Understanding the intricacies of marine propulsion systems is essential for both enthusiasts and professionals in the boating industry. This section delves into the various elements that make up these vital mechanisms, offering insights into their functions and interconnections. By familiarizing oneself with these components, individuals can enhance their knowledge and ensure optimal performance of their vessels.

Visual representations of mechanical assemblies play a crucial role in simplifying complex structures. They provide a clear overview, allowing users to identify individual elements and comprehend how they work together. This clarity is invaluable for maintenance, repairs, and upgrades, ensuring that every aspect is considered.

Moreover, having a detailed illustration of the various components aids in troubleshooting potential issues. By recognizing how each part interacts with others, users can more effectively diagnose problems and implement appropriate solutions. This understanding not only contributes to smoother operations but also extends the lifespan of the equipment.

tags: Understanding Yamaha 9.9 Outboard Motors”>

tags: Understanding Yamaha 9.9 Outboard Motors”>

This section aims to provide a comprehensive overview of the internal components and their functions within a specific type of marine propulsion system. By understanding these elements, users can better appreciate the engineering behind their equipment and facilitate maintenance and repair tasks.

Key Components Overview

Understanding the primary components is crucial for effective troubleshooting and maintenance. Each part plays a significant role in the overall functionality.

Importance of Regular Maintenance

Regular upkeep ensures optimal performance and extends the lifespan of the machinery. This section will cover essential maintenance practices.

| Component | Description | Function |

|---|---|---|

| Powerhead | The main engine assembly | Generates thrust through combustion |

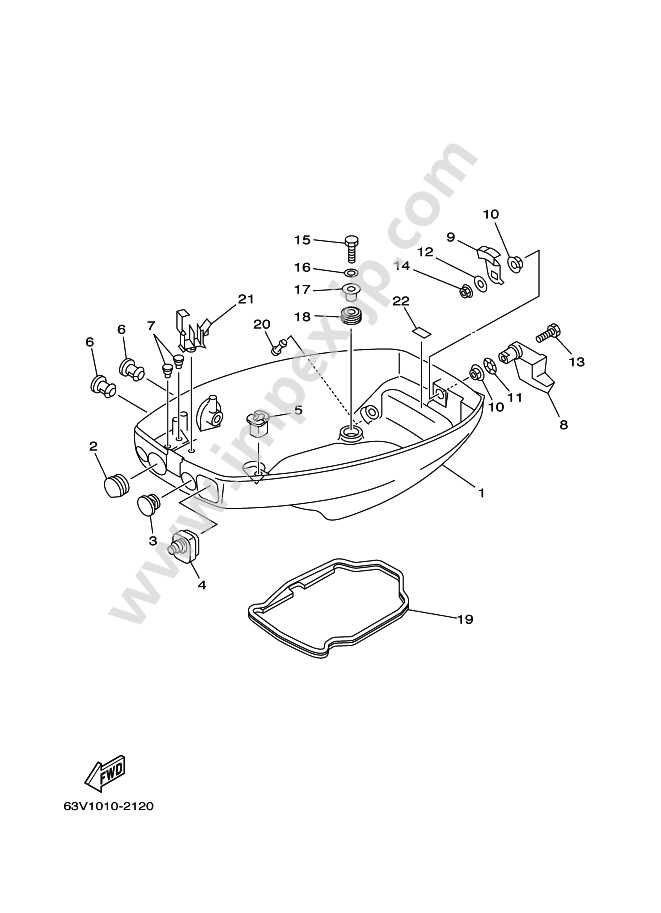

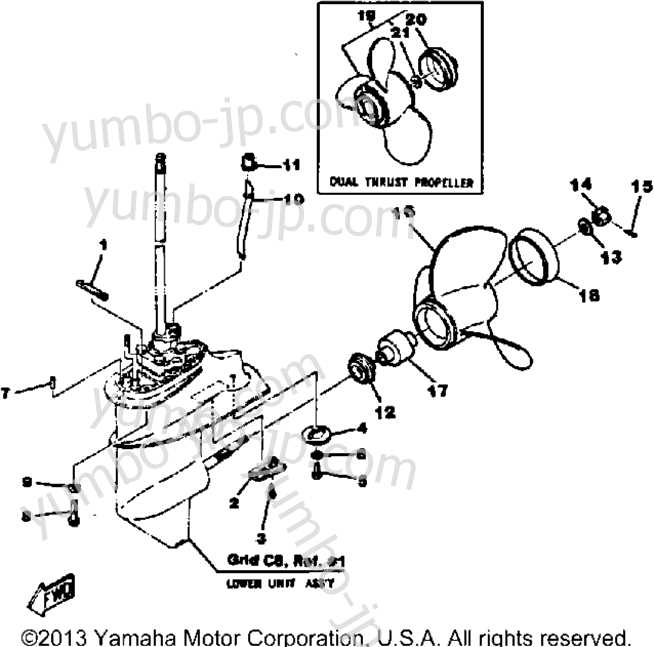

| Lower Unit | Houses the gear system | Transfers power to the propeller |

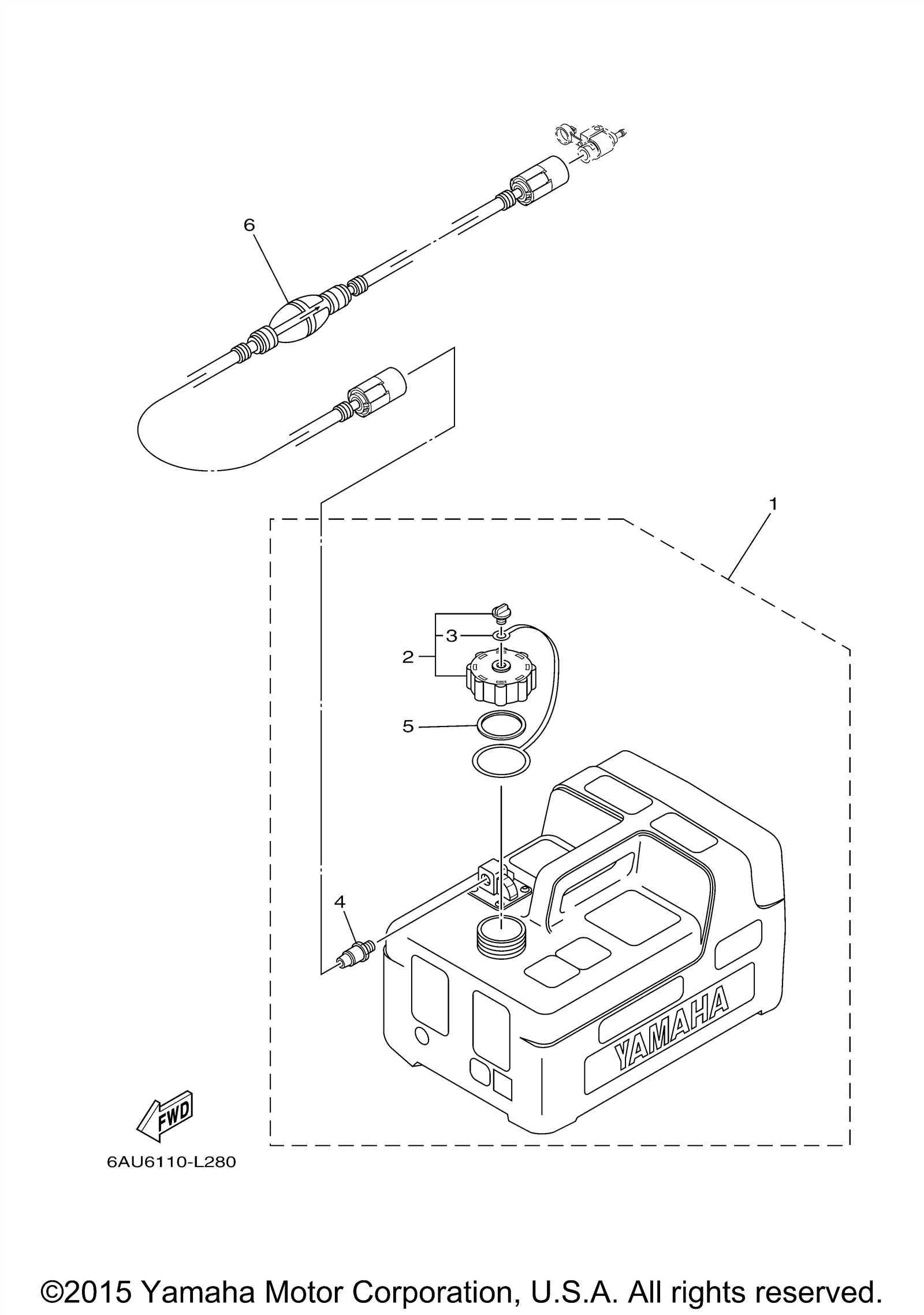

| Fuel System | Includes tank and lines | Supplies fuel to the engine |

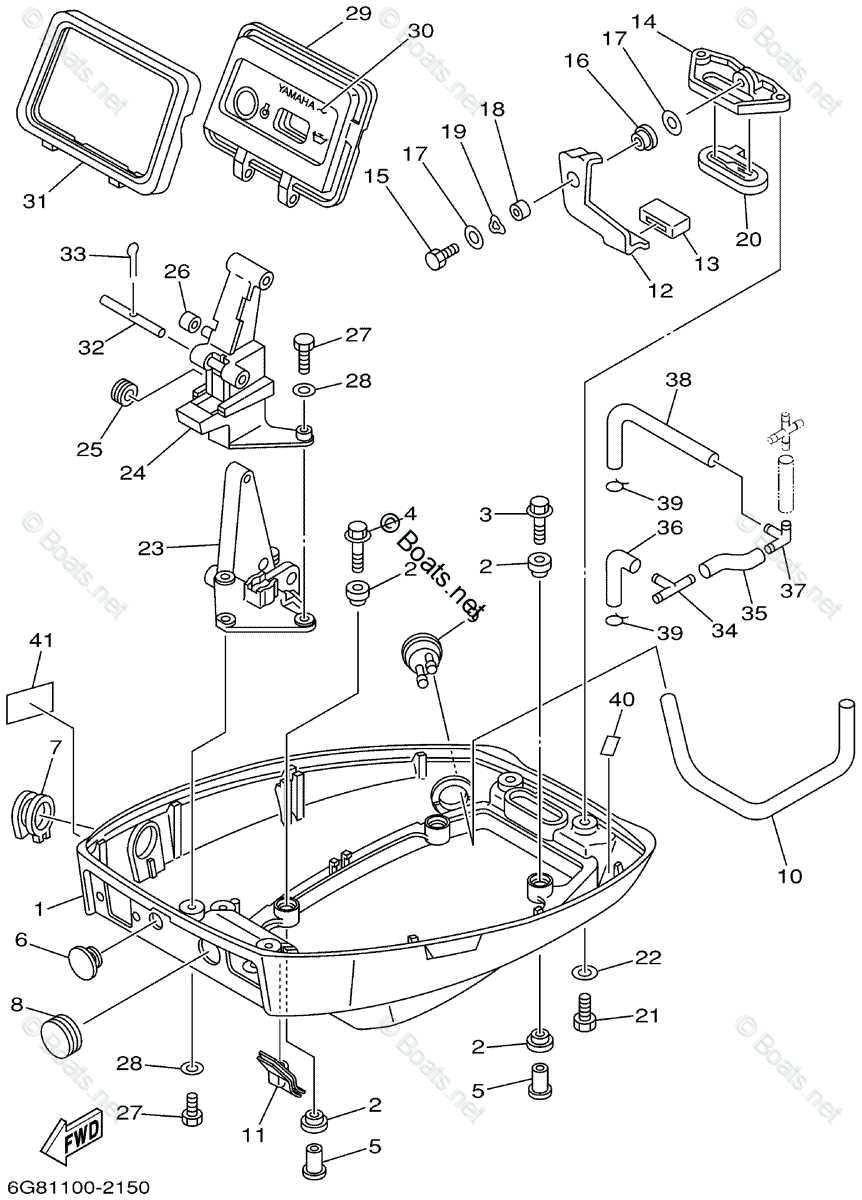

| Cooling System | Includes hoses and pumps | Prevents overheating of the engine |

Key Components of Outboard Engines

Understanding the essential elements of marine propulsion systems is crucial for both maintenance and performance optimization. These components work together to provide power, steering, and stability, ensuring a smooth experience on the water.

Power Unit

The heart of any marine engine, the power unit converts fuel into mechanical energy. This transformation is achieved through a series of carefully designed internal mechanisms, which work in harmony to maximize efficiency and minimize emissions.

Cooling System

A reliable cooling system is vital for preventing overheating during operation. It circulates coolant around the engine, maintaining optimal temperatures and prolonging the lifespan of critical components. Regular maintenance of this system is essential for safe and effective performance.

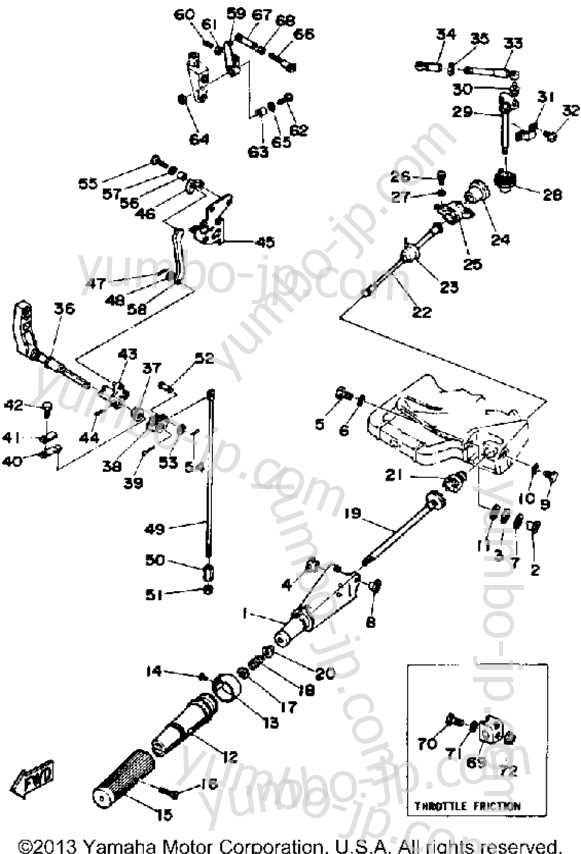

Steering Mechanism

The steering mechanism allows for precise control of the vessel’s direction. It includes various linkages and controls that translate the operator’s input into movement, providing both responsiveness and stability on the water.

Identifying Essential Spare Parts

When maintaining marine engines, recognizing critical components is vital for optimal performance. Familiarity with essential elements ensures smooth operation and enhances the longevity of the equipment.

Key Components to Consider

Start by focusing on the most crucial items that frequently require replacement. These may include the propeller, which is essential for propulsion, and the fuel filter, which ensures the engine receives clean fuel. Regular inspections of the ignition system are also important, as faulty spark plugs can lead to performance issues.

Understanding Your Equipment

Having a comprehensive understanding of the machinery allows for better identification of necessary replacements. Consulting the manual and utilizing available resources can aid in pinpointing the specific elements needed for maintenance. Ensuring you have reliable resources on hand can significantly reduce downtime and enhance efficiency.

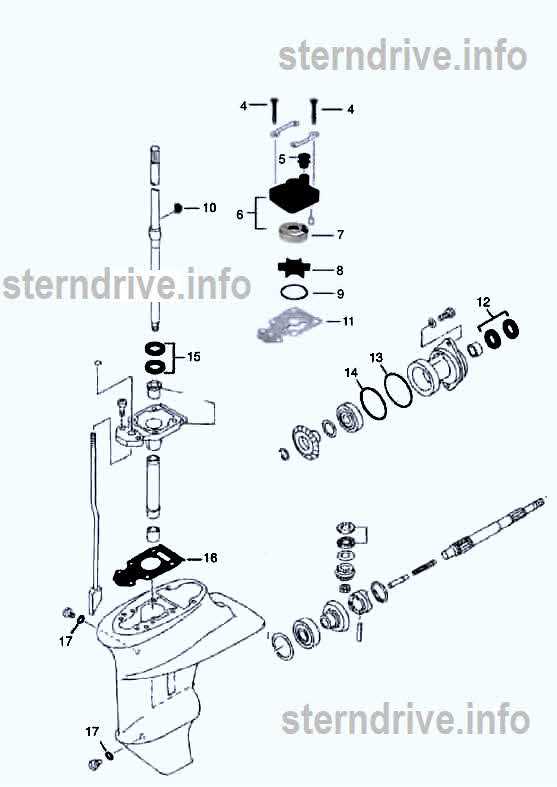

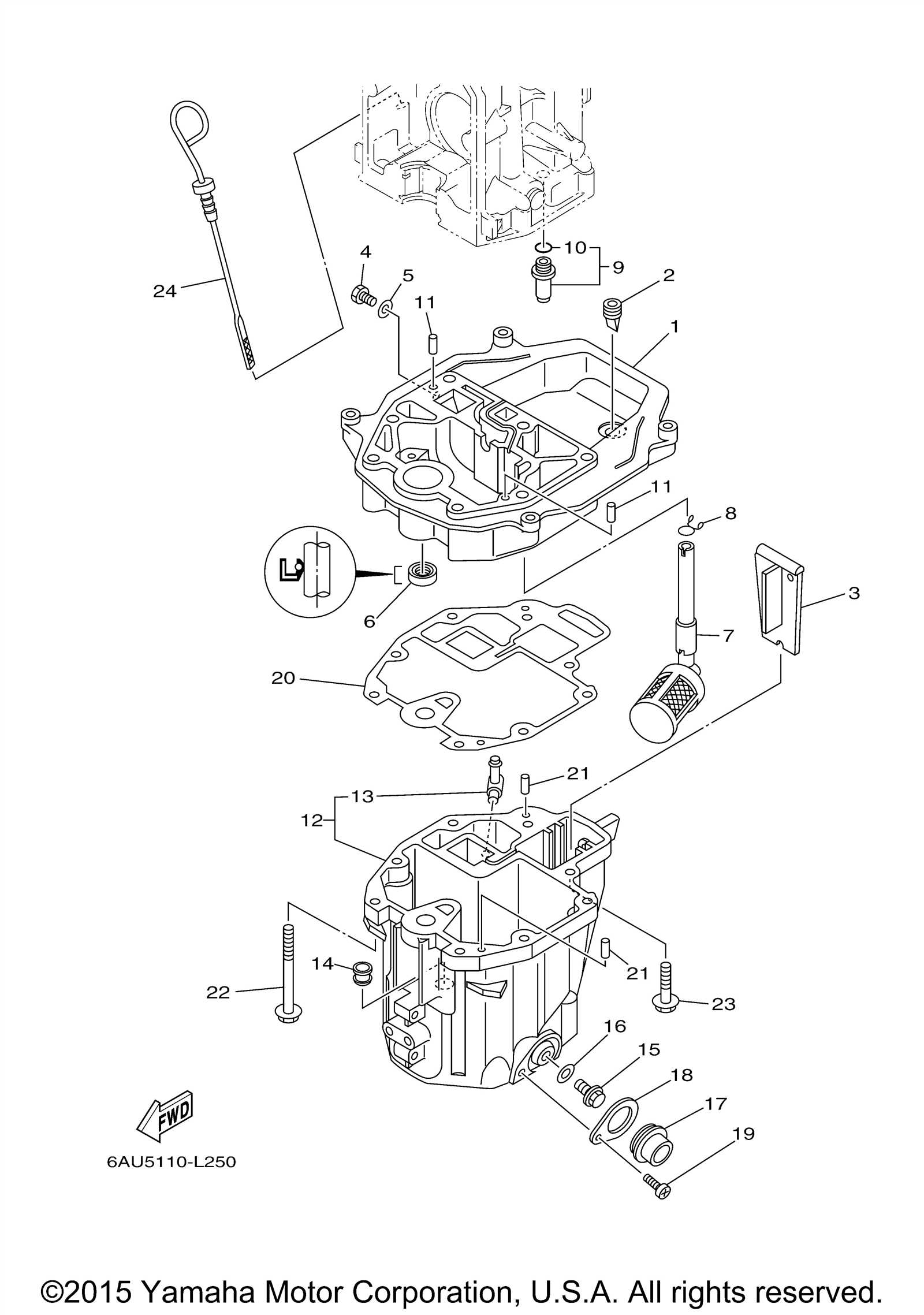

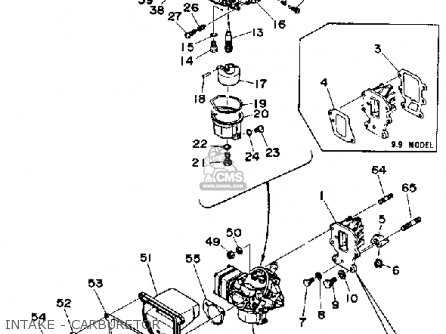

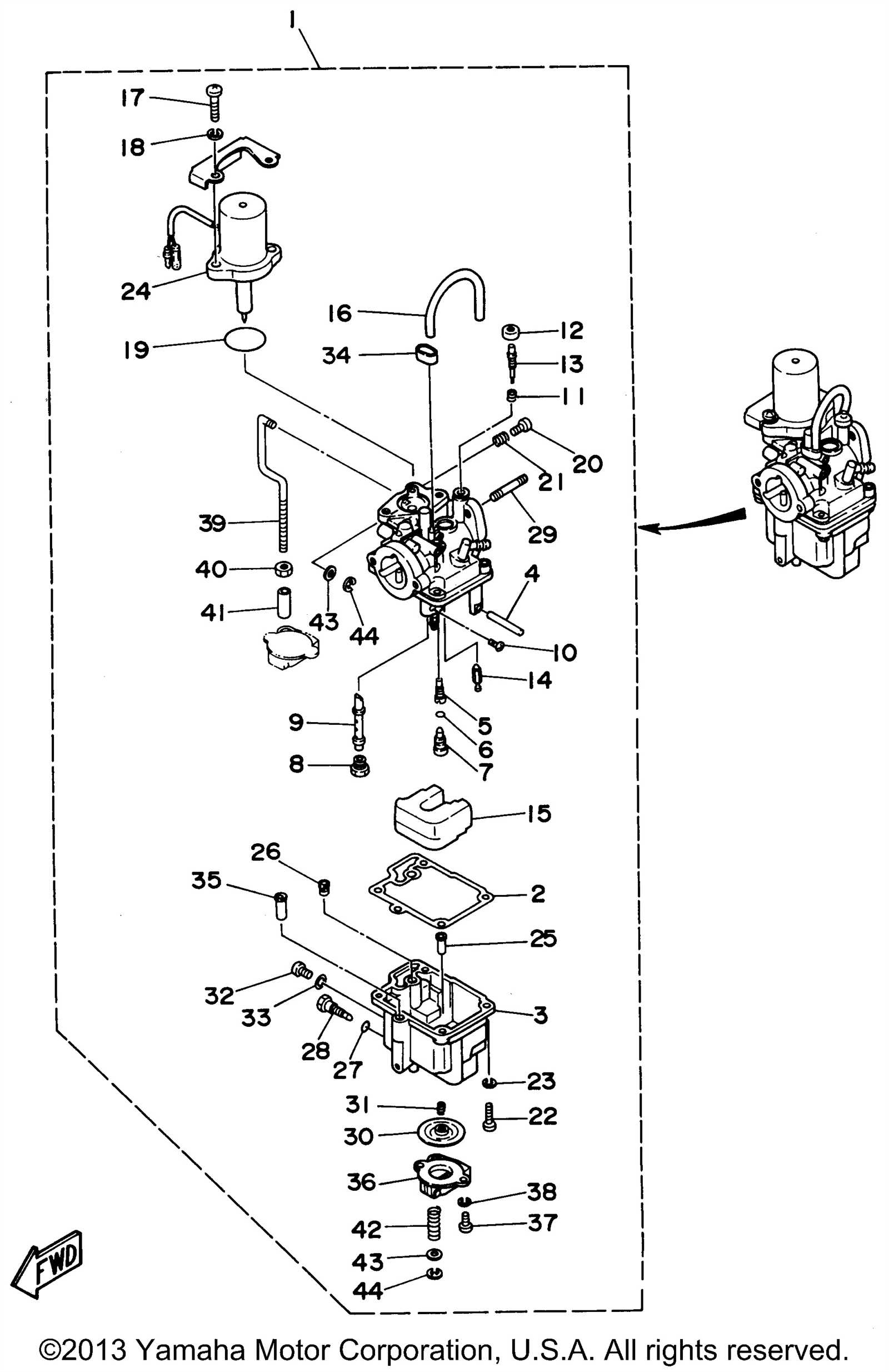

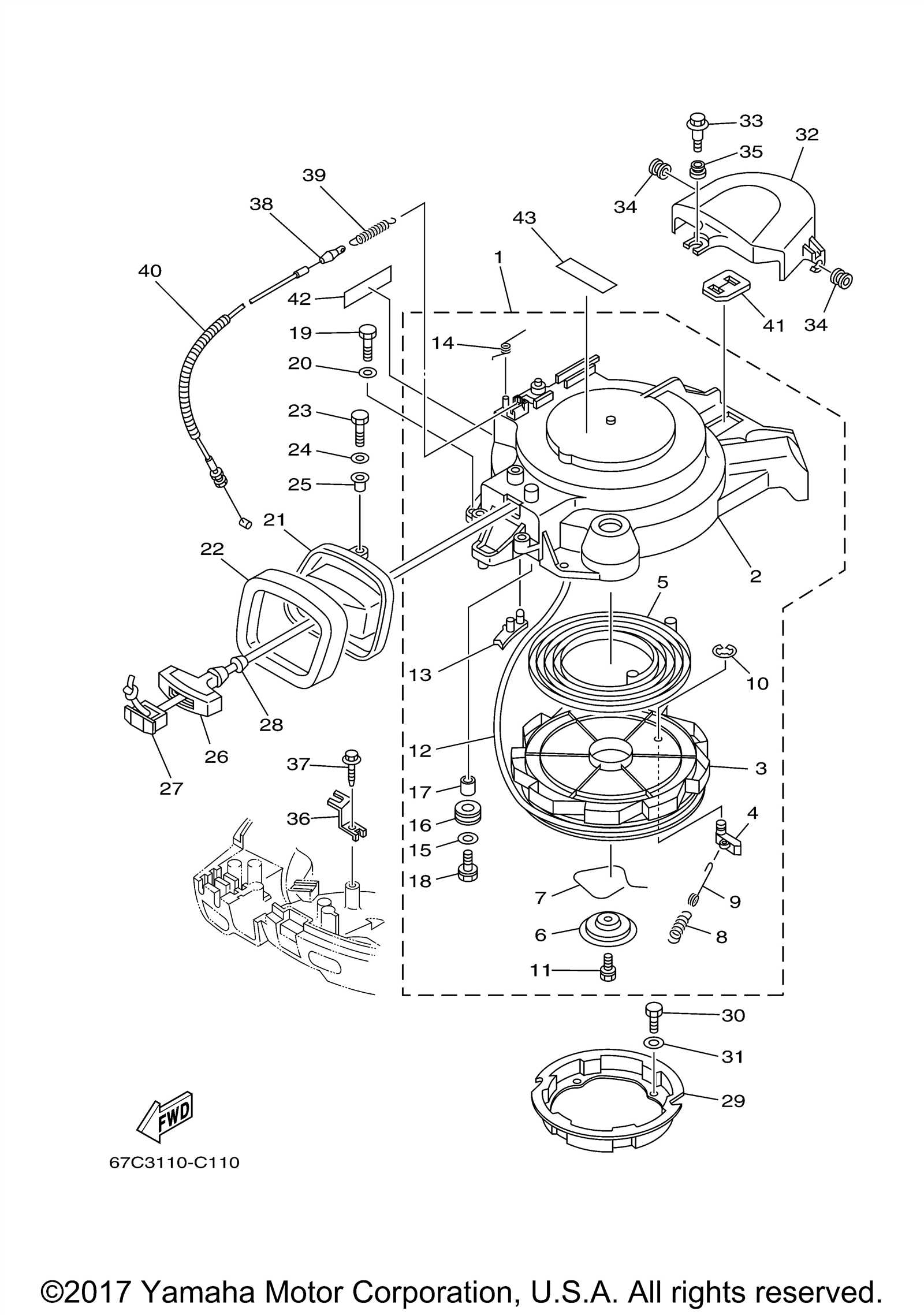

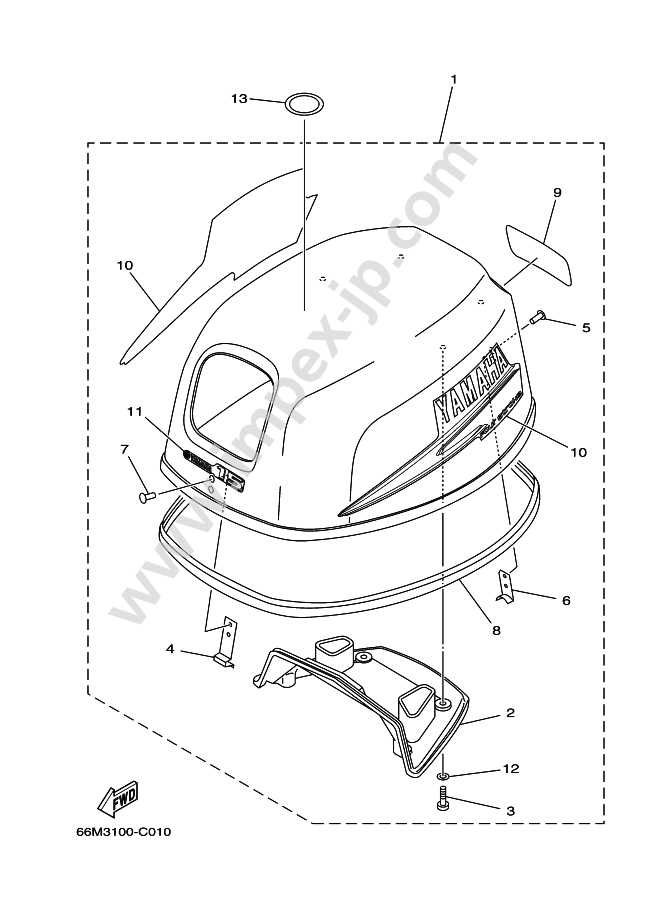

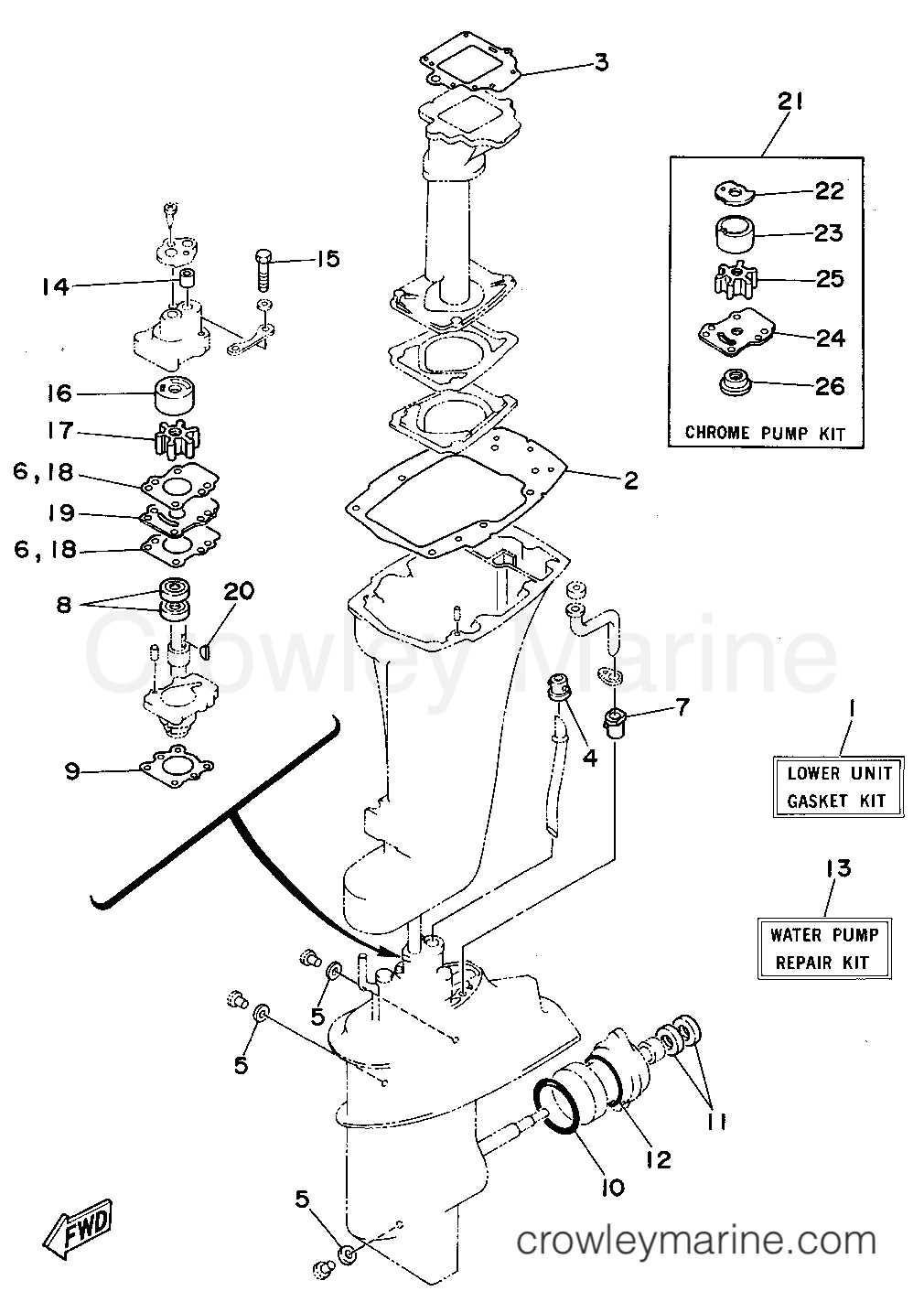

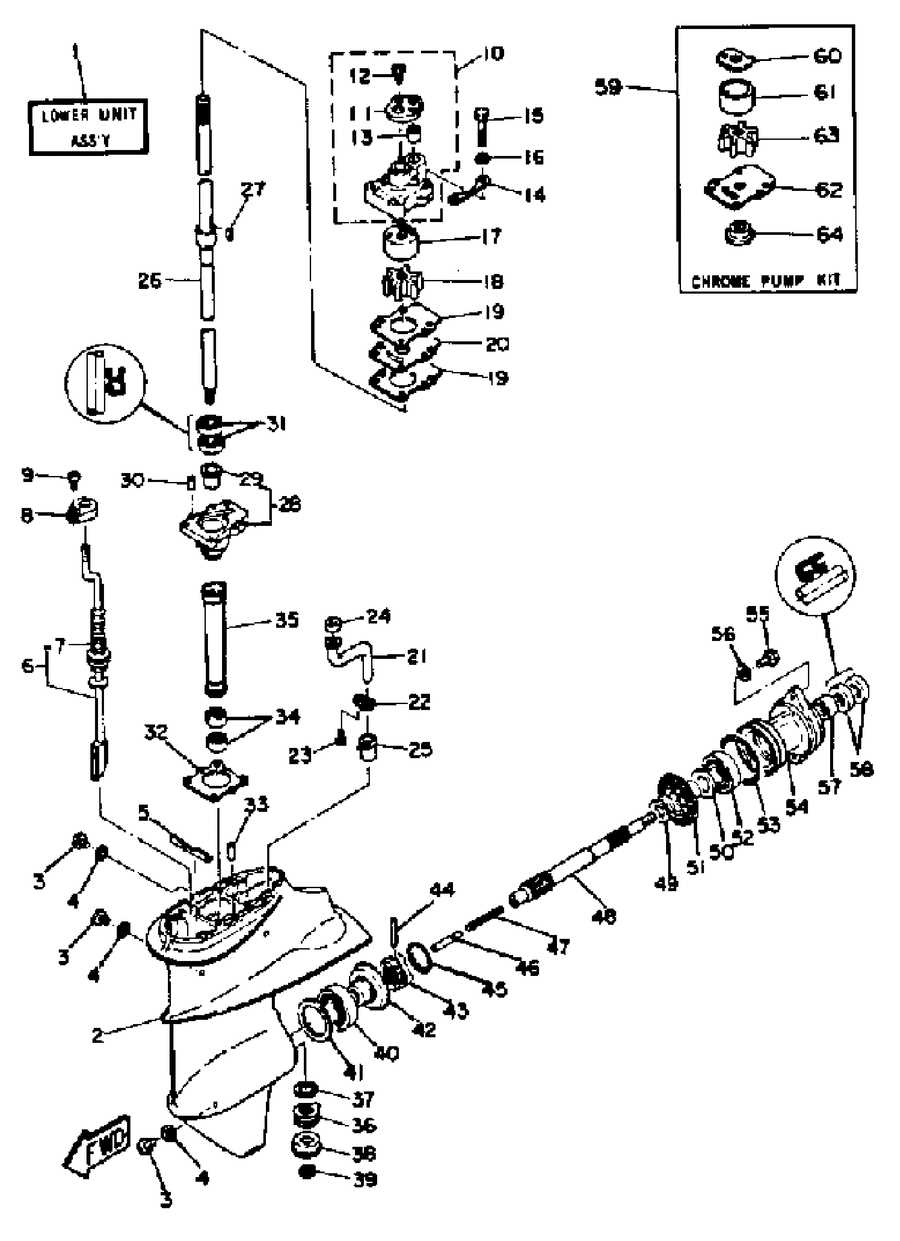

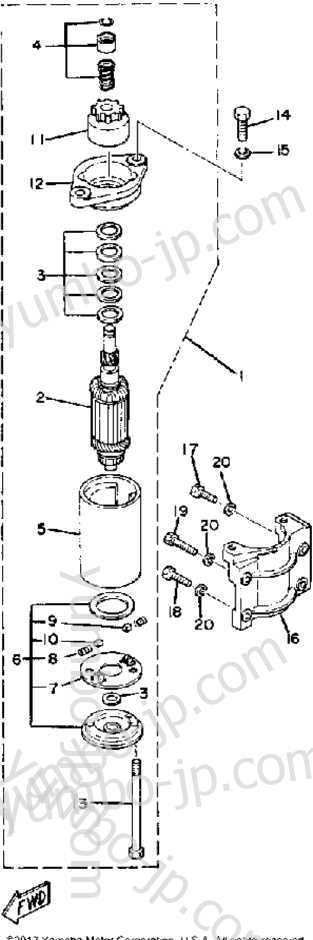

Exploring the Parts Diagram

Understanding the layout of a motor’s components is essential for effective maintenance and repair. A visual representation can greatly aid in identifying various elements and their functions, making it easier to troubleshoot issues and carry out necessary replacements.

Key Components Overview

The diagram typically showcases an array of critical components that make up the motor. Here are some of the key sections you might encounter:

- Powerhead

- Fuel system

- Cooling system

- Steering mechanism

- Propulsion unit

Benefits of Familiarity

Familiarizing yourself with the various sections of the motor can provide several advantages:

- Enhanced troubleshooting capabilities

- Improved maintenance practices

- Increased confidence in repairs

- Efficient replacement of worn components

Ultimately, a clear understanding of the motor’s structure allows for better performance and longevity.

Function of Each Engine Component

The effectiveness of any marine propulsion system relies on the harmonious operation of its individual components. Each part plays a crucial role in ensuring that the engine runs smoothly and efficiently, contributing to overall performance and reliability.

Powerhead: This is the heart of the engine, where the combustion process occurs. It generates the necessary power to drive the vessel, converting fuel into mechanical energy through a series of controlled explosions.

Lower Unit: This section houses the gearbox and driveshaft, which transfer power from the engine to the propeller. Its design allows for proper gear ratios, facilitating effective propulsion and maneuverability.

Cooling System: An essential feature that prevents overheating, this system circulates coolant around the engine components. It maintains optimal operating temperatures, ensuring longevity and efficiency.

Fuel System: This assembly delivers the right mixture of fuel and air to the combustion chamber. It includes components like the fuel pump and carburetor, which work together to ensure proper fuel atomization and combustion.

Ignition System: Responsible for initiating the combustion process, this system generates sparks at the right moment. A well-functioning ignition system is vital for smooth engine starts and consistent performance.

Exhaust System: This component directs exhaust gases away from the engine, preventing back pressure that could hinder performance. It helps in reducing noise and emissions, contributing to a cleaner environment.

Electrical System: This system powers essential components like the starter motor, lights, and instruments. It ensures that the engine has the necessary electrical energy for ignition and other functions.

Understanding the function of each component enables better maintenance and troubleshooting, leading to improved performance and reliability of the propulsion system.

How to Read the Diagram Effectively

Understanding a schematic representation can significantly enhance your ability to identify components and their relationships. By familiarizing yourself with the layout and symbols used, you can streamline your maintenance and troubleshooting efforts.

Begin by examining the overall structure of the illustration. Look for key sections that categorize various elements, which may include propulsion systems, fuel lines, and electrical connections. This will provide a roadmap for navigating the visual information.

Next, pay attention to the symbols and notations used throughout the representation. Each symbol typically corresponds to a specific part or function, so it’s essential to refer to any accompanying legend or guide that explains their meanings. This will aid in accurately interpreting the visual cues.

Focus on Connections: Note how components are linked, as this information can be vital for troubleshooting issues. Understanding these connections allows for quicker diagnosis and more effective repairs.

Practice and familiarity are key. The more you engage with the schematic, the more intuitive it will become, enabling you to work confidently with the system. Over time, this knowledge will empower you to undertake maintenance tasks with greater ease.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of marine engines. Regular attention to various components ensures optimal performance and minimizes the risk of breakdowns. Implementing a few simple practices can significantly contribute to the durability and efficiency of your equipment.

Regular Inspections

Conducting frequent checks on critical parts is vital. Look for signs of wear, corrosion, or damage, as early detection can prevent more severe issues down the line. Ensure that all connections are secure and that fluids are at appropriate levels.

Seasonal Preparation

Before and after each boating season, take time to prepare your machinery. Proper cleaning, winterization, and storage techniques can protect against environmental factors. Additionally, consider replacing any worn or outdated components to maintain peak performance.

Common Issues with Outboard Motors

Marine engines are essential for various water activities, yet they can experience a range of challenges that affect performance and reliability. Understanding these common problems can help users identify symptoms early and take appropriate measures for maintenance or repair.

One frequent issue is starting difficulties. This can result from a drained battery, faulty ignition components, or fuel delivery problems. Ensuring that the fuel system is clean and the battery is charged is crucial for smooth operation.

Another prevalent concern is overheating, which can lead to severe damage if not addressed promptly. Clogged cooling passages or a malfunctioning water pump are often the culprits. Regular checks of the cooling system can prevent this situation.

Fuel quality also plays a vital role in engine performance. Poor-quality fuel can cause misfires, reduced power, and increased emissions. Utilizing high-quality fuel and ensuring proper filtration can mitigate these issues.

Lastly, vibration and noise can indicate underlying problems, such as misalignment or worn components. Monitoring these changes can help users maintain a quiet and efficient engine.

Where to Purchase Replacement Parts

Finding suitable components for your marine engine can significantly enhance its performance and longevity. Numerous options are available for acquiring these necessary items, ranging from specialized retailers to online platforms. It’s essential to consider factors such as quality, availability, and cost when selecting a source.

Local dealers often provide a wide selection of components, along with expert advice tailored to your specific needs. These establishments may also offer the advantage of immediate availability, allowing you to make repairs without delay. Additionally, reputable online marketplaces can be an excellent resource for obtaining a broader range of options, often at competitive prices.

It is advisable to compare prices and read customer reviews to ensure you are choosing reliable suppliers. Moreover, some manufacturers may provide direct sales through their websites, ensuring that you receive genuine components designed specifically for your engine. Always prioritize purchasing from trusted sources to guarantee the best performance and safety.

Tools Required for Repairs

When undertaking maintenance tasks or repairs on marine engines, having the right tools at your disposal is essential for efficient and effective work. Proper equipment not only facilitates the process but also ensures safety and accuracy during each step of the procedure.

Essential Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle nose and regular)

- Socket set

- Adjustable wrench

Specialized Tools

- Torque wrench

- Compression tester

- Multimeter

- Seal puller

- Propeller puller

Having a well-equipped toolkit will streamline the repair process and help ensure that each task is performed with precision. It is advisable to assess the specific requirements of your project to gather any additional tools that may be necessary.

Upgrades and Modifications Available

Enhancing the performance and functionality of your marine propulsion system can significantly improve your boating experience. Various options are available to tailor your vessel to meet specific needs, whether you’re seeking better efficiency, increased speed, or enhanced durability.

Performance Enhancements

One of the most common areas for improvement is the propulsion system’s efficiency. Upgrading components such as the propeller can lead to better acceleration and fuel economy. Additionally, fine-tuning the fuel delivery system can optimize combustion, resulting in improved overall performance.

Durability and Longevity

Modifying certain elements with higher-grade materials can enhance the longevity of the propulsion system. Investing in corrosion-resistant coatings or reinforced components can protect against the harsh marine environment, ensuring reliable operation over time.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Propeller Upgrade | Changing to a more efficient propeller design | Improved speed and fuel efficiency |

| Fuel System Tuning | Adjusting fuel injectors and filters | Better fuel combustion and performance |

| Corrosion Protection | Applying protective coatings | Increased durability against marine conditions |

Resources for Further Learning

Expanding your knowledge about marine engines and their components can significantly enhance your maintenance and repair skills. Various resources are available that provide valuable insights into different aspects of these machines, from technical manuals to online forums.

Books and Manuals

- Technical handbooks that cover engine mechanics and troubleshooting techniques.

- Guides specifically focused on maintenance routines and best practices.

- Reference materials offering diagrams and illustrations for better understanding.

Online Resources

- Manufacturer websites with downloadable manuals and specifications.

- Online forums where enthusiasts share experiences and solutions.

- Video tutorials demonstrating repair techniques and maintenance procedures.