In the world of machinery, comprehending the layout of essential components is vital for effective maintenance and repair. Each model presents a unique configuration that serves specific operational needs, making it crucial for users to familiarize themselves with these intricate designs. A well-structured guide to these layouts can significantly enhance troubleshooting efficiency and extend the lifespan of the equipment.

The examination of schematics not only aids in identifying individual elements but also facilitates a deeper understanding of their interconnections. Recognizing how various parts interact can illuminate potential issues and streamline the repair process. Moreover, having a clear visual reference fosters confidence in both novice and experienced technicians.

As we delve into the specifics of these configurations, it becomes apparent that such resources are indispensable. They provide clarity and insight into the assembly of mechanical components, allowing for informed decisions during maintenance. Whether for personal use or professional application, mastering these layouts is essential for anyone involved with small engine technology.

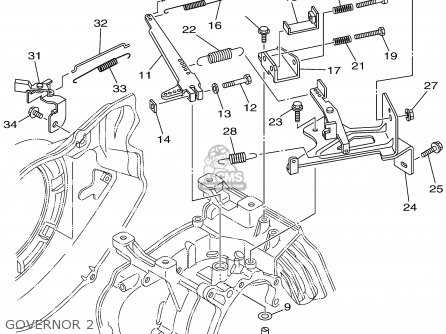

Understanding Yamaha MZ360 Components

This section explores the intricate elements that contribute to the functionality of a specific engine model. By examining each component, one can appreciate how they interact and work harmoniously to achieve optimal performance.

Key Elements

Among the essential parts, one can find various systems that ensure efficient operation. Understanding these components is crucial for maintenance and troubleshooting.

| Component | Function |

|---|---|

| Cylinder Head | Houses valves and spark plugs, facilitating combustion. |

| Piston | Converts fuel energy into mechanical motion. |

| Crankshaft | Transforms linear motion into rotational energy. |

Interconnectivity

The interaction between these elements defines the overall efficiency of the engine. A thorough understanding allows for better diagnostics and enhancements in performance.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements serve as invaluable resources, providing clear guidance on assembly and disassembly. This clarity helps in identifying specific pieces and their functions, enhancing overall efficiency during service tasks.

Benefits of Visual Guides

- Enhanced Clarity: Visual aids simplify complex structures, making it easier to comprehend how parts fit together.

- Time-Saving: Quick reference to images reduces the time spent searching for information, allowing technicians to focus on repairs.

- Accuracy in Repairs: Detailed visuals minimize the risk of errors, ensuring that every component is correctly installed or replaced.

Support for Troubleshooting

- Identification of Issues: Visual references help in pinpointing malfunctioning components quickly.

- Step-by-Step Guidance: They often include instructions that guide users through troubleshooting processes effectively.

- Education: New users can learn about the system layout and functions, fostering a deeper understanding of the equipment.

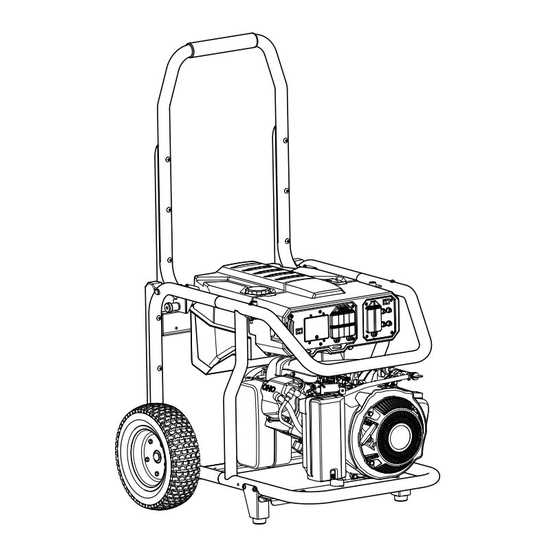

Key Features of the MZ360

This section highlights the essential attributes that make this model stand out in its category, focusing on functionality, design, and performance.

- Powerful Engine: Delivers exceptional output, ensuring robust performance in various applications.

- Compact Design: Optimized for easy transport and storage, making it ideal for both professional and recreational use.

- Durability: Constructed with high-quality materials that withstand rigorous conditions, ensuring longevity.

- User-Friendly Controls: Intuitive interface allows for effortless operation, enhancing overall user experience.

- Versatile Applications: Suitable for a wide range of tasks, from light-duty projects to heavy-duty operations.

These features collectively contribute to its reputation as a reliable choice for users seeking performance and efficiency.

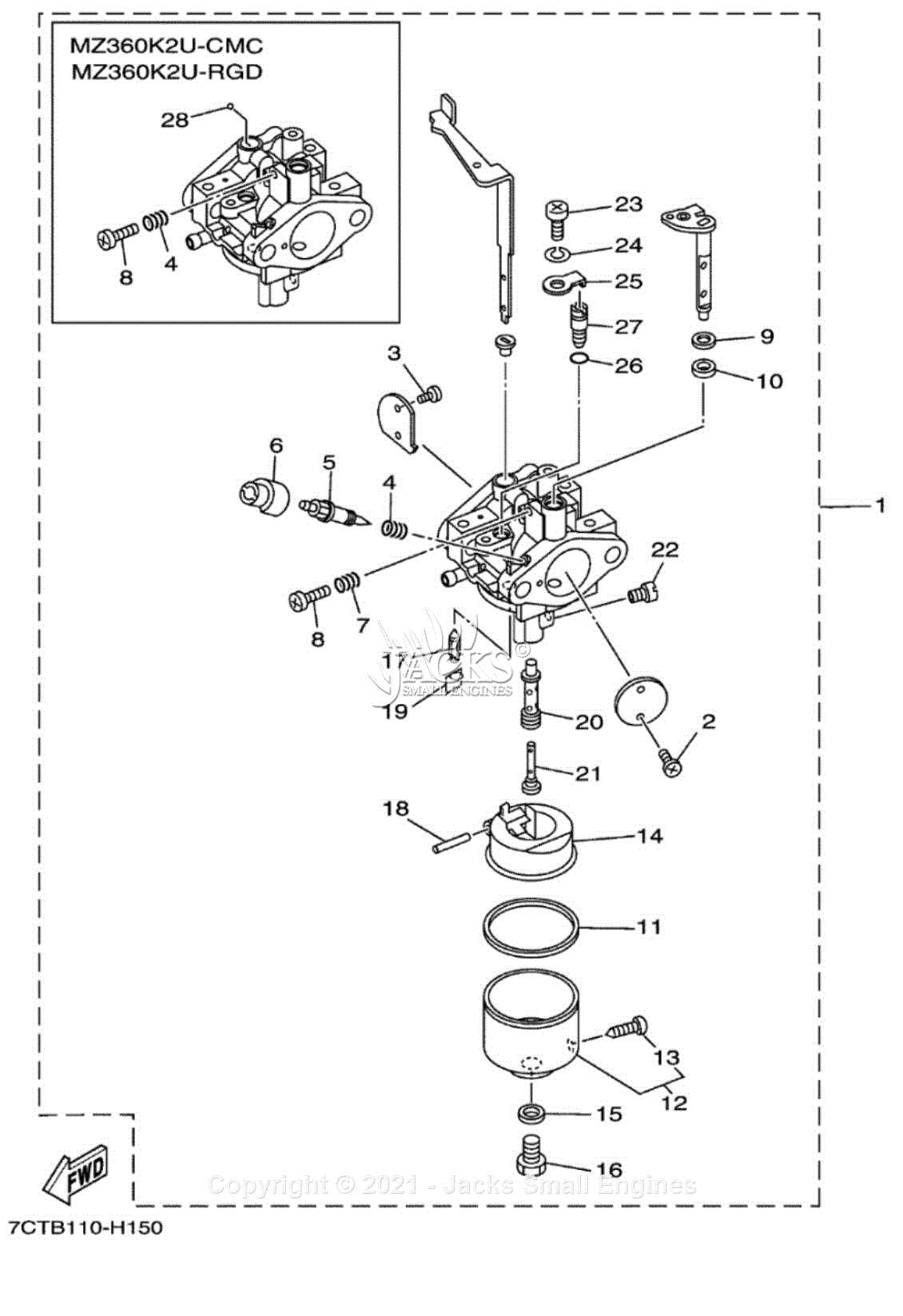

Common Replacement Parts for MZ360

When it comes to maintaining high-performance equipment, understanding the essential components that often require replacement is crucial. Regular wear and tear can lead to decreased efficiency and performance, making it necessary to identify and source the most commonly needed items to keep your machinery running smoothly.

Key Components to Consider

Among the vital elements are the ignition system components, which play a significant role in starting and operating the engine effectively. Spark plugs and ignition coils often need to be replaced to ensure reliable ignition and optimal performance.

Maintenance Essentials

Another category to pay attention to includes fuel delivery parts. Filters, fuel lines, and carburetor components can become clogged or damaged over time, leading to fuel inefficiency. Regularly checking and replacing these items can enhance overall functionality.

Being proactive about replacing these essential components can greatly extend the lifespan of your equipment and maintain its performance at peak levels.

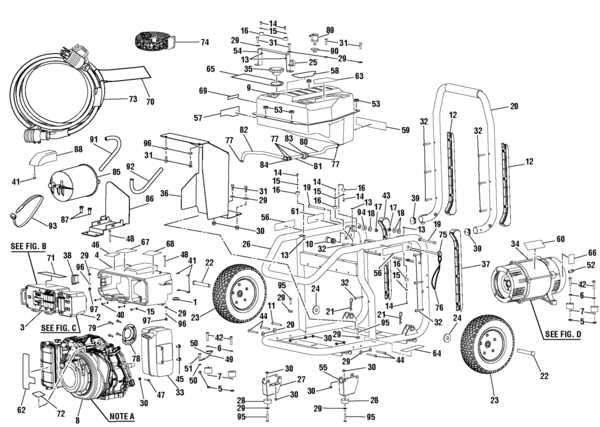

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair. It provides a visual representation of components, helping users identify each piece and its role within the overall system.

Key Elements to Identify

- Labels: Look for names or numbers that correspond to each component.

- Groups: Notice how items are clustered; this often indicates related functionalities.

- Connections: Pay attention to lines showing how parts interact or connect with each other.

Steps to Decipher the Illustration

- Start by familiarizing yourself with the overall layout.

- Identify each labeled component carefully.

- Refer to a list or catalog for detailed descriptions of each piece.

- Take notes on any specific assembly instructions or warnings.

Troubleshooting Common Issues

When operating complex machinery, encountering problems is not uncommon. Identifying and resolving these challenges can significantly enhance performance and longevity. This section aims to provide guidance on common malfunctions and effective solutions to restore optimal functionality.

Power Failures: If the equipment fails to start, check the power source and connections. Ensure that all switches are in the correct position and that any fuses are intact.

Overheating: Excessive heat can indicate a blockage or insufficient lubrication. Inspect for debris and ensure all moving parts are well-greased to maintain proper function.

Unusual Noises: Strange sounds often signal loose components or wear. Examine bolts and fasteners to ensure they are secure, and replace any worn parts as necessary.

Performance Drops: If efficiency decreases, consider the condition of filters and belts. Regular maintenance and timely replacements can prevent significant issues and ensure smooth operation.

Where to Find Authentic Parts

Locating genuine components for your equipment can significantly enhance its performance and longevity. Understanding where to source these items is crucial for ensuring quality and reliability. Various options are available that cater to different preferences and needs.

Authorized Dealers

One of the most reliable ways to obtain original components is through authorized retailers. These establishments are certified to sell genuine items and often provide warranties and support for their products.

Online Marketplaces

Numerous online platforms specialize in high-quality equipment supplies. When shopping online, ensure you verify the seller’s credibility and look for customer reviews to guarantee authenticity.

| Source | Pros | Cons |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, reliable support | Higher prices |

| Online Marketplaces | Convenience, often competitive pricing | Risk of counterfeit items |

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the extended lifespan of your equipment. Implementing systematic care routines not only enhances performance but also prevents costly repairs down the line.

- Perform routine inspections to identify wear and tear.

- Keep components clean to avoid debris buildup.

- Ensure all moving parts are lubricated as recommended.

- Store in a dry, sheltered environment to protect against the elements.

Additionally, always refer to the manufacturer’s guidelines for specific maintenance practices. Consistent attention to these details will significantly contribute to optimal functionality and longevity.

Comparison with Similar Models

In examining various models within the same category, it becomes essential to identify their unique features and performance metrics. This analysis allows for a better understanding of how each unit stands out or falls short in relation to its competitors.

- Engine Performance: Some models may offer enhanced horsepower or torque, impacting overall efficiency.

- Fuel Economy: A comparison of fuel consumption can reveal significant cost savings over time.

- Durability: Materials and construction quality can greatly influence longevity and reliability.

Ultimately, assessing these factors can guide potential buyers in making informed decisions based on their specific needs and preferences.

Upgrading Your Yamaha MZ360

Enhancing the performance and longevity of your outdoor equipment can lead to a significantly improved user experience. Whether you aim to boost efficiency, increase power output, or simply replace worn components, careful consideration of upgrades can yield substantial benefits.

Here are some effective strategies to elevate your machine:

- Engine Enhancements:

- Consider a high-performance air filter for improved airflow.

- Explore options for aftermarket exhaust systems to enhance sound and efficiency.

- Fuel System Modifications:

- Upgrade to a premium carburetor for better fuel delivery.

- Install a fuel stabilizer to protect against degradation.

- Electrical Improvements:

- Replace the ignition system for more reliable starts and better performance.

- Consider LED lighting for enhanced visibility and reduced power draw.

- Chassis Upgrades:

- Inspect and replace suspension components for improved handling.

- Upgrade tires for better traction and stability on various terrains.

Taking the time to evaluate and implement these modifications can result in a more reliable and enjoyable experience. Regular maintenance paired with thoughtful upgrades ensures that your equipment remains in top condition for years to come.

Resources for Enthusiasts and Mechanics

This section aims to provide valuable tools and references for those passionate about maintenance and repair. Whether you’re a seasoned technician or a novice hobbyist, having the right resources at your fingertips can enhance your understanding and efficiency.

- Online Forums: Engage with communities where experienced individuals share insights and troubleshooting tips.

- Manuals and Guides: Access comprehensive documentation that outlines specifications and repair procedures.

- Video Tutorials: Explore visual content that demonstrates step-by-step techniques for various tasks.

- Replacement Suppliers: Find reputable vendors that offer quality components and accessories.

Utilizing these resources can significantly enhance both knowledge and practical skills, ensuring a smoother experience in maintenance and repair endeavors.