother operation.

Versatility: These engines are suitable for a wide range of watercraft, from small boats to larger vessels. Their adaptability makes them a popular choice among recreational and professional users alike.

Essential Spare Parts for Maintenance

Proper upkeep of marine engines requires a thorough understanding of key components that play a vital role in ensuring optimal performance. Identifying and replacing these crucial elements is essential for extending the lifespan of your equipment and maintaining its efficiency.

Commonly Replaced Components

Among the frequently changed items, fuel filters and oil filters stand out as critical for smooth operation. Regularly replacing these elements helps prevent contaminants from causing damage and ensures the engine runs efficiently. Spark plugs are another important part, facilitating the ignition process and contributing to overall power delivery.

Additional Essentials

Aside from the main components, other accessories such as propeller and anode replacements should not be overlooked. These parts are essential for maintaining performance and protecting against corrosion, ensuring a longer life for your machinery. Regular checks and timely replacements of these elements will help keep your marine engine in peak condition.

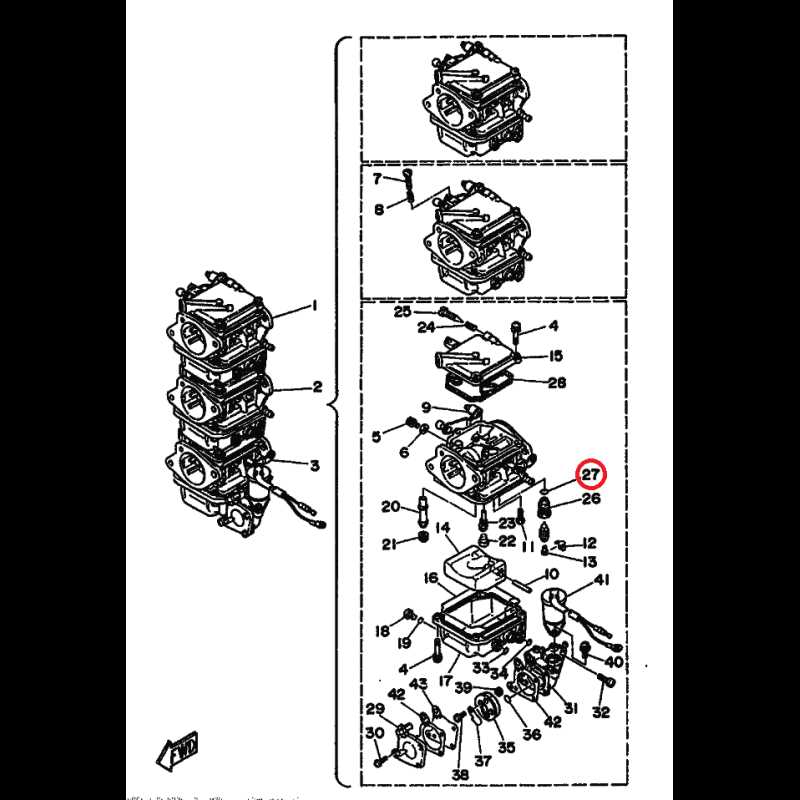

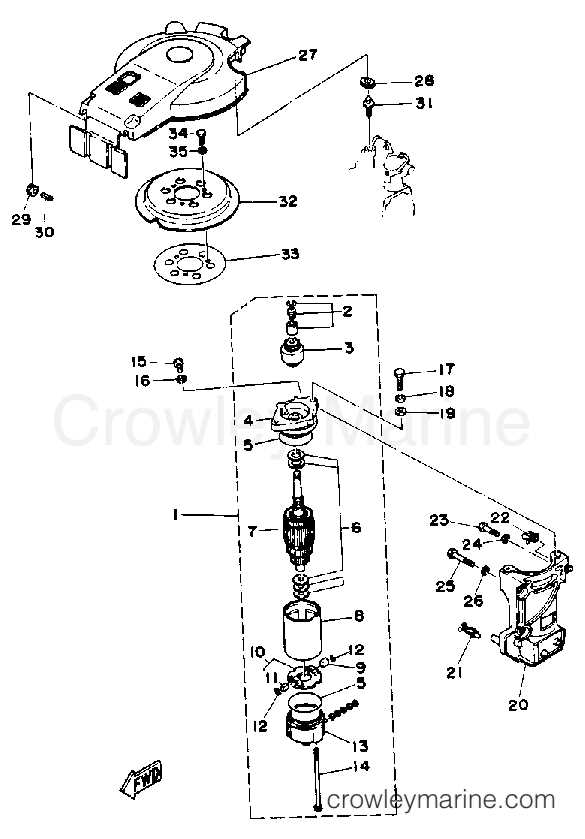

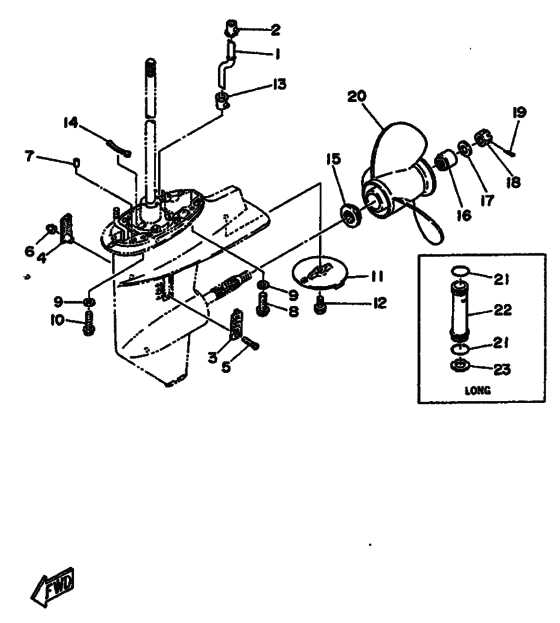

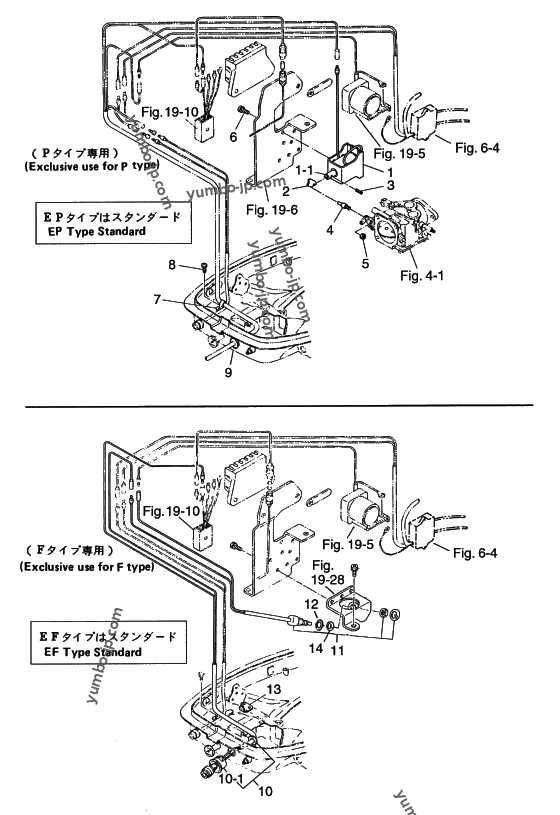

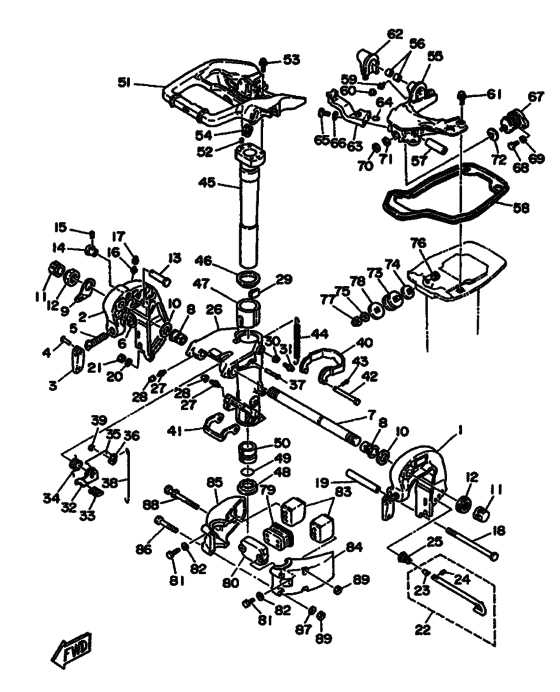

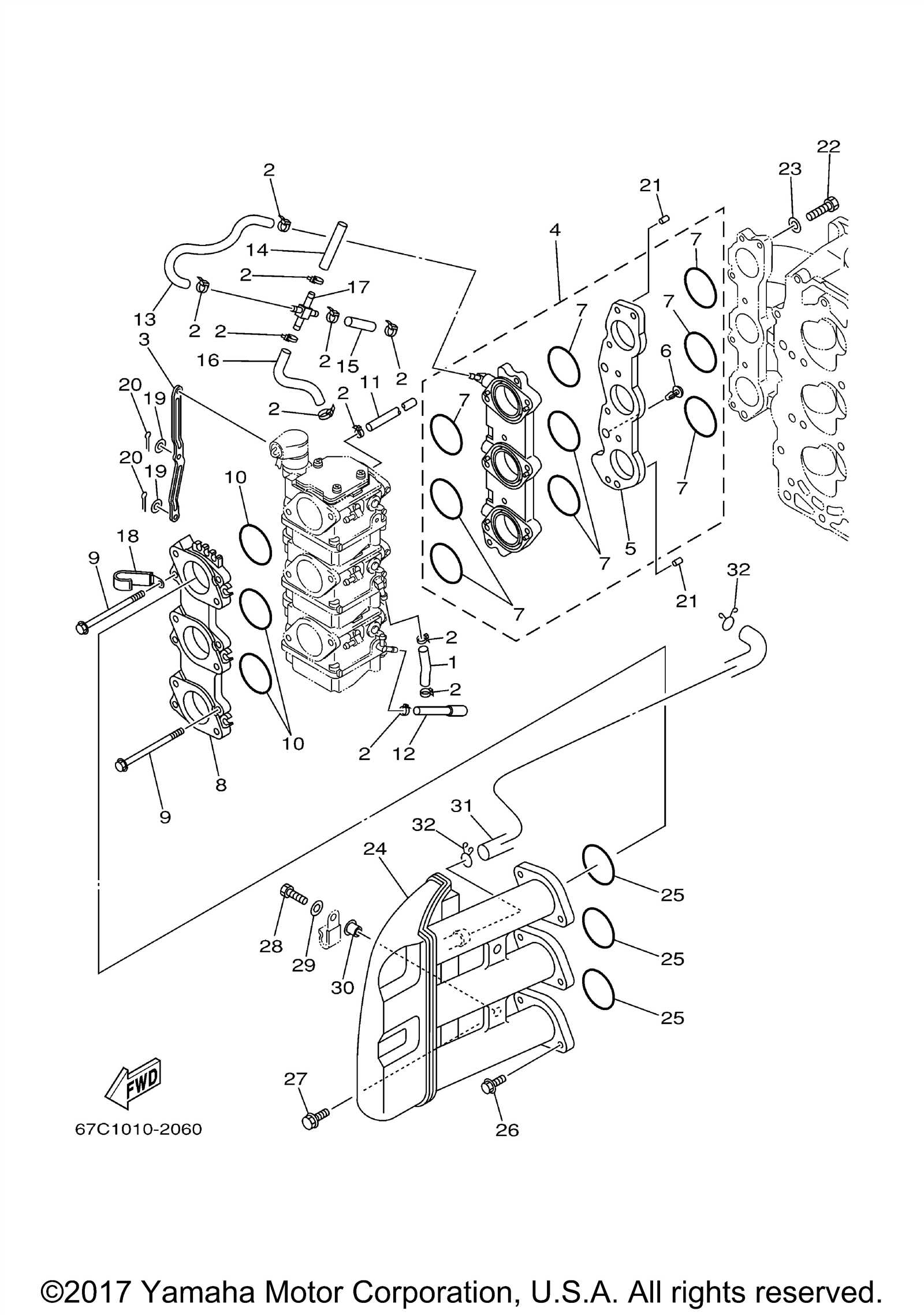

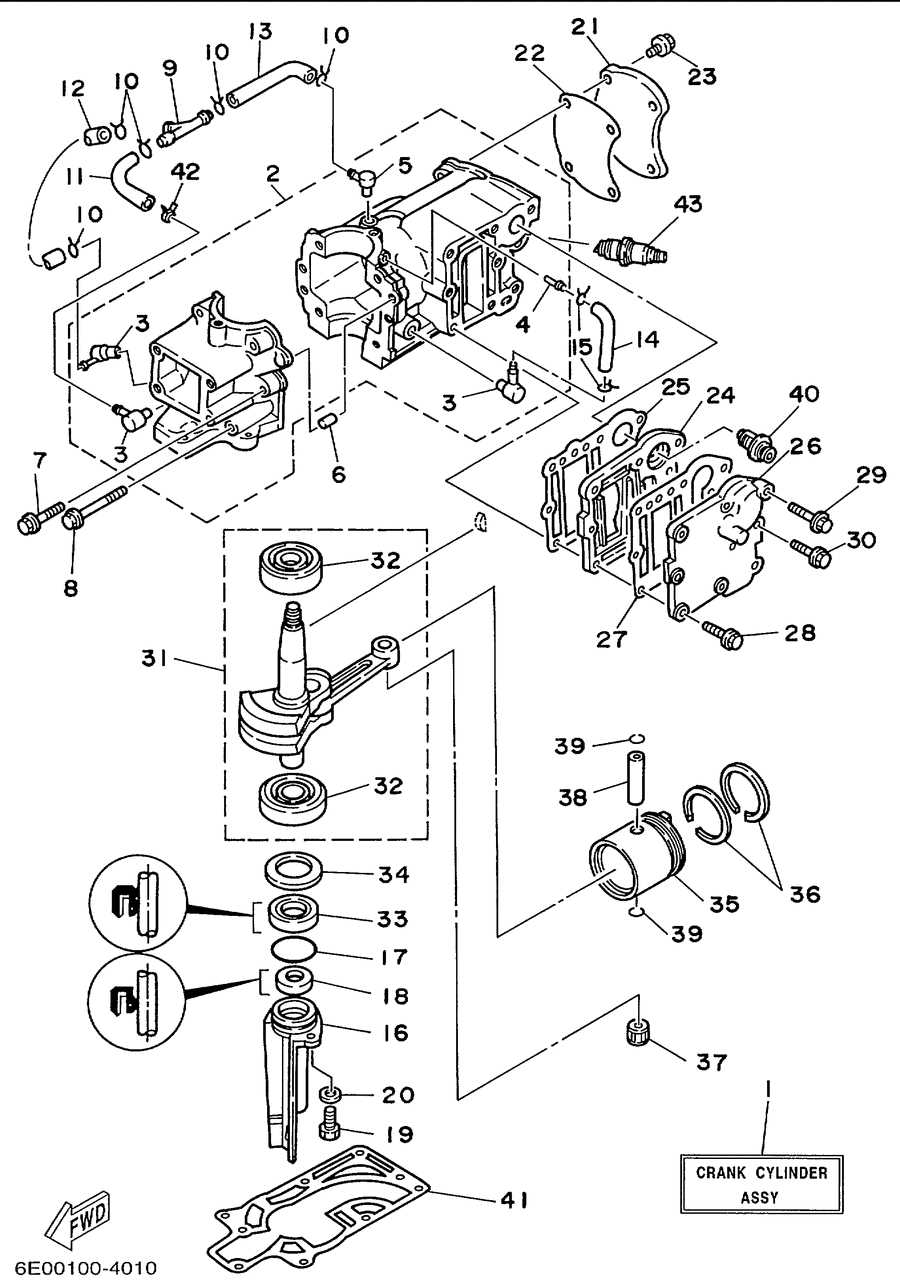

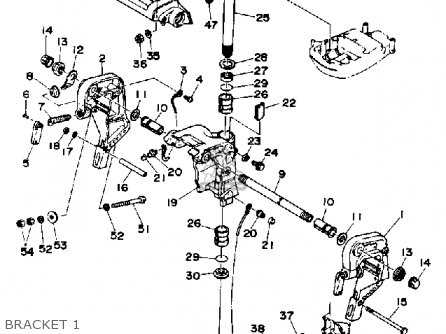

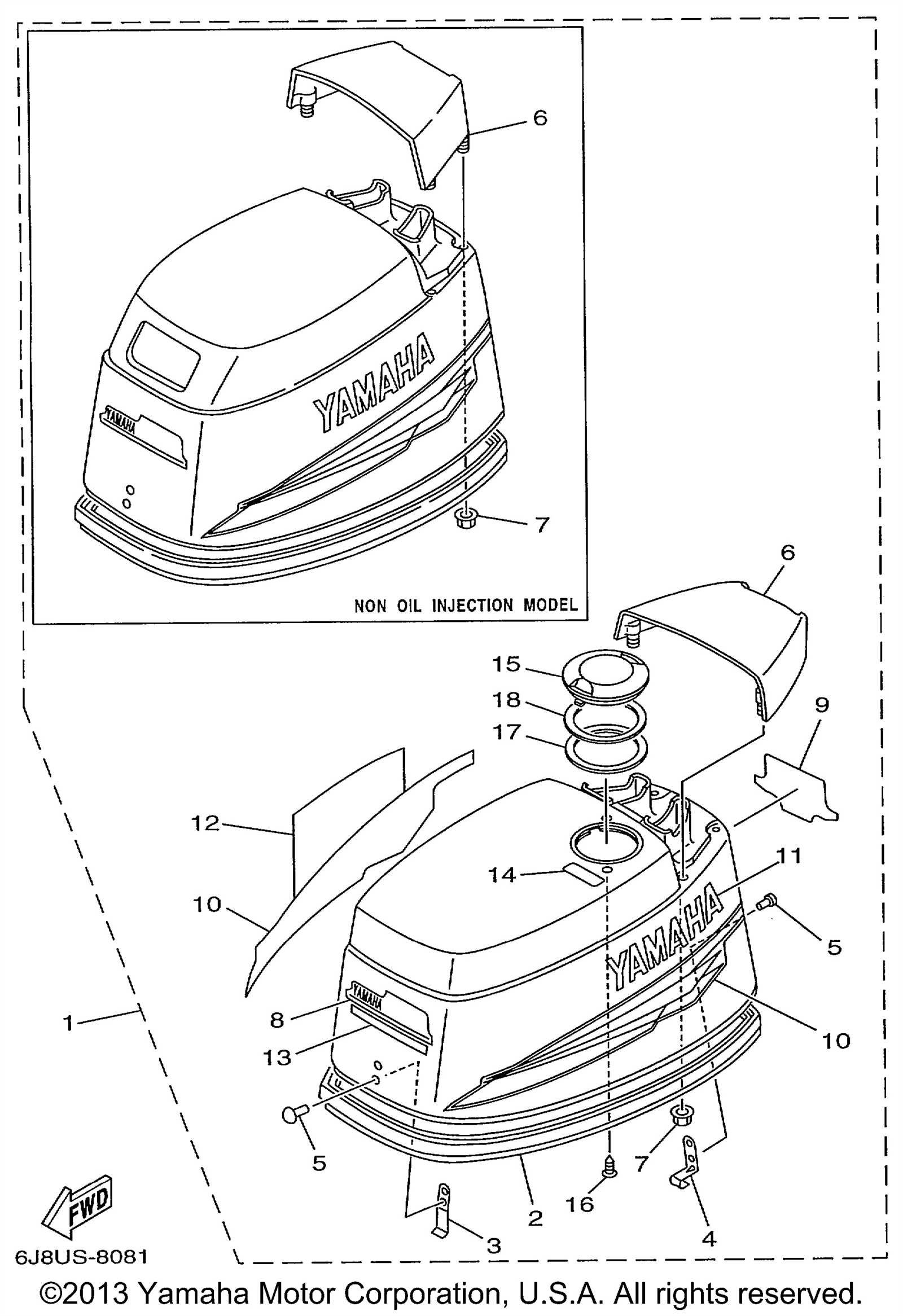

How to Interpret the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. This visual guide illustrates the relationships and functions of various elements, allowing users to identify necessary components quickly and accurately. Familiarity with this representation can greatly enhance the efficiency of troubleshooting and replacement tasks.

When analyzing the visual layout, pay attention to the labeling system used. Each section typically features distinct markings that correlate with the associated elements. These notations can range from numbers to letters, serving as a key to help locate specific components easily. Understanding this system will facilitate faster identification of items needed for repairs or upgrades.

Moreover, note the arrangement and grouping of related components. Often, items that function together are positioned in proximity, indicating their interconnected roles within the larger assembly. Recognizing these relationships is crucial for effective assembly and disassembly processes.

In conclusion, mastering the interpretation of this schematic can empower users to execute repairs confidently and enhance the longevity of their equipment.

Common Issues and Solutions

When operating a small marine engine, various challenges may arise that can affect performance and reliability. Identifying these common problems and understanding their potential remedies is essential for maintaining optimal function and extending the lifespan of the engine.

Frequent Problems Encountered

- Engine not starting or difficult to start

- Unusual noises during operation

- Overheating issues

- Inconsistent acceleration or loss of power

- Fuel leaks or contamination

Possible Solutions

- Ensure proper fuel supply and check for blockages in the fuel line.

- Inspect the battery and connections to confirm adequate power.

- Clean or replace the spark plugs to improve ignition.

- Check the cooling system for obstructions and ensure proper water flow.

- Regularly maintain and replace filters to prevent contamination.

Best Practices for Care and Maintenance

Ensuring the longevity and optimal performance of your marine engine requires consistent attention and appropriate care. Regular maintenance practices are essential to keep the machinery running smoothly and to prevent potential issues that may arise over time.

Routine Inspections: Conduct frequent inspections to identify any wear and tear on components. Look for signs of corrosion, loose fittings, or any unusual sounds during operation. Early detection can save time and money by addressing problems before they escalate.

Regular Cleaning: Keeping the exterior and internal parts clean is crucial. Use fresh water to rinse off salt, sand, and debris after each use. This practice helps prevent corrosion and build-up that can hinder performance.

Fluid Checks: Regularly monitor and replace essential fluids, including oil and fuel. Ensure that levels are within recommended limits and use high-quality fluids to enhance the overall efficiency of the engine.

Storage Considerations: Proper storage is vital when not in use. Cover the machinery to protect it from environmental factors, and consider using stabilizers in the fuel to prevent degradation. Store in a dry place to avoid moisture buildup.

Professional Servicing: Schedule periodic professional servicing to ensure that all components are functioning correctly. Trained technicians can perform detailed inspections and maintenance tasks that may be overlooked in routine checks.

By adhering to these best practices, you can significantly extend the lifespan of your marine engine while ensuring optimal performance during your outings on the water.

Tools Required for Parts Replacement

When undertaking maintenance or repairs on a marine propulsion unit, having the right tools is essential for ensuring efficiency and effectiveness. Utilizing appropriate equipment not only simplifies the process but also minimizes the risk of damage to components.

Essential Hand Tools

Basic hand tools form the backbone of any repair endeavor. A set of wrenches in various sizes, including adjustable options, is crucial for loosening and tightening fasteners. Additionally, screwdrivers with different head types and sizes will facilitate the removal of covers and securing components. Other invaluable tools include pliers for gripping and manipulating small parts and a hammer for driving components into place when necessary.

Specialized Equipment

In addition to standard tools, certain specialized instruments can enhance the replacement process. A torque wrench is vital for applying precise force to fasteners, preventing over-tightening, which can lead to damage. A multimeter may also be useful for diagnosing electrical issues, ensuring all connections are functioning correctly. Lastly, a parts organizer helps keep small components sorted and easily accessible throughout the procedure.

Step-by-Step Disassembly Process

This section outlines a systematic approach to disassembling the motor unit, ensuring that each step is clearly defined for ease of understanding. Following these guidelines will facilitate efficient removal and replacement of components.

Begin by preparing your workspace. Gather the necessary tools and materials to streamline the process:

- Wrenches of various sizes

- Screwdrivers (flathead and Phillips)

- Pliers

- Container for small parts

- Cleaning cloths

Next, follow these sequential steps for disassembly:

- Disconnect the power source: Ensure that the unit is completely powered down to prevent accidents.

- Remove the cover: Using appropriate tools, carefully detach the outer casing to access internal components.

- Take out the fuel system: Disconnect the fuel lines and remove the carburetor, taking care to note the orientation of each part.

- Extract the ignition system: Carefully detach the ignition components, including the coils and wires, making sure to remember their connections.

- Disassemble the lower unit: Unscrew and separate the lower section, checking for any worn parts that may need replacement.

- Inspect and organize: As you remove each component, clean them and place them in a designated container to keep track of all parts.

Following these steps will ensure that you effectively disassemble the unit while minimizing the risk of damage to any components.

Reassembly Tips for Your Outboard

Reassembling your marine engine requires careful attention and a methodical approach to ensure optimal performance and longevity. Following some essential guidelines can simplify the process and help avoid common pitfalls.

1. Organize Your Components: Before starting, arrange all the components systematically. Use labeled containers or trays to keep small parts separate and easy to find, which will save time during reassembly.

2. Refer to the Manual: Consult the service manual for detailed instructions and diagrams. This resource provides valuable insights into the correct order of assembly and torque specifications for fasteners.

3. Clean Surfaces: Thoroughly clean all surfaces before reassembly. Removing old gaskets, dirt, and debris ensures proper sealing and reduces the risk of leaks.

4. Apply Lubricants: Use appropriate lubricants on moving parts and seals. This practice helps prevent wear and tear and facilitates smoother operation after reassembly.

5. Double-Check Alignment: Ensure all components align correctly before tightening. Misalignment can lead to operational issues or damage over time.

6. Take Your Time: Don’t rush the process. Carefully following each step minimizes mistakes and guarantees a successful reassembly.

By adhering to these tips, you can effectively reassemble your marine engine, enhancing its functionality and ensuring a reliable experience on the water.

Where to Purchase Genuine Parts

Finding authentic components for your marine engine is essential for ensuring optimal performance and longevity. There are several reliable avenues to explore when seeking quality replacements that meet manufacturer standards.

Authorized Dealers

Visiting certified retailers guarantees access to original components. These vendors are equipped with knowledge and support for your specific needs. Here are the benefits:

- Expert advice on selecting appropriate items

- Comprehensive inventory of genuine components

- Warranty coverage for purchases

Online Retailers

The internet offers a vast marketplace for purchasing quality replacements. Consider these factors when shopping online:

- Verify seller credibility through reviews and ratings

- Ensure clear return policies for unsatisfactory items

- Look for secure payment options to protect personal information

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components for marine engines. Understanding these elements is crucial for maintaining optimal performance and ensuring longevity. Below are some frequently posed questions that can assist users in making informed decisions.

What Should I Consider When Buying Components?

When purchasing components, it’s important to assess compatibility with your specific engine model. Additionally, consider factors such as material quality, durability, and manufacturer reputation to ensure reliable performance.

How Do I Identify the Right Component?

Identifying the correct component can often be achieved by referencing the engine’s manual or contacting a knowledgeable dealer. Utilizing online resources can also help in verifying part numbers and specifications for a proper fit.

Resources for Further Learning

For those interested in deepening their understanding of marine propulsion systems, there are numerous valuable resources available. These materials can enhance your knowledge of engine components, maintenance procedures, and troubleshooting techniques, ensuring a comprehensive grasp of the subject.

Online platforms, technical manuals, and community forums serve as excellent avenues for acquiring additional insights. Engaging with these resources allows enthusiasts and professionals alike to stay updated with the latest advancements and practices in the field.

| Resource Type | Description | Link |

|---|---|---|

| Online Courses | Structured learning experiences covering various aspects of marine engines. | Visit Course |

| Technical Manuals | Detailed guides that outline maintenance and repair processes. | View Manual |

| Community Forums | Interactive platforms for sharing knowledge and experiences with peers. | Join Forum |