In the realm of engine performance, the efficient mixing of fuel and air plays a crucial role. This essential process is facilitated by intricate components that work harmoniously to ensure optimal combustion. Gaining insight into the various elements involved can significantly enhance your understanding of how engines operate and perform.

Having a clear visual representation of these components can aid in recognizing their functions and relationships. Familiarity with the layout and design of these mechanisms empowers enthusiasts and professionals alike to diagnose issues effectively and make informed decisions during maintenance. A comprehensive grasp of this system not only enhances performance but also prolongs the lifespan of the engine.

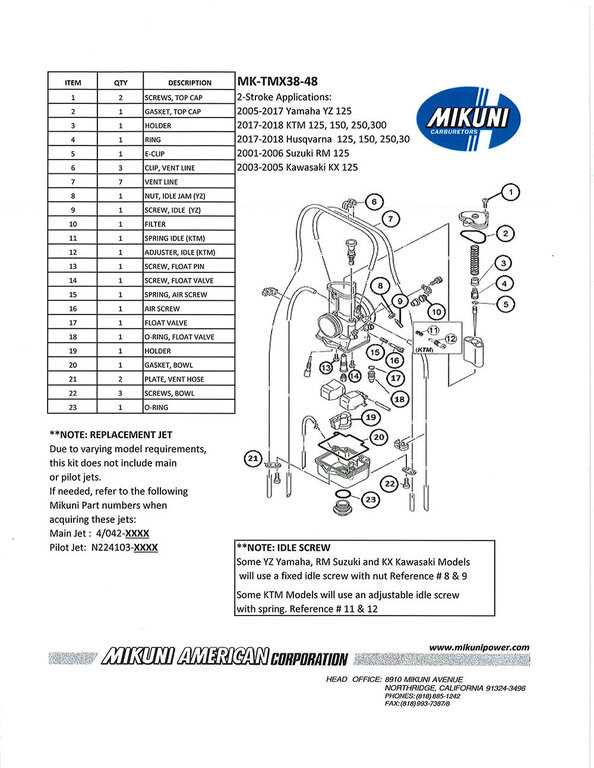

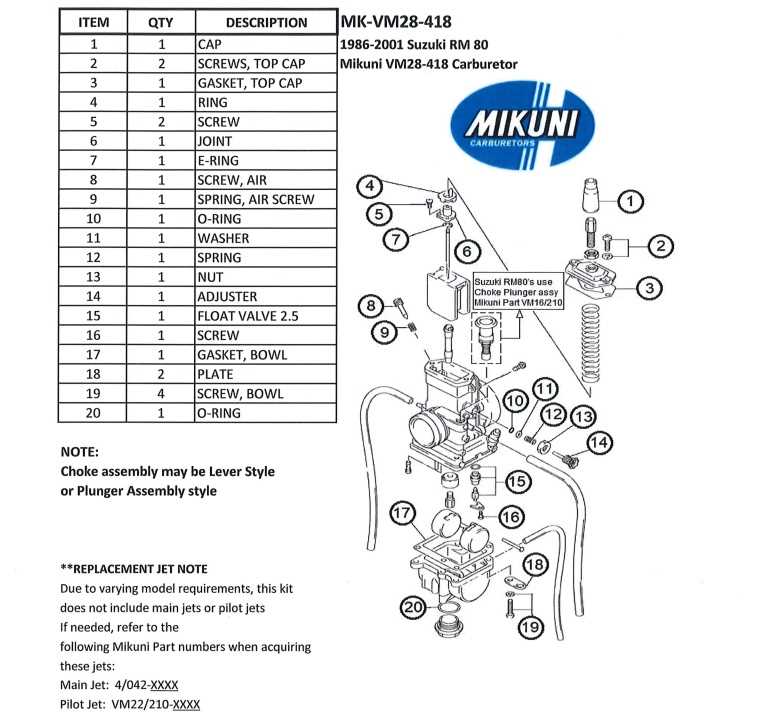

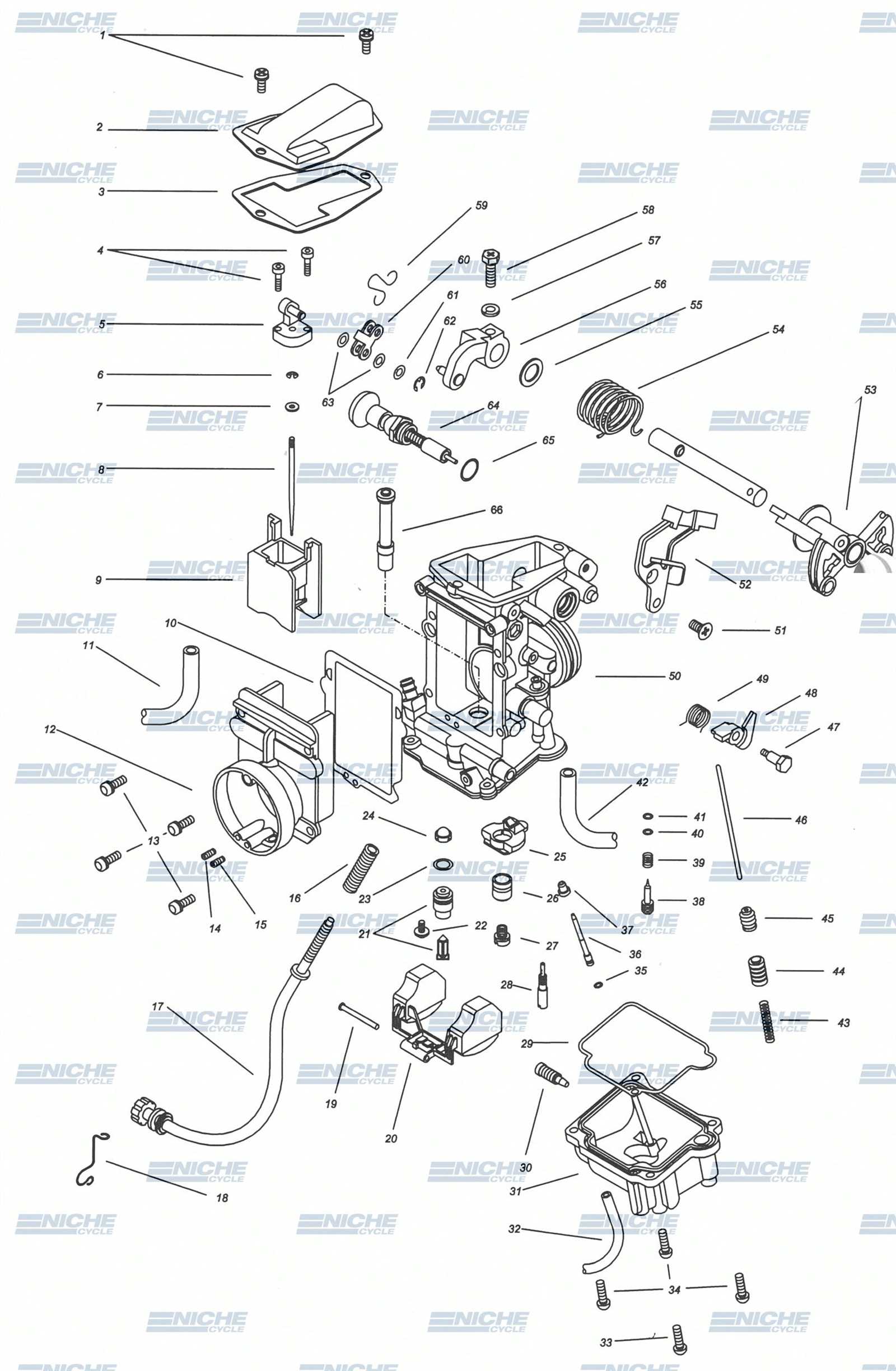

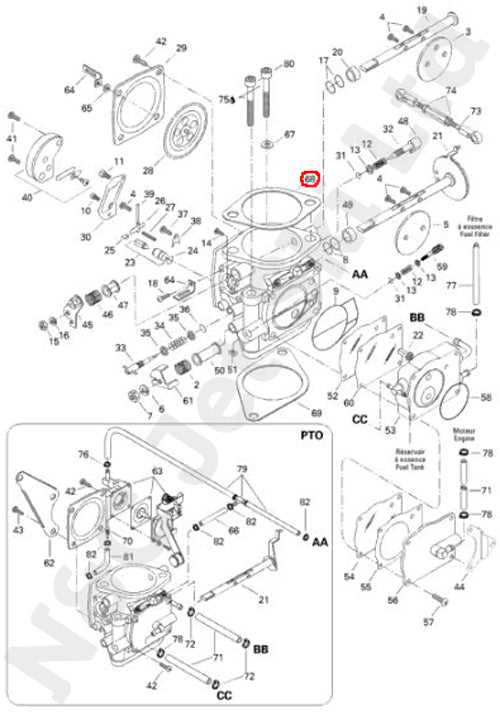

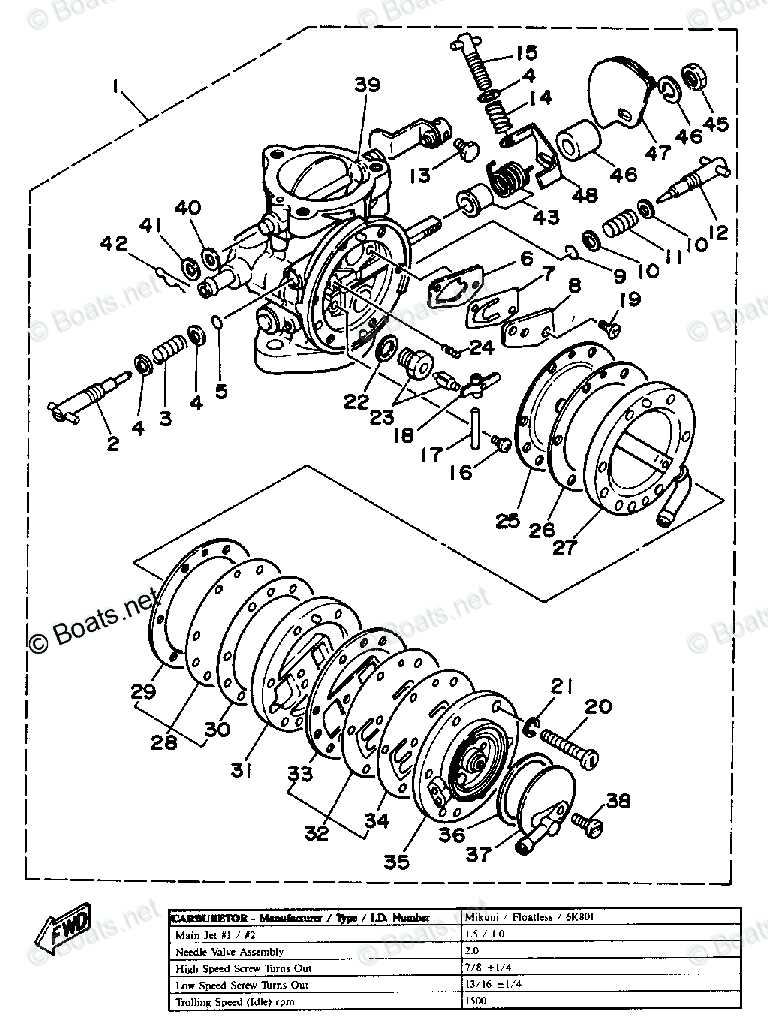

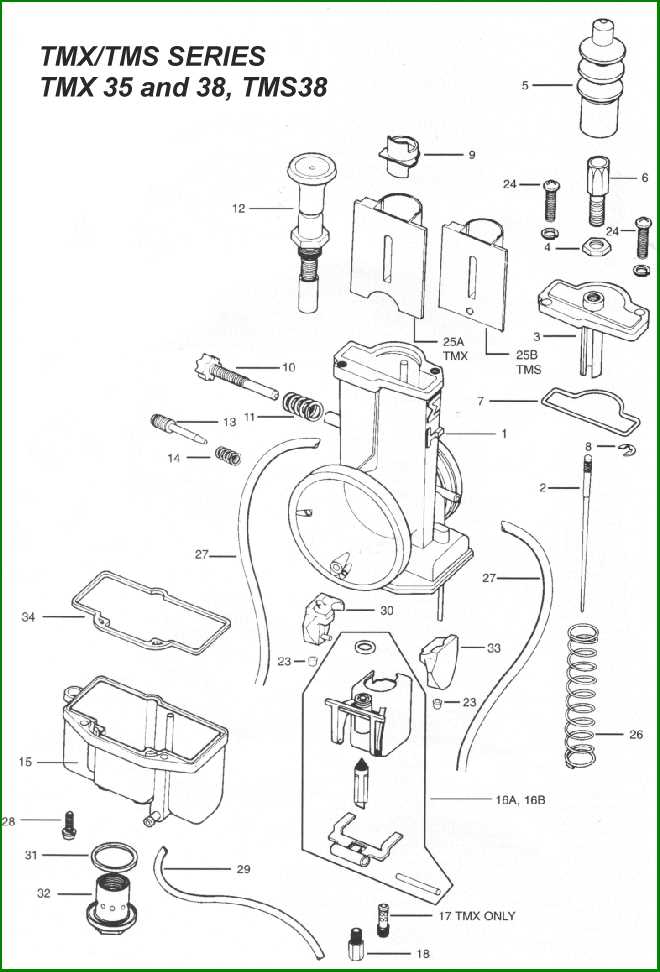

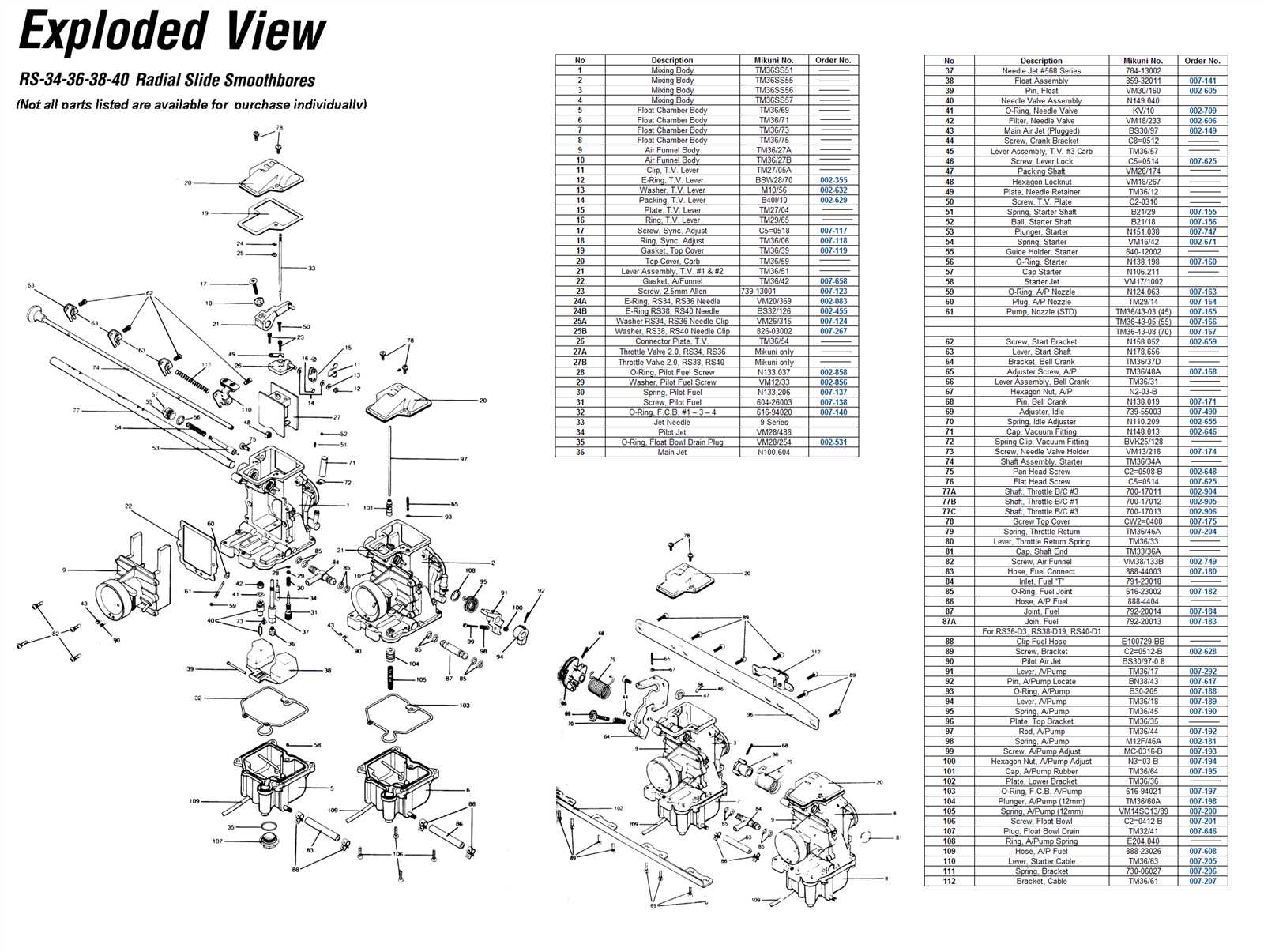

Components of Mikuni Carburetors

The intricacies of fuel management systems play a vital role in enhancing engine performance. Understanding the individual elements that comprise these mechanisms is essential for effective maintenance and optimization. Each component contributes to the overall functionality, ensuring a seamless flow of air and fuel, which is crucial for efficient combustion.

Essential Elements

- Throttle Valve: This regulates the airflow into the engine, controlling power and speed.

- Float Chamber: Maintains a consistent fuel level, allowing for proper fuel delivery.

- Jet System: Distributes fuel into the airflow, crucial for the correct fuel-air mixture.

- Needle Valve: Controls the flow of fuel from the tank, ensuring optimal supply under varying conditions.

- Choke Mechanism: Enriches the fuel mixture for easier starting, especially in cold conditions.

Supporting Components

- Air Filter: Prevents contaminants from entering the system, safeguarding internal parts.

- Fuel Lines: Transports fuel from the tank to the chamber, crucial for proper operation.

- Gaskets and Seals: Ensure airtight connections between components, preventing leaks and maintaining efficiency.

Understanding Carburetor Functionality

The process of fuel and air mixture delivery is crucial for efficient engine operation. This mechanism involves several components that work together to ensure optimal performance. Understanding how these elements interact can greatly enhance maintenance and troubleshooting efforts.

Key aspects of this functionality include:

- Airflow Management: The system relies on precise control of air intake, which influences the overall fuel combustion process.

- Fuel Delivery: An adequate supply of fuel is essential for maintaining the right mixture, ensuring smooth operation.

- Adjustment Mechanisms: Various settings allow for tuning the system to match specific engine requirements, optimizing performance under different conditions.

By familiarizing oneself with these elements, users can better appreciate the intricacies of their engine’s operation. This knowledge aids in identifying potential issues and performing necessary adjustments effectively.

Common Mikuni Models Explained

This section provides an overview of various popular designs used in fuel delivery systems, focusing on their features and applications. Understanding these types can help enthusiasts and technicians make informed decisions about maintenance and upgrades.

Types of Designs

- Flat Slide: Known for quick throttle response and smooth operation, making them suitable for racing applications.

- Round Slide: Offers a good balance of performance and reliability, commonly found in street bikes and off-road vehicles.

- Variable Venturi: These adapt to engine demands, providing efficient performance across various RPM ranges.

Applications and Benefits

Each type serves different purposes and has unique advantages:

- Flat slide systems excel in competitive settings, where every millisecond counts.

- Round slide options are favored for everyday use due to their simplicity and ease of tuning.

- Variable venturi models are ideal for versatile engines, adjusting airflow to maximize efficiency.

Identifying Key Parts and Their Roles

Understanding the essential components of a fuel delivery system is crucial for efficient engine performance. Each element plays a specific role, contributing to the overall functionality and effectiveness of the mechanism. Recognizing these vital elements allows for better maintenance and troubleshooting, ensuring that the system operates smoothly.

The throttle body regulates the air-fuel mixture entering the engine. By controlling airflow, it impacts acceleration and power output. A well-functioning throttle body ensures optimal performance, enhancing the vehicle’s responsiveness.

The float chamber maintains a constant level of fuel, allowing for a steady supply during operation. This component ensures that the engine receives the correct amount of fuel, preventing issues related to flooding or starvation. Proper adjustment of the float is essential for maintaining this balance.

The jets serve as pathways for the air-fuel mixture to enter the combustion chamber. Different sizes of jets impact the mixture’s richness, affecting engine performance. Selecting the right jet size is vital for achieving the desired power and efficiency, particularly under varying operating conditions.

The needle valve controls the fuel flow into the float chamber, responding to changes in demand. Its precise functioning is essential for maintaining the correct fuel level and ensuring that the engine receives adequate supply during various driving conditions.

By familiarizing oneself with these critical components, enthusiasts and technicians can improve their understanding of fuel delivery systems, leading to enhanced performance and reliability in their engines.

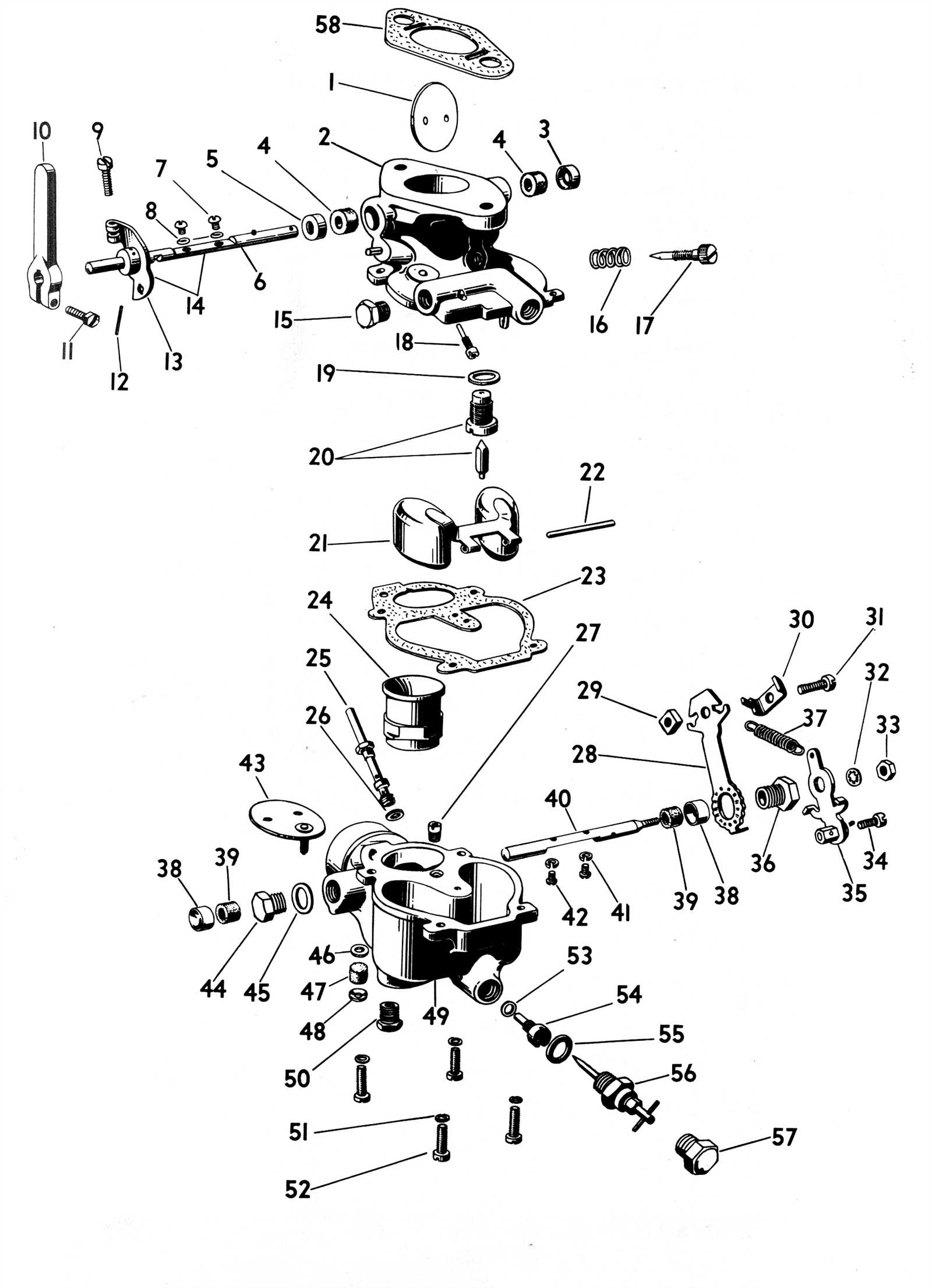

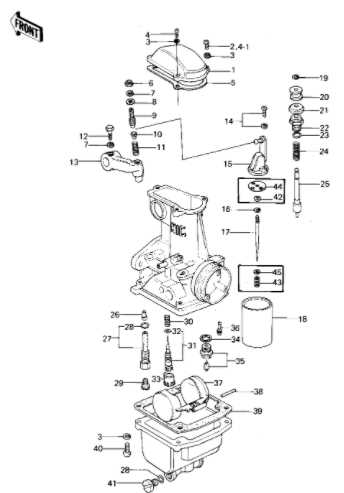

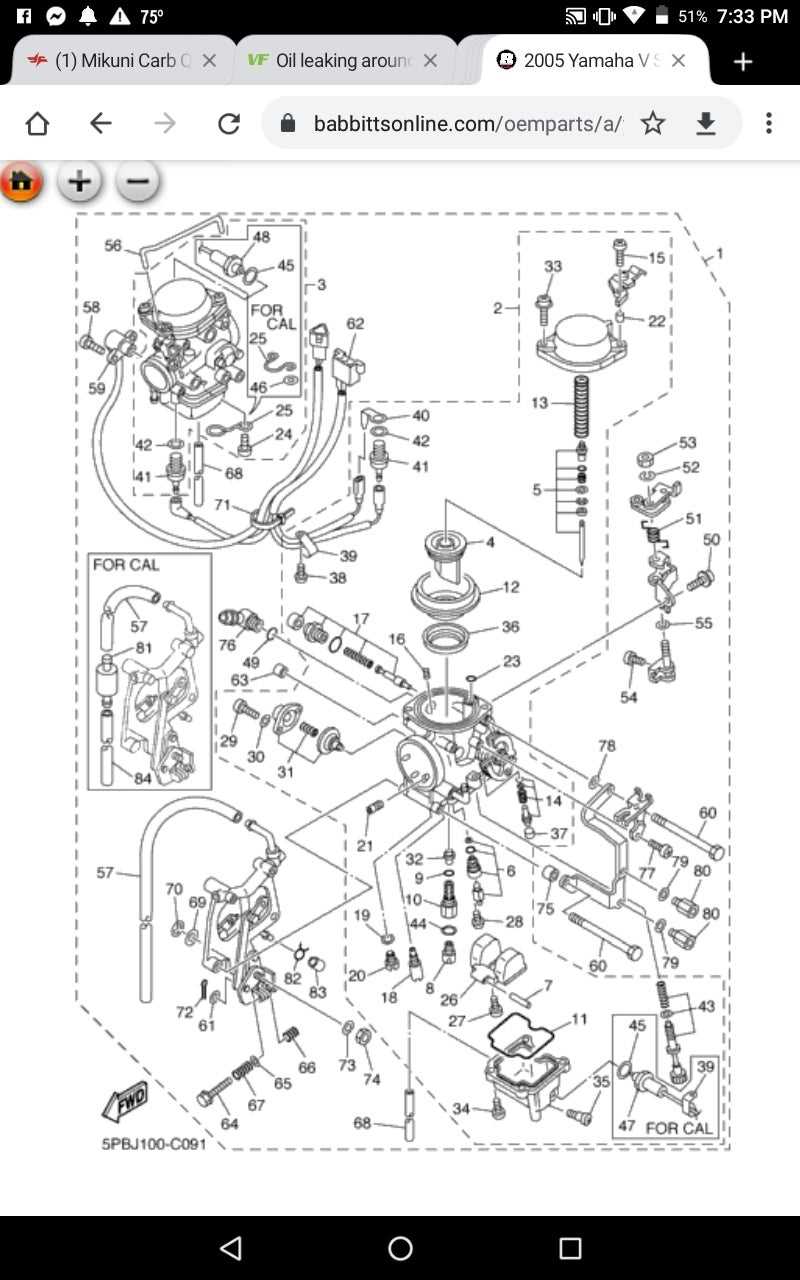

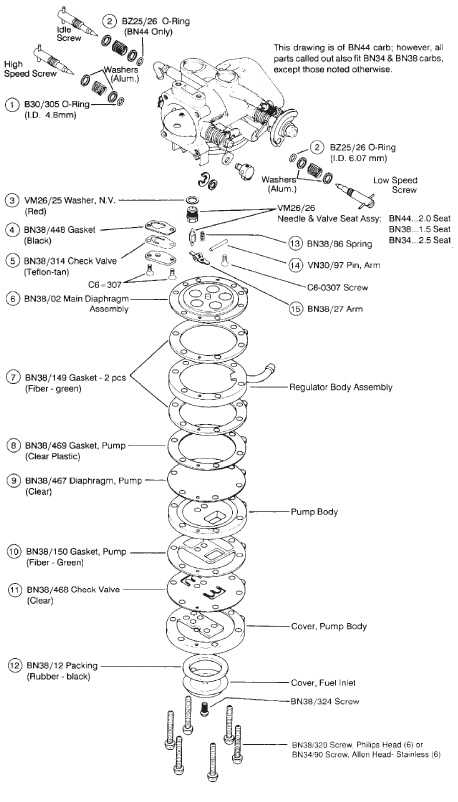

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and assembly. This visual guide provides crucial insights into the structure and function of various elements, enabling users to identify and locate specific items easily. Familiarity with this representation can significantly enhance one’s ability to perform repairs and modifications accurately.

To effectively interpret such a representation, consider the following key aspects:

| Element | Description |

|---|---|

| Labels | Each component is typically accompanied by a label that indicates its name or function, making it easier to understand the role of each part. |

| Numbers | Numerical designations often correspond to a list or key, providing additional information about specifications or replacement options. |

| Connections | Lines or arrows may illustrate how various components connect, indicating the flow of operation and integration within the system. |

| Legend | A legend or key can clarify symbols used within the representation, aiding in a deeper understanding of the schematic. |

By grasping these elements, users can enhance their proficiency in navigating complex schematics, leading to more successful repairs and modifications.

Maintenance Tips for Mikuni Carburetors

Proper upkeep of fuel delivery systems is essential for optimal engine performance. Regular care not only enhances functionality but also prolongs the lifespan of the components. Here are some valuable guidelines to ensure your system operates efficiently.

Regular Cleaning

Cleaning the internal mechanisms is crucial to prevent build-up that can lead to performance issues. Follow these steps:

- Disassemble the unit carefully to access all components.

- Use a suitable cleaning solution to remove any deposits.

- Rinse with clean fuel and let components dry completely.

Inspect Seals and Gaskets

Seals and gaskets play a vital role in maintaining pressure and preventing leaks. Regular checks should include:

- Looking for signs of wear or deterioration.

- Replacing any damaged seals promptly to avoid air leaks.

- Ensuring all connections are secure and properly fitted.

Signs of Carburetor Problems

Recognizing issues with fuel delivery systems is crucial for maintaining optimal engine performance. Various symptoms can indicate underlying malfunctions, often leading to decreased efficiency and responsiveness. Understanding these warning signs can help in diagnosing and resolving potential issues before they escalate.

Unusual Engine Behavior

One of the primary indicators of malfunction is irregular engine performance. This can manifest as stalling, rough idling, or inconsistent acceleration. When the fuel mixture is not properly regulated, it can cause hesitation during acceleration or an overall lack of power. Pay attention to any changes in the engine’s responsiveness, as these can signal deeper issues within the fuel delivery mechanism.

Fuel Leaks and Odors

Another critical sign to monitor is the presence of fuel leaks or strong gasoline odors. Leaking fuel can not only lead to performance problems but also poses safety risks. If you notice fuel pooling under the engine or detect a strong smell of gasoline, it is essential to investigate further. Ensuring that all connections are secure and that there are no cracks in the fuel delivery components can prevent more significant issues down the line.

Tools Needed for Carburetor Repair

When undertaking the restoration of fuel delivery systems, having the right instruments at hand is essential. Properly equipped, you can ensure efficient servicing and avoid unnecessary complications. Here’s a look at the key tools that will help you through the repair process.

Essential Instruments

Begin with basic hand tools, such as screwdrivers and wrenches, which are crucial for disassembly. A socket set will also be invaluable for reaching tighter areas. Don’t overlook the need for a reliable torque wrench to secure components according to manufacturer specifications.

Cleaning Supplies

To maintain optimal functionality, cleaning is vital. Invest in a high-quality cleaning solution and a set of brushes for thorough scrubbing. Additionally, compressed air can aid in clearing away debris from intricate sections, ensuring a smooth operation once reassembled.

Upgrading Mikuni Carburetor Parts

Enhancing the performance of your engine can often be achieved through the meticulous refinement of its fuel delivery system. By focusing on specific components within this system, enthusiasts can unlock improved efficiency and responsiveness, making it crucial to understand the various elements involved.

Key Components to Consider

- Jets: Upgrading fuel and air jets can significantly alter the mixture, optimizing power and performance.

- Needles: Adjusting or replacing needles can provide better control over fuel flow and enhance throttle response.

- Float Valves: Ensuring float valves are in good condition can help maintain the correct fuel level, preventing flooding or starvation.

Benefits of Upgrading

- Improved fuel efficiency, leading to reduced operational costs.

- Enhanced throttle response, allowing for a more exhilarating driving experience.

- Better overall performance, providing more power and speed when needed.

Aftermarket vs. Original Equipment Parts

When it comes to replacing components in your vehicle, the choice between aftermarket and original equipment can significantly impact performance and reliability. Each option offers unique advantages and potential drawbacks that can influence both the functionality and longevity of your machinery.

Original equipment options are manufactured by the same company that produced the vehicle, ensuring a perfect fit and adherence to the manufacturer’s standards. These components are typically subjected to rigorous testing and quality control measures, which can provide peace of mind regarding their durability and performance. However, they often come with a higher price tag, which may not be feasible for all budgets.

On the other hand, aftermarket alternatives are produced by third-party manufacturers and can vary widely in quality and price. These options often come at a more affordable cost and can sometimes offer enhanced features or performance compared to their original counterparts. However, the lack of standardization means that buyers must be diligent in selecting reputable brands to avoid inferior products that could lead to malfunctions.

Ultimately, the decision between these two choices should consider factors such as budget, desired performance, and the specific needs of your machinery. Weighing the pros and cons of each can help you make an informed choice that aligns with your expectations and requirements.

Installing a Mikuni Carburetor

Proper installation of a fuel delivery system is crucial for optimal engine performance. This process ensures that air and fuel are mixed correctly, leading to efficient combustion. Understanding the components and steps involved in the installation will help achieve a seamless setup.

Preparation Steps

Before beginning the installation, gather all necessary tools and materials. Ensure that the workspace is clean and organized. Familiarize yourself with the components involved in the system, including the mounting hardware and any gaskets required for a secure fit. Checking the condition of these items beforehand can prevent complications during the installation process.

Installation Process

Start by securing the assembly onto the designated intake manifold, ensuring a proper alignment. Tighten the bolts evenly to prevent any air leaks. Next, connect the fuel supply line and verify that all connections are tight and leak-free. Finally, adjust the settings according to the manufacturer’s specifications for optimal performance. A thorough inspection upon completion will guarantee that the installation is successful and functioning as intended.

Troubleshooting Common Issues

When dealing with fuel delivery systems, various challenges may arise that affect performance and efficiency. Identifying and resolving these problems is essential to ensure optimal functionality. This section provides insights into common complications and their potential solutions.

Identifying Performance Issues

One of the primary concerns users encounter is poor engine performance. This can manifest as difficulty starting, stalling, or lack of power. To address these issues, first check the fuel supply for blockages or contamination. Inspecting the flow of fuel can often reveal if there are any restrictions that need attention. Additionally, evaluating the air intake system is crucial, as improper airflow can lead to an imbalance that affects overall operation.

Maintenance and Adjustments

Regular maintenance is vital for sustaining efficiency and preventing future complications. Ensuring that all components are clean and functioning correctly will minimize the risk of problems. Adjustments may be required to achieve the correct balance between fuel and air. Pay special attention to any settings that influence performance, as improper calibration can lead to persistent issues. Remember that routine inspections and timely adjustments are key to maintaining smooth operation.